Capsule Counter Machine: The Complete Buying Guide In 2024

Are you looking for a capsule counter machine to tackle the issue of counting moisture sensitive capsules? Or are you interested in uplifting your current production? If you are! Then finally you have been there! As, this buying guide is holding all the essential information about a capsule counter machine.

Capsule counter machine is an innovative assembly of various components as well as intelligent features which can greatly assist you in accomplishing your daily task of capsule counting. It has been made with quality material, so that the sterility of your capsules can be preserved. Moreover, with simple operation, high adaptability and counting precision, this machine is most reliable and suitable for range of industries. Hence, it is the time to explore all the aspects of a capsule counter machine without any delay!

1.What Is A Capsule Counter Machine?

Capsule Counter Machine-Allpack

Capsule counter machine is an electronic device used for the precise counting of capsules, tablets and pills for the purpose of ensuring medication safety and production efficiency. The machine is equipped with advance features and stainless steel parts which are highly suitable for preserving the sterility of capsules.

It works by counting the capsules through detection system in order to end the false counting. Capsule counter machine is also capable of processing several other objects as well as containers for filling tablets. Hence, its scope of applicability is vast enough encompassing small to large industrial production lines.

2.How Does A Capsule Counter Machine Work?

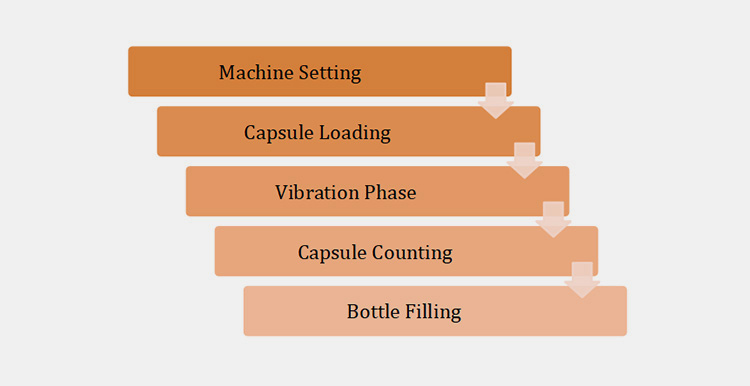

The operation of capsule counter machine is continuous and straightforward. In this way, below explanation will be helpful:

Machine Setting

Control System of capsule counter machine-Picture Courtesy: Cremer.com

To initiate the process of capsule counter machine, operator must have to adjust the setting of machine as per production requirements. Ordinarily, it will include the fixation of number of capsules which are to be counted, the adjustment of bottle filling head and bottle separator on conveyor etc.

Capsule Loading

Secondly, the hopper of capsule counter machine is required to be loaded with sufficient volume of capsules.

Vibration Phase

Softgel capsules over vibratory trays-Picture Courtesy: pharmaps.com

Now, when the above two steps are followed, the machine is ready to be started. The turning power button on will energize the vibratory motor which in turn will create shaking effect in vibratory trays. Therefore, the capsules will fall onto these trays and adopt a sequential order.

Capsule Counting

Tablets dropping to counting compartment-Picture Courtesy: Cremer.com

During the vibration phase, capsules which undergone vibratory sensation will be stored in a capsule counting compartment. Here, these capsules will be detected and counted through the integrated sensors.

Bottle Filling

Capsules falling into bottles-Picture Courtesy: IMA safe packaging solutions

Finally, the counted capsules will be delivered to sleeve hopper through which the capsules will be filled in bottles or containers.

3.There Are How Many Types Of Capsules Which Can Be Counted By A Capsule Counter Machine?

There are different types of capsules which a capsule counter machine is capable of counting. These are as follows:

Hard gel capsules

Hard gel capsules are made from hard gelatin which usually contains powder, granules or liquid dosage as well. Therefore, these capsules are divided into two types including:

Liquidfilled

Liquid filled capsules presentation idea-Picture Courtesy: healthytrailsliving.com

Liquid filled capsules hold liquid dosage of medicine. They may also contain mixture of liquid, powder, granules or capsule in capsule.

Solidfilled

Herbal powder filled capsules-Picture Courtesy: vestamarket

Hard gel capsules may also hold solid dosage inside, such as powder, granules and pellets etc.

