Allpack Disinfectant Filling Machine

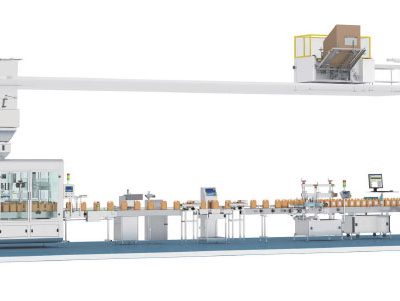

Are you looking for a disinfectant filling machine?Disinfectants work by destroying the cell wall of microbes or interfering with their metabolism.With Allpack disinfectant filling machine will help you solve everything.Allpack disinfectant filling machine automatic liquid filling line is suitable for daily chemical products,such as dishwasher,disinfectant,glass cleaner,laundry detergent,softener,personal care products,hand soap,shampoo,conditioner,shower gel,hail oil,essential oil,etc.The whole machine is in-line structure, adopts the principle of servo motor-driven filling and volumetric metering filling to realize the high precision of filling and metering. Using plc control, touch-sensitive human interface, the whole machine is convenient and intuitive to operate. Optional high-precision automatic weighing data transmission system for faster dosage adjustment.

Main Types of Disinfectants

Hydrogen Peroxide

Quaternary Ammonium Compounds

Chlorine Compounds

Alcohols

Aldehydes

Iodophors

Phenolic Compounds

Allpack Disinfectant Container Type

Alcohol Sanitizer Gel Hand Cleaner Antiseptic Disinfectant Filling Machine Automatic liquid filling line

Allpack disinfectant filling machine is specially designed to meet the different demands of daily chemical industry. Allpack is able to supply your ideal machine to deal with your disinfectant filling requirements and up to your production targets.Allpack disinfectant filling machine is suitable for various kinds of plastic bottles for daily chemical industries such as disinfectants bottle, cleaner bottles, medical alcohol bottles, bleaching water bottles, corrosive liquid bottles, etc.

The whole Allpack disinfectant liquid filling line include the automatic bottle unscrambler,disinfectant filling machine,automatic capping machine,induction sealing machine,inkjet printer,weight checking,automatic labeling machine,carton sealing&strapping machine,palletizing machine.

Allpack Disinfectant Filling Machine Features:

1.The filling nozzle is equipped with an anti-drip device to ensure no wire drawing or dripping during filling.

2.All contact materials are made of stainless steel, easy to disassemble, easy to clean, and meet hygiene requirements.

3.No need to replace parts, you can quickly adjust and replace bottles of different shapes and specifications, with strong applicability.

4.Using well-known brands of electrical and pneumatic components, the failure rate is low, the performance is stable and reliable, and the service life is long.

5.It is easy to adjust the filling volume and filling speed. It is equipped with the function of no bottle no filling. The liquid level automatically controls the feeding and has a beautiful appearance.

6.The filling head can be changed to submersible filling, which can effectively prevent the filling material from foaming or splashing, and is suitable for filling liquids that are easy to foam.

Allpack Disinfectant Filling Machine Technical Specification:

| Filling Material | Antiseptic |

| Filling Volume | 1-5L |

| Cap Type | Screw Cap / Pressing Cap |

| Function | Filling Machine |

| Filling Heads | 6-32 Filling Nozzles |

| Specification | 2400*1300*2200 |

| Bottle Shape | Round / Square |

| Capacity | 400-2200barrels/hour |

| Weight | 1850kg |

The Buyer's Guide

Disinfectant Filling Machine: The Complete Buying Guide in 2024

Have you ever noticed the viscous texture of Disinfectant can clog the filling process?

A disinfectant filling is the most significant procedure of disinfectant making industry. In today’s competitive world, a disinfectant market is highly demanded and very tough.

A disinfectant filling machine designed for the purpose of convenience, protection, and securing error-free filling. The primary aim of the equipment is to produce high-quality dispensing with high-performance and less cost expenditure.

Today’s topic is all about disinfectant filling machine where our experts has discussed its importance in raising your business. Looking to invest? We suggest reading the blog to make a right decision.

1.What Is Disinfectant Filling Machine?

A disinfectant Filling Machine which can also be called as Steriliser liquid filling machine is an equipment that serves the purpose of filling various chemicals which are sticky and have low viscosity.

Liquid based products that can be filled using this machine can be hand sanitizer, surface cleaner, washing liquid, floor cleaner, dishwashing liquid, shower gel, cosmetic cream, shampoo, honey, peanut butter, large infusions, syrups etc.

This machine is constructed of stainless steel, designed with piston filling, peristaltic pump nozzle system or pressure gravity filler to fill volumes of liquid with varying speed of bottle filling. Such fillers require explosive proof mechanism as the product is highly flammable.

This is a highly precise, operated through PLC technology, it ensures hassle free and smooth filling of liquid chemical bottles. The speed and filling volume can be adjusted accordingly as per your requirement. A disinfectant filling machine comes with ranging production specifications such as different number of filling heads, speed variability, no bottle no fill and no spill feature.

2.What Is the Importance of a Disinfectant Filling Machine?

To understand the significance of a disinfectant filling machine you must know that it has wide scope around many areas of applications. Supporting such variety of industries for filling different products, this machine has certain beneficial importance.

Rapid Filling of Products

A disinfectant filling machine allows in line filling of bottles with multiple positions for dispensing different volumes of liquid through various nozzle arrangement. Dual line option is also available for space efficient and increased productivity.

Ensures Sterile Manufacturing

The parts of disinfectant filling machine are constructed of stainless steel to provide high quality assurance according to GMP for customer services. This makes sure that the liquid chemicals manufactured are sterile, and good hygienic conditions are maintained while production of disinfectant liquids.

Allows Large Volume Production

In pharmaceuticals or any other chemicals industry, large volumetric production of sterile liquids such as infusions, syrups and vaccines are done through the use of disinfectant filling machine.

Prevents Overfilling

Filling of disinfectant using gravitational dispensing method allows quantitative filling of liquid products which are appropriate for low viscosity fluids. They have special nozzles which also control dripping and foaming with some of the liquid products that would prevent overfilling.

3.What Are the Industrial Applications Of A Disinfectant Filling Machine?

Pharmaceuticals Industry

Large volume production of sterile liquid drugs such as preparation of vials, vaccines and other parenteral formulations, antiseptic or disinfectant chemicals are manufactured using disinfectant filling machines. These machines dispense bulk volumes of these liquids into large bottles and containers.

Chemicals Industry

For the production of home based products such as toiletries and other chemicals used commonly around the house such as dishwashing liquid, laundry washing liquids, hand washing liquids, hand sanitizers, kitchen degreaser etc. These sticky chemical liquids are filled into bottles with many types of shapes containing varying quantities of these products.

Cosmetics Industry

The disinfectant filling machine is capable of dispensing low viscosity products with ambient temperature. Cosmetics industry finds its purpose in using this equipment to produce variety of beauty and cosmetic items such as shampoo, body wash, shower gel, hair conditioner etc.

Food Industry

Food industry uses this machine for quantitative filling of liquid or semi-liquid products such as honey, peanut butter, sauces pastes such as mustard paste, tomato paste and different types of seasoning pastes, edible oil, soup and salad dressings like mayonnaise, Worcestershire sauce, soy sauce, vinegar. This machine operates favourably through syringe, piston and nozzle system to fill required amount of food products in desired containers.

Agricultural Industry

In agricultural industry use of chemicals, fertilizers, pesticides and herbicides have been widely known to be used for better quality production of crops. This machine finds its purpose to manufacture fertilizers, pest control chemicals like pesticides and herbicides, insect repellents, water treatment chemicals, waste treatment chemicals etc. The machine can handle toxic, flammable, and foaming liquids therefore the filling application suits production of agricultural products too.

Pesticide Industry

A disinfectant filling machine is of utmost importance in the pesticide industry due to the hazardous nature of the substances involved. These machines are equipped with safety features, such as sealed systems and containment measures, to prevent leaks, spills, or fumes from escaping into the environment or endangering workers' health.

Water Filling Industry

Water filling industry finds it’s use in deploying disinfectant filling machine as a production line for filling of different types of water such as natural water, carbonated water, purified water, flavored water just by making few changes in various spare parts. High pressure filling nozzle made of stainless steel is used to rinse, fill and cap bottles.

Automotive Industry

In automotive industry, processing and filling of solutions such as engine oils, grease, lubricants, windshield wiper fluid, etc are dispensed using inline and rotary volumetric fillers that are incorporated in disinfectant filling machine. The machine is designed of stainless steel parts that can handle foaming and non foaming liquids with various styled nozzles and valves.

Dairy Industry

In this industry different forms of filling containers like pre-formed cups, form fill seal cups, and bottle packaging styles are adopted using Disinfectant filling machine. Dairy packaging industry fills and packages products like butter, cheese, yoghurt, cream and milk etc using this machine.

4.What is the Working Principle of Disinfectant Filling Machine?

The working principle of a disinfectant filling machine involves automating the filling process with precision. The machine is equipped with nozzles connected to the disinfectant supply.

Empty containers are positioned in designated areas, and the machine activates the flow of disinfectant into the containers.

The filling process can operate through gravity or a controlled pressure. Sensors or control mechanisms ensure the desired fill levels are achieved, prompting the machine to stop the flow of disinfectant.

The filled containers can then move to optional sealing stations or subsequent processing stages. The working principle of the machine aims to optimize efficiency, accuracy, hygiene, and cost-effectiveness in the filling of disinfectant products.

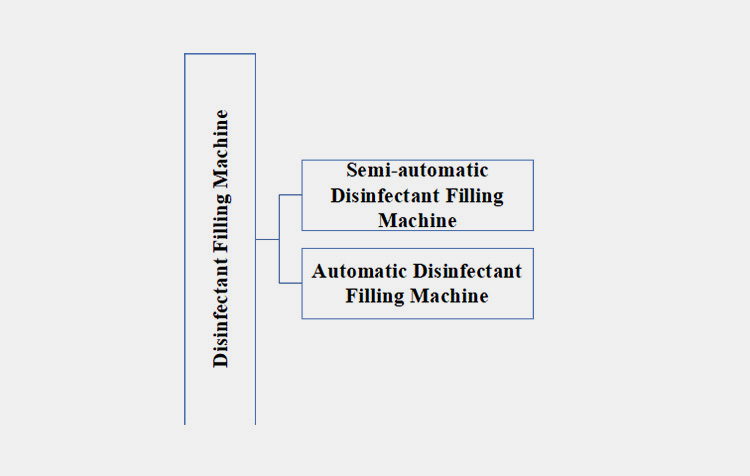

5.What are the Types of Disinfectant Filling Machine?

The disinfectant filling machine is designed to efficiently fill containers, such as bottles or containers, with disinfectant liquids while ensuring accuracy and speed. The types of this machine can be categorized as:

Based On Automation

Semi-Automatic Disinfectant Filling Machine

Semi-automatic disinfectant machine requires some manual intervention and operator assistance during the filling process. They are suitable for smaller production volumes and offer more flexibility in terms of adjusting filling parameters for different container sizes or product variations. However, they require more labor and may have a slightly lower production capacity compared to fully automatic machines.

Automatic Disinfectant Filling Machine

Automatic machine is designed to perform the filling process without significant operator intervention. These machines are highly automated and typically high automation, managing moderate to large volume production line with low downtime and minimum manpower.

They require minimal operator involvement and can operate continuously with consistent accuracy and speed. These machines are often used in industrial-scale disinfectant production facilities.

