Automatic Harpic HCl Toilet Cleaner Liquid Filling Machine Automatic Liquid Filling Line

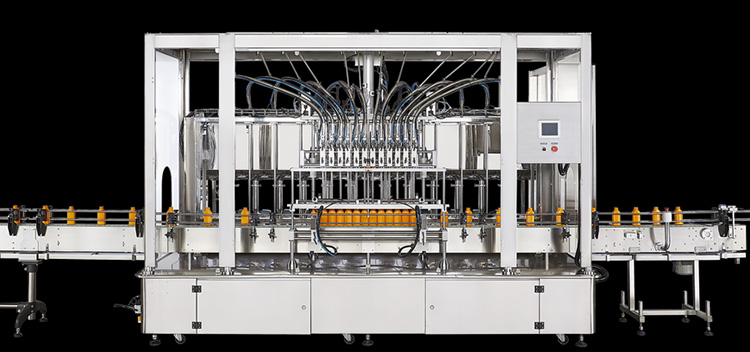

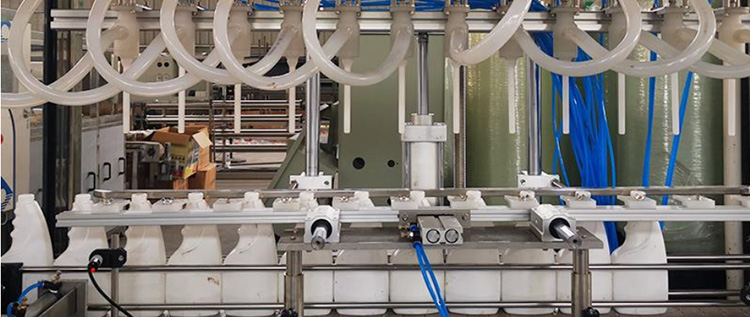

Allpack toilet cleaner liquid filling machine automatic liquid filling line is a full corrosion-protecting high-tech filler integrating into the PLC program control, photo electricity transuding, and pneumatic. The machine is specially used in the liquid filling of strongly corrosion liquid and cosmetics which can’t touch the metal. The equipment’s all parts touching liquid are manufactured with the non-metallic corrosion protection material, and designed for the descending filling function. Measurement is accurate, there is no bubble and drool as filling.

This toilet cleaner liquid filling machine’s automatic liquid filling line can be used for filling all kinds of non-viscous liquid, such as wine, liquor, vodka, whiskey, juice drinks, vinegar, soy sauce, medicine, and other liquids with aluminum caps, corks, plastic screw caps, etc. Suitable for all kinds of glass bottles, plastic bottles, and other different types of filling.

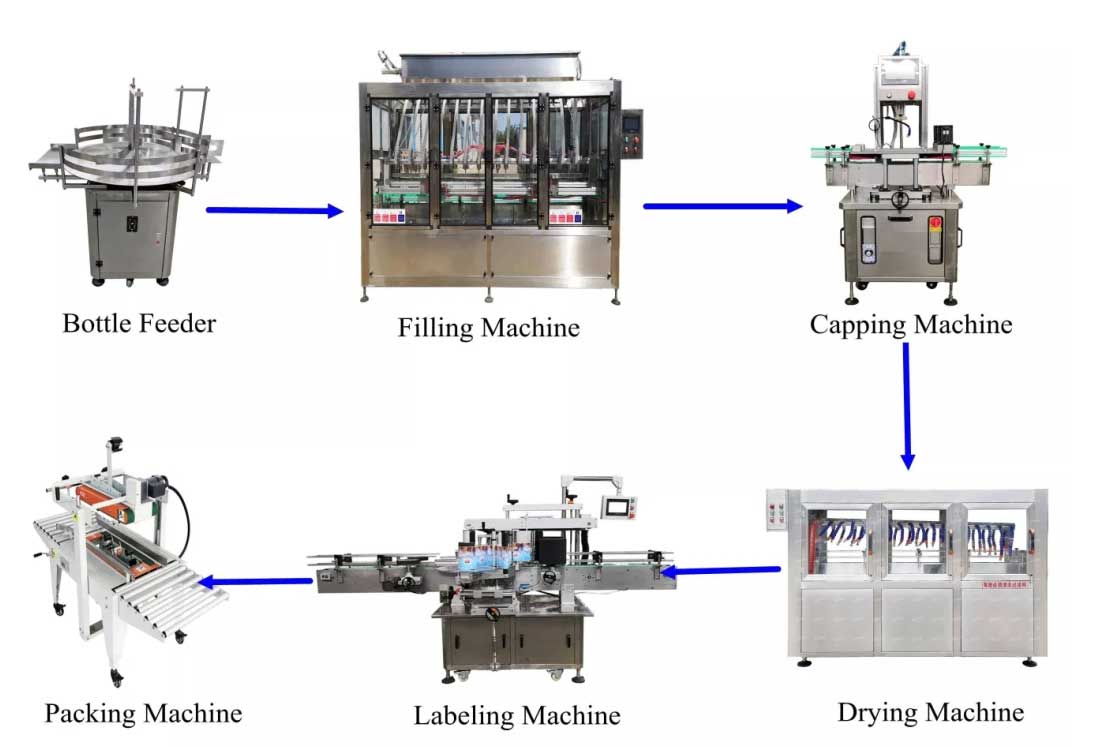

Allpack Toilet Cleaner Liquid Filling Machine Working Process:

Allpack Toilet Cleaner Liquid Filling Machine Products:

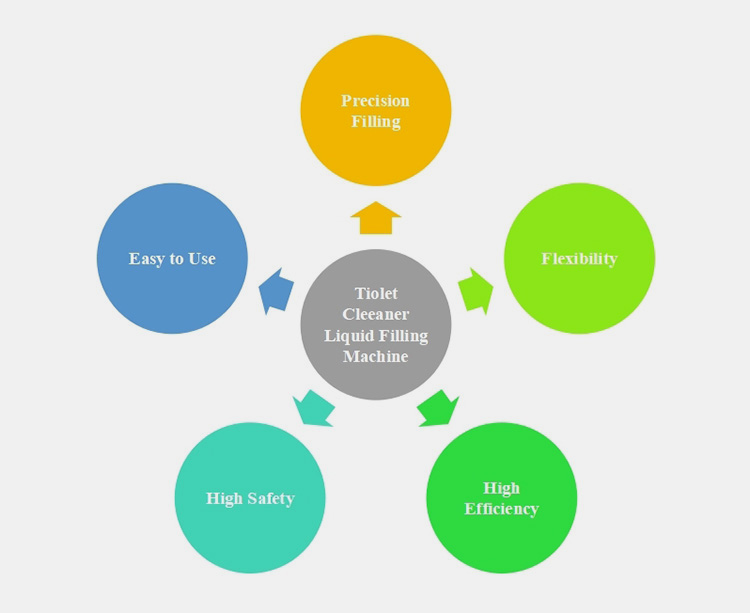

Allpack Toilet Cleaner Liquid Filling Machine Features:

1: Anti-corrosive, used for the filling of Strong Acid and Bases

2: Changing into different models without tools.

3: FESTO, SICK, SCHNEIDER allocations for stable working of the machine.

4: Easy cleaning, water can be directly used for machine cleaning.

5:Applicable Bottle Size: Diameter: 40-100mm, Height: 80-230mm

Allpack Toilet Cleaner Liquid Filling Machine Technical Specification:

|

Bottling Line

|

Linear Liquid Filling Production Line

|

||||

|

Filling nozzles

|

4~12

|

||||

|

Peoduction capacity

|

400-2200barrels/hour | ||||

|

Applicable bottle height

|

360~720mm,could customized

|

||||

|

Applicable bottle diameter

|

Φ50-Φ100,could customized

|

||||

|

Filling Volume

|

100~5000ml or customized

|

||||

|

Filling accuracy

|

±0.01%

|

||||

|

Overall size (L*W*H)(mm)

|

3000*1500*2200

|

||||

The Buyer's Guide

Toilet Cleaner Liquid Filling Machine: A Complete Buying Guide in 2024

Involved in the ever-expanding toilet cleaner packaging business?

Well! The toilet cleaner liquid filling machine is a perfect addition to your production line. Fill accuracy is a major requirement of any business and this equipment performs this task. Moreover, it has high speed and can meet your increasing production needs. Before integrating your production line with this equipment, read through this guide to learn about important aspects of a toilet cleaner liquid filling machine such as working, type, components, and so much more.

1.What is meant by Toilet Cleaner Liquid Filling Machine?

The automated toilet cleaner liquid filling machine is used to fill harsh chemicals like acid and alkaline. This machine fills a wide range of liquids with different consistencies such as toilet cleaner, kitchen oil remover, laundry detergent, hand sanitizer, etc. It is designed with metallic alloys to fill liquids like HCl (hydrochloric acid) bleach etc.

Toilet cleaner liquid filling machines are used in manufacturing facilities to automatically fill a large volume content in either jerrycan, drums, buckets, and other. The average volume ranges from between 1L-200L till 1 ton (907 L). It is designed to streamline the process of filling the liquid into containers efficiently and accurately.

2.What are the Benefits of Toilet Cleaner Liquid Filling Machine in Your Production?

A toilet cleaner liquid filling machine is known for its precision filling. There is a wide range of benefits that this equipment brings to your production lines including:

Precision Filling

The manual filling often leads to variances and inconsistencies in the final volume of containers consequently resulting in product recall. However, a toilet cleaner liquid filling machine is equipped with high-accuracy sensors and intelligent control systems that assure high fill precision in every batch.

Flexibility

This machine not only dispenses the same type of product in the same container but also, can fill containers of different dimensions and geometries with a variety of products. For loading different containers, simply the settings on the HMI screen are modified.

High Efficiency

This equipment is capable of operating at higher speeds and has high output efficiency. It can fill 60-120 bulk-capacity containers per hour with the use of about 20 filling heads. This high efficacy feature allows it to fill thousands of holding containers per shift.

Allows Multiple Shaped Containers

This machine process rectangular or square-shaped containers with four corners and a flat base. These containers include jerry cans and buckets. They are stackable and occupy less storage area.

High Safety

A manual filling is the cause of skin burns and other health-related issues. These problems are prevented by using a toilet cleaner liquid filling machine. This instrument is equipped with various safety features like closed doors and guard rails that ensure the complete safety of the operator.

Easy to Use

Although it seems like a toilet cleaner liquid filling machine is difficult to operate, it is far from reality. Once this machine is set up, it requires minimal human intervention such as loading the container. The data recipes for changing the settings of operation are loaded inside the machine computer and are recalled with just one click.

3.What Types of Industries Benefit from a Toilet Cleaner Liquid Filling Machine?

This machine is sought out in various industries due to its many advantages. Some important applications of a toilet cleaner liquid filling machine are:

Large-Scale Toilet Cleaner Production

Toilet cleaner liquid filling machines are used in facilities where toilet cleaner products are manufactured on a large scale. The machine enables high-speed and continuous filling of containers, enhancing production efficiency and output.

Cosmetic Industry

This machine is used to fill different cosmetics products. The toilet cleaner liquid filling machine serves to fill liquid face foundation, face gel, dyes, nail polish, and primers. It dispenses the product without causing any harm to its quality. Hence, this equipment preserves its original form and fragrance.

Food Industry

The toilet cleaner liquid filling machine deposits edible oil, ketchup, vinegar, soya sauces, and mayonnaise. It can fill bulk amounts of food liquid with different consistencies efficiently. Moreover, it can load different types of pasty products in huge quantities into buckets and jerrycans.

Chemical Industry

This machine is used to dispense bucketloads of chemicals such as acids and solvents. The highly chemical-resistant body of the toilet cleaner liquid filling machine allows it to fill dangerous chemicals in large shipment containers.

Personal Care Industry

The toilet cleaner liquid filling machine is considered the main equipment in the personal care industry. This industry cannot produce quality products without a toilet cleaner liquid filling machine. It loads shampoos, hand sanitizers, hand lotion, conditioners, and liquid soaps in large-capacity containers.

Agriculture Industry

A toilet cleaner liquid filling machine is an integral part of agriculture production. This machine helps to fill large containers with different chemicals, especially pesticides, insecticides, herbicides, insect-repellents, anti-bacterial, and anti-fungal agents.

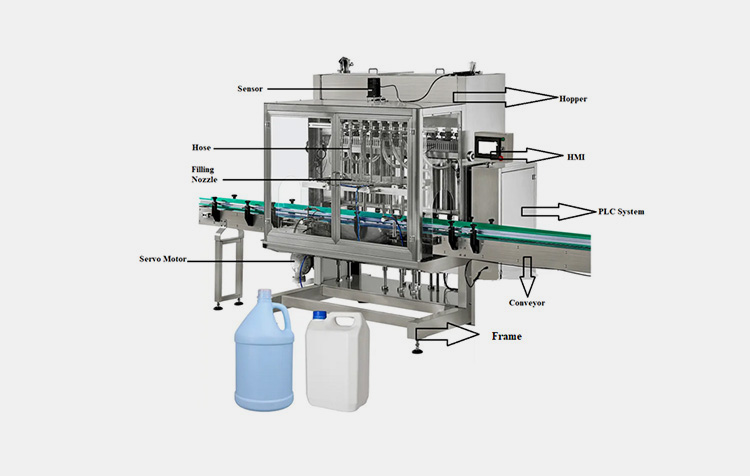

4.What are the Important Components of the Toilet Cleaner Liquid Filling Machine?

The toilet cleaner liquid filling machine is comprised of various components, each performing its role to accurately dose toilet cleaner liquid in containers. Some of these important components are detailed below:

| Hopper | It is a trough-like structure present on the upper side of the equipment. Normally, it stores bulk quantities of toilet cleaner liquid for the continuous filling operation. |

| HMI | It is a smart screen interface or press button panel for adjusting and modifying filling parameters such as fill time, the position of head dive, volume, weight, etc. This interface is also important in self-diagnosing and troubleshooting equipment. |

| PLC System | It is a processing component of a toilet cleaner liquid filling machine and works like a CPU system. It relays the instruction to different parts of a machine. |

| Conveyor | This part is equipped with drive belts and is integral in transporting containers to different stations of the machine. |

| Frame | It supports the entire construction of the machine and offers stability. |

| Servo Motor | It is a mechanical component that drives the whole system. It provides energy for conveyor movement and also maintains the synchronization between filling and container transport down the conveyor. |

| Filling Nozzle | This part is in direct contact with the container and has an orifice through which toilet cleaner liquid trickles down into the container. |

| Hose | It is manufactured using reinforced stainless-steel material and is corrosion-resistant. It is a pipe-like structure that controls the flow of toilet cleaner liquid. |

| Sensor | This is a highly sensitive part with camera vision and detects the number of containers loaded on the conveyors. Furthermore, it also checks the presence of toilet cleaner liquid in the hopper. |

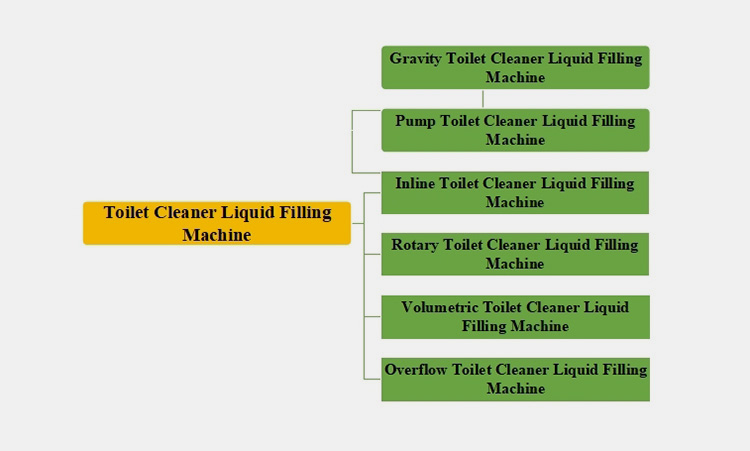

5.What are the Main Types of a Toilet Cleaner Liquid Filling Machine?

There are several ways to classify toilet cleaner liquid filling machines such as”

Classification on Level of Automation

There are two types of this equipment based on the level of automation.

Semi-Automatic Toilet Cleaner Liquid Filling Machine

It has a slightly larger size than its manual counterparts. It is capable of performing functions both manually and automatically. In a semi-automatic toilet cleaner liquid filling machine, containers are manually loaded and removed by an operator while the PLC system and automated fillers dispense products in containers.

Automatic Toilet Cleaner Liquid Filling Machine

This machine is equipped with modern technological advanced sensors and intelligent controls that automatically and precisely load toilet cleaner liquid in large-sized containers. It has a large footprint construction and is employed in mass-scale productions where high output capacity is required.

Classification on Level of Design

Gravity Toilet Cleaner Liquid Filling Machine

It has a simple design and consists of a hopper, filling nozzles, and conveyors. The products are filled using gravitational force in this machine. It fills the required volume of toilet cleaner liquid in the container using a time-based filling. It is ideal for loading free-flowing or thin-viscosity products. It is an inexpensive machine.

Pump Toilet Cleaner Liquid Filling Machine

It is complicated construction and consists of a hopper, filling nozzles, a conveyor as well a pump. Each filling nozzle is equipped with its pump. It fills the products by applying pressure on them.

It employs both time-based and pulse-based filling for dispensing products. A pulse-based filling is measured using the number of gear rotations. It is used for filling thick viscosity products but can fill products with any consistencies. It costs more than the gravity toilet cleaner liquid filling machine.

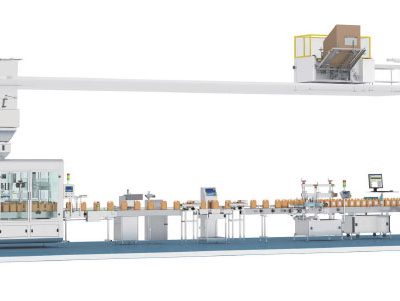

Inline Toilet Cleaner Liquid Filling Machine

This type of toilet cleaner liquid filling machine opts for a linear configuration in which containers are filled in sequence. The conveyor stops moving while the containers are being filled in this machine. The capping and labeling sections are further down the line. It is inexpensive and easily integrated into the production line. This machine is easily maintained and clean. This machine is suitable for medium-sized production.

Rotary Toilet Cleaner Liquid Filling Machine

The type of toilet cleaner liquid filling machine has a rotary configuration and containers are filled using a circular station. This equipment runs continuously and there is no need to stop it while the containers are being loaded with the products. The rotary toilet cleaner liquid filling machine can also include capping and sealing units in a rotary star wheel in addition to a filling station. It is fairly pricy and difficult to install. Since it has several filling nozzles and a rotary star wheel thus it is difficult to clean it. The rotary toilet cleaner liquid filling machine has a continuous operation, therefore, it is a more useful option for large-scale businesses.

Volumetric Toilet Cleaner Liquid Filling Machine

This type of toilet cleaner liquid filling machine fills containers to a specific volume. It is highly accurate and precise. The containers have the same volume when filled by a volumetric toilet cleaner liquid machine. This is best for opaque containers since inconsistencies in product level are not visible.

Overflow Toilet Cleaner Liquid Filling Machine

This kind of toilet cleaner liquid filling machine loads the containers to a certain level. There is a slight variation in volume when the containers are filled using this machine. This is used for filling clear glass or plastic containers as it results in a consistent product level that boosts its appearance.

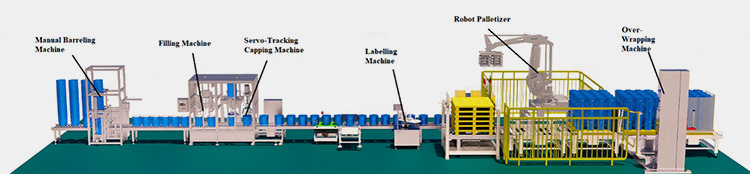

6.What is Secondary Equipment Integrated with Toilet Cleaner Liquid Filling Machine in Production Line?

Different kinds of secondary equipment are integrated with toilet cleaner liquid filling machines to ensure complete sealing and security of toilet cleaner liquid. These instruments have a particular role in packaging bulk-capacity toilet cleaner liquid. These machines are discussed below one by one:

| Barreling Machine | It is a drum-like container that cleans reusable barrels of dust and unwanted objects. Moreover, this machine also improves the outlook of the container by polishing it. |

| Servo-Tracking Capping Machine | It is a large-volume machine that protects the inner contents of containers by capping or lidding them with screw caps, twist-off caps, and metallic or plastic lids. |

| Labelling Machine | This type of large-capacity machine glues or sticks the add-on labels, stickers, information panels, or overwraps on the body of holding containers. The purpose of labeling is to enhance product display as well as inform users about the contents of containers. |

| Automatic Ink-jet Printer | It is a large-capacity machine for printing user information like bar code, batch number, and expiry date on the information panel of large holding containers. |

| Stacker | Manual lifting of large-volume containers can be quite strenuous and tiring therefore hydraulic or electric lifters are employed in industry for lifting and stacking of containers. |

| Robotic Palletizer | As the name suggests this machine includes a robotic arm lifter for easy and convenient carrying and piling of bulk housing containers. It is an outstanding machine with a higher loading capacity when compared with other palletizing instruments. Its function is to load containers on a wooden pallet structure. |

| Horizontal Strapping Machine | It is employed in the toilet cleaner liquid processing line for sideway strapping and tying of bulk volume toilet cleaner liquid vessels. Moreover, it compacts and squeezes the pallets for final strapping. |

| Automatic Sword-Piercing Strapping Machine

|

This kind of strapping machine performs vertical strapping of the containers. It has a sword-like piercing part that goes through the bottom of pallets and ties them with heavyweight steel wires or tapes. This is essential in preventing the scattering of pallets during shipment. |

| Automatic Wrapping Machine | This machine fully encloses and wraps the container pallets with stretch film for protecting and minimizing their damage. It consists of a robotic arm or turntable that aids in wrapping the pallet for keeping it tightly bound and secure during transportation. |

| Forklift Unload Bucket | It is used for the transportation of bound pallets from the processing area to a storage area. The pallet frame is easily carried out by forklift. |

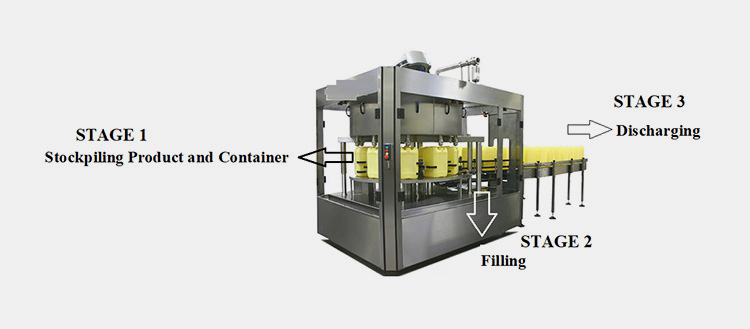

7.How Does Toilet Cleaner Liquid Filling Machine Work?

A toilet cleaner liquid filling machine operates on the same working principle as that of other liquid filling machines. Some basic steps in the working of a toilet cleaner liquid filling machine are:

STAGE 1: Stockpiling Product and Container

At this stage, the operator loads the bulk quantity of toilet cleaner liquid in the infeed hopper. Also, a robotic arm is used for stockpiling a large number of containers in the feeder system. These containers can be loaded manually by the operator.

STAGE 2: Filling

The PLC system gives signals to open ball valves and the toilet cleaner liquid is gradually discharged from the infeed hopper and moves to fill nozzles using different kinds of fillers like gravity fillers, overflow fillers, pump fillers, etc.

Filling time or volume, or weight is preprogrammed at the touchscreen or toggle button panel. The nozzle valve is completely open for dispensing toilet cleaner liquid at full speed in the container till the programmed fill setting is reached.

STAGE 3: Discharging

Once the container is filled to the required fill setting, the signal is transmitted to the PLC system by a sensor which in turn signals the closing of valves. At this stage, filling is completely stopped and the container is moved down the line towards the sealing or capping area.

8.What Type of Containers are Filled by a Toilet Cleaner Liquid Filling Machine?

A toilet cleaner liquid filling machine can be configured for dispensing variable quantities of corrosive liquids in the containers. It can pour 50ml to 220 L of liquid into diverse-sized containers.

Bottles

They are plastic or glass bottles of different shapes and sizes, ranging from small travel-sized bottles to larger household containers. These large-capacity bottles have a circular base with a long neck.

Jerrycans

A toilet cleaner liquid filling machine may also fill larger jugs or containers with handles, typically used for commercial or industrial purposes. These plastic or metal containers have ease of handling and transportation.

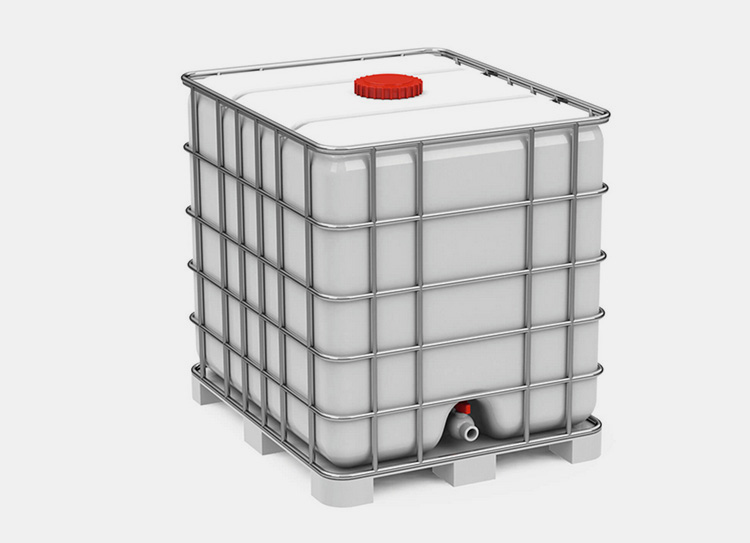

IBC

It is an industrial-grade container rectangular or cubic shape container typically employed in industrial for shipment and transportation purposes. IBCs are constructed using both plastics as well as metals.

Drums

The drums are large cylindrical tunnel-like housing containers usually employed for bulk storage of toilet cleaners and other industrial and household chemicals.

9.What are the Safety Requirements of the Toilet Cleaner Liquid Filling Machine?

Since toilet cleaner liquids are composed of hazardous chemicals thus a toilet cleaner liquid filling machine must fulfill numerous safety requirements including:

Engineering Controls

This machine should be equipped with different parts that provide a safe processing environment, such as an enclosure for close operation, mechanical handling of products, proper ventilation to remove chemical vapors from the system, etc.

Chemical-Resistant Construction

A toilet cleaner liquid filling machine must have anti-corrosive construction for handling dangerous chemicals. It must be made with stainless steel and chemical-resistant plastic. Moreover, it should be robust and able to withstand anything.

Electric and Computerized Controls

Since the exposure of electric parts to flammable chemicals can increase the risk of explosion, therefore, all-electric boards in this machine should be constructed using UL standard guidelines. Furthermore, the software must have in-built safety controls to automatically switch off the machine in case of a hazardous situation.

10.Why Regular Cleaning of Toilet Cleaner Liquid Filling Machine is Crucial?

Regular cleaning is an essential component of daily maintenance of the toilet cleaner liquid filling machine. There are several reasons why cleanliness is important.

Prevents Blockage and Clogging of Parts

This machine should be cleaned every day to get rid of debris and dust that can otherwise lead to jamming or blockage of filling nozzles causing hindrances in the movement of the piston and conveyor systems.

Ensure Top Quality of Products

Regular cleaning also ensures the quality of the toilet cleaner liquid. Negligence in cleanliness can cause contamination of products especially when the production line processes different kinds of liquids. Moreover, dust and debris go inside the product which damages its quality.

Fulfill Regulatory Guidelines

Regulatory authorities impose different regulations and hygienic sanctions that production lines must fulfill to ensure the quality of products. Therefore, routine cleanliness of a toilet cleaner liquid filling machine is essential in abiding by these hygienic and sanitation standards.

11.What is the Primary Consideration When Selecting a Toilet Cleaner Liquid Filling Machine?

Buying a toilet cleaner liquid filling machine is a heavy investment, therefore, several aspects of this handy machine should be considered before selection. These primary considerations include:

Filling Capacity

First, check the filling capacity of the machine and determine whether it is compatible with your production needs. You must take into account the filling volume loaded by the equipment per unit of time. Generally, a large-capacity machine with more than 200 liters loading volume is employed in the plants for large-capacity filling toilet cleaner liquid.

Durability

Always choose a manufacturer who is well-regarded in the market for durable and long-lasting equipment. Hygienic design with heavy-duty construction, tough materials, and top-notch components can withstand the rigorous demand of large batch filling.

Accuracy and Precision

A toilet cleaner liquid filling machine with a lower accuracy and precision error, minimizes the chances of overfills and underfills. Thus, opt toilet cleaner liquid filling machine that provides accurate control over fills. Equipment having adjustable nozzles or flow control sensors is useful in this regard.

Flexibility

The selection of a versatile machine that can accommodate a wide range of viscous products, filling volumes, and containers is the best way to accommodate your future filling goal. Therefore, determine the flexibility of equipment before buying.

Ease in Maintenance and Cleaning

Maintenance and cleaning of a toilet cleaner liquid filling machine can pose problems for the operator leading to lengthy downtimes. Therefore, selecting an easily accessible machine with quick removable parts and fast toolless changeover is an ideal way to decrease maintenance and cleaning problems.

Scalability

Last but not least, choose a toilet cleaner liquid filling machine that has a scalability option. Businesses are continuously evolving, therefore; your potential machine should be scalable to accommodate the changing filling needs.

12.How to Troubleshoot Toilet Cleaner Liquid Filling Machine?

Despite frequent maintenance and cleaning, technical failure is part of the normal working operation of the toilet cleaner liquid filling machine. However, there are a few simple troubleshooting approaches to solve these problems including:

Inconsistent Filling

Sometimes there is a slight variation in dispensing toilet cleaner liquid.

Cause

- Faulty calibration of equipment

- Old and defective seals

- Untightened clamps leading to air entry.

- Leaky hose and pipes

- Incorrect setting of fill times

Solution

- Properly recalibrate liquid.

- Replace the old seals.

- Adjust and secure clamps.

- Replace the leaky hose and pipes.

- Reprogram fill time keeping in mind the depth of a container.

Dripping

The product trickles or leaks from the filling hose, pipes, and nozzles.

Cause

- Worn-out, loose, or faulty ball valves in the filling unit

- Rusty or defective O-rings

- Hindrance in the syringe assembly

- Old filling nozzles have leaks.

Solution

- Tighten the ball valve and if dripping continues then replace the faulty ball valves.

- Install new O-rings.

- Remove dust or debris from the syringe assembly with detergent water.

- Substitute old nozzles with new ones.

Spillage

The toilet cleaner leaks or escapes from the container.

Cause

- Wrong programming of filling time

- Incorrect setting of the speed of a conveyor

- Instability of container due to damaged conveyor

Solution

- Reprogram the correct setting of filling time on the HMI touchscreen.

- Adjust the speed of the conveyor so that it is in synchronization with the filling time

- Inspect the damage to the conveyor system and repair it.

Difficult in Container Dispensing

Even though, the nozzles and syringe assembly are working fine the toilet cleaner liquid is not dispensed inside the containers.

Cause

- The fault in the opening of valves

- Improper supply of compressed air

Solution

- Restart the machine and reprogram the filling time for accurate valve opening.

- Adjust the compressed air supply to the system.

Immobile Head Dive

The head dive is unable to ascent and descent.

Cause

- Fault in airlines that control the motion of head dive.

- Pipes of air supply are disconnected.

- Incorrect programming of head dive position

Solution

- Check the airlines for defects and repair it

- Properly connect every pipe in the air supply line

- Reprogram the correct setting on HMI.

Different Shape Containers are not Failed

Cause

- The taller containers with smaller diameters are prone to tipping down the line.

- The holding vessels with unusual geometry and spherical base container often become unstable while moving on the conveyor causing tipping and spillage of product.

Solution

These unusable shaped containers with instability issues are handled by a toilet cleaner liquid filling machine using pucks. These are the plastic holders or grippers that tightly hold unstable containers during the transportation of the conveyor.

Abnormal Noises

During operation, abnormal sounds or vibrations are heard from the machine.

Cause

- Loose conveyor belts

- Untighten nuts and screw in the servo motor assembly.

Solution

- Properly tighten belt conveyors

- Secure nuts and screws in the servo motor system

Conclusion

For precise and accurate filling integrate your production line with a toilet cleaner liquid filling machine. This equipment is customized according to modern trends with advanced engineering, electric, and computerized parts to meet ever-increasing industrial demands. It ensures superior quality product filling, high safety, and durability. For more details regarding this machine, feel free to call our helpline.

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp:+86 18171018586

Tell us your material or budget, we'll reply you ASAP within 24 hours

Automatic liquid filling line Related Products