Softgel capsules

Softgel capsules in bowl-Picture Courtesy: shefinds.com

The cover of softgel capsules is made of gelatin and these softgel capsules are antioxidant in nature. It means, that softgel capsules have long shelf life and resistant to moisture and temperature. All types of softgel capsules contain liquid dosage only.

4.What Are The Uses Of A Capsule Counting Machine?

Capsule counter machine has extensive uses in range of industrial sectors due to its substantial benefits and effective counting. These applications will be considered below:

| No | Industry | Description |

| 1 | Pharmaceutical Industry

Double color capsules-Picture Courtesy: Creative Market |

The widest industry in medical field is pharmaceutical industry, where immeasurable capsules and tablets are formed every day. To facilitate the counting of such huge amount of capsules, a capsule counter machine is the first choice of pharmaceutical industry. |

| 2 | Food Industry

Candy filled jars-Picture Courtesy: candy land centerpiece |

The application of capsule counter machine is not only confined to medical sector, but it may also be used in food industries for the purpose of counting confectionaries, grains and dry fruits etc. |

| 3 | Herbal Industry

Capsules with herbs-Picture Courtesy: Creative Market |

As capsules give convenient way for consuming powder dosage by covering the bitter taste of herbal powders, most of the herbal industries rely on using capsule counter machine for counting bulk tablets. |

| 4 | Nutraceutical Industry

Nutraceutical capsules idea-Picture Courtesy: acordabonita.com |

Capsule counter machine is also used in nutraceutical industry where nutraceutical capsules are obtained from the natural food sources to give additional health benefits.

|

| 5 | Cosmetic Industry

Cosmetic softgel idea-Picture Courtesy: mademoiselle-mara.de |

Cosmetic industry is now more dependent on capsule counter machine for the reason that the industry produces large volume of hard gel and softgel capsules for glowing skin, removing black heads and dark circles etc. Hence, these capsules need to be accurately counted. |

5.Describe The Structure Of A Capsule Counter Machine?

The structure of a capsule counter machine is composed of diverse components which are described below with the function and role each perform. These are:

Structure of capsule counter machine-Picture Courtesy: itinerarymasters.com

Hopper

Hopper is the basic component of a capsule counter machine as it provides the machine with bulk of capsules for counting.

Three Stage Vibrator

This part of machine is attached with the outlet feed of hopper. It consists of three stage vibrator whose function is to align the capsules through consistent vibration.

Dust Collector

Dust collector is an effective system integrated into the capsule counter machine to separate the dust or residues from capsules and collect it in a bin through pipes.

New Platform Structure

As the name indicates, this part of machine serves as a supportive platform for the upper counting channel located on machine. By adjusting new platform structure,

Conveyor

Conveyor is an important tool in capsule counter machine which moves the bottles from one place to another.

Adjustable Base

There are four foots of this machine which can be adjusted when required.

Stainless Steel Body

The body of the machine is made up of 304 stainless steel with antibacterial and corrosion resistant surface.

Double Positioning Cylinder

Double positioning cylinders are attached with conveyor and used for the accurate positioning of bottles during operation.

Blanking Head

The area of jurisdiction of blanking Head comes after the bottle filling heads. It has been assigned with the task to separate bottles, which left blank during filling, from the rest ones.

Photoelectric Detection Module

The core component of a capsule counter machine is the photoelectric detection module where actual counting of capsules is done with sensors detecting capsules and supplying them to the filling heads.

PLC Touch Screen

It is a touch screen display representing range of options for user to fix it as per his demand, and the machine will work according to this setting.

Warning Light

This three color warning light is positioned on the top side of a capsule counter machine to keep the operator alert about machine operation. For instance, the red color indicates fault in machine, amber shows the over temperature of machine, while as, green represents that the operation ongoing is normal.

6.Explain The Benefits Of A Capsule Counter Machine?

Counting your capsules and other eligible items by a capsule counter machine can provide you with several advantages including:

Counting Precision

Capsules on vibratory trays-Picture Courtesy: indiamart

The most significant attribute of a capsule counter machine is the high level of counting precision which it gives while counting capsules. This accuracy develops from the advance detection system of machine.

Maintaining Sensitivity

Hard gel capsules in a hand-Picture Courtesy: Juice Plus

Capsule counter machine is the all-time best alternative to the counting of capsules through hands. It is because there will be always a high risk of capsules getting damaged due to moisture or the possibility of human error is also there. Therefore, capsule counter machine is safe for maintaining the sensitivity of capsules.

Preventing Contamination

Capsules & tablets presenting idea-Picture Courtesy: Pulmonary Fibrosis

Capsule counter machine has integrated system of dust collection. Through this feature, the machine is able to suck the dust and debris present over capsules. Hence, it ensures safe and hygienic Processing by preventing contamination.

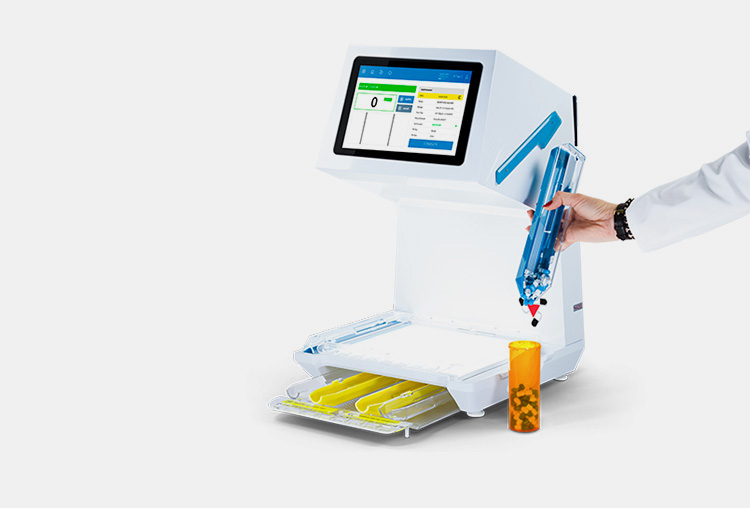

Simple Operation

Operator using capsule counter machine-Picture Courtesy: Scientific Industries

The machine follows simple procedure for counting capsules by providing operator with intuitive PLC touch screen, emergency stop, alarm light and quick parts changeover during operation.

Time Saving

Clock in a hand-Picture Courtesy: fanbooster.com

Since capsule counter machine is proficient in counting capsules, tablets and associated stuff, it will eventually cut down the time spent on manual labor.

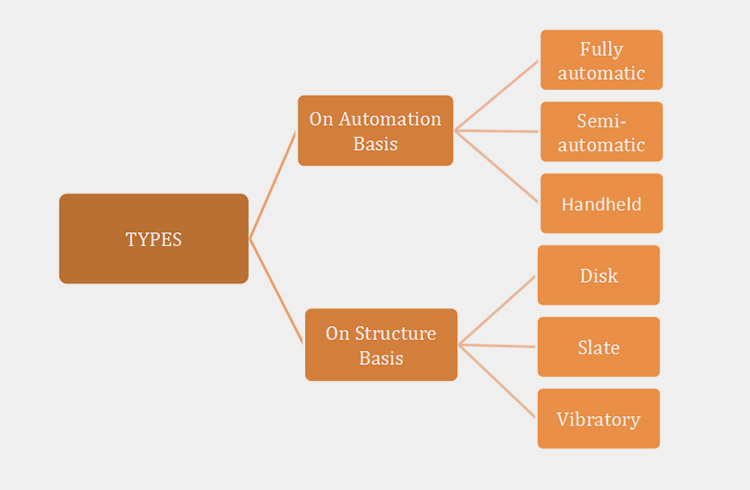

7.What Are The Different Types Of A Capsule Counter Machine?

Capsule counter machine comes in innovative types each having distinct features and automation. The types of capsule counter machine help every scale industry to get benefited from its use. These are described below in detail:

Fully Automatic Capsule Counter Machine

Fully Automatic Capsule Counter Machine-Allpack

Fully automatic capsule counter machine is high intelligence machine with automatic features of counting, alarm system, control functions, fault checking and bottle filling. It does not require operator to be constantly engaged with the machine during operation, instead it takes the responsibility of counting capsules independently. Since, the structure of fully automatic capsule counter machine is complex and designed for heavy-duty workload, it is expensive. However, the machine has efficient and precise functioning, thus, it can be used in large scale industries.

Semi-Automatic Capsule Counter Machine

Semi-Automatic Capsule Counter Machine-Allpack

Semi-automatic capsule counter machine on the other hand rely on operator to precede the process of counting capsules. It is precise in structure with few parts comprising hopper, detection system, filling nozzles and stainless steel body. Its affordable price and effective performance makes the machine suitable for medium level production.

Handheld Capsule Counter Machine

Handheld/Manual Capsule Counter Machine-Allpack

Handheld capsule counter machine is also known as manual machine for the reason that it is fully dependent on the user to accomplish the counting of capsules. Here, the Allpack model of handheld capsule counter tray can be taken as an example of handheld capsule counter. It mainly consists of a handle, capsule molds, and a supporting base. The operator simply pours the capsules onto molds and discharge the capsules when counted. This machine is good for home, laboratory and research institutions etc.

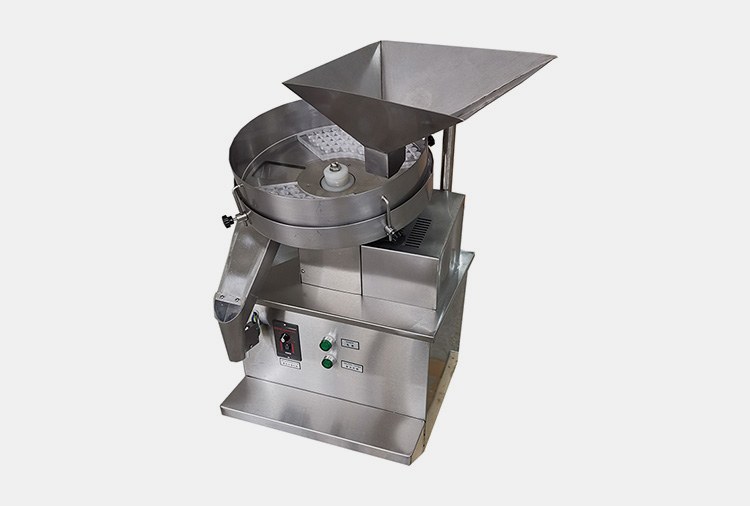

Disk Capsule Counter Machine

Disk capsule counter machine

Disk capsule counter machine is small size digital machine which can intelligently perform the task of counting tablets, capsules and grains etc., with ergonomic features. It consists of a disk as core component over which capsules are loaded and revolve for counting, small counterintelligence with digital screen, funnel box drawer and precise plastic body. With continuous process, this machine can count up to 500 capsules per minute.

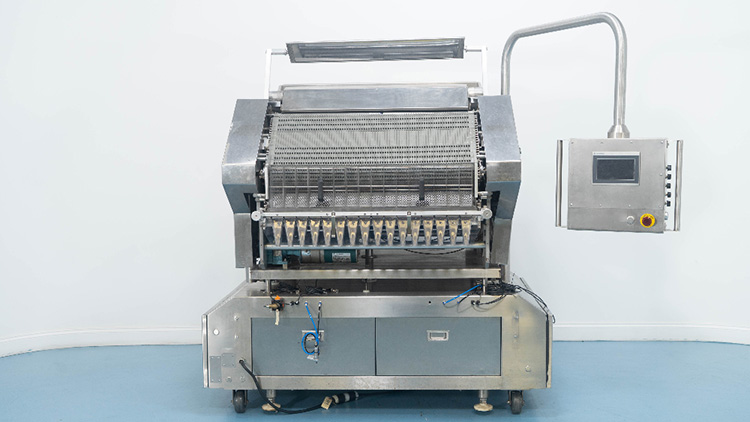

Slate Capsule Counter Machine

Slate capsule counter machine-Picture Courtesy: Surplus Solutions

Slate capsule counter machine is cutting edge machine in counting capsules. This machine has extraordinary fast performance in terms of capsule counting as well as bottle filling. This fast mechanism is the result of its super quality innovative design comprising slate with molds. During the process, capsules get entered into these molds and discharged into the bottles after counting. Industries where efficiency is the key need, this slate capsule counter machine will be perfectly suitable for such productions.

Vibratory Capsule Counter Machine

Vibratory capsule counter machine-Allpack

Vibratory capsule counter machine is the standard machine used for counting capsules, pills and tablets. It has the number of vibratory trays attached with the discharge feed of hopper on one hand, while as, with capsule counting compartment on the other. During the counting process, when capsules fall over these trays, the vibratory motion of trays arrange the capsules in a sequence. Similarly, these capsules are counted and filled into bottles via filling nozzles.

8.Which Other Products Can A Capsule Counter Machine Count?

A capsule counter machine can count numerous products including:

Tablets

Various tablets and pills-Picture Courtesy: Creative Market

All types of tablets including coated, uncoated and, compressed tablets, with varying sizes and shapes, can be counted by capsule counter machine.

Confectionaries

Multi-color chocolate chips-Picture Courtesy: themondaybox.com

Confectioneries including candies, jellies, and chocolates etc., are packed in various sizes bottles after undergoing the counting phase. This counting can be achieved by using a capsule counter machine.

Pulses

Multiple legumes-Picture Courtesy: healthyway.com

Legumes and pulses which are used for human consumption on daily basis are also entitled to be counted by a capsule counter machine.

Dry Fruits

Dry fruits in a bowl-Picture Courtesy: aufeminin

Dry fruits such as almonds, pistachio, cashews, and dry apricots etc., are eligible to be processed by this machine in order to be packed in precise form.

9.What Is The Production Line Of A Capsule Counter Machine?

Production line of capsule counter machine-Picture Courtesy: parleglobal.com

The production line of a capsule counter machine is explained in the table below:

| No | Machine | Description |

| 1 | Bottle Unscrambler | Bottle unscrambler is a machine employed to sort the bottles and take them to the conveyor belt of capsule counter machine in a well positioned manner. |

| 2 | Silica Gel Inserter | Silica gel inserter is special purpose machine designed with distinct features to cut the desiccant bags from roller and fill these bags into the bottles containing medicines or any other material. |

| 3 | Cotton Inserter | Cotton inserter is specialized equipment designed to inject the cotton into capsule filled bottles for the purpose of retaining stability inside the bottles. It uses clean cutters for cutting cotton to preserve the hygiene of capsules. |

| 4 | Capping Machine | Another important machine in the production line of capsule counter machine is bottle capping machine. It is responsible for capping the loaded bottles tightly. |

| 5 | Induction Sealing Machine | Induction sealing machine is an inevitable part of the capsule counter machine production line. It is used to create the hermetic sealing of bottles by heating the foil inside of bottles' caps via electromagnetic field. |

| 6 | Labeling Machine | The machine which gives identity to your counted capsules bottles is the labeling machine. It is resilient enough to print or apply different types of beautiful labels over bottles and containers. |

| 7 | Outserter | Outserter is a machine used for providing the capsule filled bottles with labeled leaflets over their caps. For achieving this objective, firstly, it delivers some amount of glue over bottle caps and then takes the leaflets from feeding device and apply over the glued area. |

| 8 | Exit Turntable | Exit turntable is a separate device attached to the end of production line of capsule counter machine. When bottles are get filled with counted capsules and passed the packaging phase, they eventually collected onto the exit turntable. |

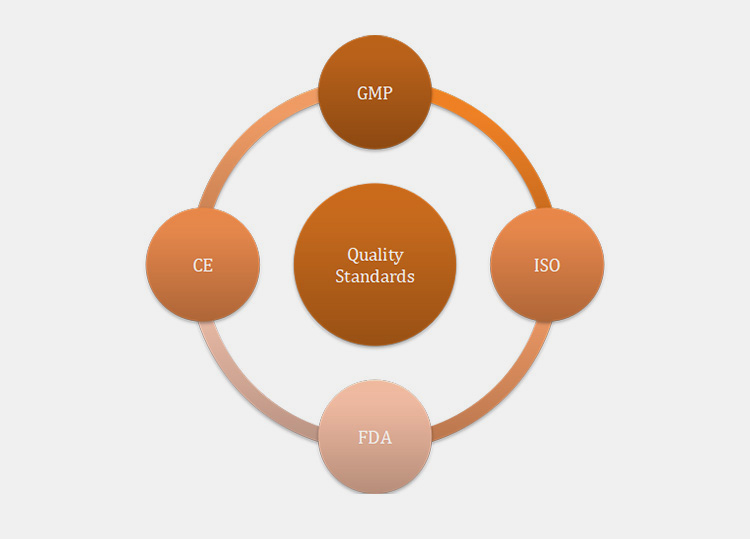

10.Which Quality Standards Are Required For A Capsule Counter Machine To Comply?

Certification stamp in hand-Picture Courtesy: ballfreeov.life

There are certain quality standards established on international level for drugs processing and associated machinery including capsule counter machine. These quality standards are as follows:

GMP

GMP is short for good manufacturing practices which is an international body regulating rules for the material used in machine. For instance, 304 stainless steel is recommended by GMP to be used in all machines which are linked to any sort of food or medical objects.

ISO

International Organization for Standardization is an independent authority founded with the main objective of maintaining standards. It thus ensures the safety and hygiene of different industrial machines.

CE

CE is the marking of European Union which is allowed to be applied over all these products which are safe and and have undergone strict environmental as well as health safety requirements.

FDA

Food and drug administration is a body responsible to control and plan the advancement of new machines and make suytgeu are is safe.

11.What Is The Preventive Maintenance Of A Capsule Counter Machine?

Technician maintaining machine-Picture Courtesy: ppsnordic.com

Taking measures for the preventive maintenance of a capsule counter machine is most important thing to do. For this, below points will be demonstrating the essential measures which should be taken:

Maintenance:Regularly maintain the capsule counter machine by moving the disk by hand before starting operation, adjusting the internal setting and rightly positioning double cylinder on conveyor belt.

Cleaning:Cleaning is an inevitable part of preventive maintenance of capsule counter machine. It is necessary to wipe out all the dust, pollution and residues from machine which may left during counting. You can also disassemble the parts of machine for excellent cleaning.

Lubrication:Lubricate the movable parts such as conveyor motor and rotary shafts daily, so, they will follow steady way for counting.

Parts Renewing:Although capsule counter machine has long life, its parts may get damaged. Therefore, timely renewing these parts can better enable the machine to work faster.

12.Write Down The Solutions For Possible Problems Caused By A Capsule Counter Machine?

The solutions to possible problems of a capsule counter machine during operation are as follows:

| No | Problems | Causes | Solutions | Pictures |

| 1 | The touch screen does not support operator use | It happens if the plug is poorly switched or the panel is polluted | Make sure to accurately connect the power supply and also clean the touch screen display after daily use |

Capsule counter machine display -Picture Courtesy: cremer.com |

| 2 | Too much vibrating noise | Either the screws of vibratory trays are loose or the trays are in contact with hopper outlet channel | Tight the screws if loosen and also check if hopper chute is attached to the vibratory trays, then maintain distance |

Capsules falling from hopper onto vibratory trays-Picture Courtesy: Xcelpros |

| 3 | Capsule spillage during filling bottles | It occurs when there is a large gap between the mouth of bottle and nozzle filler | Correct it by adjusting the height of counting channel head |

Capsule counter machine-Allpack |

| 4 | Spontaneous alarm triggers | It is because you may have placed insufficient bottles for filling or the sensors of the machine are dusty | Make sure to put enough volume of bottles for filling and clean the sensors to work accurately |

Capsule counter machine with encircled alarm-Picture Courtesy: autopack.com |

13.Which Factors Should Be Considered To Get The Best Capsule Counter Machine?

You may find it difficult to select the best capsule counter machine for your business, therefore, we have provided some of the crucial factors which must be helpful for you in making a sound purchase. These are as follows:

Nature of Production

As you are going to purchase a capsule counter machine, it is important to have extensive knowledge about the nature of your production. For instance, it will include which type of product you want to process by it. Whether these are capsules, tablets confectionaries or other material? To make it more clear, you can further delve into the categorization of your production. For example, transparent capsules cannot be counted by a disk capsule counter machine. Therefore, by knowing about your production can help you choose right solution.

Production Volume

Multiple size bottles filled with capsules and tablets-Picture Courtesy: IMA safe

The next important factor is to measure the volume of your production which is quite easy to do. By doing so, you will reach to the conclusion if fully automatic capsule counter machine will be suitable for your production or semi-automatic and manual.

After-sale Service

After-sale service should be your prime focus when investigating about the machine from vendor. It will include technical assistance, installation support, and maintenance etc.

Budget

Budget idea-Picture Courtesy: usgs.com

Budget is the crucial factor to look for as you are supposed to spend your good amount of money on capsule counter machine. In addition, there are range of capsule counter machines available in different forms with varying prices while performing the same task.

Conclusion

To summarize, capsule counter machine is an efficacious tool brought into the field to carry out the responsible task of counting capsules and other stuff including tablets and confectionaries etc. It's advance features of detection system and robust stainless steel body lead to the precise and fast counting of capsules while preserving their moisture sensitive texture. Besides, Allpack has brought for you an extensive line of capsule counter machine in all of its possible types with one-year warranty. If you are interested in purchasing a capsule counter machine, feel free to contact us!

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide