Semi-Automatic Tablet Counting Machine: The Complete Buying Guide In 2024

Got tired of repeating tablet counting to confirm accuracy? Be ready to forget this tiresome job! If you are small batch runner or having medium scale production in pharmaceutical, chemical or food industry, Allpack's striking solution of semi-automatic tablet counting machine is one-step solution to boost up your productivity, ensure counting precision and preserve hygiene.

This efficacious equipment is particularly designed for all these industries who want to automate their packaging line but are hesitant to spend huge amount on expensive machine. Therefore, the machine is perfectly equipped with ergonomic features and with having small footprint, it is affordable and easy to maintenance. So, what are you waiting for? Take start and delve into the deep sea of knowledge for exploring a semi-automatic tablet counting machine!

1.What Is A Semi-Automatic Tablet Counting Machine?

Allpack Semi-automatic tablet counting machine

Semi-automatic tablet counting machine is an electrical machine made with high quality corrosion resistant stainless steel to facilitate the tablet counting. It is particularly designed to sort, count and fill the prescribed amount of tablets, capsules and troches into bottles or containers while preserving their hygiene and sterility. While performing the assigned task, it only requires operator to load the hopper with tablets and stand with empty bottles, thereby, carrying the rest of counting task automatically.

To put into context, the machine is holding immense significance for small to medium scale production facilities due its affordable price, compact texture and the intelligent alerted system for incorrect counting.

2.Explain The Essential Features Of A Semi-Automatic Tablet Counting Machine?

A semi-automatic tablet counting machine has been made with astonishing features which are explained below:

Efficiency

Various pills-Picture Courtesy: Body Logic MD

Unlike manual tablet counting machine, semi-automatic tablet counting machine requires limited operator intervention and therefore, increase tablet counting efficiency.

High Precision

Tablets-Picture Courtesy: Plenty lifestyle

Featured with photoelectric system, the machine is able to ensure high accuracy rate during counting. In addition, the-built in weighing and dosing system enable the machine to extremely perfect counting results by preventing over or under-dosing.

Flexible

This is flexible and can be easily adjusted for meeting various needs of tablets counting. For instance, bottles with different diameters can be processed by this machine by simply adjusting the U-shaped positioner up and down.

Compact Structure

Semi-automatic tablet counting machine-Picture Courtesy: pharmatec engineering

Semi-automatic tablet counting machine is more precise and compact in its structure enabling user for easy controlling and mobilization.

Cost-effective

Cost-effective-Picture Courtesy: AH accounting

Despite having advance technological features and heavy-duty construction, the machine is cheaper than fully automatic machines which is making it more cost-effective.

3.Which Type Of Bags And Containers Can be processed By A Semi-Automatic Tablet Counting Machine?

There are range of containers and bags which a semi-automatic tablet counting machine is able to process. These are shown below:

Bags

Bags-Picture Courtesy: speckyboy.com

All types of bags including sachets, pouches, standup pouches, and stick packs made up of plastic or aluminum can be processed by a semi-automatic tablet counting machine.

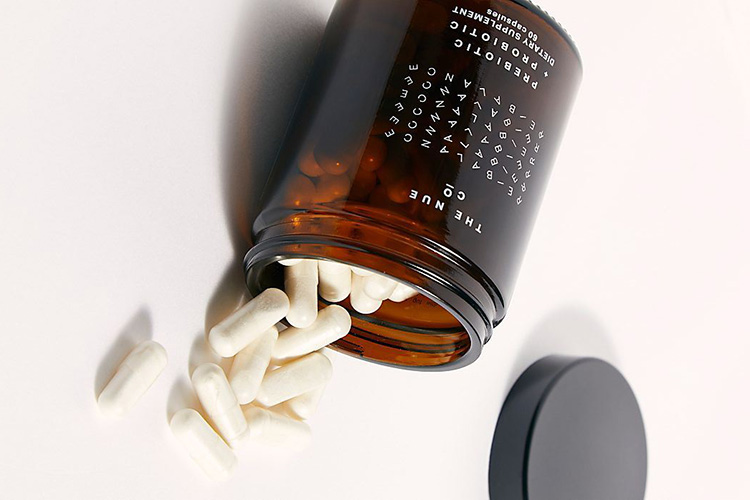

Bottles

Bottles-Picture Courtesy: thingtesting

Bottles are the most common storage containers used for holding tablets and capsules. Therefore, bottles whether of plastic or glass are often kept under the chute of semi-automatic tablet counting machine to be filled with tablets and other stuff.

Jars

Jars-Picture Courtesy: The Hive

Jars are storage containers usually made from glass or plastic. They are comparatively larger than bottles, thereby, suitable for candies and grain etc.

Cans

Cans-Picture Courtesy: food52.com

Cans are steel containers widely used for products which needs extra protection against breakage. Hence, operator may hold cans for loading under the semi-automatic tablet counting machine.

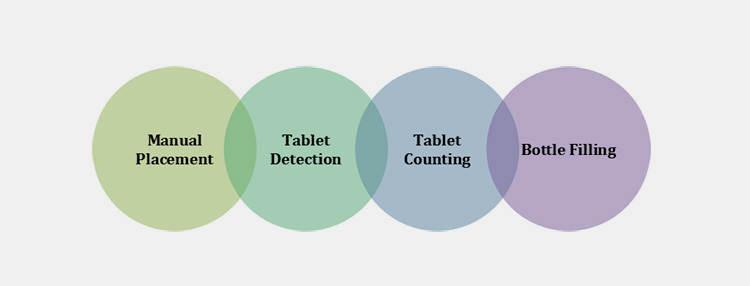

4.What Do You Know About The Working Principles Of A Semi-Automatic Tablet Counting Machine?

Semi-automatic tablet counting machine is extremely handy to use. You will get its working process just by going through the points below:

Manual Placement

Manual placement-Picture Courtesy: Technopack

To begin with the operation of the machine, the first phase consists of the manual placement of bottles under the machine filling chute and loading of hopper with tablets or capsules etc.

Tablet Detection

Tablet detection-Picture Courtesy: CVC Technology

Now, when machine is turned on, the process of tablet counting get started with tablets being released from the hopper onto vibratory tray and circular disk sequentially. At the same time, these tablets are detected by the electric photo sensor for broken tablets.

Tablet Counting

Following the pace, tablets which undergone detection phase are pushed into the tablet counting compartment. Here, the prescribed amount of tablets are counted.

Bottle Filling

At the end, counted tablets are filled into bottles or containers through V-shaped positioner one after another. These filled bottles are then manually ousted by the operator.

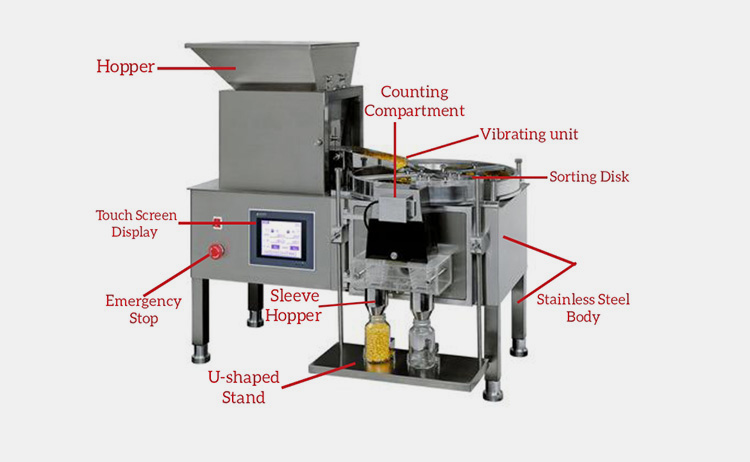

5.Describe The Structure Of A Semi-Automatic Tablet Counting Machine?

The structure of semi-automatic tablet counting machine is made up of several components each performing each crucial. They are as follows:

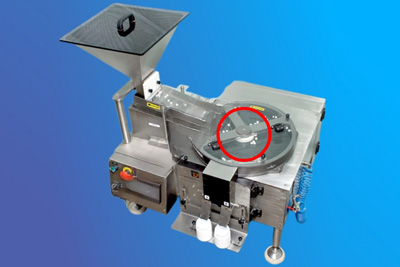

Structure of semi-automatic tablet counting machine-Picture Courtesy: CVC Technology

Hopper

Hopper is a type of container with pyramidal or conical shape which is used for holding bulk tablets or capsules in semi-automatic tablet counting machine.

Vibrating Unit

It consists of vibratory trays which is attached to the feeding hopper from where it takes the tablets and releases into sorting disk.

Sorting Disk

It is round disk where tablets are processed for accuracy. When tablets revolve in this disk, dust separator filter the dust in collection bin.

Counting Compartment

Counting compartment is a small device with integrated photoelectric system where tablets are accurately counted.

Sleeve Hopper

Sleeve hopper is V-shaped stainless steel device through which counted tablets are discharged into bottles.

U-shaped Stand

This stand is located under the sleeve hopper, over which bottles are placed for filling tablets. Its height can be adjusted with varying sizes of bottles.

Stainless Steel Body

The body of machine includes its main frame, standing support and other parts made up of stainless steel. Together they contribute to the stable performance of machine.

Touch Screen Display

Touch screen display is located on the front side of semi-automatic tablet counting machine through which user communicates the commands to machine.

Emergency Stop

It is big button with red color positioned in the front of machine. It helps the user to suddenly stop the operation in case of error or any abnormality.

6.Which Products Are Supported By A Semi-Automatic Tablet Counting Machine?

A semi-automatic tablet counting machine is capable of counting vast array of products including:

Tablets

Tablets-Picture Courtesy: Venus Galea

All types of coated, uncoated and compressed pharmaceutical tablets can be easily counted by this machine while preserving their sterility.

Hard Capsules

Capsules-Picture Courtesy: freepeople.com

Counting hard capsules containing liquid, powder or granules, is a difficult task due to their risk of getting separated, but this machine is intelligent enough to perform this task safely.

Softgel Capsules

Softgel Capsules-Picture Courtesy: brit.co

A semi-automatic tablet counting machine can be used for counting softgel capsules different types such as omega-3, vitamin and proteins softgel capsules etc.

Candies

Candies-Picture Courtesy: glaminati.com

Apart from medicines, sweets and solid dosage confectioneries such as candy, jelly, chocolate balls and bubble can also be counted via this machine.

Grains

All types of food grain including heart beans, kidney beans, pulses and cereals can be counted by using this machine.

7.What Are The Types Of A Semi-Automatic Tablet Counting Machine?

This question is holding immense pleasure for you, as it is going to disclose the huge varieties of semi-automatic tablet counting machine among which you can pick any one which compliment your needs. Let's have a look at these innovative machines:

Tabletop Semi-Automatic Tablet Counting Machine

Tabletop semi-automatic tablet counting machine

Tabletop semi-automatic tablet counting machine is unique design double-rail machine with simple vibratory system that automatically regulates the tablet counting once machine is supplied with tablets. It is capable of supporting diverse containers including bags, bottles and cans etc. Moreover, range of industries including food, medical and cosmetic can take advantage of this efficient machine for high output.

Rotary Semi-Automatic Tablet Counting Machine

Rotary semi automatic tablet counting machine

Rotary semi-automatic tablet counting machine is a light weighted machine made with electromagnetic energy which also provides easy way for operator to administer the counting process without any interruption. Several components including stainless steel rotary disk, stand, molds, a hanging brush, control unit, and a discharge funnel. The process of machine starts with loading bulk tablets into rotary disk, whose constant vibration create rotation and eventually lead to the filling of empty molds with tablets. These tablets are then fall from the molds into discharge funnel and container respectively. It is widely applicable to hospitals, food and herbal industries.

Electric Semi-Automatic Tablet Counting Machine

Electric semi-automatic tablet counting machine-Picture Courtesy: Omnia Health

Electric semi-automatic tablet counting machine is small footprint device which perfectly carry out the counting of tablets, pills and capsules. It consists of a disk, digital display, electric system, and a discharge chute. The machine simply works, when operator put the uncounted tablets onto disk, by constantly moving disk as a result of which the tablets are counted and filled into bottle or container via discharge chute. It is ideally recommend for laboratory use.

8.Differentiate Between Fully Automatic Tablet Counting Machine and Semi-Automatic Tablet Counting Machine?

