Vegetable Sesame Corn Olive Edible Oil Filling Machine Automatic liquid filling line

Allpack edible oil filling machine is suitable for filling viscous,inviscid and corrosive liquid.It’s widely applied in plant oil,chemical liquid,and daily chemical industry.It adopts linear type filling,electromechanical&instrucmental intergration controlling.It’s simple and rapid for changing the varieties with unique design and superior capability.It’s appearance accords with the international machinery concept.

Germay SIEMENS PLC and touch screen control make it intelligent protection function.Vacuum anti-dropping device ensures no leaking situation in production.Electric adjusting for volume system,frequency control and photoelectric detecting system(Germany TURCK brand) are applied in this machine.

This is a whole Automatic essential oil filling capping machine production line solution. The machine type, number of machines, speed, capacity, size, Etc. The production line would be customized according to the your actual production needs; We can develop a professional integrated filling and packaging production line plan For you.

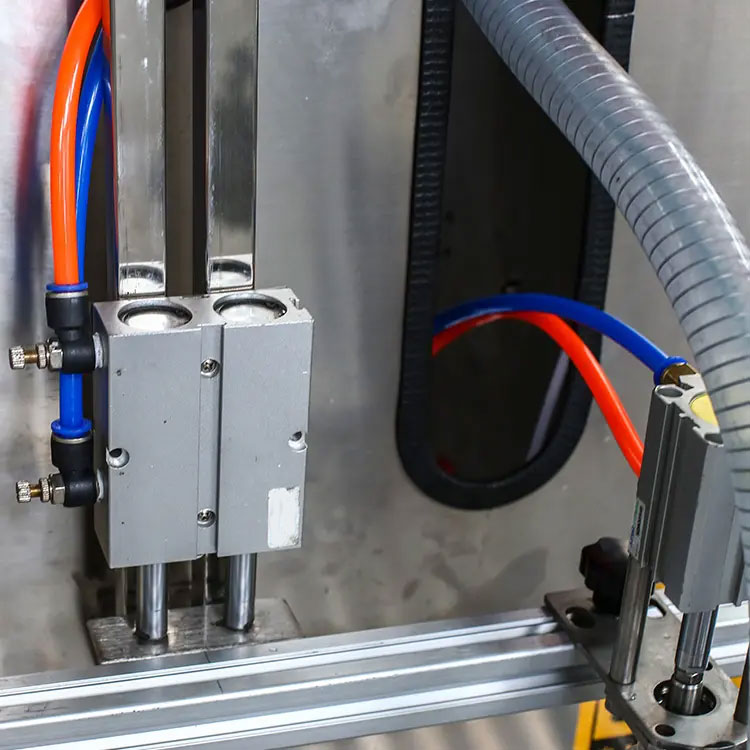

Allpack Edible Oil Filling Machine Details:

Allpack Edible Oil Filling Machine Products:

Allpack Edible Oil Filling Machine Features:

1.Large filling range and high precision

2.Compact structure and small body size.

3.The actual measurement correction method is used to adjust the filling time, digital display control.

4.Easy operation, easy cleaning and maintenance, and low maintenance cost.

5.Unique positioning control system can prevent photoelectric miscounting.

6.The ball screw dives and moves up and down stably.

7.Bottle mouth positioning device to ensure no deviation of the filling head. 8. Automatic fluid replenishment and fluid return without manual intervention.

Allpack Edible Oil Filling Machine Technical Specification:

|

Project Name:Automatic Piston / Flowmeter Filling Machine

|

Oil and Fat Products

|

|||

|

Bottle Material

|

Bottle Shape

|

Filling Range

|

Filling Heads

|

Production Capacity

|

|

PET / PP / PE / Glass / Metal

|

Round / Square

/ Unique Shape |

5-1000L

|

4-16

|

700-4000bph

|

|

Filling Valve

|

Each filling valve is controled by servo motor ,realizing segmented high-and low-speed control ; vacuum resorption devices without leakage.

|

|||

|

Cap closing

method |

applicability for both crowning and capping, mechanical instant sealing or servocontrolled sealing

|

|||

|

Bottle components

|

rapid replacement without tools, such as star wheels for bottle infeed and outfeed, and bottleneck clamps

|

|||

|

Filling precision

|

limit deviation: ±2-3g standard deviation: 1.5

|

|||

|

User Ambient Conditions

|

Temperature:10~40℃;Humidity:No dew

|

|||

|

User Electrical Supply Specification

|

Voltage:380V±5%, 3phase; Frequency:50HZ±1%

|

|||

The Buyer's Guide

Edible Oil Filling Machine: The Complete Buying Guide In 2023

Isn't it hectic to rely on conventional filling machines for edible oil processing while facing the challenges of imprecise filling, time consumption and inefficiency? Definitely! It is one of the stressful things when dealing with large production scale. However, the trailblazing of advance equipment such as edible oil filling machine has resolved these issues to great extent.

Now, industries are focused on adopting modern technology to tackle the filling issues of edible oil, beverages, chemicals and other liquids. If you are also among them, and looking to get the comprehensive solution for your manufacturing, then, this guide is going to be of great significance for you. So, let's delve into the sea of knowledge, where diverse aspects of edible oil filling machine including its features, categories, procedure and much more can be found!

1.What Is Edible Oil Filling Machine?

Edible oil is derived from the fats of plants and animals, often used as cooking agent. These edible oils are available in range of forms depending upon the type of ingredient used for extracting such as sunflower oil, olive oil, avocado oil and others. To process such vast number of oils, edible oil filling machine has been brought into the field to address the very problems of product waste, overfilling and unsaturated nature.

Edible oil filling machine is ideally equipped with standard quality tools which fully assures precision, hygiene and accuracy during process. It is made up of highly compact stainless steel which reduces the chance of corrosion that might cause as a result of flammable oil reaction. The machine works by taking the prescribed amount of edible oil from hopper, and majestically fills it into series of containers waiting to be loaded. This entire process is done efficiently without requiring additional labors which is why; fields like chemical, medical and dyes also find it compatible to their needs.

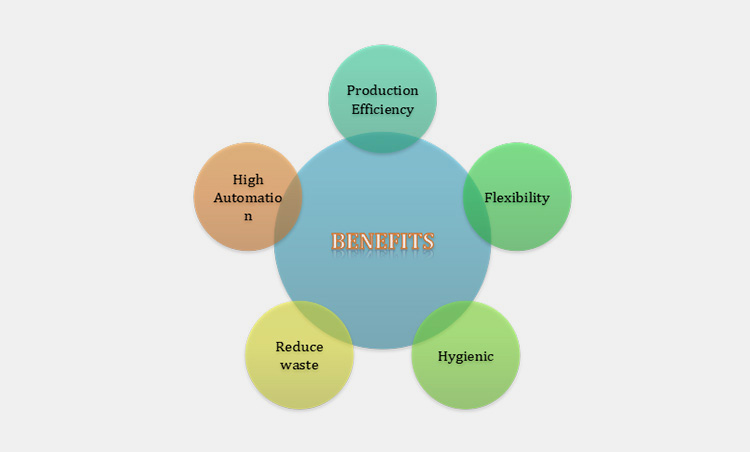

2.What Are The Benefits Of Using Edible Oil Filling Machine?

Including edible oil filling machine into your production line can give you substantial benefits some of which are highlighted below:

Production Efficiency

No doubt, the invention of such efficacious equipment is backed by the need of high productivity and edible oil filling machine has honestly fulfilled this aim. Its ergonomic features ultimately give you ultrafast results by turning non-stop cycles of empty containers into filled ones.

Flexibility

Another attribute of edible oil filling machine is its flexibility which shows its resilience to wide range of products including cosmetics, chemicals and pesticides etc. In addition, the machine also accepts the different sizes of containers for filling.

High Automation

This machine is designed with innovative technology of high automation including the separate units for synchronized flow and the capability to be integrated with other machines. Together, it contributes in enabling the machine to carry out entire process independently.

Reduce Waste

The incorporated photoelectric sensor, self-centered reciprocating nozzles and effective monitoring system puts their efforts to reduce product overfilling and make sure precise filling.

Hygienic

It is notable that edible oil filling machine has an enclosed structure as well as double-speed filling valves which fully eliminates the occurrence of oil splashing and contamination.

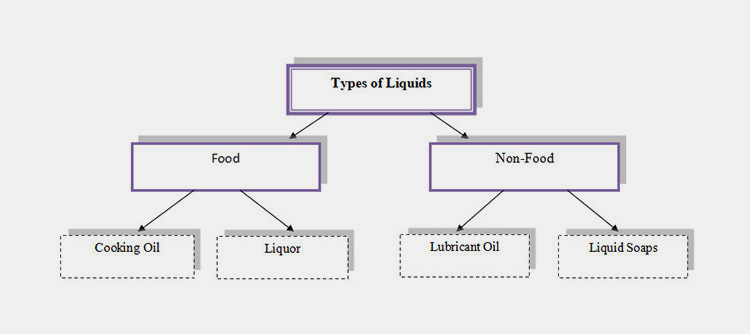

3.Is It Okay to Fill Other Liquids By Edible Oil Filling Machine?

This question carries great significance, as most of the business owners are concerned about the liquids which an edible oil filling machine is capable of processing. So, here we have provided details about them:

Cooking Oil

Cooking oils are derived from plants and their seeds which we use in our daily life consumption including in cooking meals, baking and frying etc. Therefore, their use is limitless. Hence, edible oil filling machine has been admired for its efficiency and precision by performing these oil in containers.

Essential Oil

Essential oil refers to oil which is made from the extraction of plants. The vary benefits and fragrance it holds are together helpful for treating stress, fungal infection and better sleep. Hence, they are also eligible to be processed by edible oil filling machine.

Lubricant Oil

Lubricant oil is a fluid substance obtained from minerals, vegetables and can be made synthetically. Is has crucial role in reducing friction, corrosion and preventing wear of machine parts. Therefore, it is essential for vehicles, machines and electronics. Such substances are easily processed by edible oil filling machine.

Engine Oil

Engine or motor oil is used for automobiles and motorcycle etc., are designed for ultimate engine performance to work under pressure. They all can be processed by edible oil filling machine.

Liquid Soaps

As the name depicts, liquid soap is a form of liquids utilized in houses, hotels and restaurants for washing hands, face and dish etc. They are liable to be processed by this machine.

Liquor

Liquor is a form of alcoholic drink made by the distillation of several ingredients including fruits, vegetables and sweeteners. To load it into large containers, edible oil filling machine is always remained suitable option.

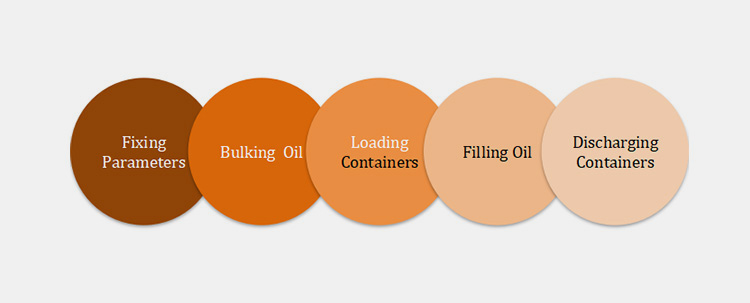

4.How Does Edible Oil Filling Machine Work?

The working mechanism of edible oil filling machine is undemanding; requiring less maintenance and minimal user interference. The following key steps will better display you its functioning:

Fixing Parameters

Picture Courtesy: Sulzer

One of the initial steps of operating edible oil filling machine is to set its basic parameters which includes the adjustment of oil volume that has to be filled in each bottle, speed of conveyor and flow of filling. It can be straightforwardly done by using user-friendly touch screen display.

Bulking Oil

Now, when the specifications of machine are adjusted, operator can dump the bulk of edible oil into hopper. In case of gigantic volume, a feeding station may be attached to the filling machine via pump.

Loading Containers

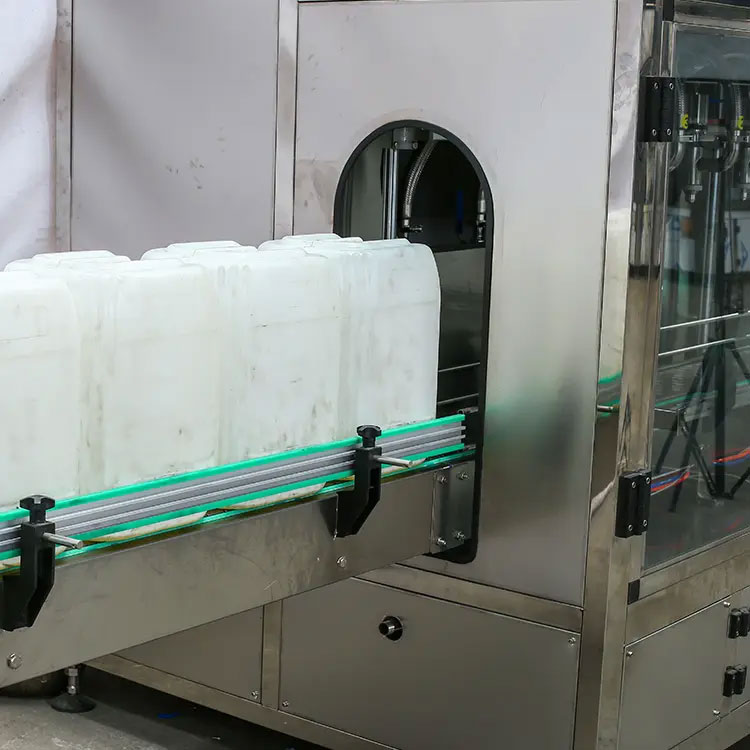

Proceeding forward, empty containers are loaded into the machine one after another and transported towards the filling station of machine through conveyor belt.

Filling Oil

The filling process begins right after containers are loaded one by one. Bottles coming from inlet feed are superbly filled by the consistent dispensing of oil via filling nozzles. Each filled container is well detected by sensors to make sure no bottle is left unfilled. This process of filling edible oil goes on until the desired numbers of containers are filled.

Discharging Containers

Finally, the filled containers come out of the machine towards their further processing of capping, labeling and wrapping etc.

5.Name The Types Of Edible Oil Filled By Edible Oil Filling Machine?

Do you know the different types of edible oil used in daily life? If not! This part of guide is going to be an interesting for you, as it will enumerate the range of edible oil available in market. In addition, each possesses different benefits for health and often used to treat illness. These all can be filled by edible oil filling machine such as:

- Olive Oil

- Canola Oil

- Peanut Oil

- Coconut Oil

- Sunflower Oil

- Avocado Oil

- Safflower Oil

- Corn Oil

- Soybean Oil

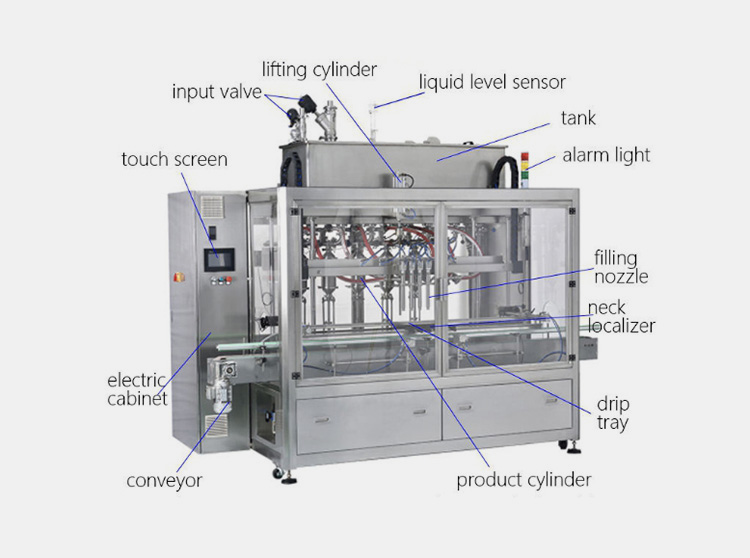

6.Describe The Various Components Of Edible Oil Filling Machine?

The latest and sophisticated edible oil filling machine is made up of high quality components which together make the smooth functioning of machine possible. These major parts are described below:

Material Tank

Tank is located on the top of edible oil filling machine. It works as a material holding place where bulk oil is deposited before operation started.

Electric Cabinet

This part of machine is known as the control system of machine which has entire electric system installed inside. On its upper side has a screen with the help of which control cabinet functions.

Touch Screen

Touch screen display is located above the control cabinet. It has several keys that helps in easy understanding of machine features including filling volume, speed and leveling etc. Moreover, by using it, user can simply communicate commands to the machine.

Liquid Level Sensor

Liquid sensor is integrated into machine to detect the level of liquid on the basis of which nozzles stop or continue delivering oil into containers.

Drip Tray

Drip try is a crucial device that is fitted into machine for the purpose of catching oil during processing, so that dripping and leakage of oil on ground could be prevented.

Product Cylinder

Product cylinder is a significant component of edible oil filling machine that has been assigned with the function to generate pressure in oil for moving into linear direction right into containers.

Lifting Cylinder

Lifting cylinder is made up of stainless steel employed to undertake the task of lifting containers smoothly during operation.

Input Valve

Input valve is place above machine to infuse required amount of air needed for product cylinder to generate pressure.

Filling Nozzle

Edible oil is first taken from hopper through product pathway. The end of this pathway is known as filling nozzles or filling heads through which oil is directly dispensed into the containers.

Conveyor

Conveyor is the transportation device work as a road for mobilizing bottles from inlet feed station towards filling station and discharge station respectively.

Neck Localizer

As the name indicates, this part of machine has been assigned with the task of positioning containers mouth to be directly under filling nozzles. It greatly helps in reducing waste and ensuring filling accuracy.

7.Write Down The Different Types Of Edible Oil Filling Machine?

You would find wide number of edible oil filling machines in the market each integrated with unique specifications. To better know which is suitable for your needs, consider the following details about various types of edible oil filling machine:

Fully Automatic Edible Oil Filling Machine

Picture Courtesy: Borun Machinery

Fully automatic edible oil filling machine is innovative equipment that carries along with it exceptional features. Its advance automated system makes the machine independent, eventually, free of human errors, product waste as well as time consumption. Although it is expensive due to complex machinery, however, large scale industries prefer fully automatic machine for its consistent operation and higher throughput.

Semi-Automatic Edible Oil Filling Machine

Semi-automatic edible oil filling machine on the other hand, allows user interference to contribute in completing the filling task. It is precise in structure, cost-effective and easily mobilized. These are the reasons, why new into business owners and medium scale industrialists are highly concerned about taking benefit of it.

Gravity Filling Machine

Picture Courtesy: E-PAK Machinery

Gravity filling machine is the most economical and easy to use machines which facilitates the filling of oil by measuring weight. It has the capacity of filling 4000 bottles per hour and fill volumes ranging from 8 liters to 25 liters. Gravity filling machine is perfect for processing free flowing liquids which remain same with ambient temperature. It can be upgraded to fix 16 filling nozzles for increasing production output. Such types of machines are appreciated for high degree of filling precision and mostly used in industries like food, chemical and pharmaceutical.

Piston Filling Machine

Picture Courtesy: Vkpack

Piston filling machine is another type of edible oil filling machine employed to undertake large volume of edible oil into containers such as jerry cans and drums etc. It uses a piston to dispense exact amount of edible oil in each bottle. Moreover, piston filling machine is desirable for both free flowing and viscous liquids including lubricants, oil and cream etc.

Volumetric Filling Machine

Picture Courtesy: E-PAK Machinery

The name of machine in itself justifies the function which it performs. It works to deliver precise amount of edible oil by following the principle of amount displaced from machine. In addition, the filling of liquids by measuring volume makes it more desirable for thick fluids. The advance features of machine enable it to fill volumes ranging from 8 liters to 20 liters with 2-12 filling nozzles.

Linear Edible Oil Filling Machine

Picture Courtesy: Seedoilpress

Linear edible oil filling machine fills the containers in a sequence. It is one of the most used filling machines for decades. The reason that it fills bottles in a serialized form, so, the number of filling heads are fixed to 1, 2, 4, 8 or sometimes 20. As the machine has small footprint and simple components, it is affordable and beneficial for small to medium scale industries.

Rotary Edible Oil Filling Machine

Picture Courtesy: Borun Machinery

Contrary to linear filling machine, rotary edible oil filling machine is more complex, specialized and effective enough. It accomplishes the filling in a rotational movement where large numbers of bottles from 20 to 50 are filled at the same time along with their capping and screwing. Its constant filling is the key to reaching high production volumes. Similarly, huge scale firms always look for incorporating it into their production.

8.How Edible Oil Filling Machine Can Be Distinguished From Traditional Filling Machine?

The formation of edible oil filling machine is a big win for today's large businesses. As most of the traditional oil filling problems has been resolved. It can be analyzed by the underlying differences between both machines:

| Features | Traditional Oil Filling Machine | Edible Oil Filling Machine |

| Automation | Ø Low degree of automation

Ø Often manual or semi-automatic in nature |

Ø High degree of automation

Ø Fully automatic in nature |

| Structure | Ø Precise structure

Ø Consists of few parts |

Ø Comprehensive structure

Ø Comprises complex components |

| Process | Ø Non-continuous operation

Ø Hectic due to manual intervention |

Ø Consistent process

Ø Easy done automatically |

| Speed & Capacity | Ø Limited capacity | Ø High capacity of filling 4000 containers per hour |

| Level of Precision | Ø Low precision with possibility of dripping and splashing | Ø High level of accuracy with enclosed structure |

| Speed | Ø Slow processing | Ø Efficient performance |

| Application | Ø Home based or small scale industries | Ø Medium to large scale industries |

| Picture |  |

|

9.In Which Areas Edible Oil Filling Machine Is Mostly Employed?

Edible oil filling machine has extensive application encompasses food, non-food, medical and chemical etc. Here is the glimpse of these areas:

Food Industry - For Productivity

Edible oil filling machine has been appreciated for its long-lasting productivity in the food industry. Today, it is used for the filling of almost every type of liquid food including cooking oil, sauces, beverages, dressings and more.

Agrochemical Industry - For Environmental Sustainability

Environmental sustainability is the key concern where there is processing of chemicals. Therefore, industries like agrochemical and pesticides desire for an equipment to take this aim while ensuring hazardous free filling of fertilizers, herbicides, fungicides, liming and insecticides. Here, the use of an edible oil filling machine becomes inevitable.

Daily Chemical Industry - For Safety

Edible oil filling machine is also suitable for the safe filling of wide range of daily chemical agents such as laundry detergents, disinfectants, dishwashing liquids and organic solvents etc.

Automotive Oil and Lubricant Industry - For Precision

Picture Courtesy: Serac

This machine has also presence in automotive industry for its feature of precise filling which indeed is crucial for products like lube oil, coolants, engine oil and diesel etc.

Pharmaceutical Industry - For Hygiene

As far as pharmaceutical industry is concerned, edible oil filling machine has been used for its filling of syrups, surgical fluids and other medications under enclosed processing and hygienic environment.

10.Which Factors Are Responsible For Enhancing The Efficiency Of Edible Oil Filling Machine?

There are several factors which is considered can enhance the efficiency of edible oil filling machine and help in the smooth running for a lifetime. They are as follows:

Regular Maintenance

Despite the fact, that edible oil filling machine is simple to operate and requires less maintenance, there is always a room for improvement. It implies, that you have to be concerned for the regular maintenance of your machine which include examining the various parts to avoid failure of physical properties.

Cleaning

Picture Courtesy: Serac

Cleaning is another important step which must not be neglected. Try to ensure cleaning of material tank and filling nozzles by scrubbing and flushing water. It will help to disinfect the bacteria and prevent product caking.

Lubrication

Lubricating your machine every weak can reduce the friction and wear on moving parts. Furthermore, it can excel the performance of different parts, consequently, increasing the efficiency of machine.

11.What Are The Common Storage Containers Filled By Edible Oil Filling Machine?

It is worthy to take note of the containers commonly used for edible oil in market today. They can be divided into two categories:

With Respect To Storage

Picture Courtesy: wary international

The common storage capacities of edible oil containers filled by edible oil filling machine are:

- 8 liters

- 10 liters

- 15 liters

- 18 liters

- 20 liters

- 25 liters

With Respect To Shape

There are three types of shapes used for edible oil containers including:

- Jerrycans with handle

- Round containers with handle

- Square tin containers with holding rings

- PET Buckets with lids and holding rings

12.What Are The Safety Measures Of Edible Oil Filling Machine?

There are some safety measures which an edible oil filling machine holds. These are enumerated below:

Mature Alarm System:

The mature alarm system is integrated with machine for safe operation. In case of error, it rings quickly to alert the operator.

Emergency Stop:

The emergency stop button is located on the front of machine with large size and red color. It can be brought into operation by pressing after sudden mishap to stop machine on the spot.

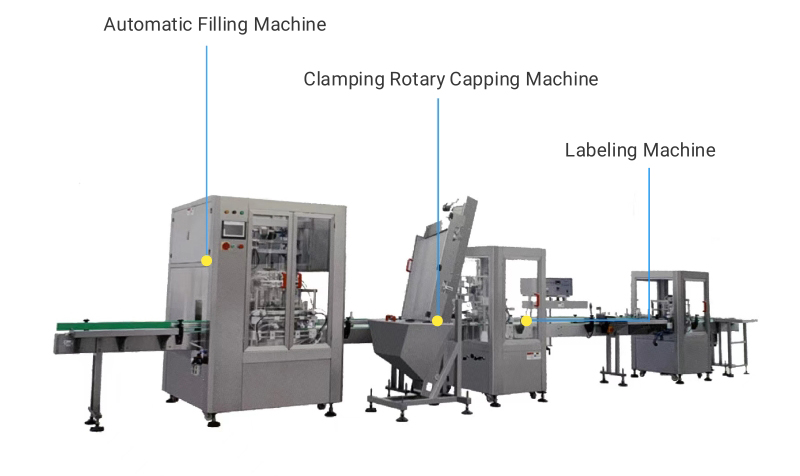

13.What Machines Can Be Integrated With Edible Oil Filling Machine To Make The Production Line?

Large number of machines can be integrated with edible oil filling machine to facilitate the huge production volume. In this respect, machines described below are of higher importance:

| No | Machine | Description | |

| 1 | Automatic Capping Machine | It is one of the inevitable equipment attached to the edible oil filling machine for the purpose of capping lids over filled containers. |  |

| 2 | Servo Tracking Capping Machine | Another device is servo tracking capping machine which is used to carry out the task of capping containers by picking and placing lids. During capping, it makes sure to maintain smooth flow of bottles. | |

| 3 | Automatic Labeling Machine | Automatic labeling machine works as a label applicator for range of containers. It holds a film or sticker roller backed by adhesive which is applied over containers when passing through the machine. |  |

| 4 | Stacker | Stacker is a heavy-duty machine often used in medium to large scale industries for handling bulk material. It piles the containers onto a stockpile, so, they can be collectively sealed and wrapped. |  |

| 5 | Robotic Palletizer | Robotic palletizer is an automatic machine that makes the process of stacking material easy. It picks up one or multiple containers and places them on a pallet. |  |

| 6 | Automatic Strapping Machine | It refers to a packaging machine employed to secure package of goods and containers by fastening them together via flat steel or plastic bands. |  |

| 7 | Sword Piercing Strapping Machine | Sword piercing strapping machine is designed to firmly bind stacked boxes by using PET plastic steel belts. Its main purpose is to prevent scattering of goods during cargo transportation. |  |

| 8 | Wrapping Machine | Wrapping machine is equipped with several components for the sake of wrapping flexible thin plastic over palletized goods to ensure final step of packaging is achieved. |  |

| 9 | Forklift | Forklift is an industrial lift truck with pronged device in front. Its function is to lift and move packed goods towards final destination of shipping in containers and storage facilities. |  |

14.How To Diagnose The Common Pitfalls Of Edible Oil Filling Machine?

To avoid potential breakdowns when using an edible oil filling machine, you should diagnose common pitfalls highlighted in the table below:

| No | Pitfalls | Causes | Diagnosis | Picture |

| 1 | Inconsistent Filling | Filling principles may not be adjusted correctly, or the machine is not seated well | Review the fill principles and make sure machine is on same leveling over floor; relocate if unleveled |  |

| 2 | Back Pressure | This issue often occurs in overflow machines when material is circulated back to hopper. If return tubes are blocked for any reason the back pressure create problem in filling | It can be overcome by clearing tubes and keeping every sort of debris and caking away from them |  |

| 3 | Unaligned filling nozzle and bottle mouth | It happens when there are problems in the height of nozzle and space between containers | Fix the height of filling head near to bottles and adjust bottles spacing accordingly |  |

| 4 | Slow speed of pneumatic cylinder | Low air pressure and leaked tube or damaged air circuit are the notable causes | Keep the air pressure at 0.6Mpa*, seal tube and exchange air source treatment |  |

15.What Are The Necessary Factors For Purchasing Best Edible Oil Filling Machine?

It is obvious that you must have to go through the necessary considerations whenever intending to make a purchase, especially if it is related to your business growth. Therefore, we have marked some essential factors for you to take note of, before purchasing an edible oil filling machine:

Analyzing Current Production

Analyzing your current production is the foremost thing you should look for. By doing so, you will be able to determine which type of edible oil filling machine you are in need of; automatic or semi-automatic. If you are running large business you may also require auxiliary devices to integrate with main machine. Hence, it will give you chance to make the best ultimate purchase at once.

Product Specifications

Is your oil free flowing, semi-viscous or thick? Does it contain flammable constituents? Answering these questions will enable you pick right option. For instance, piston filling machine is suitable for viscous while as gravity filling machine is good for watery edible oil. Similarly, oil containing combustible constituents will require explosion proof machine.

Quality Certifications

As there are numerous industries working to produce edible oil filling machines, it becomes hard to choose right one. Here, you have to be vigilant to check whether the company is complying international quality standards which include GMP's, EU, ISO and FDA. It will guarantee the quality of machine.

Size and Type of Containers

Are you using same size of containers or of various sizes? Do they require crimp cap, press-on cap, screw cap or lid? Possibilities are countless! Therefore, it is always better to opt for machine which is more flexible and requires low changeover time.

Conclusion

To summarize, edible oil filling machine is an important equipment whose need is growing everyday around the world for its efficiency, precision and resilience. If you are also interested in making it part of your production line, don't waste your time in thinking, just take a step forward toward making final decision. In this way, if you want to learn more about or interested in All Pack outstanding machinery, just leave a msg on given link. We will answer you ASAP!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp:+86 18171018586

Tell us your material or budget, we'll reply you ASAP within 24 hours

Automatic liquid filling line Related Products