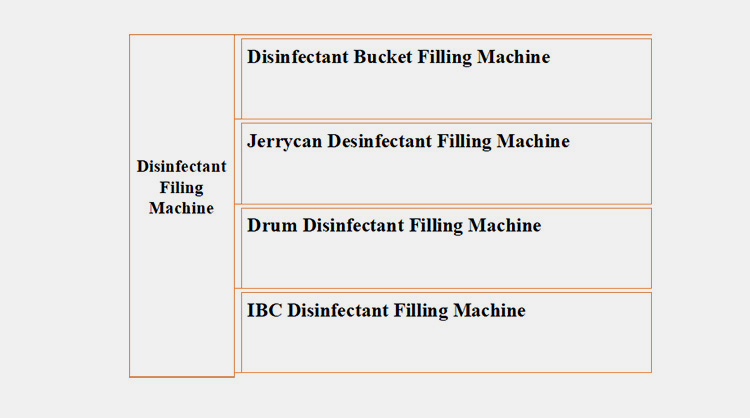

Based On Type of Container

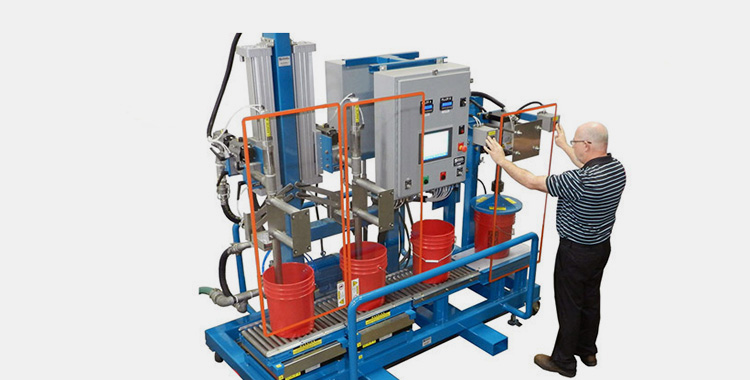

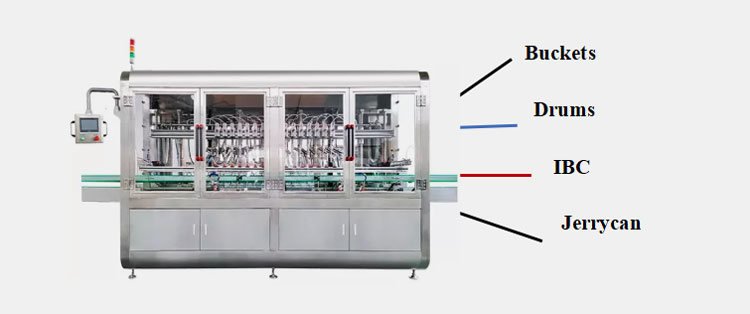

Disinfectant Bucket Filling Machine

A disinfectant bucket-filling machine is a specialized piece of equipment designed to automate the process of filling disinfectant solutions into buckets or pails. It consists of a conveyor system that transports empty buckets to the filling station, where a filling mechanism accurately dispenses the disinfectant solution into the buckets.

Jerrycan Disinfectant Filling Machine

A jerrycan disinfectant filling machine is a specialized equipment designed to automate the process of filling disinfectant solutions into jerrycans.

The machine ensures precise control over the filling volume, accommodating jerrycans of various sizes. This automation enhances productivity and efficiency in industries requiring bulk quantities of disinfectant to be filled into jerrycans, such as manufacturing, sanitation, and cleaning.

Drum Disinfectant Filling Machine

The drum disinfectant filling machine significantly improves efficiency, productivity, and accuracy in industries that require the filling of large quantities of disinfectant into drums. It eliminates manual labor and ensures consistent filling volumes, reducing the risk of product wastage and improving overall production efficiency.

IBC Disinfectant Filling Machine

IBC disinfectant filling machines greatly enhance productivity, accuracy, and efficiency in industries that require large-scale filling operations. By automating the process, these machines reduce manual labor, minimize product wastage, and ensure consistent filling volumes, resulting in improved production output and cost-effectiveness.

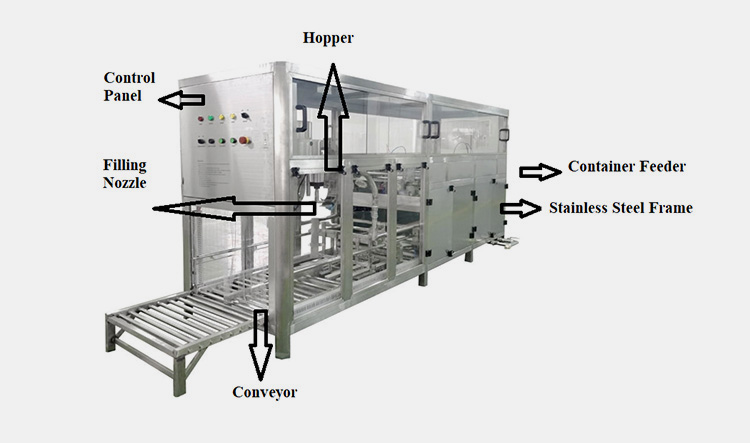

6.Describe the Main Components of Disinfectant Filling Machine?

Control Panel

This machine adopts the system of PLC technology which controls and operates the disinfectant filling machine by insertion of manual touchscreen commands that can adjust speed and required filling instructions for dispensing of different volumes of liquid.

Filling Nozzle

Filling nozzles are responsible for releasing the desired liquid which are controlled by the servo motor. These nozzles dip into the bottles and fill required amount of fluid and can also keep a check on foaming issues and prevent overfilling.

Hopper

This part of the filling machine is a funnel shaped component that serves as a storage tank for the liquid product that is supposed to be delivered and released by the nozzles.

Conveyor

Conveyor system of disinfectant filling machine transfers the bottles or containers to the production line . It allows accurate and precise filling of liquid and semi-liquid products according to different volumes.

Container Feeder

A container feeder device helps in transferring of containers to the conveyor system for further filling process.

Stainless Steel Frame

This steel frame designed to build the machine ensures protection and safety while operating of this equipment. All electronic components are secured in the stainless-steel cabinet which allows the user to work at a safe distance.

7.What is the Auxiliary Equipment of Disinfectant Filling Machine?

The auxiliary equipment commonly used with a disinfectant filling machine for a production line targeting large volume containers includes:

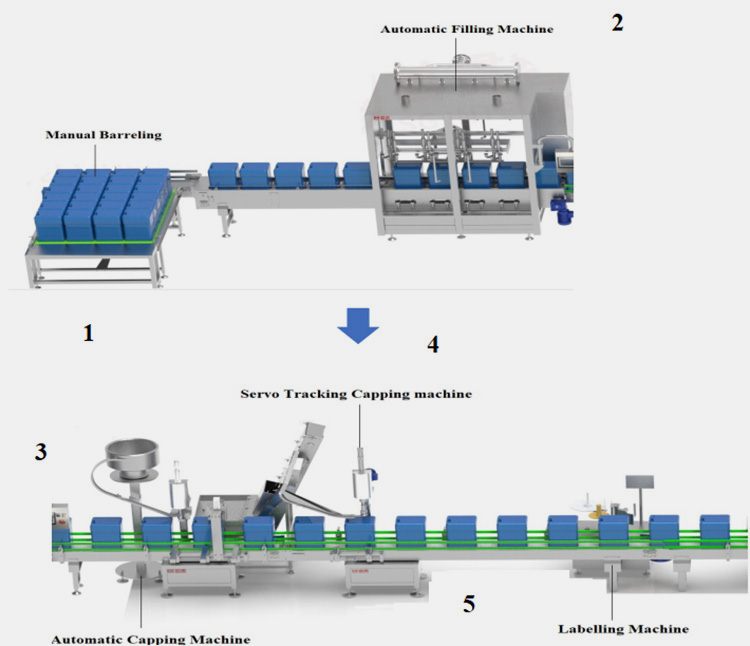

Manual Barreling:Used for manually placing the empty containers in position for filling.

Automatic Filling Machine:Empty bottles/containers comes in contact with filling nozzles where auto-detector senses the presence of bottle to fill disinfectant and moves to next machine.

Automatic Capping Machine:Automatically applies caps or closures to the filled containers, ensuring a secure seal.

Servo Tracking Capping Machine:Ensures accurate and consistent capping by adjusting to the position and size of each container.

Labeling Machine:Applies labels to the containers, providing product information and branding.

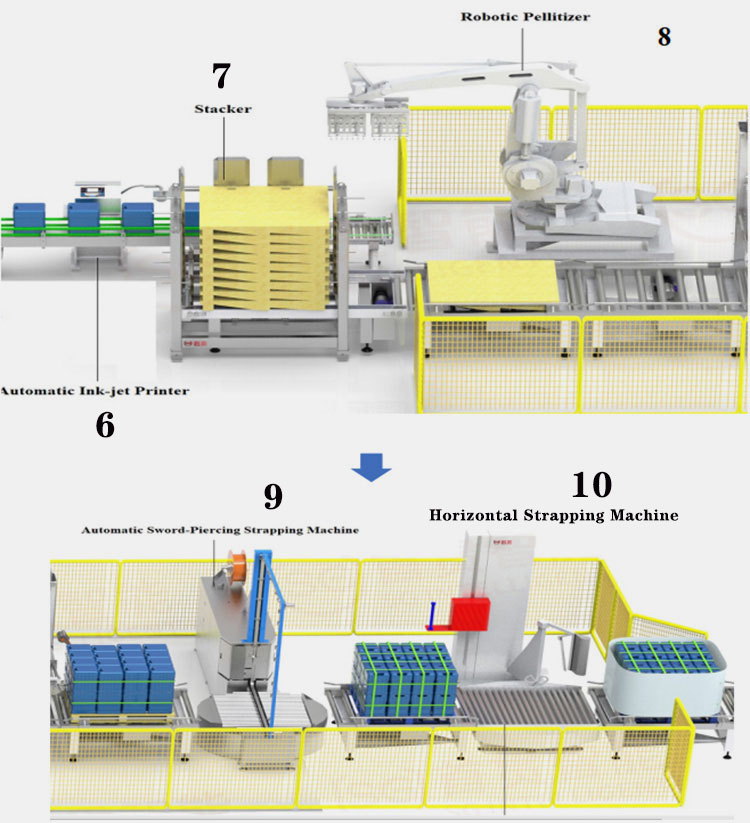

Automatic Inkjet Printer:Prints product information, batch numbers, or expiration dates directly on the containers.

Stacker:Arranges the filled and capped containers in an organized manner for further processing or packaging.

Robotic Palletizer:Automatically stacks the filled and capped containers on pallets, ready for shipment or storage.

Automatic Sword-Piercing Strapping Machine: Utilizes a sword-like tool to pierce through the strapping material, creating a secure and tamper-evident seal.

Horizontal Strapping Machine:Applies horizontal straps to secure the stacked containers on pallets, preventing shifting or damage during transportation.

These auxiliary equipment components work in conjunction with the disinfectant filling machine to create an efficient production line for filling, capping, labeling, stacking, and packaging of final product for transportation.

8.What Products Can a Disinfectant Filling Machine Fill?

Don’t you think it is important to have disinfectant-specific filling machines according to its requirement? Yes, this is because it is depending upon the unique characteristics of the textures and nature of your product that might be corrosive, viscous, alcohol-based, or oxidizing, etc.

| Liquid Disinfectants Liquids with variable viscosities or with batch variations such as alcohol, solvents, mouthwash, cleaner, and bleach are good examples as even corrosive liquids and chemicals comes in this category. |

|

| Gel Disinfectants Hand Sanitizers have low to medium viscosity, paired with a device to be filled with that consistency accurately.Some gel disinfectants are designed for specific surfaces or objects, providing effective disinfection in areas that require a concentrated application. |

|

| Foam Disinfectants

Foam disinfectants require specialized foam nozzles that are designed to deliver the foam formulation into containers with precision. These nozzles ensure that the foam is dispensed evenly and at the desired consistency. |

|

| Aerosol Disinfectants

Aerosol disinfectants are disinfectant products that are packaged and dispensed in aerosol cans. These cans contain the disinfectant formulation under pressure, allowing it to be released as a fine mist or spray when the valve or nozzle is actuated like Lysol disinfectant spray, Clorox disinfecting spray, and Dettol disinfectant spray. |

|

9.What Type of Fillers a Disinfectant Filling Machine Have?

Is it important to consider the type of machine? Yes, it is! A disinfectant filling machine can be equipped with different types of fillers depending on the specific requirements of the disinfectant product being filled. Here are some common types of fillers that may be used in a disinfectant filling machine:

Gravity Fillers

Gravity fillers rely on the force of gravity to fill containers with disinfectant. The disinfectant flows from a holding tank or reservoir into the containers, and the fill volume is controlled by adjusting the height or time of the fill. Gravity fillers are suitable for low to medium viscosity disinfectants.

Piston Fillers

Piston fillers use a piston mechanism to draw disinfectant from a supply source and deposit it into the containers. The piston movement creates a suction effect that accurately fills the containers to the desired volume. Piston fillers are suitable for filling both low and high-viscosity disinfectants. The working volume capacity is mainly around 1000L with a pneumatic control pump to adjust the filling volume accurately with high filling precision.

Pump Fillers

Pump fillers utilize a pump mechanism to transfer disinfectant from a supply source into the containers.

The pump generates pressure to move the disinfectant through the system and control the fill volume. Pump fillers are suitable for filling various viscosities of disinfectants. These machines are commonly used in industrial or commercial settings where large quantities of disinfectant need to be filled efficiently and accurately.

Volumetric Fillers

Volumetric fillers measure a fixed volume of disinfectant and dispense it into the containers. They can use different mechanisms such as rotary valves, rotary pumps, or augers to achieve accurate volumetric filling.

Volumetric disinfectant filling machines may also incorporate additional features such as container indexing, automatic capping, and labelling capabilities to further streamline the filling process.

Overflow Fillers

Overflow fillers are commonly used for filling disinfectants into containers with narrow necks. The fill nozzle submerges into the container, and the disinfectant overflows into a catch basin, ensuring that the container is filled to a consistent level. Overflow fillers are suitable for filling liquids with foaming tendencies.

Time-Pressure Fillers

Time-pressure fillers utilize a combination of time and pressure to control the fill volume. The disinfectant is introduced into the containers for a specific duration at a controlled pressure, ensuring accurate and repeatable filling.

Time pressure fillers use pumps for fast filling in the bottles to save time and space by using multiple heads needed for required production rate.

10.What Types of Containers a Disinfectant Filling Machines Can Fill?

Disinfectant filling machine is designed to fill various types of containers used for packaging disinfectant products. The specific types of containers that a disinfectant filling machine can handle may vary depending on the machine's design and capabilities. However, here are some common types of containers that disinfectant-filling machines can typically fill. For example:

Buckets

Disinfectant filling machines can be equipped to fill disinfectants into buckets of various sizes. These buckets often have handles and are used for storing larger quantities of disinfectant for industrial or commercial use.

Buckets come in various sizes, typically ranging from a few litres to several gallons. The filling capacity of buckets can vary from 10 litre (2.6 gallons) for smaller buckets to 20 litres (5.28 gallons) or more for larger buckets.

Drums

Disinfectant filling machines can handle filling disinfectants into drums, typically made of steel or plastic. Drums are commonly used for storing and transporting bulk quantities of disinfectants.

Drums are available in different sizes and capacities. Standard drum sizes include 55 gallons (208 litres) and 30 gallons (113 litres). However, drums can also have smaller or larger capacities, such as 5 gallons (19 litres) or 10 gallons (38 litres), depending on the specific application.

IBC (Intermediate Bulk Containers)

Disinfectant filling machines can fill disinfectants into IBCs, which are large containers used for storing and transporting bulk quantities of liquids. IBCs are commonly made of plastic or metal and have a capacity ranging from hundreds to thousands of litres.

IBCs are designed for storing and transporting bulk quantities of liquids. They typically have capacities ranging from 275 gallons (1,041 litres) to 330 gallons (1,249 litres) for standard IBCs. However, larger IBCs can have capacities up to 550 gallons (2,082 litres)

Jerrycans

Disinfectant filling machines are equipped with features and capabilities that allow them to fill disinfectants into jerry cans of various sizes and shapes.

These jerry cans often have handles, allowing for ease of use and transportation. The filling process is designed to be accurate and precise, ensuring the correct amount of disinfectant is dispensed into each jerry can. The capacity of jerry cans used in disinfectant filling machines can vary from 1 to 5 litres (0.26 to 1.32 gallons) to 20 litres (5.28 gallons).

11.How to Extend Life of Disinfectant Filling Machine?

To ensure that your filling machine works appropriately for an undefined period of time and gives you good source of return on your investment, you must make sure that you follow these points below to extend life of the machine.

Keep a check on your machine’s component parts and their individual functioning. Inspection of your disinfectant filling machine for any signs of wear and tear by your technician team can maintain its quality and ensure productivity.

Make sure that changeable parts of the machine-like nozzle tips and seals are in working condition that would prevent any leakage or malfunctioning issues. Replace worn out parts with genuine parts to prolong machine’s service for a longer run.

The machine operators must be trained enough to handle technological problems and their adequate working, in other case the equipment might be damaged.

Cleanliness and proper maintenance for the prevention of dirt and contamination ensures efficiency in working of the machine.

12.What are the Technical Problems and Solutions of Disinfectant Filling Machine?

Although convenient for operation and maintenance, similar to other industrial equipment, a disinfectant filling machine also undergoes some technological errors that deem it difficult for the operator to carry out functioning. But to avoid the hassle and prevent delayed working, technicians have found out their troubleshooting.

| PROBLEMS | SOLUTIONS |

| Unlevelled Filling

|

Make sure that the machine is accurately placed on the production floor level to avoid difference in filling precision due to unusual placement of equipment.

Filling time must be adjusted accordingly. Nozzles and tubes must be inspected for any leakage or blockage. There must be correct spacers between each to ensure even filling. |

| Head Dive malfunctioning

|

Check the airlines or compressor for any blockage of air.

PLC screen must be checked for it’s settings, the operator must ensure that it is set to function automatically. |

| Extra foaming in Containers

|

Filling time must be adjusted so that any excess foam flows out of the bottles.

Spacers between the nozzles must be checked whether the nozzle has filling precision according to the bottle or not. Anti-foam nozzles can be employed to control excessive foaming in bottles while product filling. |

| Blockage of filling nozzles

|

Check and clean the nozzles for blockage or any dirt clogged which might cause problems in filling accuracy. |

| Contamination

|

To prevent contaminants from entering the production process, must check for proper cleaning and maintenance of machine parts |

Conclusion

While designing any type of filling machine, it is mandatory to take notice of what type of product would be filled inside, as the liquid viscosity directs what type of fillers will be deployed by the machine. For instance, high-viscosity to low-viscosity products requires a specific class of disinfectant fillers e.g., piston or pump fillers, etc., to deliver the product effectively into containers. If you’re facing difficulties in selecting the right disinfectant filling machine, don’t worry! Please catch us simply by messaging our Team Now.

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp:+86 18171018586

Automatic liquid filling line Related Products