To know the differences between fully automatic tablet counting machine and semi-automatic tablet counting machine consider the table below:

| No | Factors | Fully Automatic Tablet Counting Machine | Semi-Automatic Tablet Counting Machine |

| 1 | Nature | It is fully automatic by nature with minimum or no manual intervention | It is semi-automatic in nature which is upon user for functioning |

| 2 | Process | It follows continuous process until the desired number of bottles are filled and stop automatically | The process of semi-automatic tablet counting machine is continuous until the user is involved in bottle loading and unloading |

| 3 | Structure | It has complex structure with large number of components, thus, cover more space | It is precise and compact which requires less room surface and is easy to mobilize |

| 4 | Speed | Its speed is extraordinary due to full automation of process | It is efficient than manual tablet counting machine but slower as compared to fully automatic tablet counting machine |

| 5 | Cost | It is expensive due to heavy-duty construction and integrated features | It is cost-effective and affordable to purchase |

| 6 | Application | Large scale industries | Small to medium volume production facilities |

| 7 | Pictures |

Full automatic tablet counting machine |

Semi automatic tablet counting machine |

9.What Are The Applications Of A Semi-Automatic Tablet Counting Machine?

There is a long list of small to medium scale industries where the use of a semi-automatic tablet counting machine is undeniable. These industries are highlighted below in detail:

Pharmaceutical Industry

Pharmaceutical pills-Picture Courtesy: health central.com

Pharmaceutical industry is all time top sector where the entire processing is based on tablets, whether it is manufacturing, counting or packaging. Hence, this precise machine is the perfect choice for undertaking the counting and filling of tablets, pills, hard capsules and softgels.

Veterinary Industry

Pet pills-Picture Courtesy: topdogtips.com

With growing concern for animals' treatment, veterinary industry has been instrumental in providing effective drugs for this purpose. Here, a semi-automatic tablet counting machine can play its role in this respect.

Food Industry

Candies-Picture Courtesy: seriousshops.com

Huge number of food items including gummies, candies, chocolates, and bubbles need to be counted before their packaging. Therefore, semi-automatic tablet counting machine is the best suitable to perform this task.

Cosmetic Industry

Nutritional gummies-Picture Courtesy: bloglovin.com

As cosmetic industry is engaged in producing beauty gummies, vitamin capsules and softgels, it is clear that a semi-automatic tablet counting machine is relevant to be used there.

Agricultural Industry

Seeds-Picture Courtesy: homedepot.com

You might be surprised after reading that agricultural industry can be among the areas where this machine can be used. However, it has been long that different agricultural seeds such as cereals, beans and rice etc., are counted during their packaging.

10.What Are The Drawbacks Of A Semi-Automatic Tablet Counting Machine?

Drawbacks-Picture Courtesy: grammartop.com

Where semi-automatic tablet counting machine holds lucrative features for your benefits, there are some limitations on its part which are taken into account. These include:

Require Manual Intervention

Semi-automatic tablet counting machine relies upon manual intervention. It means that one person must be needed for operation, otherwise, the machine cannot accomplish the tablet counting.

Limited Capacity

This machine has limited capacity of counting tablets per hour as a result of which it cannot boost the production level of any industry.

11.How To Maintain A Semi-Automatic Tablet Counting Machine?

Maintenance-Picture Courtesy: examples.com

Maintaining your semi-automatic tablet counting machine on regular basis is the key to its long life working. Hence, it must be consistently maintained for which we have enlisted few steps for your ease:

Configuration Setting

It is important to alter the parameters of machine in accordance with quantity of tablets required for counting and filling each bottle. For instance, the amount of tablets for different cycles may not be homogeneous rather it varies accordingly. Therefore, the regular modification of counting number on HMI must be checked.

Structural Adjustment

As semi-automatic tablet counting machine is relied upon user for functioning, it is necessary to adjust the height of bottle positioning stand and hopper with changing diameter of bottles.

Parts Cleaning

Cleaning is the most essential step in maintenance to disinfect machine, it must be done thereafter daily workout. For this following points can be used:

- Disassemble the hopper and wash it ethanol rag and purified water

- Use a brush or vacuum cleaner to remove dust from vibratory tray and circulating disk

- Clean the touch screen display by wiping it with tidy cloth

Parts Lubrication

There are few parts of the machine which are in constant state of revolutionary motion. Therefore, it is obligatory to keep them lubricated to avoid jamming and friction. For this, lubrication oil can be used for parts like motor located below rotating disk.

12.Give Remedies To Cure General Errors Of A Semi-Automatic Tablet Counting Machine?

In order to solve the general problems occur when operating a semi-automatic tablet counting machine, the underlying remedies can be useful:

| No | Errors | Causes | Remedies | Pictures |

| 1 | Filling of two bottles at once | It happens when the screw of changing flipper get loose | Make sure to well tight the screw of flipper for filling one bottle at the time |

|

| 2 | Inaccurate counting | If the feeding hopper is located too high, it may result in overlapping tablets | Modify the height of feeding hopper |

|

| 3 | Tablet Dispersion | The change in bottle diameter requires change in the height of bottle holding stand | Adjust the height of bottle holder to that of diameter of bottle |

|

| 4 | Rotating disk does not move | It may be jammed with tablet stuck in it or the motor, gear or screws need adjustment | Remove the tablet by hand, tigh screws and lubricate the motor located below the disc |

|

13.What Quality Standards Should A Semi-Automatic Tablet Counting Machine Comply?

Standards-Picture Courtesy: freepik.com

There are several quality standards established for the regulation of safe and quality equipment. Hence, a semi-automatic tablet counting machine must comply these standards in order to be a quality machine. These include:

ISO

International Organization for Standardization is the broad non governmental organization formed for the purpose of promoting safe goods. An ISO certified semi-automatic tablet counting machine will be one having outstanding machinery in terms of quality as well as protection.

CGMP

Current good manufacturing practices is the most important standard developed to improve the quality regulations in areas including pharmaceutical, chemical and biotechnology field. A quality semi-automatic tablet counting machine will be always complying cGMP's principles.

CE

CE is a standard fixed by European Union to allow goods' an access in European market which are eligible to the EU safety, health, and environmental requirements.

FDA

Food and Drug Administration is an agency established to ensure that drugs, products and associated equipment being made are fully safe and hygienic. Therefore, semi-automatic tablet counting machine must follow the rules prescribed by FDA.

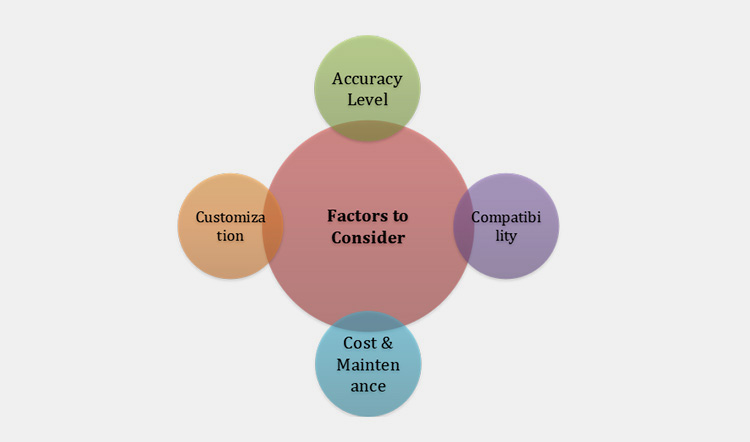

14.What Should Be Considered To Purchase Good Quality Semi-Automatic Tablet Counting Machine?

When purchasing a semi-automatic tablet counting machine, remember to consider the essential factors highlighted below:

Accuracy Level

If you are opting for a semi-automatic tablet counting machine instead of manual one, it means that accuracy and precision of counting is in your priority list. Therefore, it is necessary to check the sensors and optics of machine which can help you attain desired accuracy.

Compatibility

Another factor to look for is the resilience of machine. Make sure it can process multiple objects such as tablets, capsules and candies etc.

Cost and Maintenance

Cost&Maintain-Picture Courtesy: manwinwin.com

Before making any decision, consider the cost of machine as there are different semi-automatic tablet counting machines with varying prices. Along with that, ask your vendor for the maintenance of machine and even test the machine once. Together it will lead you to make a sound purchase.

Conclusion

To summarize the discussion, a semi-automatic tablet counting machine is most precise and effective machine with low cost and maintenance requirements. Manufacturers from diverse sectors can take advantage of this machine with the help of above guidelines. Besides, you can also get your smart semi-automatic tablet counting machine from Allpack inventory where quality is the condition for every equipment. If you are interested in buying this machine feel free to contact us via given website!

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide