Electronic Tablet Counter: The Complete Buying Guide in 2024

There’s no wonder about the increasing reliance on automation in various pharmaceutical and other production sectors concerning with dispensing of tablets. An electronic tablet counter is a state-of-the-art machine that has pretty amazing features, therefore adopted by various manufacturing companies for easy counting tasks.

If you’re thinking about its basic concept; it emerged various decades ago, when two brothers John and Frank Kirby brought the idea of a digital tablet counter. From that day, you can see upcoming modern interventions in the robust device of electronic tablet counter.

Before making a final purchase, go through this article to find relevant information gathered by our experts for your understanding and making a great selection.

1.What is an electronic tablet counter?

An electronic tablet counter is an automated device required in pharmacies as the medication is closely visualized and counted where there’s simply no room for error. The machine is an advanced technique that is responsible for quickly and conveniently filling tablets. The machine has effectively replaced manual counting with a spatula and tray, so production is free of labor costs that are considered substantial for saving your time and improving profit.

Due to its compact size, it can best fit in crowded lab spaces and seldom needs calibration. Today, electronic tablet counter mainly works by a micro-controller unit that is mainly based on photodetectors to sense and verify the presence of tablets and allow dispensing. The machine itself can be employed for integration with various machines such as capping, sealing, and labeling to bring complete packaging jobs simultaneously.

2.What is the Use of an Electronic Tablet Counter?

An electronic tablet counter has a broad range of usage in several industries. This is because of high accuracy, efficiency, and fast results. Here are some important industries that commonly utilize the machine.

Pharmaceutical Industry

An electronic tablet counter is an integral device that is essentially important for the right and fast dosage delivery e.g., tablets, capsules, pills, and caplets. This machine guarantees each counted and filled tablet is correctly packed and perfect to further sale without any errors or risk of contamination.

Nutraceutical Industry

Like above, a nutraceutical industry packaging department needs an electronic tablet counter for accurate and easy delivery of products such as vitamins, supplements, and probiotics, in the form of gelatin capsules, tablets, and others.

Food and Beverage Industry

In the food and beverage industry, an electronic tablet counter is used for counting and filling of products such as chewing gums, candies, beans, gummies, etc.,

Cosmetics Industry

In the cosmetics industry, an electronic tablet counter is used to count and fill products such as serums, waxing beads, and hair products that are mostly filled in gelatin capsules or other formulations. The machine ensures that packaging of respective products is accurate and consistent.

Chemical Industry

Chemical industry is the one where precise and authentic products are worthwhile. For this, you need an electronic tablet counter for fast and exact measurements in the packaging of chemicals products such as buffer pellets, tablets, and various chemicals in the form of solid tablets, granules, or pellets form.

Veterinary Medicine

This sector of drug development is also similar to pharma and neutraceutical industries where packaging of capsules, tablets, or other animal related products are counted and filled with electronic tablet counter.

Herbal Industry

This sector is flourishing day by day due to increased awareness about the benefits of herbal/organic supplementations. The packaging of herbal tablets, pills, capsules, pellets, granules is filled and counted with an electronic tablet counter.

Research and Development (R&D)

The research and development sectors are the one that deals with electronic tablet counter first for testing and trial studies on the tablets. For this, each step is taken place with high monitoring and extreme accuracy. The electronic tablet counter is significantly important in R&D departments.

3.What are the Benefits of Electronic Tablet Counter?

An electronic tablet counter is a complete packaging system that offers several benefits to your business:

Accuracy and Precision

Picture Courtesy: Allma.net

These two terms define an electronic tablet counter as the most significant selling device. The state of art equipment that has replaced the manual handling of tablet counting to modernize method with 99.99% highly precise and accurate.

Affordable

Picture Courtesy:Bellatrex

With offering so many benefits, this productive device is of very low cost. Moreover, this machine saves your time, reduce downtime, save labor, and save your money.

Long Term Usage

Picture Courtesy: Ipharmachine

The electronic tablet counter is made up of highly stainless steel that offer maximum resistant against environmental conditions as well as protectant against accumulation of debris, dust, or sticky particles. Moreover, machine is highly durable and easy to clean and maintain that’s ultimately offering a long term usage time.

Available in Various Types

Picture Courtesy: CE King Limited

Whether running small, moderate, or large production set ups; an electronic tablet counter is presented in several types depending on size of set-ups and your plan. You can avail high automation in smaller budgets or small installations space.

Integration

Picture Courtesy:ROPP

Nevertheless, any production line can’t be completed without incorporating an electronic tablet counter. This is an excellent machine that allows users to flexibly integrate the unit with other machines of the production line without any hectic procedures or need a hectic installation plan.

4.How does an electronic tablet counter work?

A modern electronic tablet counter basically relies on automatic controlled counting using a microcontroller for operation. The main working of an electronic tablet counter is composed of two basic parts.

Part. I

In the beginning, the two main sections such as the feeding unit and vibratory tray. The tablets to be counted are loaded into the feeding unit for processing. The feeding hopper transfers them randomly over the vibratory tray that is designed with proper channels that vibrate gently and continuously to align tablets. The vibratory tray features photo-detecting sensors for the scanning process. These channels are easy to adjust so they can be useful for various shapes and sizes of tablets.

Part. II

In part I, the main work is controlled by vibration and photodetector that helps in sorting or positioning of tablets followed by scanners. In part II, the vibration leads the tablet to reach till edge of the tray, and with the help of the force of gravity tablet falls. The tablet was knocked down onto a glass turntable controlled by a geared motor. The filling nozzle of the machine is mounted with LED light which is designed in such a way that blocks the LED light when each tablet crosses from it individually. This blocking of light registered the tablet as a tally on the electronic tablet counter.

Part. III

Once bottles are filled with the required number of counted tablets; it become moved to the next machine while the next bottle comes into the right position for filling.

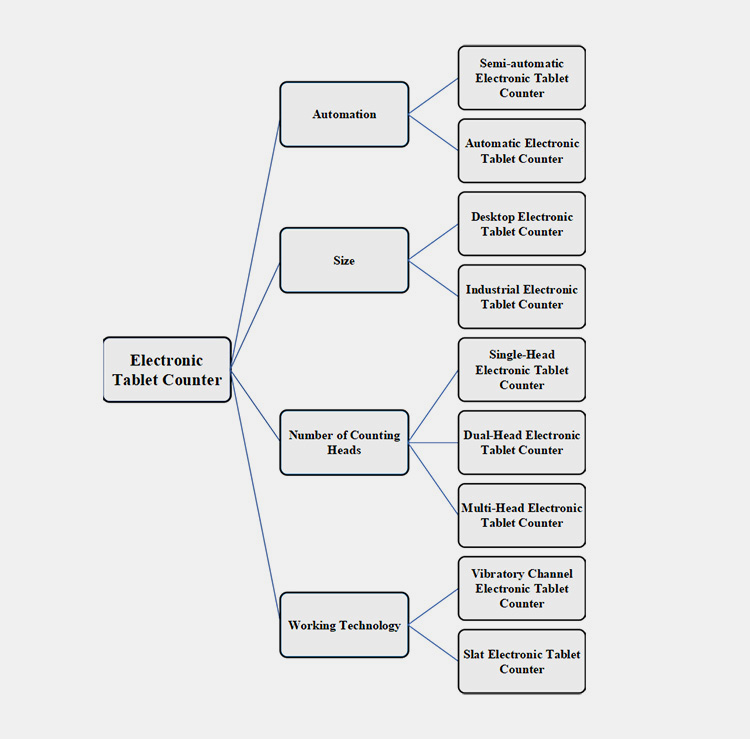

5.What is the classification of an electronic tablet counter?

There are different classes of electronic tablet counter with different designs and technologies to cater demands of both small and large-scale pharmaceutical, food, and other industries. A complete order of classes of electronic tablet counters is discussed below for your knowledge.

Classification Based on Automation

Semi-automatic Electronic Tablet Counter

Picture Courtesy: IMA

This type of electronic tablet counter has photoelectric sensors for precise and repeatable pill and gummy counting. However, its tablet counting capacity is low because it is a small-scale machine with one to two counting heads. Moreover, operators have to load and unload containers by hand for counting and filling.

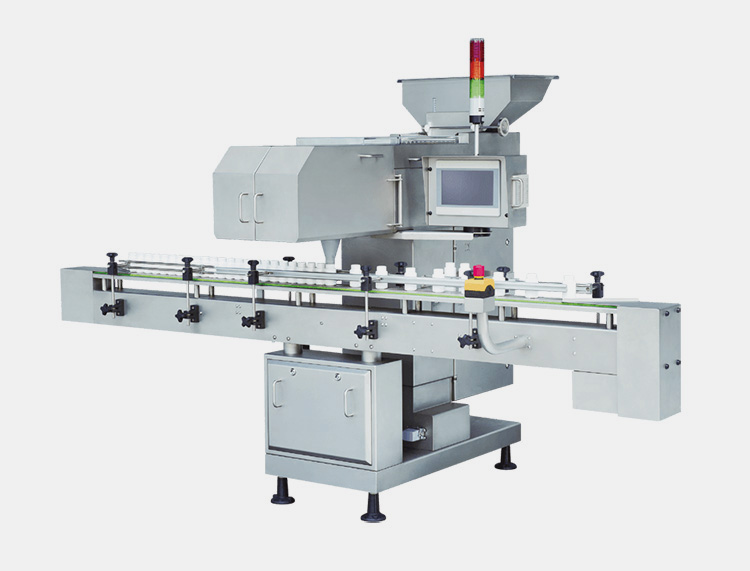

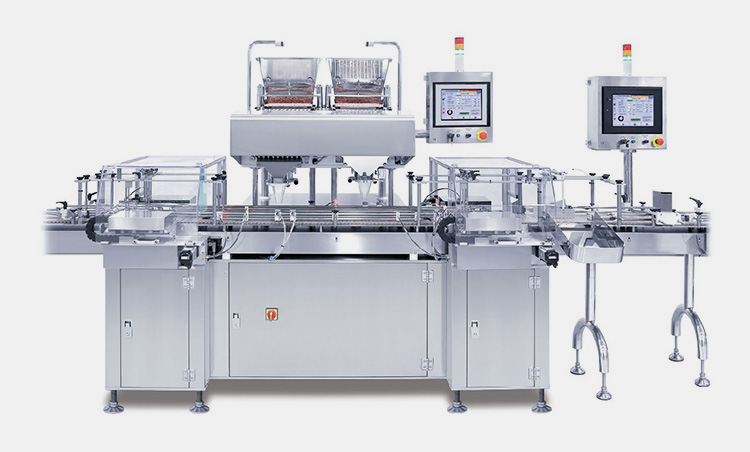

Automatic Electronic Tablet Counter

Picture Courtesy: IMA

This machine offers automation in tablet counting and filling. It is equipped with container loading units that automatically load containers for counting. Highly accurate sensors and vibratory channels perform the counting of pills or other related products. Moreover, HMI and PLC systems in this machine aid in a fast format change. It can process thousands of pills per minute.

Classification Based on Size

Bench-Top Electronic Tablet Counter

Picture Courtesy: Kirby Lester

This machine is compact and lightweight and is placed on a bench or desktop. It is an ideal electronic tablet counter for settings with limited space. Furthermore, it can easily transported to different places without much effort. It is equipped with special channels and electronic systems for counting various products without change of parts.

Industrial Electronic Tablet Counter

Picture Courtesy: Countec

It is a heavy industrial unit specially designed for integration in mass-scale businesses. It requires more space for its setup since it consists of multiple counting heads, vibratory disks, heavy-duty sensors, rejection systems, and other controls that automate this system and provide higher processivity.

Classification Based on Number of Counting Heads

Single-Head Electronic Tablet Counter

Picture Courtesy: SED Pharma

As the name indicates, this machine has only one counting or filling head and typically fills only one container at a time. This counting head has built-in sensors that allow accuracy in tablet or pill counting. However, because its counting capacity is low, it is employed in small-scale industries that deal with a low volume of products on a daily basis.

Dual-Head Electronic Tablet Counter

Picture Courtesy: Ascend Packaging Systems

This machine has dual counting heads that are responsible for concurrently counting and filling products in two bottles or jars. These individual channels are equipped with their separate photoelectric sensors that aid in the filling of two vessels in the same instant. This results in higher production efficiency because it can process more products in one go than its single-head counter-art.

Multi-Head Electronic Tablet Counter

Picture Courtesy: IMA

It consists of more than two counting channels like four, eight, and twelve, and can process multiple containers simultaneously. Like dual-head electronic tablet counter, these counting heads also come with their own photoelectric sensors and product-rejecting systems. Multi-head tablet counters are part of large production plants because it has higher processivity than other types.

Classification Based on Working Technology

Vibratory Channel Electronic Tablet Counter

Picture Courtesy: C.E. King

This type of electronic tablet counter has vibratory plates or trays that vibrate to align, position, and guide pills through these outlets. With vibration, the pills move across the plates and are positioned in channels. This machine is versatile because it accommodates products of any shape and size.

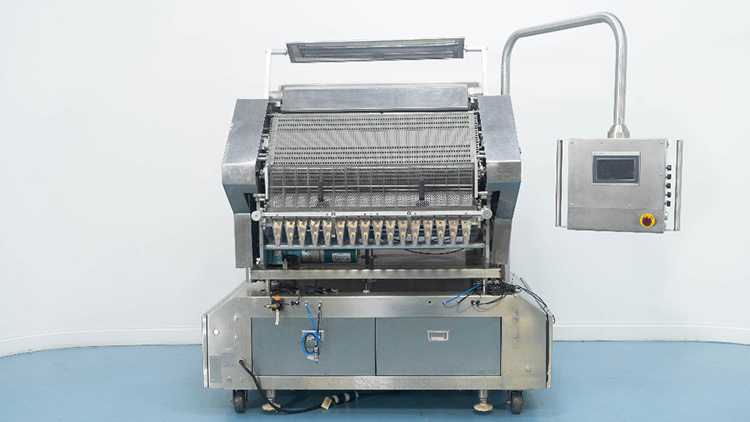

Slat Electronic Tablet Counter

Picture Courtesy: Surplus Solution

This machine has rotary horizontal slats with precise compartments or spaces for fitting products. With the rotation of slats, the pills are aligned in the disk pockets. It normally processes products with uniform geometries and dimensions that fit into fixed-size slots. Slat electronic tablet counter has greater accuracy and higher output.

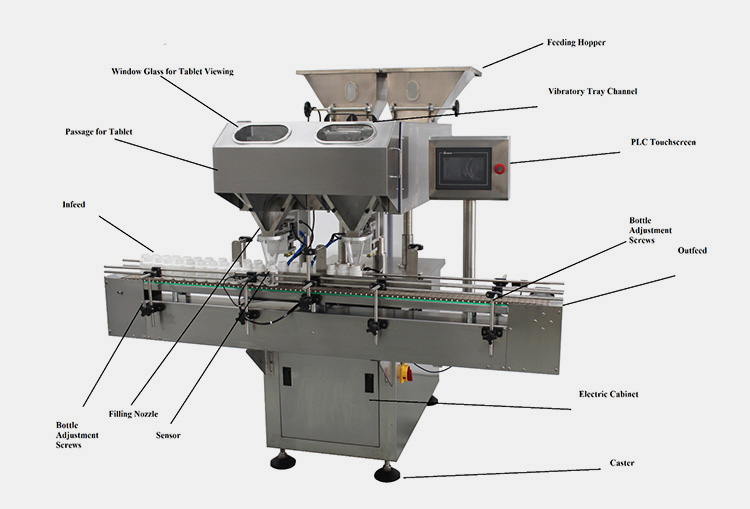

6.What are the Parts of the electronic tablet counter?

For knowing the parts of an electronic tablet counter, we have illustrated an automatic electronic tablet counter for your understanding. Please check below the basic components and their roles in the operating system.

Parts of Electronic Tablet Counter

Feeding Hopper

This is a unit where an operator loads the bulk of tablets for processing into the machine.

Vibratory Tray Channels

At the upper most part of the machine, a vibratory tray is present which is designed with various aligned channels that vibrates and allow the tablets to attain proper orientation and movement to the next unit for easy and accurate counting.

Window Glass for Tablet Viewing

During procedure, a window glass for tablet viewing allow user to visualize the movement of tablets inside the machine. The purpose of presenting the glass is to inspect the operation.

Passage for Tablets

This pathway allows fixed way to pass the tablets from vibratory tray toward counting unit. This passage is helpful in controlling the flow of products without chances of deviating from the unit.

PLC Touchscreen

The brain of the machine where user can incorporate required data using touchscreen interface. This is a flexible and easy way to set the machine for operating, monitoring, and troubleshooting.

Infeed

This unit is responsible for delivering bottles or any packaging materials inside the tablet counter. In other words, this is known as a conveyor.

Outfeed

This unit is responsible for discharging out the bottles of packaging material out of the system towards the next machine.

Bottle Adjustment Screw

Dealing with different types and shapes of bottles or packaging products is not a problem with electronic tablet counter as by the help of adjustment screw, the unit is easy to accommodate the various bottles with different height or position.

Filling Nozzle

The filling nozzle is responsible for counting and filling tablets, pills, capsules, etc, this unit is designed with a narrow passage that ensures the system allows accurate and precise filling without any error.

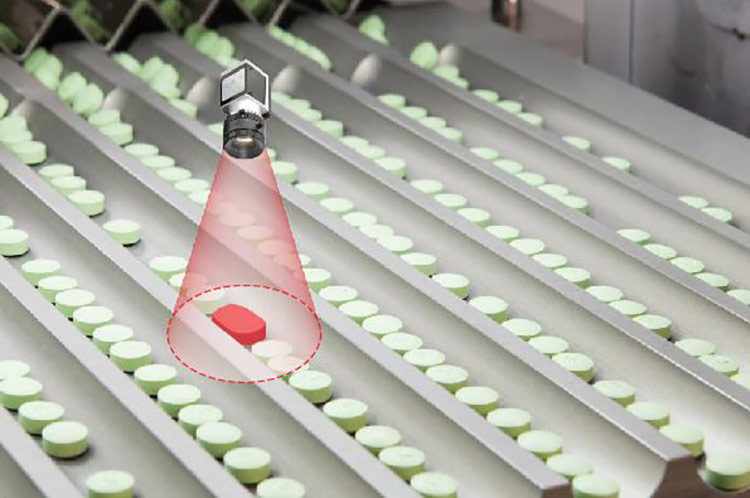

Sensor

The unit is responsible for detecting the presence of tablets. The sensors are mainly present adjacent to the filling nozzle where the presence of a bottle is notified, and the accurate size of tablets are filled. Moreover, the vibratory trays are also featured with sensors that detect faulty tablet and rejects them before filling.

Electric Cabinet

Indeed, every machine is designed with essential electrical components to run the system efficiently. The electrical cabinet is responsible for housing integral wiring inside the machine such as motor, circuit board, wires, plugs, control units etc.,

Caster

The machine is based on a strong platform with moveable wheels that allow users to set the machine and install it easily at the assigned location.

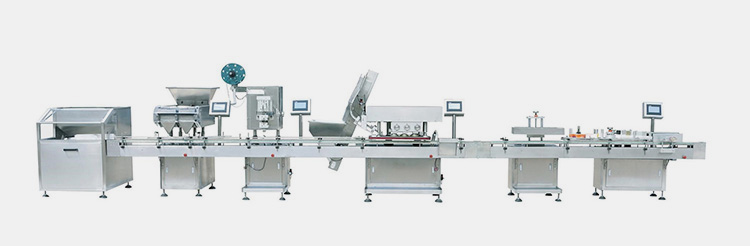

7.What is the Production machine list involved with the electronic tablet counter?

The Production Line of Electronic Tablet Counter

Bottle Unscrambler

This is the machine that begins with almost every production line. The random set of bottles is loaded into the unscrambler tank where high-air blowers and vibratory trays ensure an alignment of disoriented bottles for an efficient supply of the bottles/containers.

Electronic Tablet Counter

To proceed with the packaging production, the second machine is an electronic tablet counter that works by giving a high output when the operator infeed the data depending upon the requirement. The most amazing feature of this machine is the electronic sensor that enables high efficiency and accuracy.

Desiccant Inserter

After passing through the electronic tablet counter, the next machine is the desiccant inserter which helps in placing the desiccant at the right position. The purpose of this machine is to improve the quality of products by placing the moisture-absorbing packets into each container.

Capping Machine

Once the bottles are filled with desiccant, it is time to secure them by putting and screwing the lids over the bottlenecks. This ensures the tight and sustained sealing of the entire formulation.

Induction Sealing Machine

To create an induction sealing on the containers or bottles; the product is passed through an induction sealing machine where electromagnetic heat induces the melting of the lid covering composed of foil or sealing layer. Once the bottle is cold down, the melted layered forms a secured closure and preserves the product till opened by a user.

Labeling Machine

To improve branding, marketing, and information about the products. A labeling machine is used; it ensures an accurate and correct placement of labels over the surface of the bottle. Various types of machines such as wrap-around, and shrink-sleeve labels depend upon the consumer’s requirement.

8.What Other Things Electronic Tablet Counter Can Count?

Other than tablets, an electronic tablet counting machine can cater to various things such as:

Capsules

An electronic tablet counter can deal with capsules of various shapes and sizes. For example: soft gelatin capsules, hard gelatin capsules, irregular shapes capsules (star, fish, balls), filled with semi-solid, solid, and liquid inside.

Chewing Gums

Using an electronic tablet counter for counting chewing gums and other related products is always recommended for their packaging.

Gummy Candies

The electronic tablet counter machine is an ideal equipment for counting and packaging soft and chewy gummy candies.

Chocolates

The counting and filling of chocolate required an electronic tablet counter in the packaging line.

Seeds

The packaging of agricultural products, such as seeds requires an electronic tablet counter in the production line.

Intricate Stones, Gem, and Jewellery

An electronic tablet counter is significantly important in sorting, counting, and filling jewelry pieces efficiently.

Nuts and Grains

The electronic tablet counter is a useful machine for counting and filling nuts, grains, or related dry fruits for accurate packaging.

9.What Packaging Material Electronic Tablet Counter Can Use?

There are different packaging materials that can be used by electronic tablet counter. If you looking to know them, the mentioned below names are as follows:

Bottles

Different sizes and shapes of bottles can be flexibly used by electronic tablet counter to fill tablets, pills, capsules, etc., whether it is made of plastic or glass; the machine can adjust them via various features such as bottle adjustment screws.

Pouches

An electronic tablet counter can pack pouches that are made up of either foil, plastic, or laminated.

Jars

Electronic tablet counter can deal with jars made up of various materials and different sizes. The machine is suitable for counting small, moderate, or large quantities of tablets.

Vials

The electronic tablet counter is suitable for counting and filling tablets in vials of various sizes. For example thyroxine, or specialized formulation.

10.What are the basic problems that occur with electronic tablet counter?

The electronic tablet counter is no-doubt a reliable or robust machine; but sometimes the machine can encounter with technical problems. Discussed below are some major points you must know.

Tablets are Stuck in the Counter

Picture courtesy: PKN

This is the common condition where tablets are unable to move and starts accumulating and piling up. To correct the problem, experts suggest modulating the speed of running process, for example controlling the loading of tablets from hopper, the controlled movement in channels and appropriate counting speed. Plus, the lubrication of each moveable part can also help in flexible movement of the product, hence in case of irregular vibration can also lead to tablets jamming that can be avoided via proper maintenance.

Single Tablet but Multiple Counting!

Picture courtesy: SED Pharma

When tablets are flowing from hopper to vibratory channels, they’re in the bulk and randomly transferred. Sometime due to speed of vibrations and movement of vibratory channels lead them to overlap each other and make them count as one during the process. This problem can be avoided when you slow down the vibratory and movement of tablets in the channels. Moreover, by cleaning the scanners or sensor can efficiently detects the presence of the tablet. Therefore, cleaning the sensors and controlling the speed can helps in the prevention of this error.

Machine Fails to Sense the Presence of Filling Material

Whether bottle or container, an electronic tablet counter is failed to detect its presence and starts offering tablets which ultimately creates a mess and product wastage. To cater to these issues, it is recommended to calibrate the machine, i.e., the conveyor. Regular cleaning of sensors can prevent the recurrence of this problem.

11.What are Buying Tips for Electronic Tablet Counter?

Buying a machine is a tricky task, we have mentioned the following tips that would help decide the right choice.

Pick The Machine with The Most Robust and User-Friendly Features

Picture Courtesy:MAKWELL

Whether you’re selecting a large electronic tablet counter or a portable one, it must be featured with robust and user-friendly specifications. The machine should be very practical and allow easy handling features.

The Machine Must Suits Your Capacity

Selecting a machine that can count accurate and large production batches is good if you’re dealing with bigger projects. Similarly, if your production capacity is not reaching hundreds of tablets then better to go for easy and simple versions.

Think About the Integrating Power of the Electronic Tablet Counter

Consider the extent of integration of the electronic tablet counter with other machines. For example, how effectively it can carry out good tasks when combined with other machines.

Conclusion

In conclusion, an electronic tablet counter is the most significant machine for improving your business due to the various important factors that we discussed above. So, always think carefully before making a final decision as your whole production relies on this robust equipment. Allpack is the hub for supplying the original and advanced electronic tablet counter that you deserve! Please contact our team to find useful consultation without any charges. Message us now to open the horizon of skyrocketing profitability.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide