Screw Counting Machine: The Complete Buying Guide In 2024

Screw Counting Machine: The Complete Buying Guide In 2024

In order to reduce the risk of human error, reducing the need for labors, and ensure that the packaging process runs smoothly and efficiently, more and more packaging machines are put into production and use. The screw counting machine is one of them.

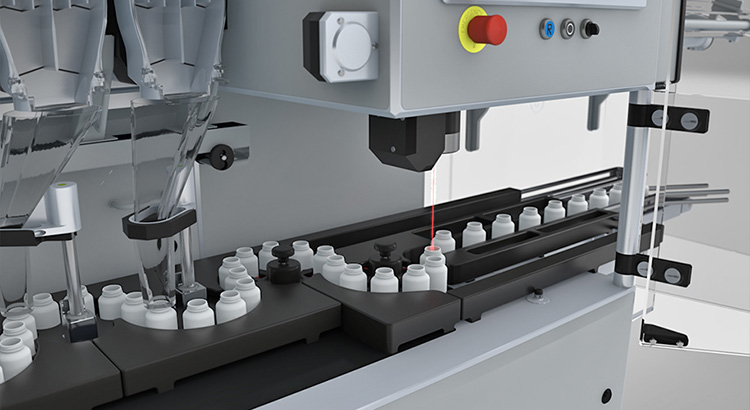

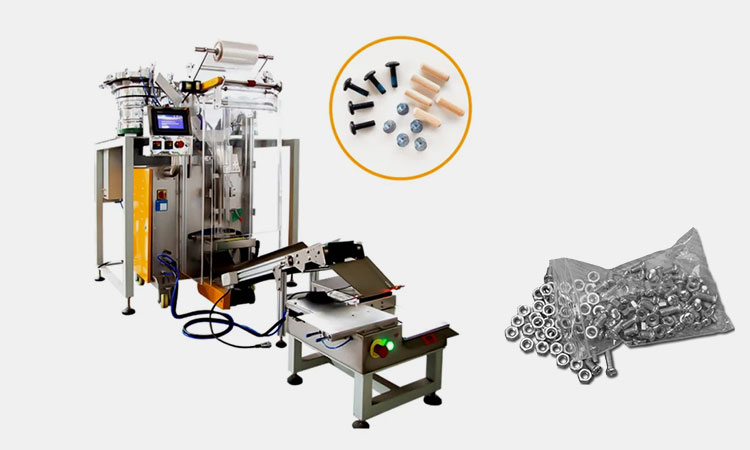

Screw Counting Machine-sourced: feiyu

Do you want to increase productivity for your packaging business? Is the error rate of manual work higher now than that of machines? And the cost of labor even exceeds the production cost of the machine? This complete buying guide about screw counting machine can provide you with the most detailed information. Let's dig out now!

1.What Is Screw Counting Machine?

What Is Screw Counting Machine-sourced: feiyupacking

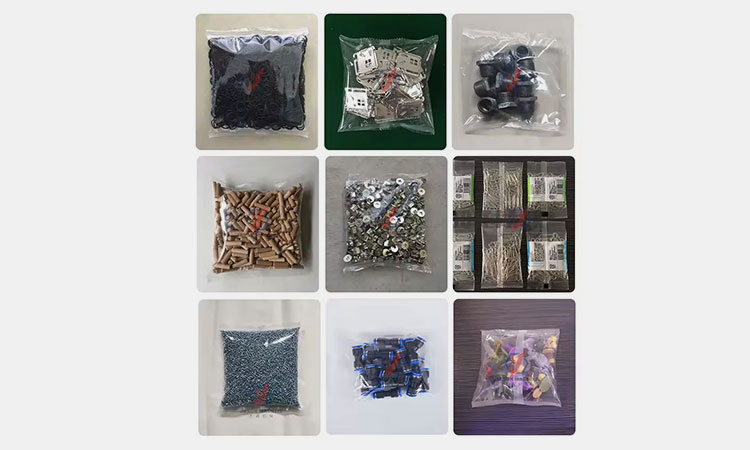

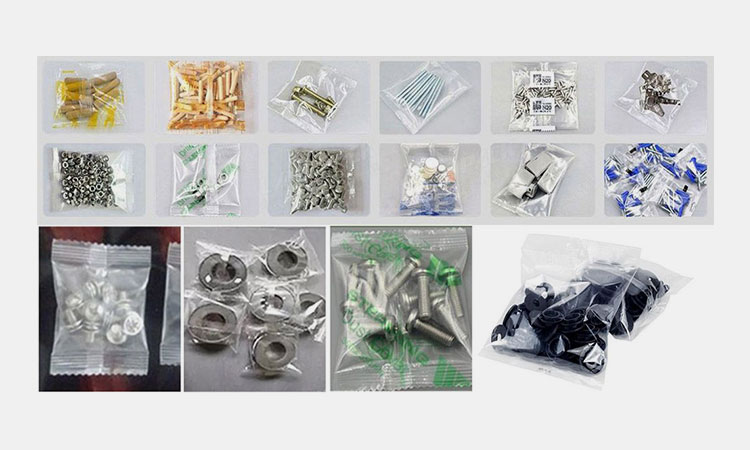

Screw counting machine, also called as screw counting and packing machine, nut bolt counting machine, is widely used to count and package the screws, bolts, nuts, washers into different pouches and boxes. The screw counter is an essential tool in many industrial environments for your application.

In addition to counting and packaging, the screw counter also has functions such as screw quality inspection, labels and patterns printing. It also reduces the risk of your human error and ensures the packaging process runs smoothly and efficiently, thereby increasing production efficiency.

2.What Industries Are Screw Counting Machine Mainly Applied For?

The screw counting machine is used in a wide range of industries, including:

Hardware Industries

Hardware Industries-sourced: Feiyu

All types of screws, nuts, bolts, washers, fasteners, hardware assortment kits, sliding parts, door track kits, wrenches, door rollers, cabinet pulls, cabinet rings, door hanger, dresser knobs, switches from your home or industry can be counted and packed by this screw counting machine with high efficiency and quality.

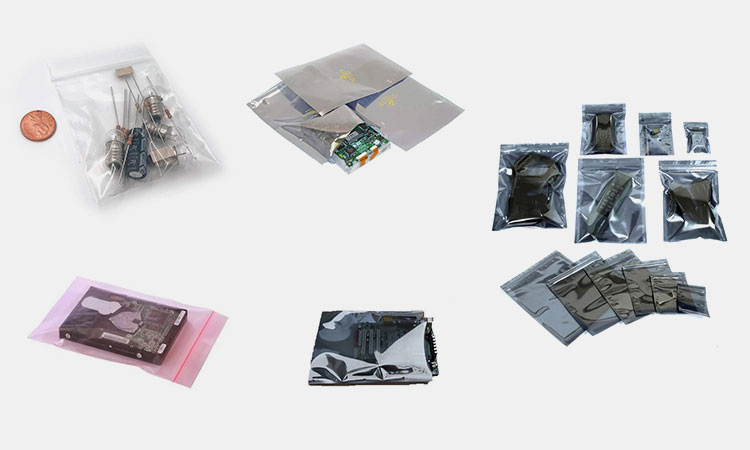

Electronics Industry

Electronics Industry-sourced: teachersource

Various electronic devices and parts can be counted and packed by the screw counting machine, such as connectors, chargers, earphones, battery, resistors, capacitors, relays, IC, transistors, fuses, etc.

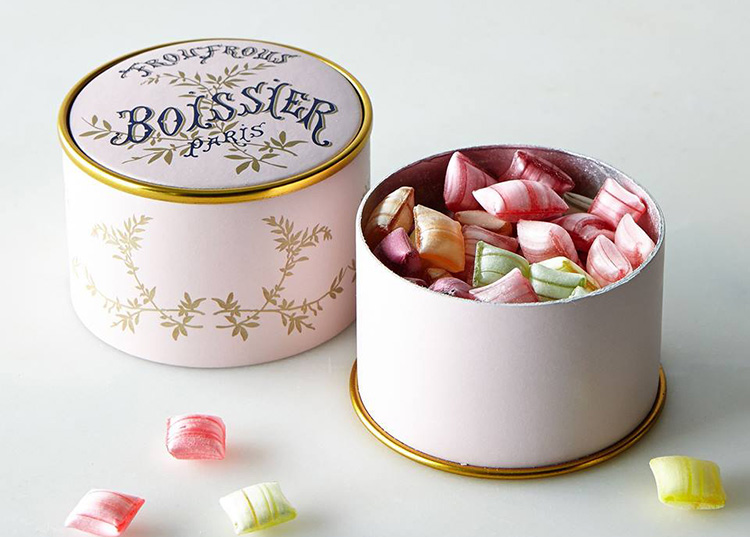

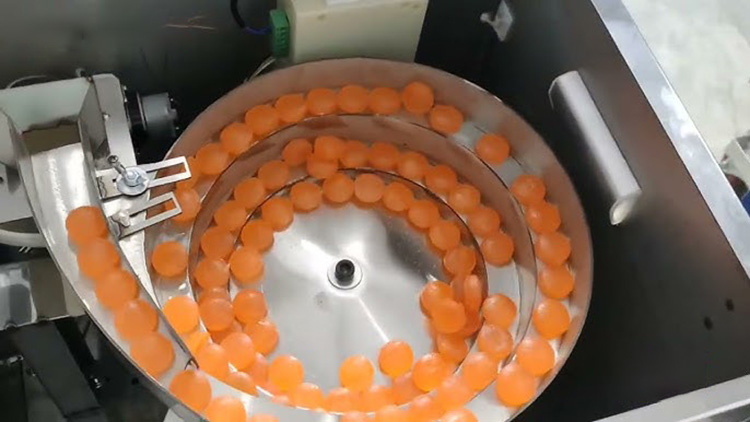

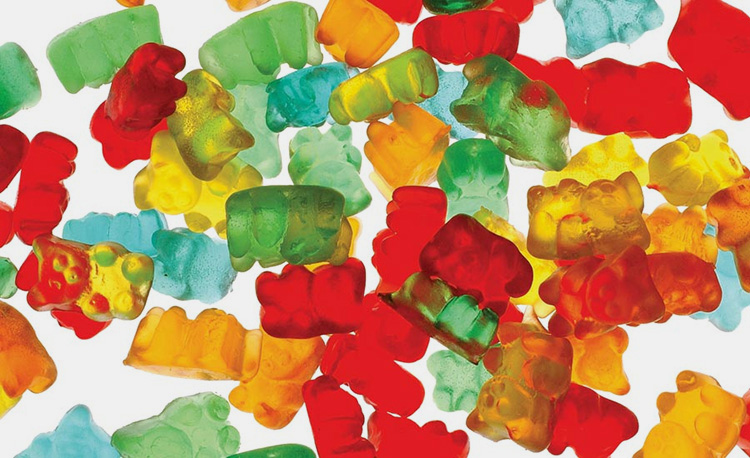

Food Industries

Food Industries-sourced:oumapack

The food industry also widely uses screw counting machines to improve their packaging efficiency. These include but are not limited to candies, gummy bears, gums, grains, seeds, pet foods, fertilizers, nuts, coffee pods, fruits, chinese herbs, vegetables, frozen foods, etc.

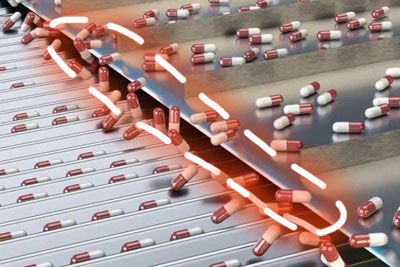

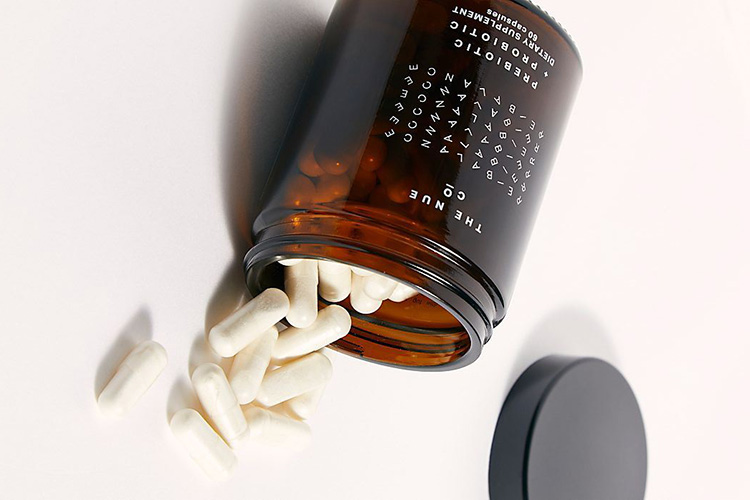

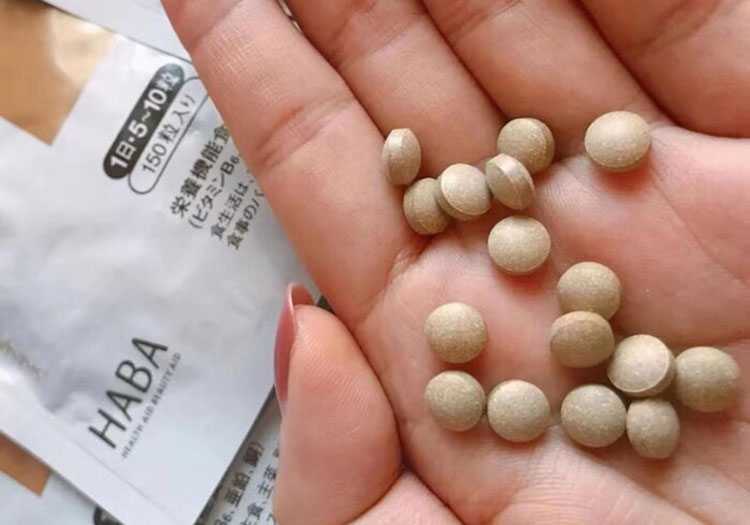

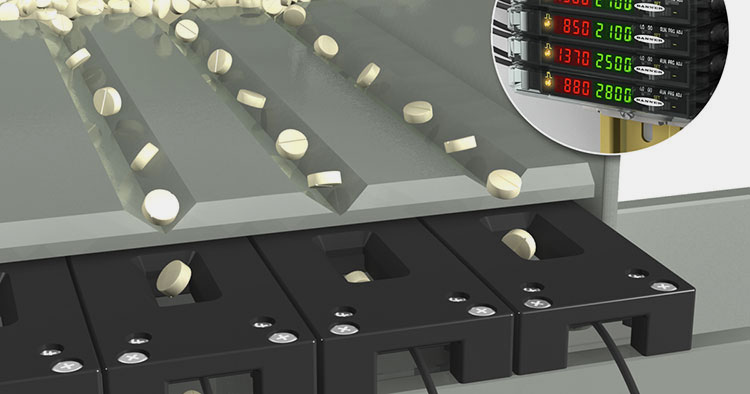

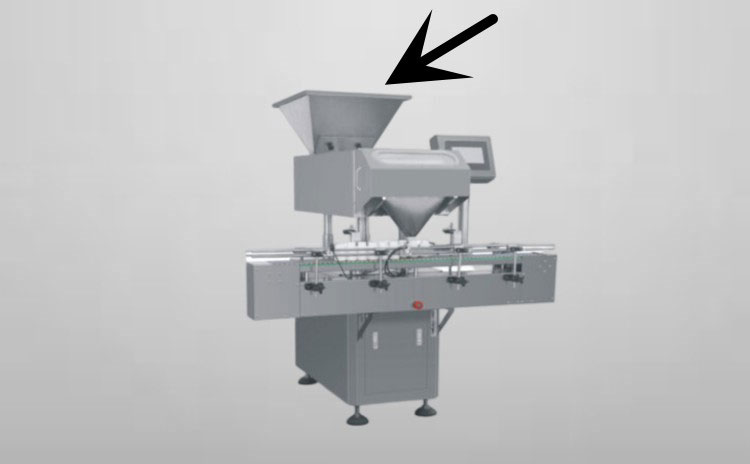

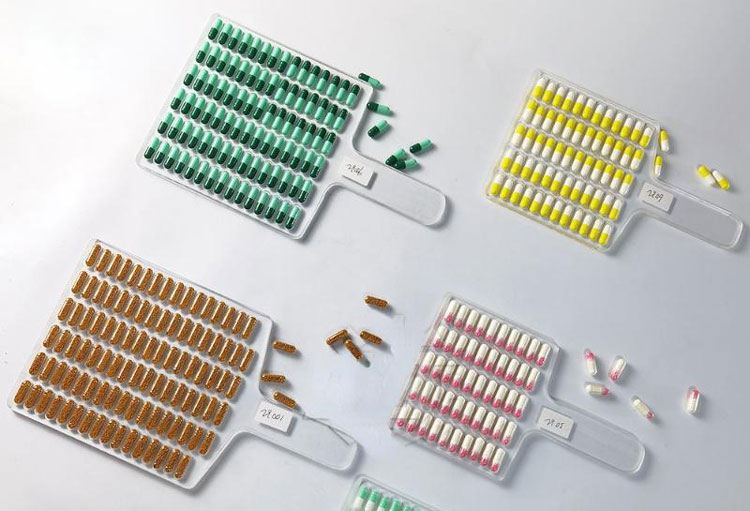

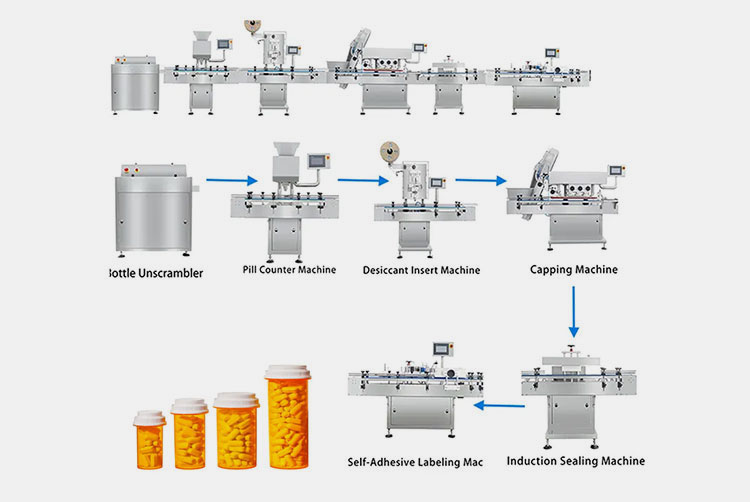

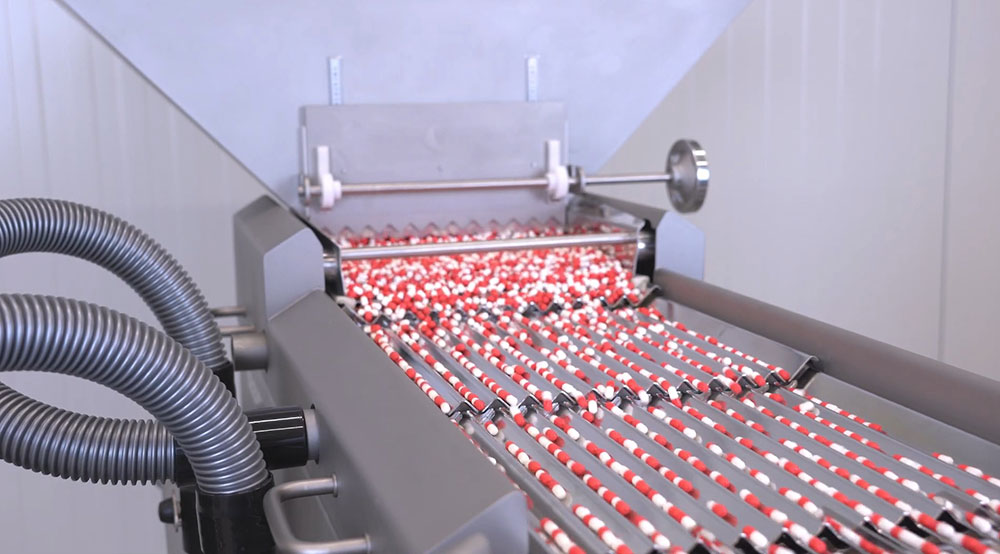

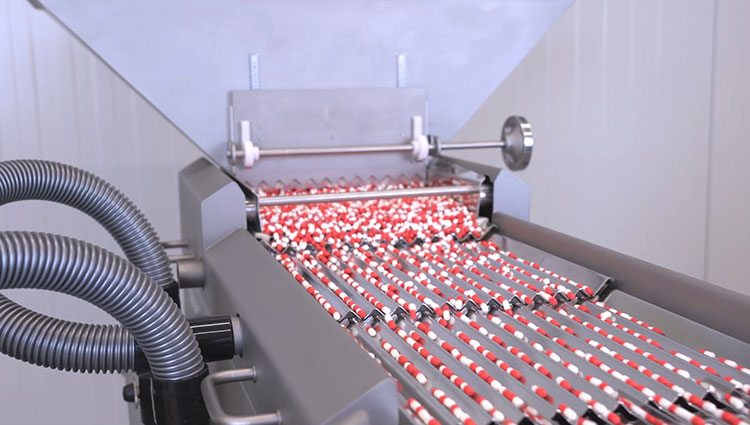

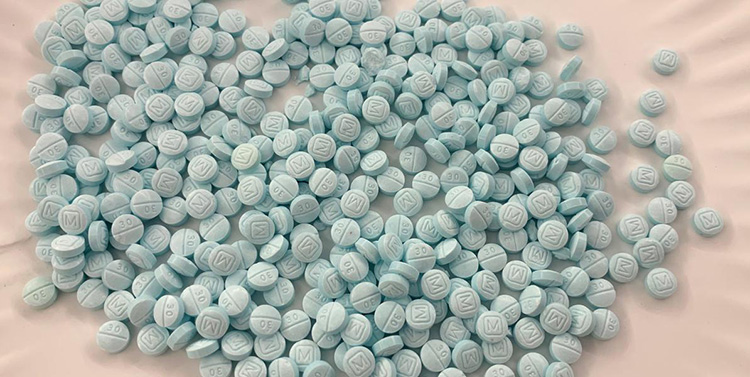

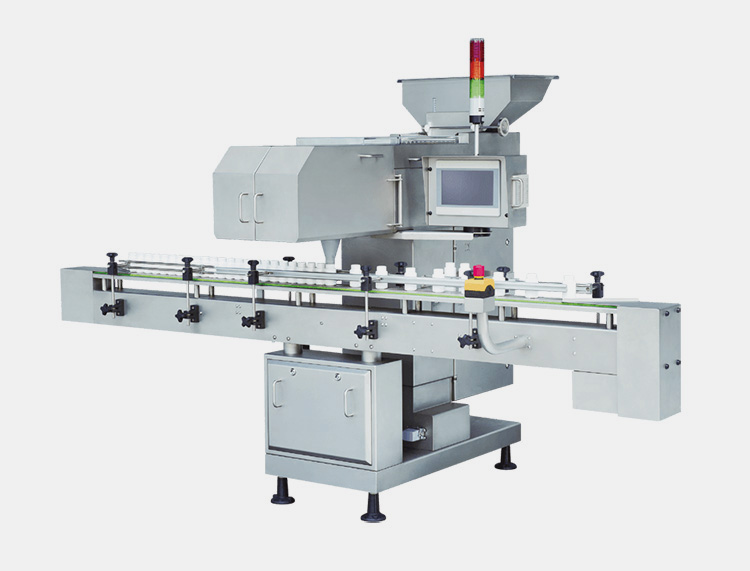

Pharmaceutical Industry

Pharmaceutical Industry-sourced: whitecrosspharmacy

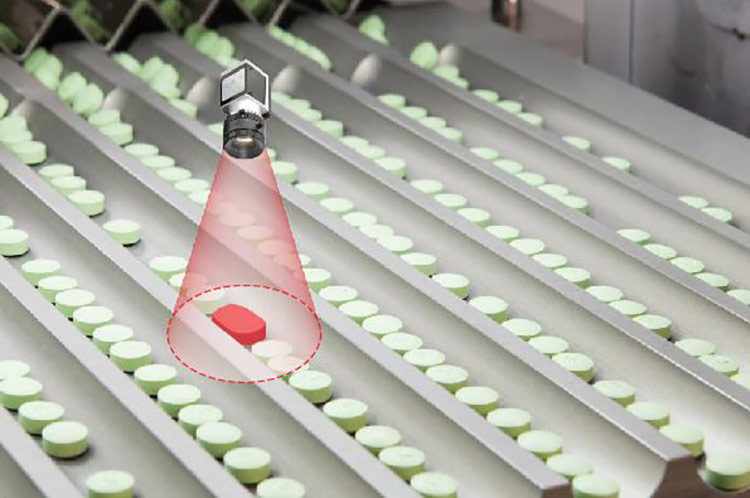

Screw counting machines can be used for various counting and packaging of pharmaceutical pills, vitamin tablets, dietary supplement capsules, health care product tablets and capsules in your daily life. It can also perform quality inspection and remove damaged or incomplete products to ensure the quality of your products.

Toy Industries

Toy Industries-sourced: lego

Many children's and adult toys can also be counted and packaged using screw counting machines. The product types of the toy industry include food toys, plastic toys, Lego toys, puppet toys, doll toys, decorative toys, animation toys, etc.

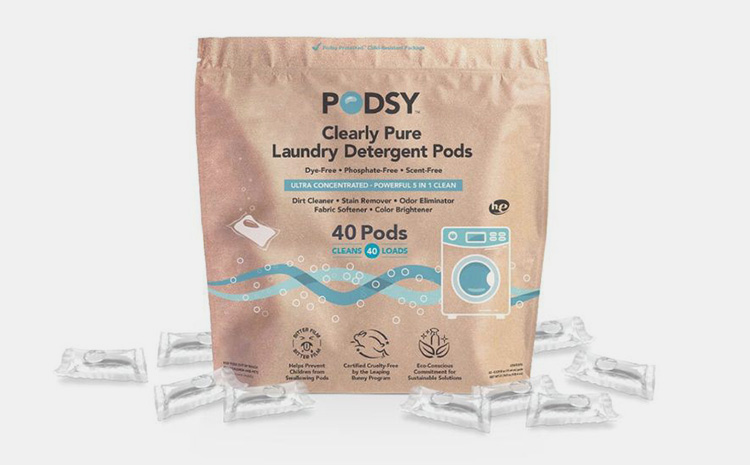

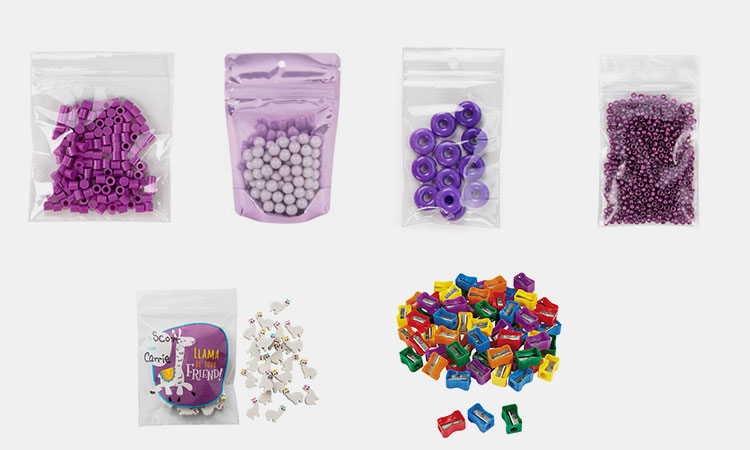

Daily Necessities Industries

Daily Necessities Industry-sourced: orientaltrading

Various daily necessities in daily life that only need to be counted and packaged can be processed using screw counting machines. These include various cleaning pills needed for the kitchen and bathroom, buttons and zippers for clothes, erasers, pencil sharpeners, small parts for bicycles, air conditioners, refrigerators, doors, etc.

3.What Are The Bag Styles And Materials Applied For Screw Counting Machine?

There are plenty of bag styles and bag materials for your choice to be applied in the screw counting machine. You can make good uses of this machine according to your product types, the bag packaging styles and materials.

Bag Styles

Back Seal Bags

Back Seal Bags-sourced: pouchespackingmachine

Back seal bags are bags that are sealed from the bottom and then have a central seam on the back. It is mainly used for packaging of various snack foods, toys, pharmaceutical pills, daily necessities, etc. The back seal bags are small, convenient, beautiful, and convenient for you to purchase and carry.

Three-side Seal Bags

Three-side Seal Bags-sourced: gozenpackaging

The three-side seal bag, also called as flat pouch, is a bag with three sealing sides with an open end. The differences between them are that the front and back panels are sealed on three sides and folded on one side. The three-side seal bags facilitate easy filling and sealing during your product process.

Four-side Seal Bags

Four-side Seal Bags-sourced: ilovesportsgirl

Four-side seal bags are also called as quad seal bags, block bottom bags. It is sealed on all four sides. This four-sided sealing design can provide you with better safety and prevent product leakage.

Pillow Bags

Pillow Bags-sourced: thimonnier

Also called as pillow pouches, pillow bags are mainly composed of bottom, top and back seals. Its back seal extends the entire length of the bag. Therefore, it is also known as "T-shaped seal bag". This type of packaging is one of the most economical forms of packaging.

Gusset Bags

Gusset Bags-sourced: cuymer

Gusset bags are designed with extra material for side or bottom support. Compared to flat bags, the gusset bags are able to hold more weight and increase fill capacity. With its own support ability, it can well display your brand on the shelf.

Bags with Euro Hole

Bags with Euro Hole-sourced: cecopack

Bags with euro hole are suitable for common sales hooks. Because it can be hung and displayed, this allows you to better see and remove the product. Most of the types of bags like flat bags can be designed and cut with euro holes. These holes protect the contents of the bag from dust and moisture.

Bags With Round Hole

Bags With Round Hole-sourced: primepacks

Bags with round hole are often applied for product packaging and retail display. Through the round holes, you can hang your products on the hooks for display and sale. Not only that, this also saves you on display costs.

Bag Materials

Different packaging materials are suitable for different products to be packaged and sold. Do you frequently use the following common product packaging materials?

Aluminizer

Aluminizer-sourced: PATIKIL

The aluminizer is a bag material made of high-purity aluminum on plastic film through high-temperature and vacuum plating. It prevents light and oxygen from entering the bag and helps maintain your quality of the product inside. But the cost of such bags is higher.

Composite Membrane

Composite Membrane-sourced: pandwhole

The composite membrane is a material made by laminating multiple layers of plastic or metallized films together and then heat-sealing the composite. It is often used to package products that require high grease or gas barrier properties.

Filter Paper

Filter Paper-sourced: recordpower

The filter paper is specially used to separate solid particles from liquids or gases. It is made of cellulose and has good filtration and absorption properties.

Printing Film

Printing Film-sourced: getpacked

The printing film is one of the most commonly used flexible packaging materials. It is available in rolls and in any packaging format. This material can be used in high-speed molding, filling and sealing applications, and more.

4.How Can A Screw Counting Machine Benefit Your Business?

The screw counting machine can provide you with automatic loading, counting, metering, filling, packaging and other steps. Providing you with efficient and effective screw counting and packaging solutions.

Accurate Counting

Accurate Counting-sourced: fastenerpackingmachine

There are different counting system for your choice all with high counting accuracy, including mechanical counting system, optic fiber counting system, and weighing counting system. All of the counting system can be combined together for your upmost counting accuracy.

Intelligent Packaging

Intelligent Packaging-sourced: doublemachine

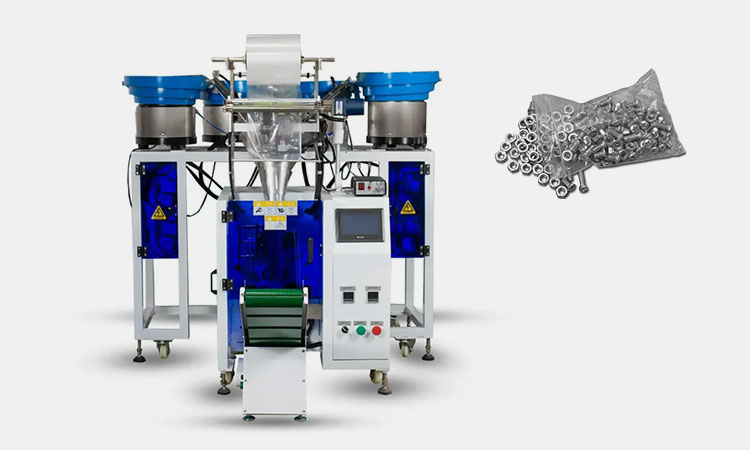

The screw packaging system contains four main parts including counting counting system, feeding system, packing system, and accessary system. It is controlled by PLC and touch screen and can automatically help you finish complete processing, counting, metering, filling, packaging, etc.

High Productivity

High Productivity-sourced: mudgefasteners

The fully automatic screw counting machine can automatically and easily complete counting, packaging and sealing of various products with high speed. It can easily increase your productivity and productivity by directly following the set procedures.

Flexibility and Versatility

Flexibility and Versatility-sourced: viajesvidatour

The screw counting machine can be flexibly used in production and packaging in various industries. By converting packaging formats, it can be changed, updated, and expanded based on product changes and your needs, making your production process smoother.

Save Time and Reduce Error

Save Time and Reduce Error-sourced:

Using a screw counting machine will significantly improve your productivity, reducing manual counting errors, and improve your counting accuracy and packaging quality. By streamlining your production processes, you can significantly save more time and reduce errors.

5.Are There Limitations Of Screw Counting Machine?

The screw counting machine can serve in most industries. While it can greatly improve your productivity, inevitably, it also has limitations.

Parts Wearing

Parts Wearing-sourced: acroperda

Machine parts wearing is inevitable for most packaging machines, especially when the machine is used frequently and running non-stop. This problem can be effectively dealt with by intermittently stopping the machine or purchasing replaceable wear parts.

Equipment Failure

Equipment Failure-sourced: talabulilm

Any equipment has the possibility of failure, so you need to be equipped with appropriate engineers to deal with such problems at any time. Or you need to train your own employees to detect and supervise the operation of the machine in a timely manner.

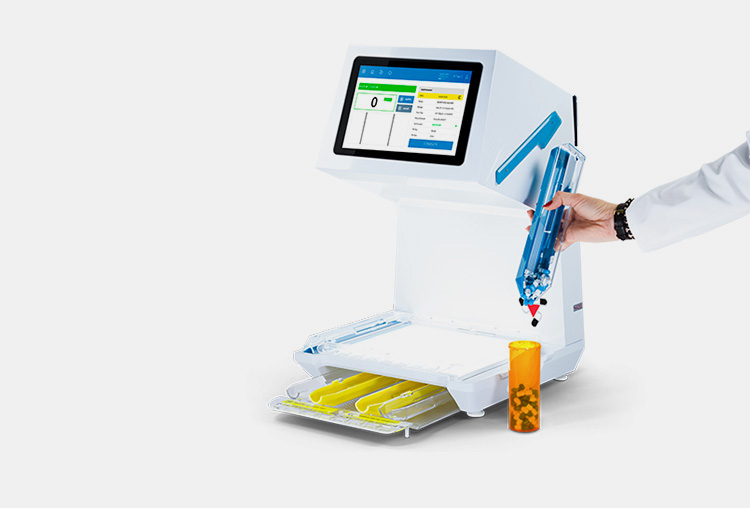

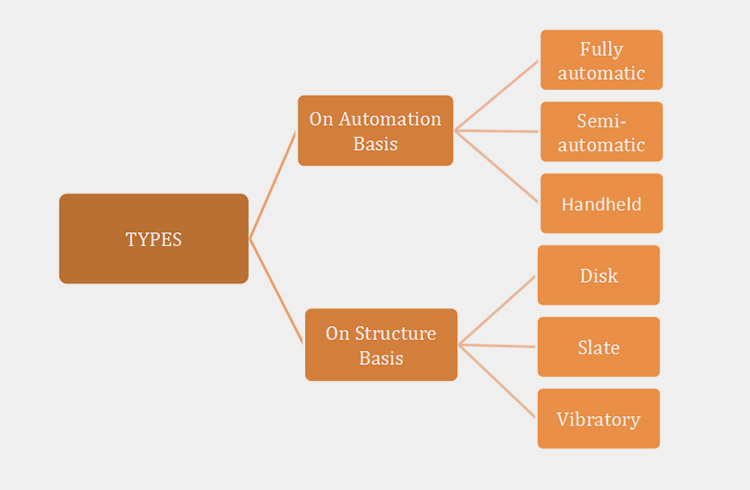

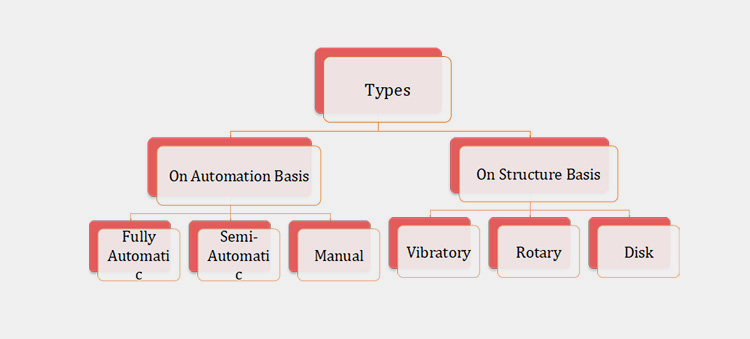

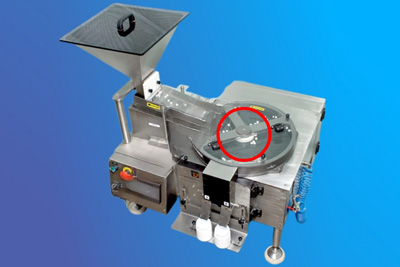

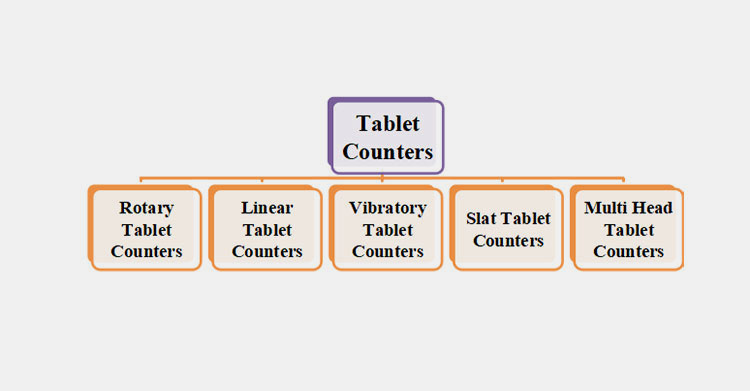

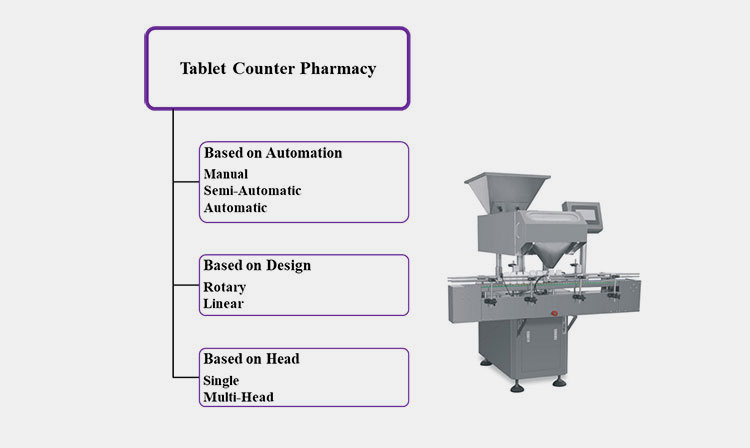

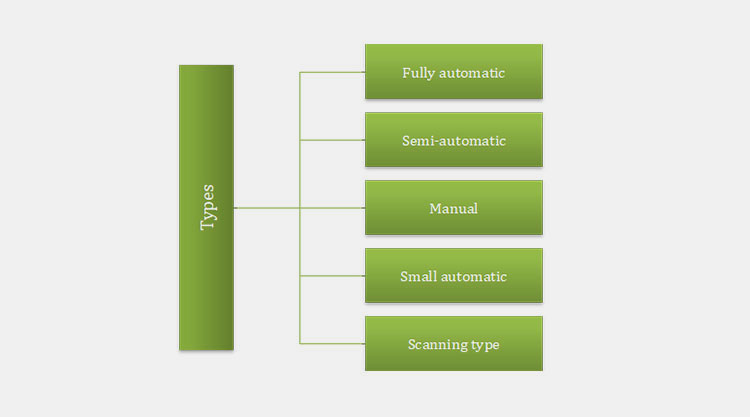

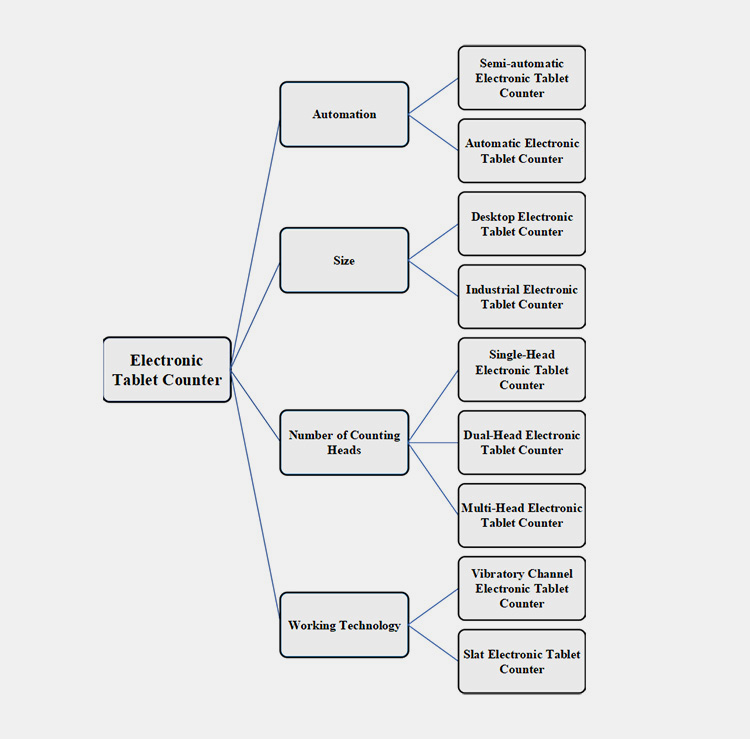

6.What Are The Types Of Screw Counting Machine?

Are you curious about the screw counting machine types? There are multiple choices for your consideration.

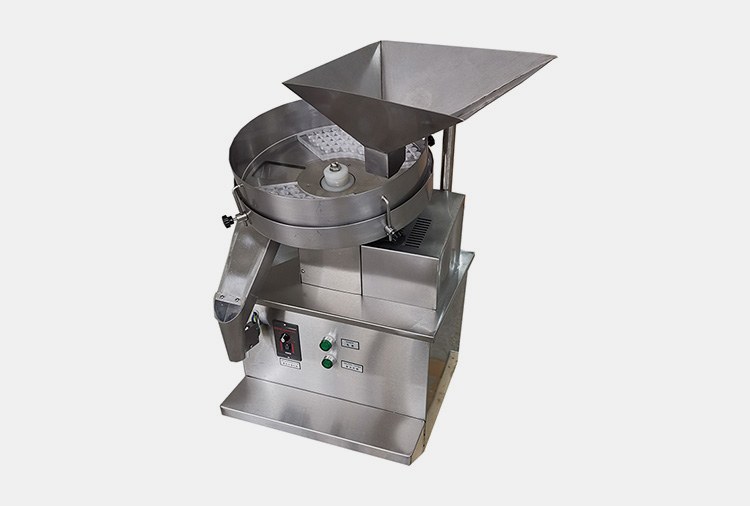

Vertical Screw Counting Machine

Vertical Screw Counting Machine-sourced: combiweight

The vertical screw counting machine adopts a vertical design and is equipped with a vibration bowl. Using PLC control system, it can automatically complete screw sorting, counting, packaging, printing and other steps. You can choose other auxiliary equipment, such as printers, labeling machines, conveyor belts.

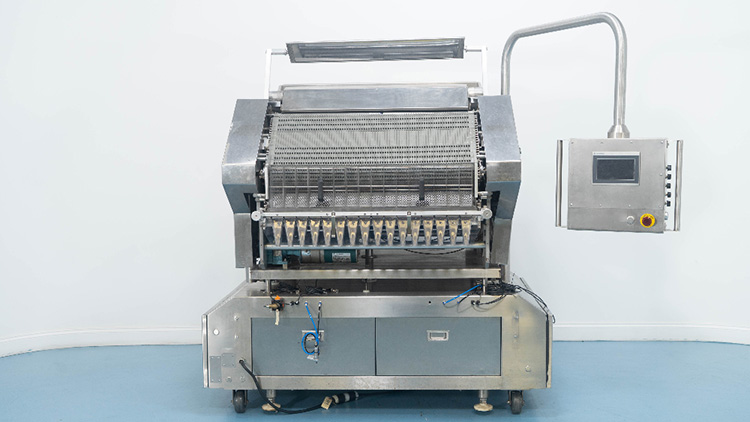

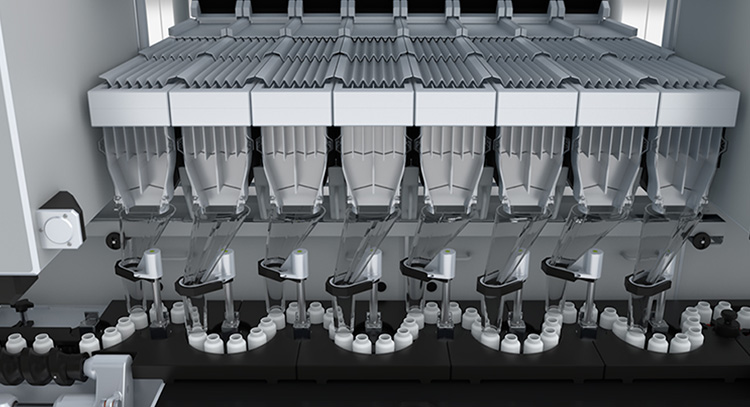

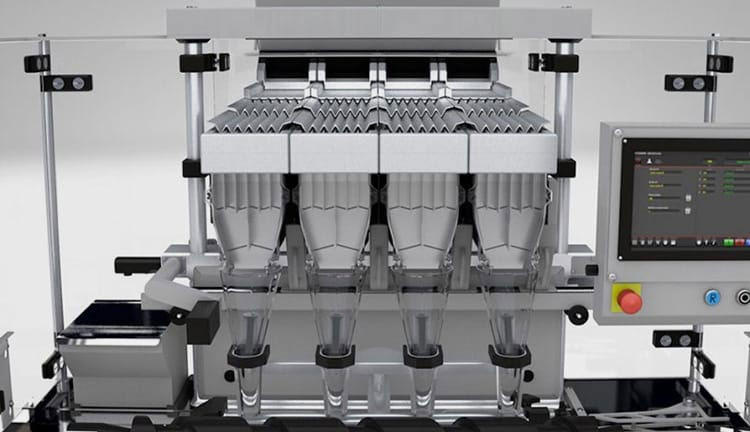

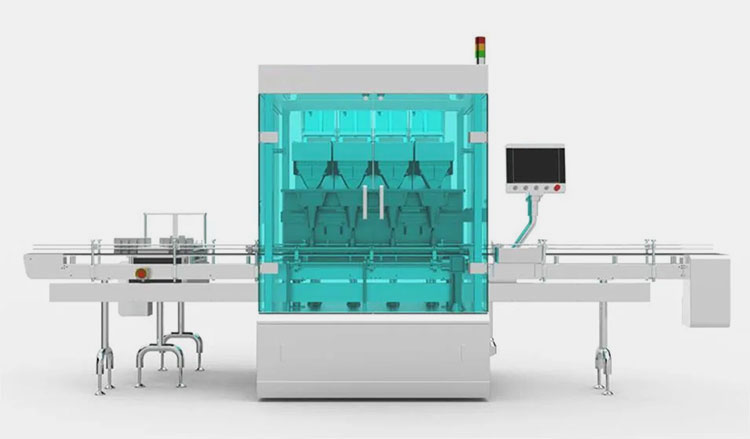

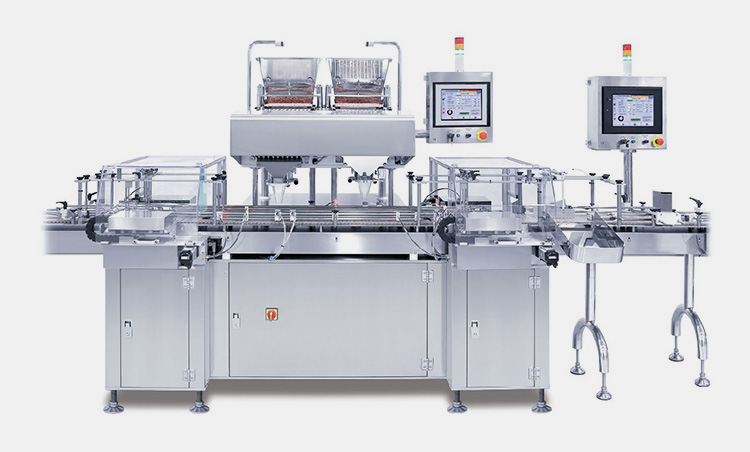

Multiple Feeder Screw Counting Machine

Multiple Feeder Screw Counting Machine-sourced: doublemachine

The multiple feeder screw counting machine uses multiple vibration bowl and filling systems such as fiber optics re-inspection or completed fiber optics counting for your high productivity and efficiency.

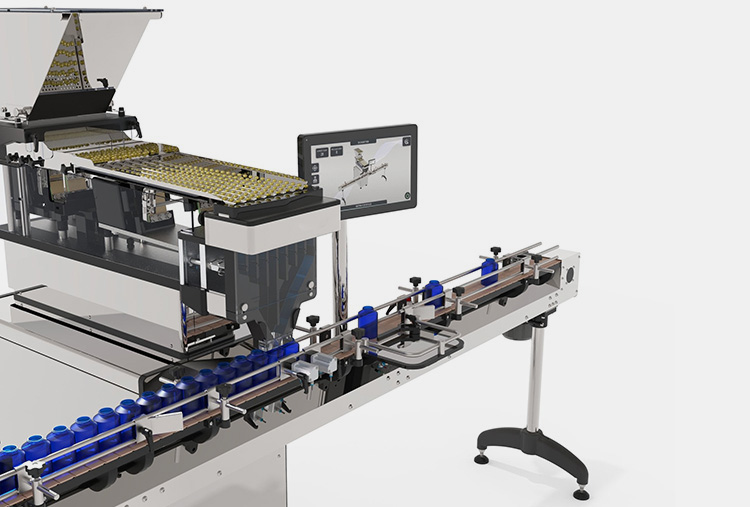

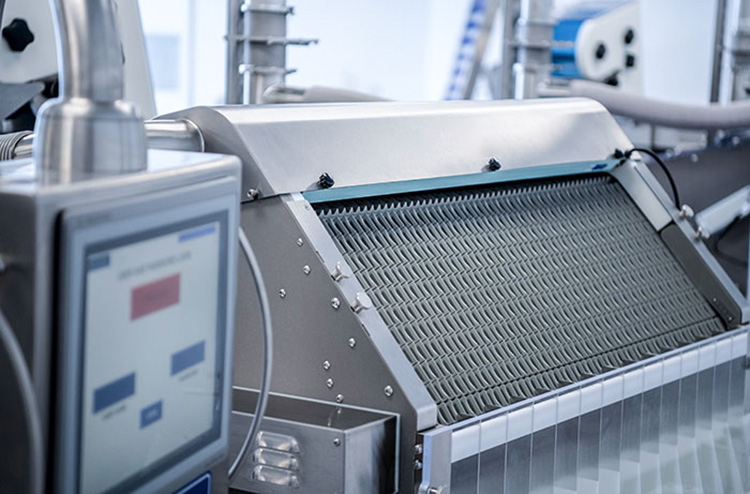

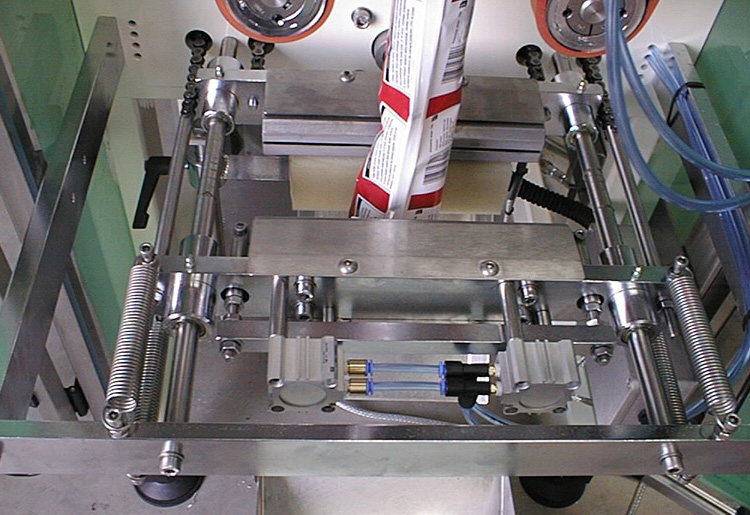

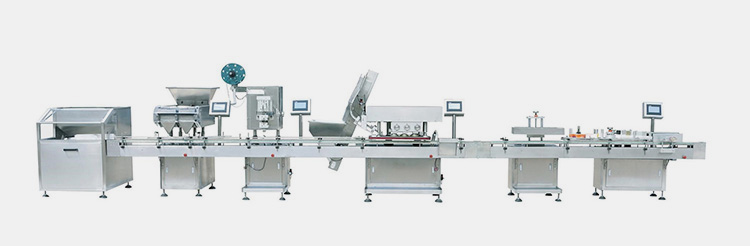

Screw Counting Machine With Conveyor

Screw Counting Machine With Conveyor-sourced: easternpackaging

The screw counting machine with vertical product conveyor can help you finish feeding, measuring, filling, sealing, date printing, charging (exhausting), counting, and finished product delivery when it equips with feeding and measuring equipment. the automatically product loading and feeding. It can save you more time.

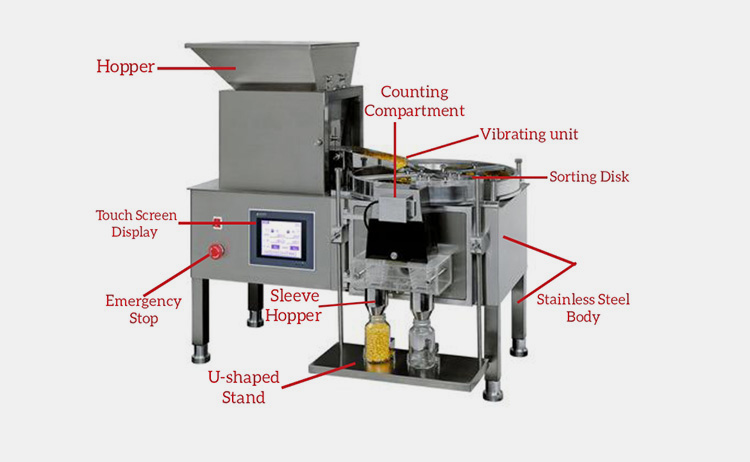

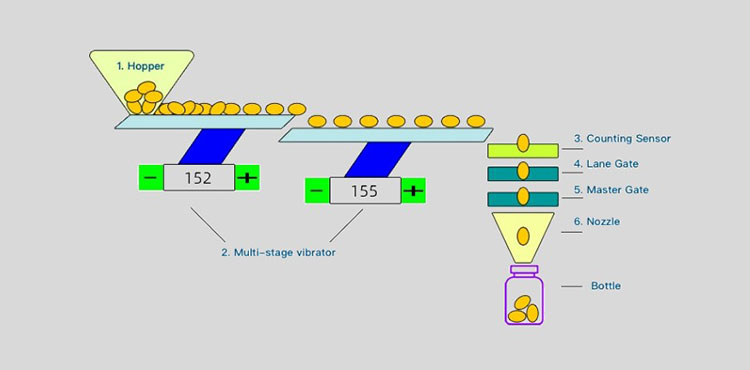

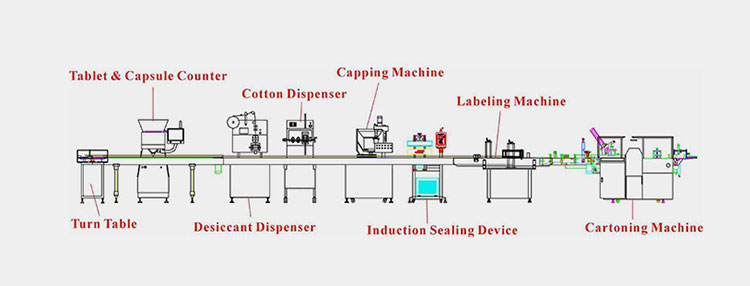

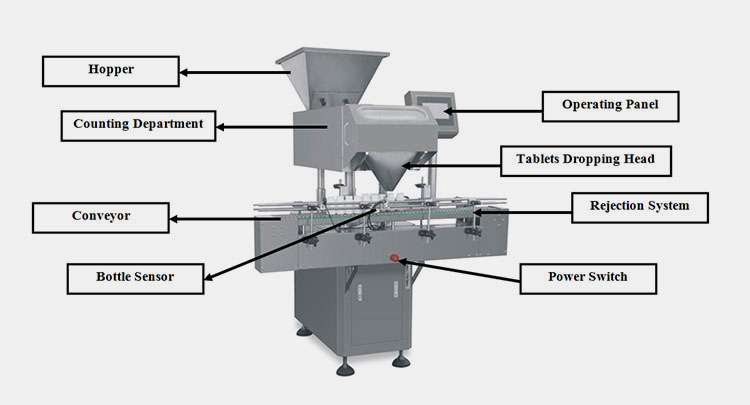

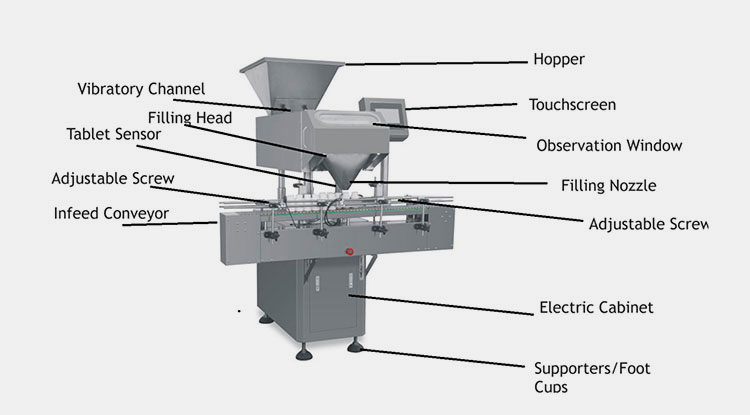

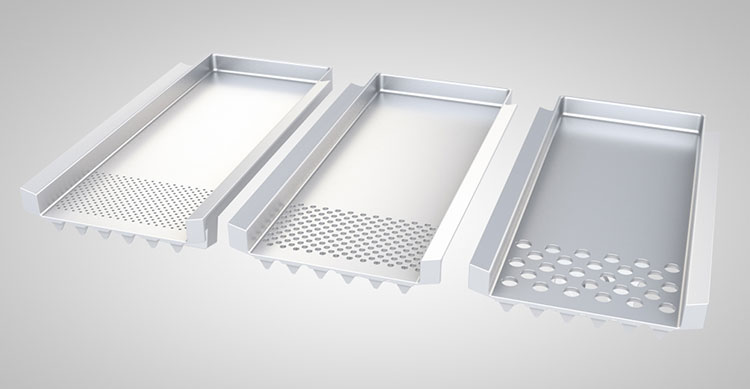

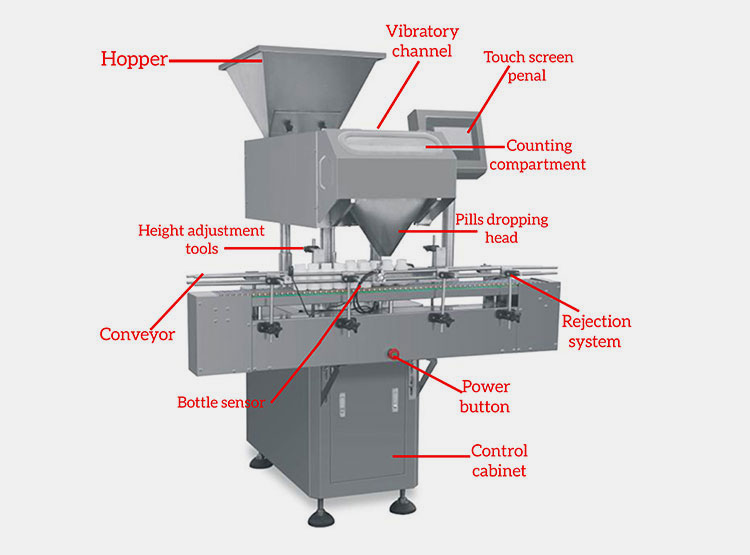

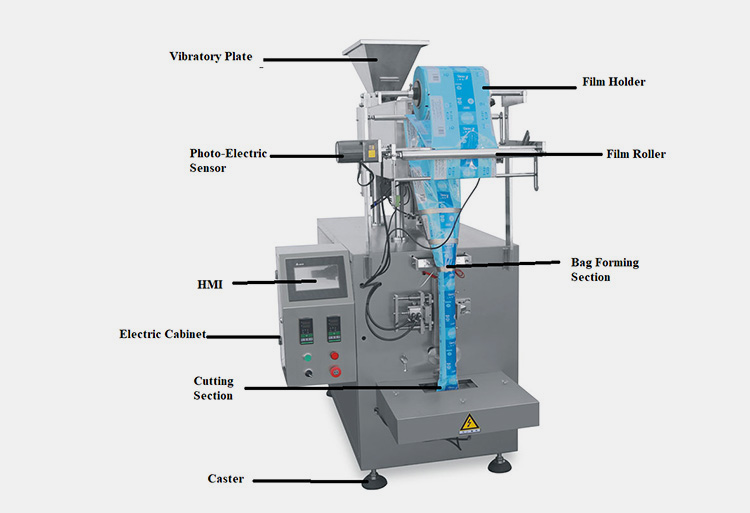

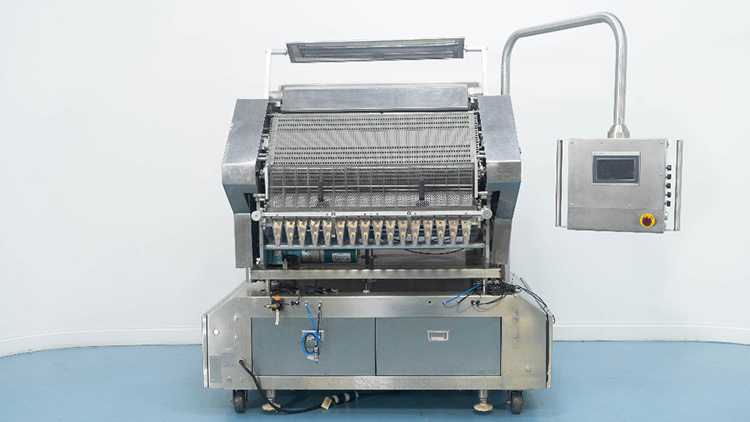

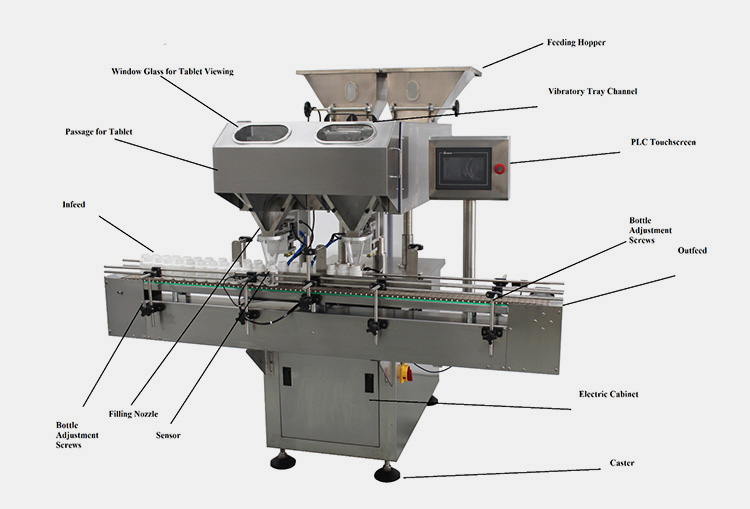

7.What Are The Main Components Of Screw Counting Machine?

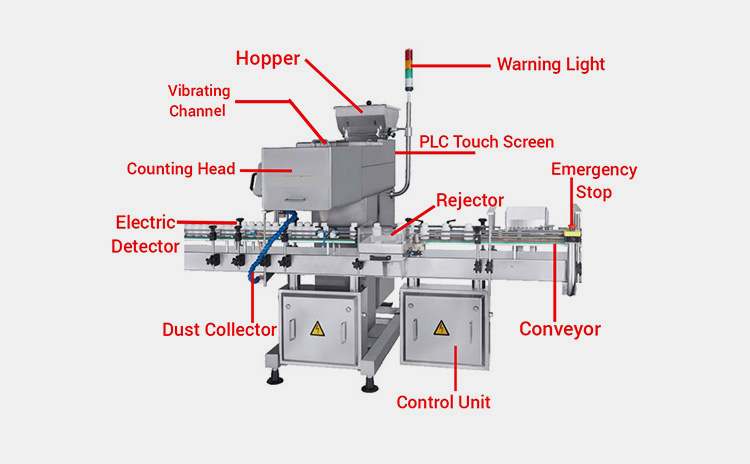

Main Components Of Screw Counting Machine-sourced: feiyupacking

To know well about the screw counting machine, you need to learn about the main components and know how it works. The main parts are:

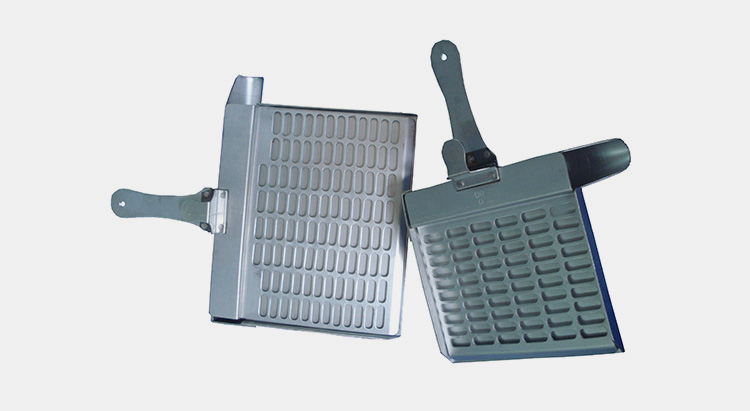

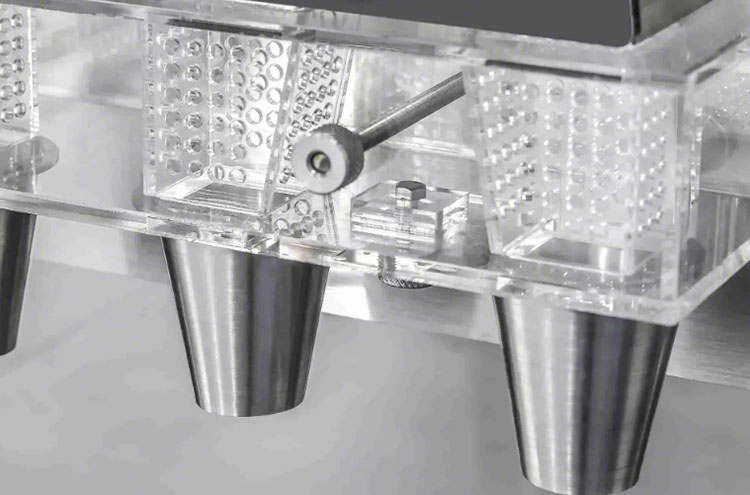

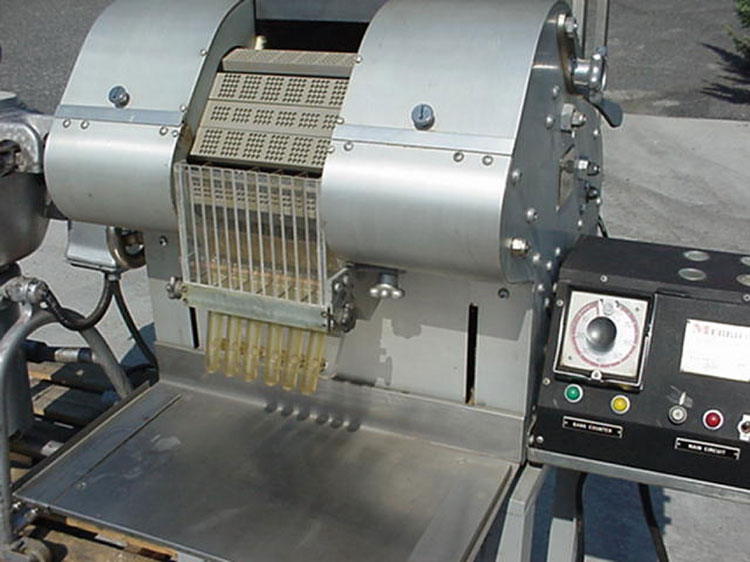

Fiber Counting System

The fiber counting system mainly consists of vibration hopper, vibration bowl and optic fiber counting device. It mainly uses the anti-shock, delay and other functions of optical fiber to count different types of accessories. Through PLC control, the number of accessories can be easily adjusted.

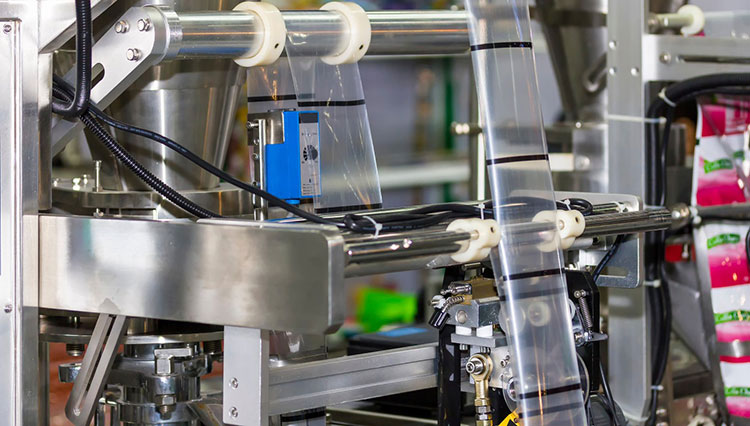

Composite Packing Films

Composite packing films are new type of packaging materials that combines different or more materials to create one for packaging, including paper-polyethylene, plastic-aluminum, plastic-paper-aluminum, and cardboard-polyethylene, etc. Such materials are more durable and safer.

PLC Control System

The PLC control system can offer you logical, intelligent, and accurate screw feeding, counting, packaging and sealing effects. You can set the corresponding program according to your own needs to automate the entire process.

Bag Former

The bag former is specially designed for processing flat roll film into finished bags. After the screws are counted and transferred into the packing system, the finished bag will be formed and filled with the screws. Equipped with heat sealing system, the screw bags will be filled and sealed accurately and neatly.

Weighing Checker

The weigher checker is specially used for weighing, quality inspection and defective product removal of screw packaging bags after packaging is completed. It can re-check the quantity and quality of screws in the bag, and automatically remove defective or abnormal screw packaging bags to ensure the quality of your final product.

Bag Conveyor

The bag conveyor is used for taking off the finished products out or to next production machine. It ensures that the packaging process runs smoothly and efficiently, reducing the need for labor and increasing productivity. It can be assembled and modified according to your needs, including rollers, axles, surfaces.

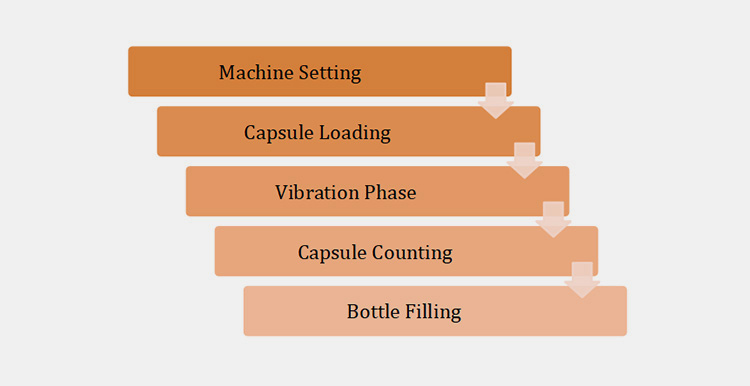

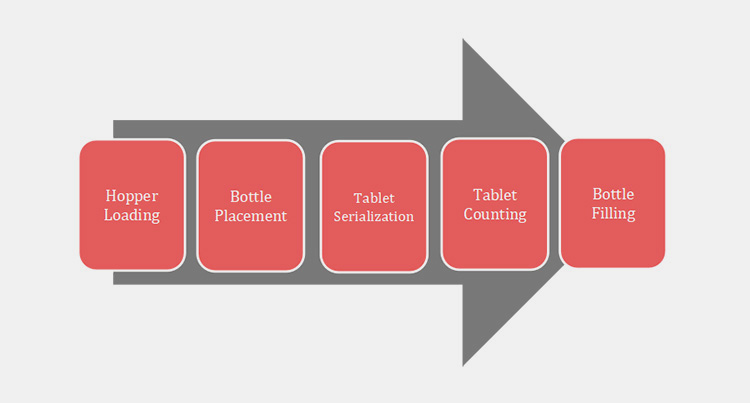

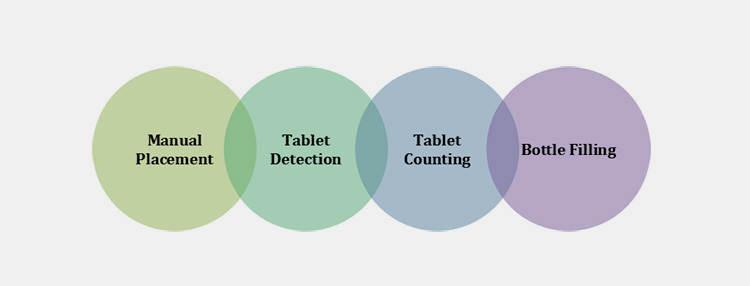

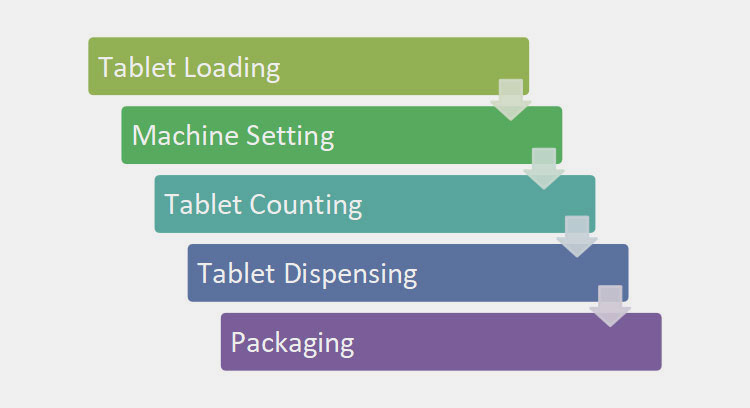

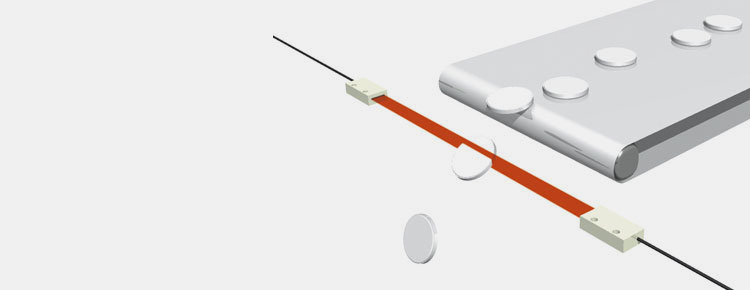

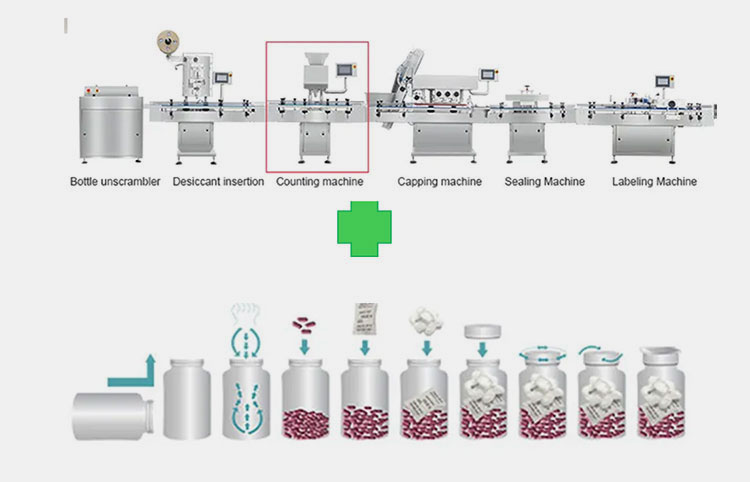

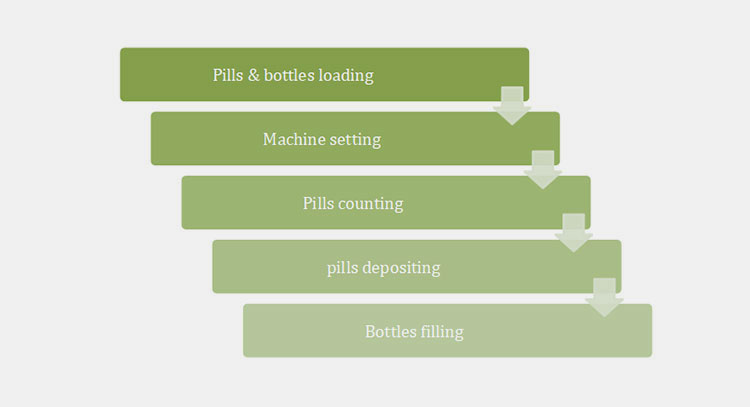

8.What Is The Working Principle Of Screw Counting Machine?

Working Principle Of Screw Counting Machine-sourced

Following the working principle of screw counting machine, you might get the best understanding of this type of machine.

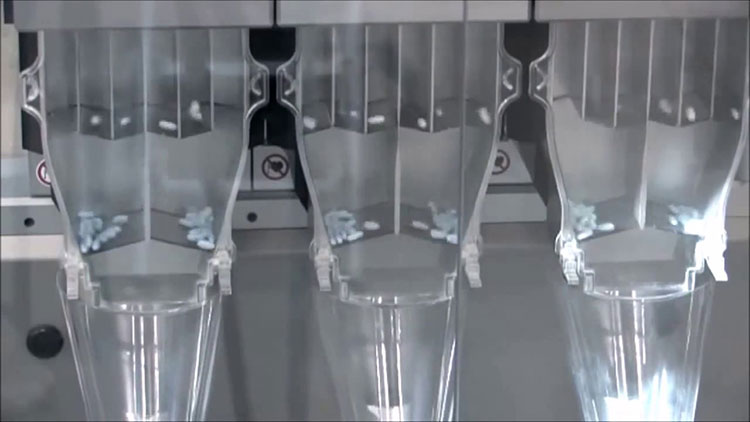

Screw feeding: Feed or load the products you need to count, like screws, nails, fastens, pills, hard-wares, etc. into the vibration hopper or a bulk container. You can use auxiliary tools such as conveyor belts or vibrating feeders to feed the products Transfer from storage container to counting area.

Screw counting: After the product reaches the counting area, the optical sensor detects individual products passing a specific point when passing through the fiber optic electronic eye. When these products are counted, the sensor receives the signal and sends the products to the packaging system.

Screw packaging: When screws are loaded into the packing system, they will be inserted and filled into pouches that made already by the bag former.

Sealing and cutting: When the counted products are filled into the pouches, the equipment will use heat sealing to seal the bags. Sealed products will be cut from the linking bags to facilitate subsequent label printing.

Labeling and printing (optional): If you need it, the screw counting machine can integrate labeling or printing functions to add product information, barcodes or other relevant details to the packaging for you.

Finished conveyor (optional): Once the packaging is complete, the finished product is discharged from the machine by the finished conveyor.

Check weight device (optional): This step is for the final weight and quality check of screw bags.

9.What Are The Optional Equipment You Can Choose For Your Screw Counting Machine?

Are there any optional equipment you can choose for improving your screw counting and packing efficiency? Sure, they are:

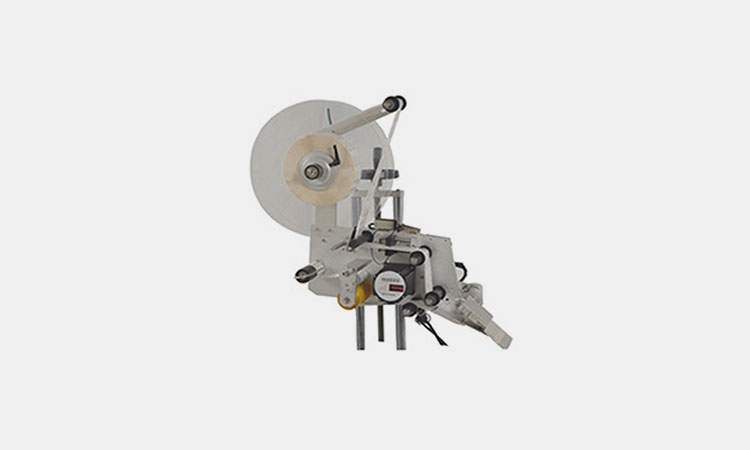

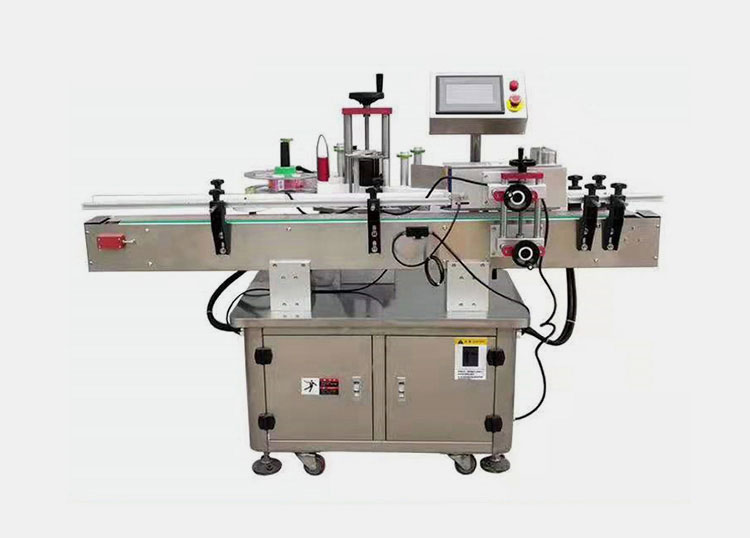

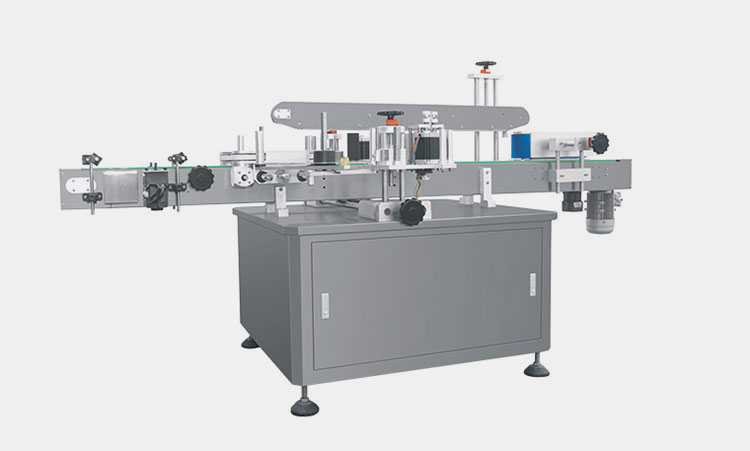

Labeling Machine

Labeling Machine-sourced: feiyumachinery

The labeling machine is another accessory that can be added to the screw counting machine. It can be connected and integrated into a screw counting and packing line. The labeling machine can quickly and accurately apply labels to pack bags and ensure that the packed screws are identifiable and organized.

Printer

ALLPACK Dikai Printer

The printer can provide you with a full range of inkjet coding solutions. It is widely used in printing packaging bags for various snack foods, medicines, household paper, cosmetics, and hardware products.

Check Weigher

Check Weigher-sourced: evalcan

A very useful addition to the screw counting machine is the check weigher. It can re-check the quantity and quality of screws in the bag, and automatically remove defective or abnormal screw packaging bags to ensure the quality of your final product.

10.How To Troubleshoot Your Screw Counting Machine?

During the use of screw counting machine, various problems will inevitably occur.

Machine Problems:

Incorrect Machine Calibration

Incorrect Machine Calibration-sourced: aptean

Before starting up and commissioning the machine, you need to calibrate it so that the subsequent machines can run smoothly. Improper machine calibration may cause product to become stuck or misaligned.

Solutions

Before use, it must be calibrated according to the manufacturer's requirements.

Machine Stops or Shuts Down

Machine Stops or Shuts Down-sourced: countingpacking

Improper stopping or shutting down will affect the operation and efficiency of the machine. Therefore, you need to rule out whether the power supply is faulty, whether the machine is overloaded or overheated during operation, or whether the sensor is faulty.

Solutions

Check and adjust the machine's power supply, sensors, etc.

Excessive Noise or Vibration

Excessive Noise or Vibration-sourced: kevcor

Excessive noise or vibration may be due to a mechanical problem with the machine. It may be because the screws, nuts or bolts of machine parts are loose, the motor, belt, gear, etc. are jammed or malfunctioned, or the machine parts are worn.

Solutions

Correctly tighten loose parts;

Replace loose or worn parts promptly;

Check and adjust problems with motors, belts, and gears;

Packaging Problems:

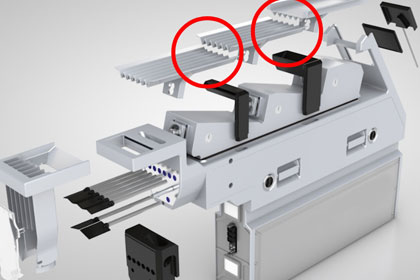

Product jam

Product Jam-sourced: honmonpack

Incorrect feeding method will cause your product blockage or misalignment;

Solutions

You need to make sure the product that is fed into the machine correctly and the vibration bowl is working properly;

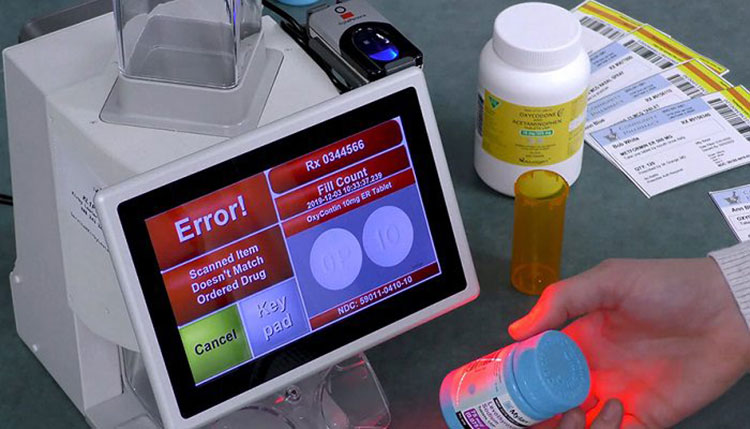

Incorrect Count

Incorrect Count-sourced: landpack

If there is an error in counting, there may be a problem with the program settings, or there may be a malfunction in the counting system;

Solutions

Before official use, the equipment must be put into trial operation and the program and related parameters must be debugged;

Check whether the counting system is insensitive or malfunctions;

Check whether there is any jamming at the product inlet and outlet;

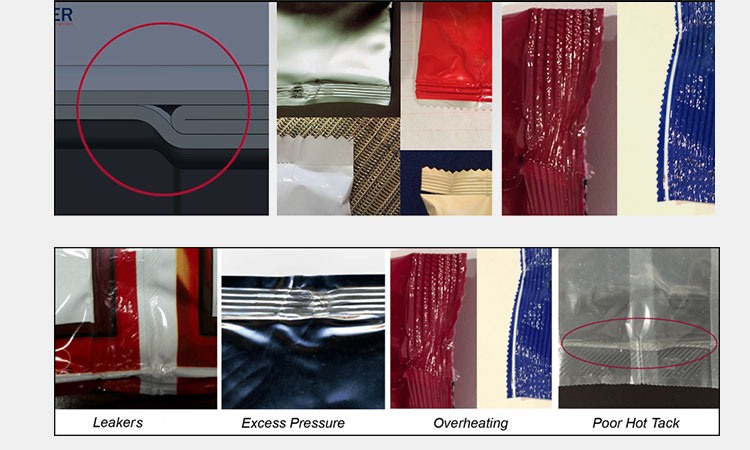

Poor Seals

Poor Seals-sourced: greenercorp

If the temperature of the screw counting machine's sealer is incorrect or too low, the seal will become weak or not seal at all. If the temperature is too high, bubbles and discoloration will occur in the sealing port, affecting the appearance.

Solutions

Use a thermometer to check seal temperature and adjust if necessary.

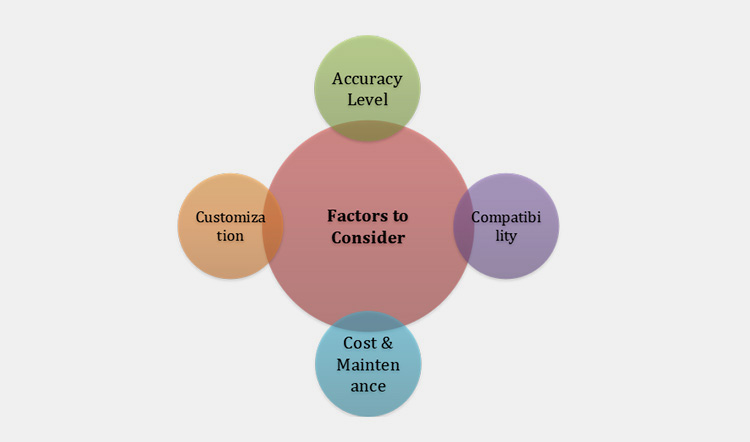

11.What Should You Consider When You Are Choosing A Screw Counting Machine?

Looking for a suitable screw counting machine with good quality? How to choose the best one? With so many options available, deciding which to choose can be overwhelming. Following the tips below.

Speed Requirements

Speed Requirements-sourced: tree

The speed requirements are related to the packaging speed and efficiency of the product. You can choose different models of equipment by how many screw bags you want to count and fill per minute.

Labeling Requirements

Labeling Requirements-sourced: jbtc

Some screw counting machines may not be with the labeling function. If you want to have a screw counting machine with integrated labeling capabilities, you can choose according to such standards.

Machine Size

The size of the equipment's footprint influences the decision on the space available in your production facility. And if you want to use it with other devices, you need to take the size of the machine into consideration.

Flexibility and Adaptability

Flexibility and Adaptability-sourced: ayudjobs

Decide based on your own packaging needs. If you want to choose a screw counting machine that is highly adaptable and flexible and can be applied to any product, then you should choose a fully automatic model.

Conclusion:

The screw counting machine is a highly customizable machine. It can be tailored to you and meet the specific needs of each industry. Through this complete buying guide of screw counting machine, you can understand the power and wide application of this machine. If you have any other questions, your consultation is welcome!

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide

Screw Counting Machine: The Complete Buying Guide In 2024 Read More »

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours