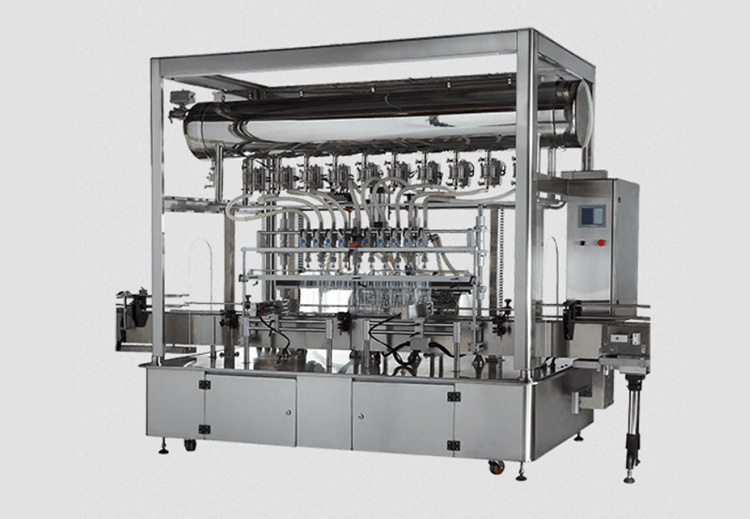

Liquid/Engine Oil/Paint Filling Machine For Cans/Buckets/Pails Automatic liquid filling line

Allpack paint filling machine automatic liquid filling line is widely used in food and chemical industries.The paint filling machine ranges from simple single head units to high speed multi-head machines with cappers to suit. Built to the highest industry standards and used by many major companies world-wide, these machines can cater for a wide range of viscosities from paint to inks, water to mayonnaise, soft-gels, creams, oils etc.This automatic liquid filling line contains semi automatic, automatic in-line, pneumatic and electric servo drive volumetric fillers, weigh fillers and drum/IBC fillers. They are fast, accurate, reliable and flexible, and we can provide bespoke innovative filling solutions for special applications.

Allpack Paint Filling Machine Features:

1.This paint filling machine automatic liquid filling line is specially made for bottles/jars/cans/buckets/jerry cans/drums filling of different products like juice,wine,spirit,soybean sauce,water,vinegar,edible oil,liquid fertilizer,lubricant oil,toilet cleaner,medium liquids,liquid drinks,other chemical and biology liquids in food,cosmetic, chemical industries.

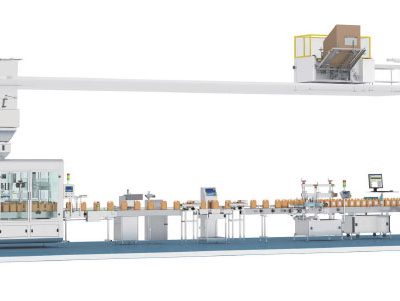

2.The whole filling production line is consist of filling machines, capping machines, labeling machines. Bottle unscrambler machine, filling machine,capping machine,labeling machine, ink coding machine and packaging machine can be added as an option and combine freely.

3.The whole liquid filling production line is a full automatic system, PLC control, 7 inch touch screen operator, Simens, Schneider, Airtac, Omron world famous electric and pneumatic components.

4.All the machines are made of good quality 304/316 stainless steel and alloy aluminum. If for corrosive products, anti-corrosion machines by PVC PP material can be customized.

5.Filling volumes can be adjusted easily in the touch screen. We use quick and fast joints for building the machines which is easy for dismentling the machines and maintenance,and convenient for cleaning.

6.The machines are with automatic liquid level control system for feeding, which is very high automation.

7.The filling nozzles are specially made for anti-drips with years of experience which prevent the products dripping on the bottles while filling.

8.Filling nozzles are customized depends on your capacity required,2 nozzles,4 nozzles,6 nozzles,8 nozzles,10 nozzles,12 nozzles are available.

9.Weighing filling, volumetric filling,gravity filling, flow meter filling available depends on different products.

10.Capping machine can be adjusted for different sizes of caps, jerry cans, buckets, jars. Capping torque adjustable of magnetism.

Allpack Paint Filling Machine Technical Specification:

|

Number of filling heads |

6 heads |

|

Filling capacity |

5-1000L |

|

Filling form |

Multiple heads into bottle bottom fast or slow filling |

|

Filling speed |

400-2200barrels/hour |

|

Filling accuracy |

±1% |

|

Cap putting form |

Elevator cap sorter feeding |

|

Capping form |

Servo grab and screw cap |

|

Capping speed |

50-60 barrels/minute |

|

Total power |

3KW, AC220V/380V, 50/60Hz |

| Program control |

PLC+ touch screen |

|

Net weight |

600KG |

| Materials of liquid contacting parts such as filling nozzle and chute: 316L # stainless steel and PVC pipe. | |

The Buyer's Guide

Paint Filling Machine: The Complete Buying Guide in 2024

Beautiful, luminescent, and eye-catching that decorate your walls and furniture, etc are all filled inside robust containers by paint filling machines.

Filling processes are revolved around two aspects-speed and accuracy. Using a paint filling machine, in your production lines can boost both these aspects. Without this machine, you cannot fill paints up to the required standard. Therefore, if you are wondering about adding a paint filling machine to your plant or are in the process of upgrading your existing machine, it is very important to choose the right kind of equipment.

Read through this guide to discover all the essential characteristics and features of this machine.

1.How Can You Define Paint Filling Machine?

The paint filling machine is a major part of the paint manufacturing line. It is mainly used for the filling of paint buckets and other related containers. This is a specialized machine used to reduce manual labor and the risk of errors.

It can fill according to the size of the paint bucket; the filling method is set according to the weight or type of piston used. Filling capacity can be divided into 10-100ml ,50-1000ml,1-5L,5-30L,200L,even 1 Ton. This product can fill a variety of liquids like ink, color paste, dyes, coating, paint, and electrical materials with high efficiency, hygiene, and accuracy.

The item that can be filled with this machine are glues, paints, inks, sealants solvents, resins, coatings, and many more.

2.What are the Advantages of Using a Paint Filling Machine in Your Production Line?

The paint filling machine is widely popular in various industries because of its wide-ranging benefits. The advantages of using a paint filling machine are as follows.

Increased Production Speeds

The paint filling machine can help to fill thousands of buckets and containers in less period. The speed depends on the fill heads of the equipment and also the viscosities of paint products. Moreover, this machine can fill multiple containers simultaneously, reducing the processing time required for each batch.

Easy Operation

This equipment is easy to handle because only some parameters like indexing times, fill times, and pump speeds are adjusted and altered on the HMI screen, and machine filling operation will be adjusted accordingly. The paint filling machine can easily line up containers and buckets to fill accordingly.

Long term Usage

The paint filling machine is durable since it is made with heavy metals and stainless-steel alloys. This machine has a long working life because machine parts are less prone to wear and tear. It needs less maintenance and regular supervision from employees that prevent any issues in the future.

Versatility of Filling

The paint filling machine can fill different container types and sizes by simply adjusting a few options. This equipment can also load any paint product with specific measurements. It can fill both thick and thin liquids, giving the freedom to use one machine for different products.

Upgradeable

The paint filling machine is easily upgradeable because if more filling nozzles are needed in the future, then they can easily be added to the old machine. Therefore, there is no need to buy a new machine to expand the business.

Cleanliness

As a paint filling machine is regularly employed for packaging hundreds to tons of paint containers daily, therefore, this machine is constructed from easier-to-disassemble and clean parts. It has a classic design that aids in sanitation efforts.

Consistent filling

The paint filling machine is optimized to fill different viscosity liquids with the same consistency at the required levels. The paint filling machine is one of the best options when the liquid is to be filled inside transparent buckets. This machine ensures that the product has the same height every time.

Moreover, maintaining precision is essential for paints thus, this machine is a perfect choice that controls and minimizes errors to reduce product wastage Paint filling machine ensures accurate fill volumes and minimizes variations leading to consistent product quality and customer satisfaction.

Enhanced Safety

The manual filling of some liquids can be hazardous; the paint filling machine eliminates the risk of accidents and exposure to hazardous substances by automating the process. In addition to this, the machine reduces the chances of splashes and spills in the workplace.

3.What are the Diverse Applications of a Paint Filling Machine?

Every industry has to pack its liquid products for selling and shipment. The paint filling machine has applications in all industries, some of which are mentioned below.

Paint Processing Industry

The paint filling machine loads different paint products such as oil paints, acrylic, enamels, wood polishes, etc in bulk-sized containers such as drums, pails, or jerrycans. This machine is used to fill containers with a precise amount of liquid paint.

Automotive industry

In the automobile industry, the paint filling machine plays an important role by coating the car, truck, or any other vehicle with paint and providing protection to the steel body. Moreover, paint can also be used for aesthetic purposes. This equipment fills lacquer, coatings, glues, and oils in large containers that are often used during vehicle construction and repair.

Construction Industry

In the construction industry, paint filling machines are employed for filling different kinds of construction plants that coat the interior and exterior surfaces of houses or other buildings.

Other products used in construction like primers, varnishes, and sealants are also filled and sealed safely by this machine.

Cosmetic Industry

The cosmetic industry is one of the biggest industries around the world which uses different kinds of paints and inks for decorating the packaging These decorative paints and inks employed for the beatification of cosmetic packaging, are packed inside the containers using a paint filling machine.

Moreover, this machine has great use in this industry, for packaging nail polishes, cleansers, foundations, lotions, waxes, serums, etc in large containers.

Food And Beverage Industry

In the food and beverage industry, this machine can work at faster speeds to fill large containers, jars, buckets, and kegs with different food items (ketchup, sauces, juices, and drinks). It loads bulk-capacity containers with products such as curry paste, condiments, ice cream, yogurt, milk, juices, etc. It can line the buckets and produce tight seals to avoid leakage.

Chemical Industry

The paint filling machine is employed in the chemical industry for filling containers with adhesives, coatings, solvents, lubricants, and other liquid products used in various manufacturing processes. This machine fills the liquid of different consistency with high accuracy and precision which is why the paint filling machine is part of the routine processing and packaging of chemicals.

Furniture and Woodworking Industry

Furniture manufacturing and woodworking industries utilize the paint filling machine for filling buckets with wood stains, lacquers, clear coats, and other finishes. The consistency of these liquids is maintained by using this equipment during dispensing in large pails, drums, and kegs.

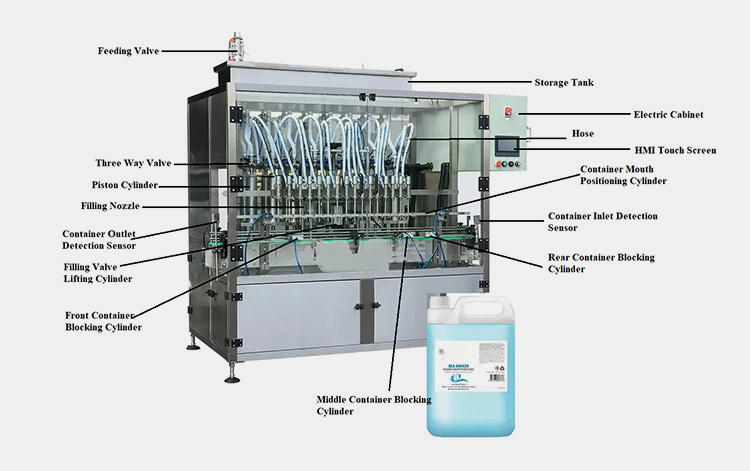

4.What are the Basic Components of Paint Filling Machine?

A paint filling machine is composed of several integral components that play a specific role in accurate paint filling. Some of these components are detailed below for your understanding:

Feed Valve

It is opened for moving paints from the storage tank to the piston cylinder. After complete loading, it is closed for preventing the additional flow of products from a storage tank.

Three-Way Valve

It has a lever that is moved to 90° for changing the direction of paints passing through the hopper into the piston cylinder. It is connected to pipelines in which paint flows. A three-way valve is also called a multi-port valve since it has three openings for mixing the fluids.

Piston Cylinder

It is an assembly consisting of a piston and cylinder. A piston is a cylindrical device, that moves inside the much larger cylinder with the pressure of liquid paint. When the piston moves forward in the cylinder, the pressure generated as a result, draws the paint into the cylinder, while its backward movement forces the paint inside the filling nozzles.

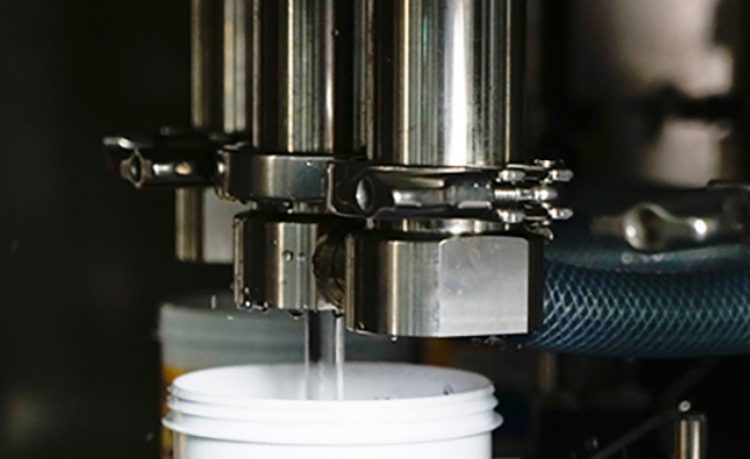

Filling Nozzles

They are long tubing that dispenses the paints inside the pails, buckets, or drums. Filling nozzles are made of stainless steel and have clamps for regulating the flow of paints. They are also anti-drip tubes that prevent splash.

Container Detection Sensor

These sensors are highly sensitive electro-mechanical or pneumatic sensors, that detect the presence of containers on the conveyors. These are two types of container detection sensors-container inlet detection sensors and container outlet detection sensors. These two sensors identify the location of the incoming and outgoing containers on the conveyors.

Filling Valve Lifting Cylinder

This is a hydraulic cylinder that is raised upward for the opening of the filling valve. This cylinder is lifted upward for dispensing paints inside the containers. The filling valve is closed when the lifting cylinder is lowered and paints are not loaded inside the containers.

Container Blocking Cylinder

There are three kinds of container blocking cylinder-front, rear, and middle. These cylinders prevent the containers from tumbling during filling.

HMI Touch Screen

This is an intuitive and intelligent display screen for adjusting and programming operational filling parameters It typically displays the progress of the filling process and also assists in troubleshooting.

Hose

It is a stainless-steel reinforced tubing for moving the paints from a storage tank to a piston cylinder.

Electric Cabinet

It is an electronic panel on which switches, buttons, wires, and knobs are fixed for controlling the equipment. It is designed with explosion-proof materials for preventing electric shocks and fire incidences. This electric cabinet has a utilitarian application.

Storage Tank

This a storage device in which paints are loaded before the start of operation. At the beginning of the filling operation, the paint goes from this tank into the filling nozzles

5.What are the Different Classes of a Paint Filling Machine?

Paint filling machines are classified in several ways, depending upon the level of automation and design configuration of the machine.

Classification on Level of Automation

There are two kinds of paint filling machines when categorized based on the level of automation. These are:

Semi-automatic Paint Filling Machine

It is a type of paint filling machine that executes paint filling steps both autonomously and manually. The containers for filling are loaded by the operator on the conveyors while filling is automatically carried out via the PLC system as well as sensors. After filling, containers are removed by the operator.

It is suitable for small and medium-size production as it has average production capacity. This machine requires operation supervision.

Automatic Paint Filing Machine

This machine occupies much larger floor space than its semi-automatic counterpart. It performs every operation step automatically using robotic arms. Moreover, it is designed to reduce labor intervention.

Automatic paint filling machine has a higher production capacity and can fill tons of paint per day, therefore, it is employed in mass-scale production plants.

Classification of Design Configuration

There are two types of paint filling machines based on equipment design configuration.

Linear Paint Filling Machine

This machine has a straight line or Z shape configuration and is equipped with a conveyor system. The paint containers are filled in sequence in a linear paint filling machine. It has one to eight filling nozzles however; it may have up to twenty filling nozzles. The capping and labeling units are present down the line. It is easily upgraded by adding more filling heads.

This type of paint filling machine is relatively cheap and easier to integrate in production lines.

Rotary Paint Filling Machine

It has a circular configuration and containers are transported through various circular stations for filling, capping, or labeling. The rotating star wheel has the filling heads and once the containers are filled, they are moved to the next station.

In the rotary type of paint filling machine, the operation is not paused while filling, therefore, it has a higher filling speed and is employed in higher production businesses.

6.What is the Working Principle of Paint Filling Machine?

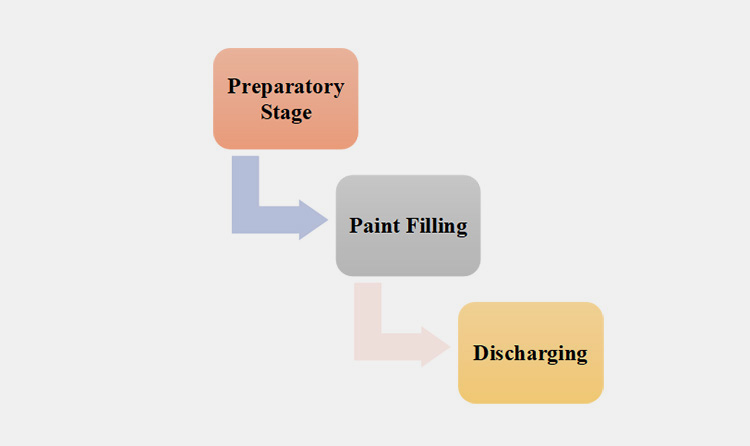

The working principle of the paint filling machine is precise and synchronized with each stage occurring for a specific duration. There are three main steps in working of paint filling machine such as:

| Preparatory Stage | In this stage, the bulk quantity of containers is loaded into the feeder device. Also, large volumes of paint are stored in the storage tank before starting the machine. The preparatory stage ensures an uninterpreted filling process. The containers are placed one by one on the conveyor. |

| Paint Filling | When the container reaches the filling nozzle, a sensor senses its presence and sends the signal to the PLC unit. This computerized system in turn signals for valve opening and paint is moved from the hopper to the filling nozzle after passing through the hose. When a container is filled to require capacity, the PLC unit signal for valve closing and filling stops. |

| Discharging | At this stage, the filled containers are unloaded from the paint filling machine and are transported to the capping or labeling machine for downstream processing. |

7.What Kinds of Paints Are Filled Using Paint Filling Machine?

Paint filling machine dispenses wide-variety of paint inside the containers such as:

- Oil-based Paints

- Watercolor Paints

- Solvent paints

- Acrylic paints

- Emulsion based paints

- Bituminous Paint

- Fluid Acrylics

Moreover, it also loads containers with coatings, inks, and resins.

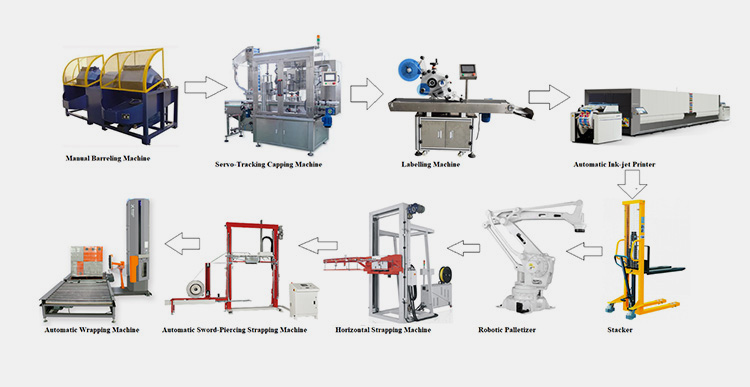

8.What are the Secondary Machines Used with a Paint Filling Machine?

There are different kinds of secondary machines used with a paint filling machine including:

Manual Barreling Machine

It is a polishing machine that has a tumbler for cleaning and removing defects such as scratches, rusting, or sharp edges from metallic reusable containers such as pails or drums.

Servo-Tracking Capping Machine

It is a large-volume machine that handles large-capacity containers for capping, lidding, and sealing purposes. This machine is equipped with servo motors that regulate the torque of the capping head.

Labelling Machine

It is an automatic machine that affixes or sticks pre-printed labels or stickers, usually supplied as a reel or film roll over the body of large-capacity containers.

Automatic Ink-jet Printer

It is a large volume high-definition printer system that prints important information such as barcode, batch number, and expiry date over the labels of containers.

Stacker

This is a large-capacity robust hydraulic or electric lift system that packs containers over one another. It aids in future palletizing and strapping.

Robotic Palletizer

This is a heavy-duty robotic arm that carries up to 40 kilograms and stacks the pallet up to the height of 1.8 mm. It loads container stacks on the wooden pallet-like construction for their convenient bundling.

Horizontal Strapping Machine

This machine fastens the pallet bundle tightly using strong straps. It cuts plastic or metallic straps and uses them to bind pallets sideways. In this way, the bundle is tied with heavy-duty tapes or adhesives.

Automatic Sword-Piercing Strapping Machine

It is a large bundling device employed for strapping already bundled pallets by a blade-like device. This device goes to the bottom of bundles and ties these pallet packages vertically. PET tape is employed by the automatic sword-piercing strapping device to fasten the bundle adjacent to the surface.

Automatic Wrapping Machine

For tightly binding and securing large paint pallets, an automatic wrapping machine is employed at the end of the production line. This machine uses a stretch film for completely wrapping pallets. The pallet is carried to the wrapping zone by the conveyor where a robotic arm or turntable is employed for enclosing pallets.

9.How to Optimize the Use of Paint Filling Machine?

Optimizing the use of a paint filling machine results in gaining maximum benefit from this equipment which translates into its higher production capacity. There are different ways to optimize its efficiency including:

Integration of Industry 4 Concept

Installing Industry 4 automation technologies such as remote connectivity, robotics, maintaining the digital schedule of maintenance, robotics, etc., in your paint filling machine increase its efficiency. The real-time data analysis and machine learning algorithm predict the performance of the equipment according to different filling parameters, which assist in optimizing the use of the machine.

Filling Systems According to Product Type

If a filler is compatible with the nature of the filling product, it will boost the efficiency of the instrument and also increase the operational life of the paint filing machine.

Neck Gripper for Unstable Containers

For decreasing product spillage and preventing the wastage of paints, it is best to use a neck gripper or pucks for holding unstable containers. This also averts the chance of paint mess down the line.

Use CIP Systems

By using these systems, hard-to-reach places are easily cleaned consequently removing the chance of paint stickiness with the interior of the filling system. This in turn prevents the clogging or blocking of the filling unit and improves the filling speed.

10.Does Paint Filling Machine Handle Different Size Containers?

Paint filling machine is versatile and flexible equipment and it can easily process not only small bottles or cans but also large-sized containers. This machine is widely employed for filling large buckets or pails having liters to tons of paint.

The paint filling machine can dispense paint in large acrylic bottles as well as drums with a capacity of about 50 liters to 200 liters to 1 ton.

11.What are Different Nozzle Options for Paint Filling Machines?

The paint filling machine has different nozzle options to handle variations in paints. Some basic nozzle options are:

Ball-Check Nozzles

They have a spring and ball-like structure on the nozzle top. When paint products flow inside the ball-check nozzle, due to pressure, the ball is forced upward and hence paints are easily dispensed from the nozzle opening. When paint flow stops, the ball occupies its original position consequently closing the nozzle vessel.

Valve-in-Tip Nozzle

This type of nozzle has a valve at the tip of the nozzle. It is also referred to as a positive shut-off nozzle or non-drip nozzle. This shutting off of paint streams can happen either at the apex of a nozzle or its crown.

Valve-in-tip nozzle is employed for preventing problems such as dripping or stringing. It loads high-viscosity paints such as oil paints.

Straight-Through Nozzles

It is an all-purpose nozzle routinely installed in a paint filling machine. It is an open nozzle without any structure controlling the flow of paints. It comes in different sizes and diameters and is equipped with individual pumps to maintain the stream of paints.

Overflow Nozzles

These nozzles are utilized for dispensing thin viscosity paints. They dive into the container, reach its bottom, and are forced to open. Once the container is filled to level, the nozzle retracts and the paint filling is shut off.

12.What are the Benefits of Using Conveyor Systems in Paint Filling Machines?

The use of conveyor systems in a paint filling machine brings wide-ranging benefits to the production plant. Read on to discover the different advantages of conveyor systems.

High Throughput

The steady motion of conveyor systems results in a higher number of paints filled containers. This in turn leads to meeting the paint packaging quota and resulting in more paint products in the market.

Efficient Utilization of Floor Space

The conveyor systems can be installed in different ways which aid in the effective utility of the floor space in your plant and also prevent cluttering of equipment.

Reduce Labor Wages

Since conveyor systems automatically move products from one station to another, this reduces the number of operators needed to load and unload containers and ultimately cutting down your labor wages.

Control Over Filling Speed

By using a conveyor, you can easily alter the speed of your filling assembly. The products can be moved either at high or low speed to avert hazardous hurrying or sluggish downtime.

Safety

When you equip your paint filling machine with conveyor systems, you eliminate the use of heavy machinery. This also decreases the need for lifting heavy containers by the operators and in turn, reduces the risk of strain and injuries.

13.What is the Difference between Piston Paint Filling Machine and Over Flow Paint Filling Machine?

A piston paint filling machine and overflow paint filling machines are subcategories of paint filling machines. However, these two machines differ in their design and working. A few of these differences are discussed below:

| Piston Paint Filling Machine | Over Flow Paint Filling Machine |

| This machine uses a piston pump to load a pre-selected volume of paints into a container. | This machine fills pails and drums containers up to a certain level. |

| The piston paint filling machine has a fast speed. | The overflow paint filling machine has a slow filling speed. |

| This machine is used for paints having different viscosities. | This machine is employed for filling thin and free-flowing chemicals. |

| It is used for filling an opaque container | It is used for filling clear containers for aesthetic purposes. |

| There is no filling volume variation in different batches by using this equipment. | There is a slight volume variation from batch to batch when this machine is employed for filling. |

14.Is there any device to Guarantee The Safety of the Paint Filling Machine?

Yes, there is a device known as explosion proof, fire retardant, or anti-explosion that guarantees process safety during work.

An explosion proof device is a safety specification that a modern paint filling machine is equipped with. Paint is a flammable substance composed of organic volatile chemicals that are filled by machines. The prime reason for this unit is to keep the environment and workspace safe.

When a machine is in a working state it emits heat, sometimes long working hours increase the probability of a spark or igniting a fire. Therefore, the electrical unit is embedded in a specialized cabinet that is doubled plated entirely coated with anti-explosion material such as copper-aluminum alloys, stainless steel, silver, aluminum, and galvanized steel.

An explosive proof device has the affinity to withstand fire up to 700 Fahrenheit up to approx. 1000 Fahrenheit. The sealed device is composed of explosion proof wiring, electrical components, a motor, wires, coils, and circulatory tubes.

15.Why Precision Filling Matters in Paint Filling Machine?

Precision Filling is important because of two reasons which are:

Over Filling

If a paint filling machine dispenses a huge amount of paint than required, it causes an overflow of containers and also leads to product giveaways. Thus, expenses add over time leading to huge losses. Therefore, a precisely calibrated paint filling machine is employed to avoid the issue of overfilling.

Under Filling

Sometimes, a non-calibrated paint filling machine can underfill the container than mentioned on the label of the container, attracting the attention of trading regulatory authorities and causing product recall from the market and harsh monetary penalties. Moreover, it also results in a loss of customer trust in the quality of paint products. Hence, to prevent underfilling it is essential to use high precision paint filling machine.

16.How Does a Gravimetric Paint Filling Machine Different From a Volumetric Paint Filling Machine?

A gravimetric paint filling machine and a volumetric paint filling machine, are routinely employed for filling the paints. However, both these machines have different approaches for filling paint. Some of the differences between both these machines are discussed below:

| Gravimetric Paint Filling Machine | Volumetric Paint Filling Machine |

| This machine dispenses the required weight of the paints in the containers. | This machine loads the required volume of the paints in the containers. |

| It consists of a hopper, filling nozzles, a metering device, PLC controllers, and a weighing sensor. | It consists of a hopper, filling nozzles, a metering unit, and a PLC system. |

| It does not require regular calibration. | It needs regular calibration with each new batch/ |

| The gravimetric paint filling machine has sensors and weighing checking systems to detect the paint filling rate. | The volumetric paint filling machine does not have any system to measure paint filling throughput. |

| It has high filling accuracy. | It has limited filling accuracy. |

| This machine has a slow filling speed. | This machine has a high filling speed as compared to its gravimetric counterpart. |

17.How to Use Paint Filling Machines for Reducing Carbon Footprint?

Sustainability is now the focus of many industries and manufacturers are committed to reduce carbon footprint. There are different ways by which a paint filling machine contributes to lower carbon footprint including:

Lower Energy Requirement

High consumption of fossil fuels has a severe impact on climate change. However, a paint filling machine has minimal energy requirements and does not consume fossil fuel instead, it is operated electrically or pneumatically.

Maintaining Efficiency

It is important in increasing the sustainability of the equipment. Regular and scheduled maintenance is essential in prolonging the operational life of a paint filling machine and boosting its efficiency.

Digitization

The paint filling machine is furnished with modern computerized systems and technology that digitize the paint filling operations and reduce the need of using paper for record keeping. In this way, this machine minimizes the negative effect of paper on the environment.

Reusing the Containers

A paint filling machine often fills buckets and drums that are recycled and reused. This decreases landfill and increases the sustainability of the equipment.

18.How Can You Remedy the Technical Problems that Arise in a Paint Filling Machine?

Even if you are doing routine maintenance of your paint filling machine, there is still a chance that unexpected issues arise with this equipment. However, there is no need to worry as these issues are easily resolved. Some troubleshooting tips are:

Abnormal Vibrations or Sound

During a run, abnormal sounds or vibrations are heard from the paint filling machine.

Reason

- Untightened belts or seals or nuts and screws

- Machine parts are not properly aligned.

- Inadequate oiling of parts that are prone to friction.

Remedy

- Inspect and tightened all the untightened components such as belts or screws

- Properly align all the parts

- Lubricate all joints and balls

Clogging or Jamming of Filling System

Sometimes there is little or no paint flow through the filling unit

Reason

- Dust or debris buildup in filling nozzles

- Product accumulation in supply lines

- Improper filtration of product

Remedy

- Clean the filling nozzles with water and dry cloth

- Use cleaning systems to properly clean the supply line

- Replace the old filtration unit

Failure in Machine Computerized System

Sometimes PLC panel and touch screen are not working properly or remain unresponsive.

Reason

- Loose electric connections and improper power supply

- Incorrect software settings

Remedy

- Turn on the machine again after properly setting up every connection

- Adjust the settings on the HMI touchscreen

Leakage of Paints from Filling Nozzle

Reason

- Improper placement of a container

- Slack or wobbly assembly of hose and pipe

- Old and faulty O-rings

- Defective seals and clamps

Remedy

- Properly position the container under the nozzle

- Tighten assembly of hose and pipes

- Replace damaged O-rings

- Install new seals and clamps

Variation in Paint Filling

Reason

- Incorrect machine calibration

- Equipment is not properly leveled

- Product buildup in nozzles

- Inaccurate programming of filling time parameter

- Damaged seals

Remedy

- Properly calibrate machine

- Adjust the positioning of the machine so that it is properly leveled

- Remove product buildup from nozzles

- Adjust the filling time parameter

- Replace damaged seals

Contaminants in Filled Containers

Sometimes dust or other foreign substances are seen inside the paint containers

Reason

- Debris accumulation in filling nozzles and pipes

- Failure to properly maintain the cleaning schedule of equipment

- A dirty container is used for filling

Remedy

- Thoroughly clean nozzles and pipes

- Maintain a proper cleaning schedule

- Wash the containers before filling

Conclusion

A paint filling machine is a worthy investment since it is highly precise and accurate, filling thousands of containers in a short duration. Not only this equipment is robust and versatile but also it streamlines your filling plant. You can optimize its use by integrating advanced (Industry 4) technology and CIP system into your equipment. Hopefully, by going through this guide, you have learned about various ways to boost your filling capacity. For machine purchase; please contact our Team Right Now.

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp:+86 18171018586

Tell us your material or budget, we'll reply you ASAP within 24 hours

Automatic liquid filling line Related Products