Multi-Lane 4 Side Sealing Particle Packing Machine: The Complete Buying Guide In 2024

Convenience comes from the portability of sachets. Nowadays, people favor small particle product sachets over large pouches because they are cost-effective and easy to carry around in luggage and bags. But how the precise volume of particle products is packed in 4 side sealing sachets.

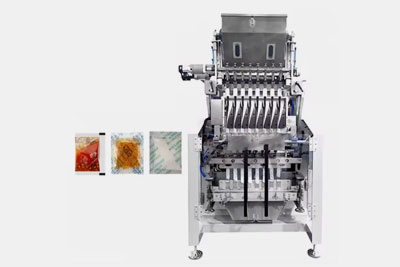

The answer is by multi-lane 4 side sealing particle packing machine. This machine is the latest addition to the series of technologically advanced machines. It packs different types of particle products in convenient to use 4 side seal sachets with accuracy and lower product wastage.

To use this machine in the best way possible, carefully read this buying guide. This buying guide answers your every query about the multi-lane 4 side sealing particle packing machine.

1.What is a Multi-Lane 4 Side Sealing Particle Packing Machine?

Multi-Lane 4 Side Sealing Particle Packing Machine

Multi-lane 4 side sealing particle packing machine is defined as a sophisticated piece of technology that packs a complete range of particles including granules and powders. It features numerous lanes for forming, filling, and sealing multiple sachets in one setting. These multiple packaging’s translate into a high output rate.

The 4 side sealing in the machine name refers to the sealing of sachets and other bags on all four sides which are two longitudinal and two lateral sides. Multi-lane 4 side sealing packing machine creates a secure and tough seal that prevents the access of contaminants and environmental agents inside the packaging.

It processes soft, abrasive, free-flowing, and non-free-flowing granules and powders in different industrial sectors.

2.Enlist the Benefits of Multi-Lane 4 Side Sealing Particle Packing Machine.

Multi-lane 4 side sealing particle packing machine is known for its safety, hygiene, and efficiency. It comes with substantial benefits that bring success to the industries. Some of the benefits are as follows.

Speed is Everything

Increased Speed by Multi-Lane 4 Side Sealing Particle Packing Machine- Picture Courtesy: Ragecoffee.uk

Multi-lane 4 side sealing particle packing machine has various lanes with which it can form, fill, code, cut, and, seal multiple sachets concurrently. This simultaneous processing can increase the rate of production capacity. This increased speed increases the profit margins of the businesses.

High Protection

Protection by Multi-Lane 4 Side Sealing Particle Packing Machine

Multi-lane 4 side sealing particle packing machine seals the packaging at all four sides, increasing the security and safety of the inner packed particles. These seals are airtight and leak-proof, inhibiting the entry of air, water, dust, and other foreign objects inside the packaging. The increased protection offered by the multi-lane 4 side sealing particle packing machine boosts the product quality.

Accuracy and No Batch Variation

Accuracy by Multi-Lane 4 Side Sealing Particle Packing Machine

Multi-lane 4 side sealing particle packing machine is equipped with automatic weighing and metering devices. These devices allow precise particle filling in the packaging. Moreover, with an accurate forming station, consistently sized and shaped packaging is formed every time. Thus, using a multi-lane 4 side sealing particle packing machine guarantees consistency in every batch.

Flexibility and Versatility

Flexibility of Multi-Lane 4 Side Sealing Particle Packing Machine- Picture Courtesy: Tratenor

Multi-lane 4 side sealing particle packing machine forms a different set of packaging with just one click of a button. This feature is useful for businesses accommodating different packaging. Cut and seal sachets are versatile with a multi-lane 4 side sealing particle packing machine. Besides packaging, this machine can process different types of particles diverging in shape, size, and nature.

Ease in Maintaining and Cleaning

Ease in Maintaining Multi-Lane 4 Side Sealing Particle Packing Machine- Picture Courtesy: Jochamp

This machine is constructed with durable and resilient stainless steel material. This material has ease of cleaning in addition to its corrosion resistance. Every component is easily disassembled making it easier to clean and maintain this machine.

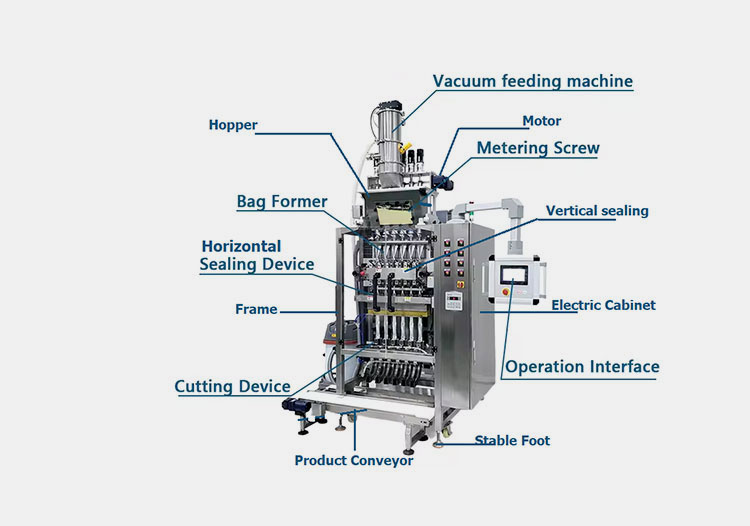

3.What Can You Tell Us About the Basic Parts of Multi-Lane 4 Side Sealing Particle Packing Machine?

Multi-lane 4 side sealing particle packing machine consists of different fundamental parts that offer complete harmony in the operation. These components are discussed in detail one by one below:

Parts Of Multi-Lane 4 Side Sealing Particle Packing Machine

| Hopper | It is the major part of the machine. In the hopper, the particle powders are fed which are then supplied to the filling devices. |

| Vacuum Feeder | This part is the useful part that plays an important role in transferring the powders and other particles to the filling devices. It uses a vacuum to supply particles to the dosing system. |

| Motor | It is one of the fundamental components of the multi-lane 4 side sealing particle packing machine. It is found on the upper side of the machine. Electric energy powers this component. It converts the necessary electric energy and provides other parts with mechanical energy. |

| Metering Screw | It is present underneath the hopper. Its basic objective is to measure the precise amount of powders. |

| Bag Former | The bag former is the main forming part that creates a 4 side seal packing. It is a funnel-shaped part that wraps the film around itself to fabricate square or rectangular packing. |

| Vertical Sealing | It is the part that creates a vertical sealing around the longitudinal seams of the sachets. |

| Horizontal Sealing Device | It is a device that uses pressure, heat, or ultrasonic waves to seal the top and bottom edges of the 4 side seal sachet. |

| Frame | It is the core part of the machine that supports all the interior parts of the machine. The frame is formed of stainless steel that offers hygienic quality to the overall structure of the machine. |

| Electric Cabinet | It is the powerhouse of the multi-lane 4 side sealing particle packaging machine. It is useful because it accommodates different types of electric connections. |

| Operation Interface | An operational interface is defined as a display screen interface where programming of machine operational settings occurs. Users easily set different parameters using the operational interface. |

| Stable Foot | Multiple stable feet are present at the lower section of the machine to keep it balanced and levelled. |

| Cutting Device | The cutting devices are present below the horizontal sealing bars. Their main function is to cut packed sachets from processing sachets using sharp cuts. |

| Product Conveyor | It is a separate tool installed at the bottom of the machine. Finished packaging is discharged on the product conveyor. |

4.What are the Classes of a Multi-Lane 4 Side Sealing Particle Packing Machine?

You see different makes of multi-lane 4 side sealing particle packing machines. These categories differ based on filling and motion type.

Filling Type

Auger Multi-Lane 4 Side Sealing Particle Packing Machine

Auger Multi-Lane 4 Side Sealing Particle Packing Machine

It is a specialized machine that has auger auger-filling device to fill powders and granules. The rotation of auger screws moves the particle products from the hopper to the filling system. It is the most used machine for filling the powders. These auger devices in this machine load accurate quantities of the products inside the bags.

Multi-Head Weighing Multi-Lane 4 Side Sealing Particle Packing Machine

Multi-Head Weighing Multi-Lane 4 Side Sealing Particle Packing Machine

This machine has multiple weighing heads, multiple fill buckets and load cells. These load cells measure, weigh, and dispense accurate quantities of particles in the lanes. Weighing and dosing in this machine are carried out by the weighing heads. This machine achieves high-speed dosing through its multiple heads.

Volumetric Cup Multi-Lane 4 Side Sealing Particle Packing Machine

Volumetric Cup Multi-Lane 4 Side Sealing Particle Packing Machine

This type of multi-lane 4 side sealing particle packing machine has multiple volumetric cups that play an important role in the dosing of exact volumes of particles in the bags. The materials are moved from the hopper to the volumetric cups from where they travel to the filling nozzles. This machine is versatile in its processing as it packs a diverse range of particles.

Motion Type

Intermittent Motion Multi-Lane 4 Side Sealing Particle Packing Machine

Intermittent Motion Multi-Lane 4 Side Sealing Particle Packing Machine

As the name suggests, this machine stops after every step of the packaging. It allows for accuracy in the filling, forming, and sealing because of its intermittent processing. There is no variation in batches and product wastage using this type of multi-lane 4 side sealing particle packing machine.

Continuous Multi-Lane 4 Side Sealing Particle Packing Machine

Continuous Multi-Lane 4 Side Sealing Particle Packing Machine

This type of multi-lane 4 side sealing particle packing machine does not stop in the processing cycle, rather it performs forming, filling, and sealing steps uninterruptedly. Due to this continuous processing, it achieves high processing speeds. It employs continuous motion technology to pack multiple products in one go.

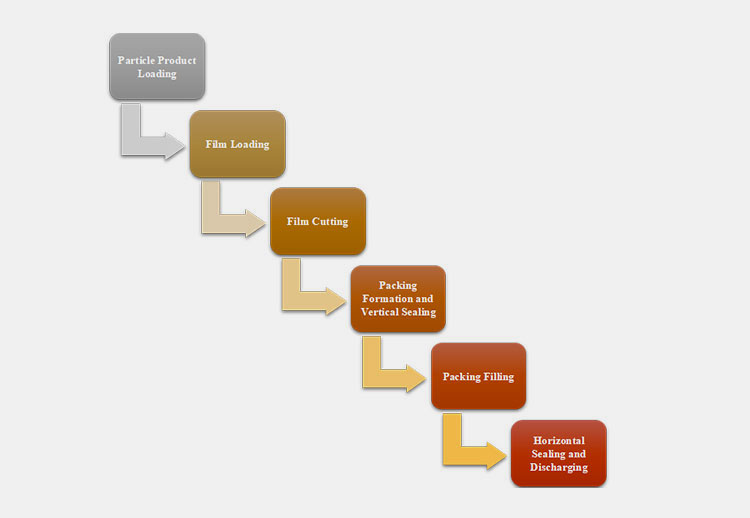

5.Enumerate the Working Steps of a Multi-Lane 4 Side Sealing Particle Packing Machine.

Multi-lane 4 side sealing particle packing machine is composed of different parts to carry out different operational steps. The easy way to learn about the working of a multi-lane 4 side sealing particle packing machine is to understand the basics of operational steps:

| Particle Product Loading

Particle Product Loading |

Before starting the machine, it is essential to feed the product hopper with the bulk volume of the product. The hoppers are filled manually by the operator or by the feed tank attached to the hopper. |

| Film Loading

Film Loading |

In the next step, a large film roll is fixed on the film holder and a section of film is unwound and moves over the roller. These processes are vital in keeping the film on track and maintaining a constant film tension. |

| Film Cutting

Film Cutting |

Circular cutters present before the forming station cuts the flat film layer into individual smaller strips. These strips then go towards their respective forming station |

| Packing Formation and Vertical Sealing

Packing Forming |

On film reaching the forming station, the actual process of packing formation occurs. Strips of film are gathered and wrapped around the forming station to assemble into tube-like packing. Now the bottom part and side seams are fused by the horizontal and vertical sealer, respectively. |

| Packing Filling

Packing Filling- Picture Courtesy: Chengyipacking |

After the packing formation, the filling devices- auger, multi-head weigher, and volumetric cup filler- start weighing the exact quantities of the powders and other particle products. These quantities are fed into packing by the vacuum feeder and filling nozzles. |

| Horizontal Sealing and Discharging

Horizontal Sealing and Discharging |

Now the transverse sealer comes into play and forms an airtight seal at the top. These transverse sealers seal the bottom of the subsequent sachet at the same time. Once the packing is sealed, it is cut from the other pack through the sharp cutter. After the packaging process is finished, the next step is the safe discharge of 4 side seals packing in the collection bin or on the product conveyor. The latter takes the finished packing to the next packaging machine. |

6.What are the Industrial Uses of the Multi-Lane 4 Side Sealing Particle Packing Machine?

Almost every industry of the world involves powder and other particle product packaging. These industries use a multi-lane 4 side sealing particle packing machine for particle packing. Some of the industrial uses of this machine are highlighted below:

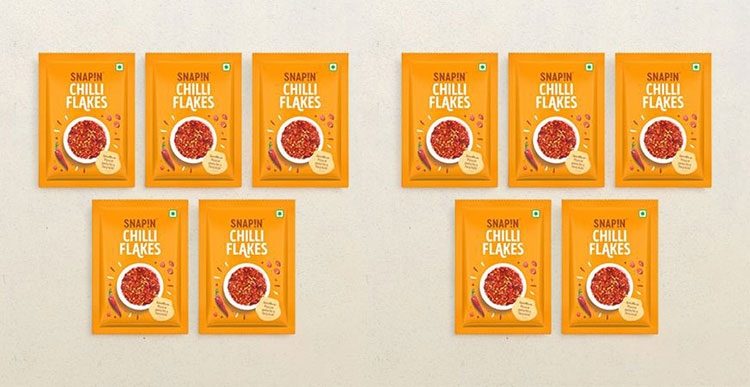

Food Industry

Use of Multi-Lane 4 Side Sealing Particle Packing Machine in Food Industry- Picture Courtesy: Zepto

This industry is one of the biggest users of the multi-lane 4 side sealing particle packing machine. This industry employs this machine because the latter delivers food particles in convenient sachets. This machine packs different types of spices, sugar, salts, chillis, powdered flavoring, etc in the small sachet packing.

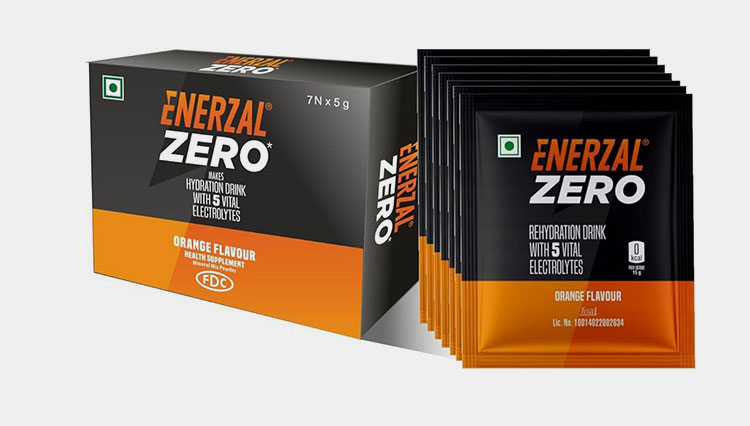

Beverage Industry

Use of Multi-Lane 4 Side Sealing Particle Packing Machine in Beverage Industry

Other than the food industry, the beverage industry also utilizes this machine for packaging tea leaves, ground tea, coffee beans, powdered coffee, instant coffee and juices in the 4-side sealing sachets. Its use in the beverage industry cannot be overlooked because the multi-lane 4 side sealing particle packing machine has versatile applications in the beverage industry.

Medical and Health Care Industry

Use of Multi-Lane 4 Side Sealing Particle Packing Machine in Medical Industry- Picture Courtesy: PharmEasy

With the innovation in the medical and healthcare sector, pharmaceutical drugs, nutraceuticals and herbal supplements also come in powdered form in addition to tablets and capsules. These powders are packed in compact sachet bags for instant effect. It is a preferred machine in the medical industry because of its extreme accuracy in dose packaging.

Agriculture Industry

Use of Multi-Lane 4 Side Sealing Particle Packing Machine in Agriculture Industry

Yes, this machine is also utilized in the agriculture industry for packaging diverse kinds of agriculture particle products like fertilizers, herbicides, pesticides, manure, and different soils in compact 4-side seal sachet. Multi-lane 4 side sealing particle packaging machine is a noteworthy addition to the agriculture industry, as it packs small economical retail agricultural packs.

Cosmetic Industry

Use of Multi-Lane 4 Side Sealing Particle Packing Machine in Cosmetic Industry

The multi-lane 4 side sealing particle packaging machine is also seen in every cosmetic industry that deals in cosmetic powders. It packs small volumes of cosmetic powders like face powders, talcum powders, eye shades, blushes, foundation powders, bath salts, and body wash powders in small sachets.

7.What are the 4 Side Sealing Packaging Formats Processed by Multi-Lane 4 Side Sealing Particle Packing Machine?

A multi-lane 4 side sealing particle packing machine processes different types of 4 side sealing packaging formats. Below, are some examples of the packaging format handled by a multi-lane 4 side sealing particle packing machine.

| Typical 4 Side Seal Sachet

This sachet has a typical rectangular or square shape with four different corners and edges. It is sealed at four sides: two lateral and two longitudinal. This sachet has leakproof sealing that offers the highest protection. |

Typical 4 Side Seal Sachet- Picture Courtesy: kikiexcellent |

| Sachet With Euro Hole

This type of sachet has a small round or slot hole in the top seal. It provides convenience in hanging and using this sachet. This hole increases the marketability of the sachet by hanging it on display shelves. |

Sachet With Euro Hole- Picture Courtesy: Flexi Packaging Solutions |

| Continuous Sachets

These are the continuous sachets joined by small perforations. The settings on multi-lane 4 side sealing particle are adjusted on output such unique design. |

Continuous Sachet- Picture Courtesy: Eman Argo |

| Flat Cut Sachet

It is one of the most common cuts present in the sachets. It has a simple flat-cut design with no embellishment. It decreases the chances of cutting. This type of sachet is used in the cosmetic and medical industries. |

Flat Cut Sachet- Picture Courtesy: Coretamp |

| Jagged Cut Sachet

It features a zigzag cut pattern on the top seal of the sachet. This cut design is different from flat cut and boosts a better visual appeal. This design has a striking presence, increasing buying chances. |

Jagged Cut Sachet |

| Tear Notch Sachet

This type of sachet created by a multi-lane 4 side sealing particle packing machine supports a small cut on the top seal. This tear-away cut or perforation is present to aid in opening. |

Tear Notch Sachet- Picture Courtesy: Next Cash and Carry |

8.What are the Product Types Processed by the Multi-Lane 4 Side Sealing Particle Packing Machine?

Multi-lane 4 side sealing particle packing machine processes wide varieties of product types such as:

Condiments and Spices

Condiments and Spices

Nowadays, spices and condiment powders are packed into small sachets by the multi-lane 4 side sealing particle packing machine. These flavouring agents in smaller sachets are best for travelling, hiking, and camping.

Snacks

Snacks

This machine also packs different types of snacks like popcorn kernels, small servings of chips, cookies, and crackers in small bags. Snacks require stringent sealing which is done by a multi-lane 4 side sealing particle packing machine.

Curry Powders and Seasoning

Curry Powders and Seasoning

Curry powders and seasonings increase the savoriness of the different cuisines and are also packed in convenient-to-use and easier-to-handle smaller sachets by the multi-lane 4 side sealing particle packing machine.

Detergent Powders

Detergent Powders- Picture Courtesy: OkCredit

Detergent powders need a leakproof seal, as humidity causes the stickiness of these powders. Therefore, a multi-lane 4 side sealing particle packing machine is employed to seal these detergent powders.

Seeds

Seeds

Seeds both edible and non-edible are tiny particles, demanding additional caution while packing. This is the reason why seeds and bulbs for gardening and horticulture are packed by this machine.

Nuts and Bolts

Nuts and Bolts

This machine also packs different types of nails, nuts, bolts, screws, and smaller hardware products.

9.Differentiate between the Multi-Lane 4 Side Sealing Particle Packing Machine and the Multi-Lane 4 Side Sealing Liquid Packing Machine.

Both of these machines are tailored to process products at high speeds and can handle large volumes of products. However, the multi-lane 4 side sealing particle packing machine and the multi-lane 4 side liquid packing machine handle different types of products. Some key differences between these machines are discussed below:

| Features | Multi-Lane 4 Side Sealing Particle Packing Machine | Multi-Lane 4 Side Sealing Liquid Packing Machine |

| Picture |

Multi-Lane 4 Side Sealing Particle Packing Machine |

Multi-Lane 4 Side Sealing Liquid Packing Machine |

| Products | It packs different powders, granular items, and small particle products. | It packs different types of liquids. |

| Dosing Systems | Multi-lane 4 side sealing particle packing machine has an auger, multi-head weigher, and volumetric cup fillers for filling different particles. | Multi-lane 4 side sealing liquid packing machine has a flowmeter, piston, and pump fillers. |

| Applications | It packs different powders like sugar, salts, chilli, curry powder, pet treats, etc. in 4-side seal sachets. | It dispenses different liquids like juices, pastes, sauces, and shampoo in a 4-side seal sachet. |

| Versatility | This machine easily handles dry particles differing in size, shape, and cohesivity. | This machine processes liquids varying in viscosity and flow. |

10.What are Cleaning and Maintenance Protocols for the Multi-Lane 4 Side Sealing Particle Packing Machine?

Maintenance of Multi-Lane 4 Side Sealing Particle Packing Machine- Picture Courtesy: SED Pharma

For efficient packaging and long serviceable life of multi-lane 4 side sealing particle packaging machine, businesses should pay special attention to its cleaning and maintenance. Let us take a look at cleaning and maintenance protocols.

| Cleaning | Gently clean the exterior of the frame and stable foot. Also, wipe down the parts like the hopper, feeder, and filling nozzles to avert the chances of cross-contamination.

Once a week, perform a deep cleaning of the machine by removing all the parts and washing them with a mild cleaning agent that is effective in removing product residue. Use sanitisers to sterilize the machine. |

| Maintenance | Check and tighten all the loose nuts, gears, and bearings.

Inspect the working order of gaskets and seals, and replace them if they show any indications of wear and tear. It is essential to lubricate and oil every machine joint to reduce frictional buildup. Calibrate the filling and forming system to ensure accuracy. Check and align the filling devices and filling nozzles for smooth product flow. Update machine software. Replace the parts if they are beyond repair to prevent excess downtime. |

11.Troubleshoot the Common Issues in Multi-Lane 4 Side Sealing Particle Packing Machine.

When operating the multi-lane 4 side sealing particle packing machine, some basic issues might arise leading to delays in production and increased downtime. However, these issues are easily troubleshooted if you learn about these problems and their solutions beforehand. We are presenting some common problems, their causes, and their troubleshooting just for you.

| Causes | Solution | Image |

| Product Jamming | ||

| Hoppers are overfilled with particles.

Presence of foreign objects in the hopper and other filling devices. Stickiness of the particle product in the hopper. |

Adjust the level of products in the hopper to prevent overfilling.

Clean the machine so that it is free of dust and other debris. Add anti-caking agents to the product to avoid its stickiness. |

Product Jamming- Picture Courtesy: Chengyipacking |

| Inconsistent Fills | ||

| Inadequate settings of fill parameters.

Inconsistent particle product flow. Damaged filling systems and fill nozzles. Inadequate calibration of the fill systems |

Readjust the fill parameters.

Use vibratory feed mechanisms to ascertain consistency in the product flow. Replace or repair old and damaged parts. Recalibrate the auger and volumetric cup devices. |

Inconsistent Fills |

| Incomplete Cutting of the Film | ||

| Dull cutting blades

Out-of-alignment cutting blades Inaccurate cut timings. |

Sharpen the cutting blades and replace them if needed.

Correctly align the cutting blades with the film and sealing jaws. Readjust the cut timings on the operational interface. |

Incomplete Cutting of the Film |

| Sealing Jaws are Not Sealing Properly | ||

| Uncleaned sealing jaws

Incorrect sealing temperature and pressure Sealing jaws are not aligned properly. Damaged or old sealing jaws. |

Properly clean the sealing jaws.

Adjust sealing pressure and temperature. Align the sealing jaws with the film. Replace worn-out and defective sealing bars. |

Sealing Jaws are Not Sealing Properly |

| Incorrect Packing Formation | ||

| Inaccurate aligning of forming collar

Incorrect alignment of the film Inconsistent tension in the film |

Check and correct the alignment of the forming collar.

Readjust the alignment of the film. Adjust the roller bars to ascertain proper tension in the film. |

|

12.How to Select the Best Multi-Lane 4 Side Sealing Particle Packing Machine for Business?

When selecting the best multi-lane 4 side sealing particle packing machine it is vital to consider your long-term production goals and budget. Here are some useful suggestions that will help you in reaching a well-versed choice.

Determine Product Needs

Determine Product Needs

First select what type of particle product will you package like powders, granules or small snacks. This will allow you to select an appropriate filling device like an auger, volumetric filler, or multi-head weigher.

Access Your Output Rate

Access Your Output Rate- Picture Courtesy: Kings Kuma

After determining your product type, the next step is to access your production rate. If you are running a larger production, then you must go for the machine with higher production speed. Small businesses prefer machines with low production speeds because these machines meet their needs.

Estimate Costs

Estimate Costs

Estimate and compare the purchase costs of different machines and check if these fall under your calculated budget. Also, consider the utility consumption of the machine and its maintenance and repair costs while purchasing.

Check Machine Technology

Check Machine Technology- Picture Courtesy: Siemens

Examine machine automation level as machines with advanced controls require lower labour supervision. Also, check if the machine has an intelligent interface because this lowers processing time.

Evaluate Regulatory Compliance

Evaluate Regulatory Compliance

It is important to ensure that your preferred machine must comply with all necessary quality standards like GMP, FDA, CE, and ISO. This ascertains the safety and quality of the packaging of particle products.

Conclusion

In a nutshell, a multi-lane 4 side sealing particle packing machine is an intelligent solution that uplifts your business. This machine presents a great deal of advantages to businesses like extreme efficiency, high speed, excellent accuracy, and versatility of packing. So, do not hesitate and opt for this high-tech and advanced range machine. If you are experiencing problems regarding procuring a multi-lane 4 side sealing particle packing machine then contact us, Allpack through message or call because we have the best range of machines.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide