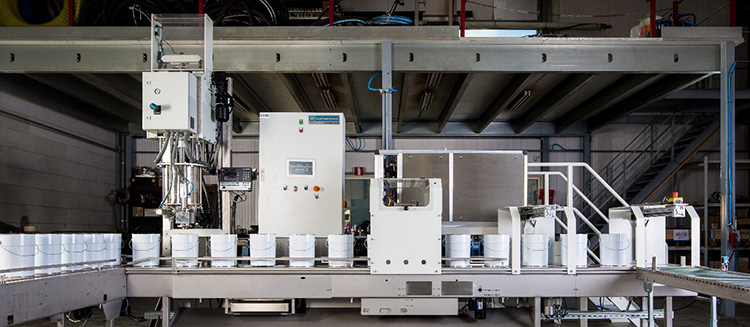

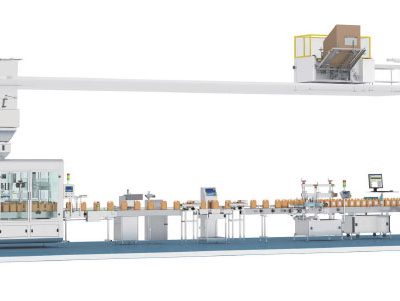

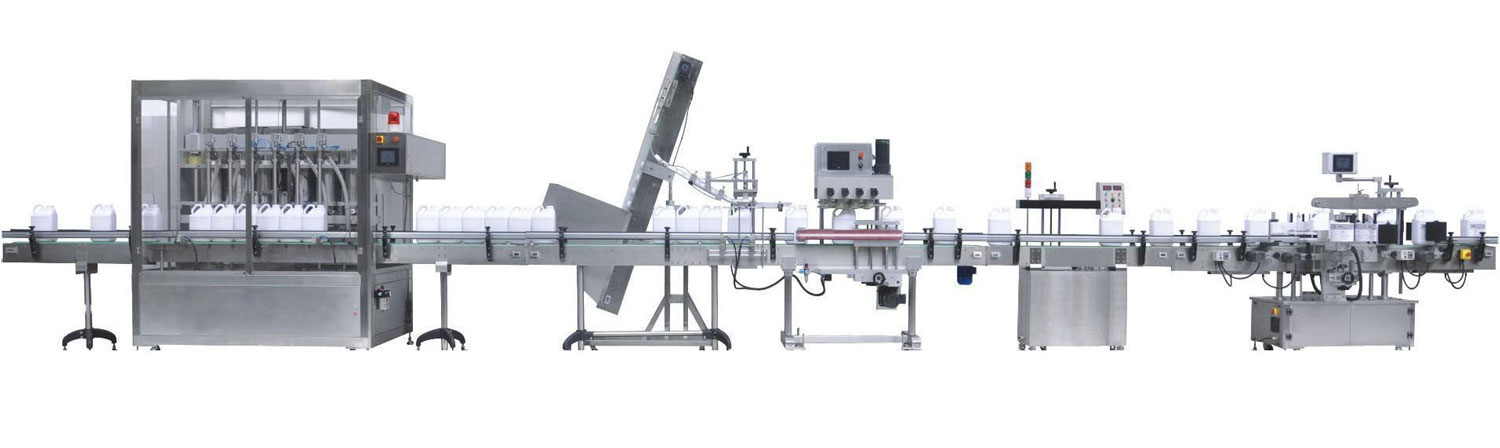

Big Drum Bucket Pail Plastic Barrel Multi Head Coating Filling Machine Automatic liquid filling line

Allpack coating filling machine automatic liquid filling line is a full automatic control system consist of filling machines, capping machines, labeling machines. It is specially designed for all kinds of cans, buckets filling of different products like liquid fertilizer, lubricant oil, edible oil, paste, other chemical and biology liquids in food, cosmetic, chemical industries.This automatic liquid filling line can be customized base on different products, filling volume and capacity required. Bottle unscrambler machine,filling machine,capping machine,labeling machine, ink coding machine and packaging machines can be added an option and combine freely.

Allpack Coating Filling Machine Features:

1.Touch-screen and instrument communication,directly on the touch screen adjustment measurement,without adjustment of the instrument's cumbersome procedures.

2.Automaic pressure cover, greatly save the time of manual pressure cover, improve efficiency and save labor .

3.This type of filling machine is suitable 1-20L variety bucket,filling it with a flexiable, filling fast,accurate measurement,good stability,is not affected by the oil viscosity and temperature characteristics.

4.Suitable for the majority of small and medium enterprises small package filling, can filling paints,lubricants,fertilizer and other materials.

Allpack Coating Filling Machine Technical Specification:

| Filling speed | Adapt to barrel type | Fllig accuracy | Weight Filler Power |

| 400-2200barrels/hour | Drums of all types | +0. 1% | 2.2KW |

| Feeding way | Operation way | Ambient temperature | Lid Pressing Power |

| Variable frequency ge ar pump delivery or high tower flow (custo mer choice) | PLC Touch screen(meter) operation | 10-40℃ | 0.75KW |

| Machine Material | Motor | Machine Total Length | Machine Height |

| Stainless steel | Explosion Proof type | 5m | About 1.8m |

The Buyer's Guide

Coating Filling Machine: The Complete Buying Guide in 2024

Is investing in a coating filling machine worth it? A lot of people have confusion in their minds when spending money on any equipment.

A coating filling machine is an integral component involved in the manufacturing line as it benefits you by reducing your labor cost, giving high work efficiency, and completing the process very accurately.

When you’re planning to purchase a coating filling machine, you must keep in mind that there are various models available in the market with different filling nozzles, automation, and filling containers.

Every customer knows their specific needs and desired product type.

In this article, we will guide you on important points that you must know before making the final decision. So, we assure you that by the end of the article, you would be able to select the right type.

1.What is Coating Filling Machine?

This is an advanced machine that is utilized to fill coating materials of various consistency into containers such as paints. This machine is specially designed for this purpose where the thick consistency of the coating material cannot damage the machine or clog between circulatory pipes. Amazingly, the coating filling machine has made this process faster, more efficient, and very accurate for the entire industrial era.

Depending upon different viscosity levels of material and flowability; coating filling machine is available in different types in the market. If you have a smaller production facility or a larger one, you can pick any type of best for you.

The machine is presented in semi-automatic and automatic versions. A coating filling machine is a compact unit that can work flexibly by integrating with other units of the production facility such as conveyor, capping, labeling machine, etc., Beside this, the machine can manage various products such as thin coating solutions, pesticides, ink, disinfectants, and others.

2.How is Coating Filling Machine Worth Buying?

Buying a coating filling machine can benefit you in multiple ways corresponding to your business growth and sustainability. Some of these benefits are highlighted below:

Filling Accuracy

The coating filling machine is famous for its filling accuracy which it manifests during operation. It fills each container with precise amount of coating and immediately stop filling when desired volume of coating is reached. This ultimately prevent product waste.

Production Efficiency

One of its foremost attributes is production efficiency. The automated system allows faster filling of bulk containers in one run and gives exceptional production efficiency which is the core concern of every industry.

Flexibility

The coating filling machine is most versatile in a way that you can fill different sizes of containers along with range of products such as paints, molten products and cosmetics etc., by using same machine.

Simple Operation

The machine only requires setting of basic parameters such as fixing filling duration, pump speed, and indexing time with the help of HMI. The rest process of filling is continuously done by machine. Hence, it needs low operator interaction making it more user-friendly.

Customization

Customization is the key to the successful operation of coating filling machine with increase in production. For instance, it can be upgraded by additional filling nozzles and hopper to bear large number of containers.

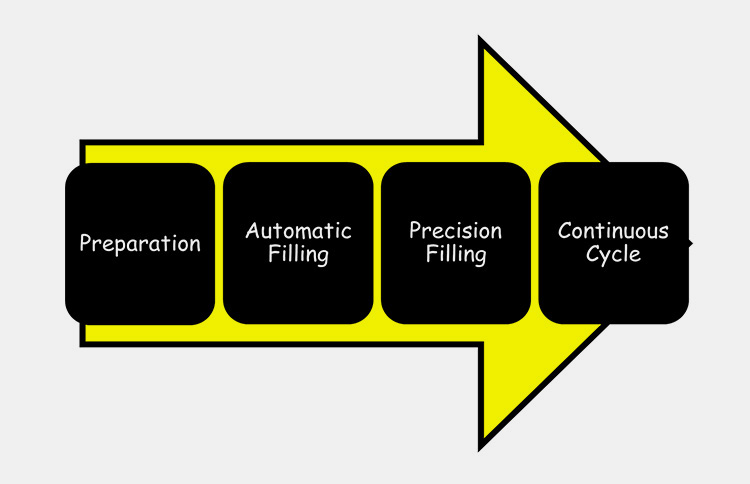

3.How a Coating Filling Machine Works?

Let’s understand the inner workings, which can help to make informed decisions when selecting the perfect option for your business needs. So, let's delve into the fascinating journey of a coating-filling machine and explore its working process through the following stages:

Preparation

At the beginning of the process, empty containers are carefully positioned on a conveyor, ready to be filled with solvent. The conveyor smoothly transports the containers into the filling machine, ensuring a steady flow of production.

Automatic Filling

Thanks to its automatic capabilities! the machine takes charge of container arrangement and initiates the filling process in a programmed manner. Depending on the number of filling nozzles available, the machine efficiently fills each container one by one. As a container reaches the designated point, the machine detects its presence and activates the filling mechanism.

Precision Filling

The filling machine offers a range of options for filling volume and duration, allowing for precise control over the filling process. Once the predetermined time has elapsed, the machine automatically releases the filled containers. Simultaneously, a fresh batch of empty containers is released, ready to be filled with the next round of solvent.

Continuous Cycle

This efficient machine follows the same systematic procedure until the entire batch of containers is successfully filled. It seamlessly repeats the process, ensuring a smooth and continuous workflow.

4.What Industries Require Coating Filling Machine?

A coating filling machine finds application in various industries across different sectors. Let's delve into the fascinating world of how solvents are incorporated into packaging in different industries.

Paint Industry

A coating filling machine is basically used in the paint industry to fill thin as well as thick paint solutions into respective containers effectively. The paint industry is mostly at high risk of flammable chemicals, so a coating filling machine is a great solution where explosion-resistant properties ensure a safe work environment and accurate filling.

Food Industry

In the food industry, coating filling machine are used to ensure contamination-free packaging and hygienic delivery of products to consumers. These machines handle both high and low-viscosity products, including water, carbonated drinks, wine, juices, sauces, and pastes used in various food items such as dressings.

Pharmaceutical Industry

In the pharmaceutical industry, precise dosing of liquids is crucial for delivering medicines. coating filling machine are employed to fill medicinal liquids into bottles and containers, ensuring effectiveness and sterility. These machines can handle different viscosity levels, accurately filling syrups, suspensions, injectables, and medicinal shampoos.

Cosmetics Industry

The cosmetics industry relies on coating filling machine to maintain quality standards and achieve consistent filling of different products into uniquely shaped bottles and containers. From eyeliner and lip gloss to body lotions and hair care products, these machines use volumetric nozzles and piston pumps for precise filling.

Chemical Industry

The chemical industry utilizes coating filling machine for filling various chemical agents, including household cleaning liquids, paints, inks, and flammables of different viscosities. These machines handle a wide range of chemicals, from daily-use household products to industrial applications.

Agricultural Industry

In the agricultural sector, a coating filling machine is used for filling herbicides, pesticides, and fertilizers. With anti-corrosive stainless-steel construction, these machines can handle different types of agrochemicals safely. They ensure accurate filling into containers of various sizes, from pails and drums to bottles and jerry cans, without any product wastage.

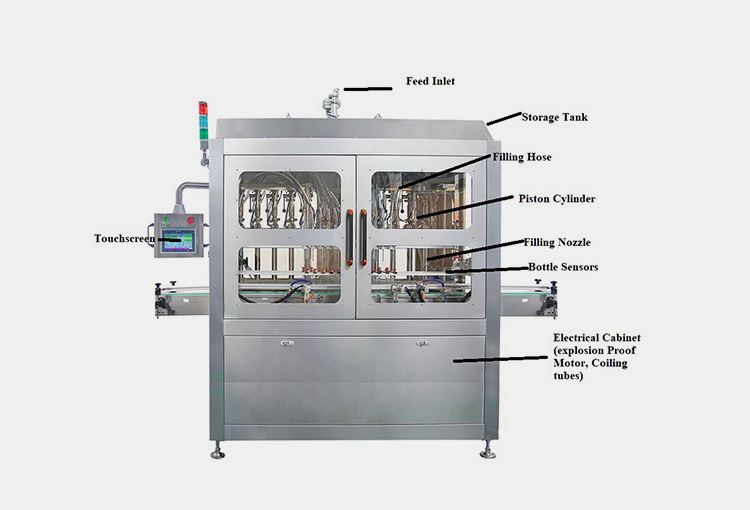

5.What is the Structure of Coating Filling Machine?

The robust structure of coating filling machine is composed of several components which together contribute to its efficiency. These are as follows:

Feed Inlet

Feed inlet is a device used to receive the upcoming stream of coating into machine. With the help of feed inlet, liquid entrainment problem can be solved in coating filling machine.

Storage Tank

Every coating filling machine has a place which is fixed for storing bulk volume of liquid to deposit into containers. This part of machine is often located at the top of machine and is known as storage tank.

Filling Hose

It is connected with storage tank and works as a product pathway by taking liquid coating from tank towards filling nozzles.

Piston Cylinder

Piston is a part of combustion that moves inside the cylinder leading to creation of mechanical force which helps in the running of machine.

Filling Nozzle

A filling nozzle is one of the significant components of coating filling machine that precisely fill each container by delivering desired volume of liquid.

Bottle Sensor

Bottle sensor is essential for eliminating the error of leaving empty bottles. During filling process, it synchronize product and containers while sending message to machine to end or resume filling.

Touch Screen

The integrated touch screen display allows easy human interaction with machine. By using it, machine can be operated and controlled without any effort.

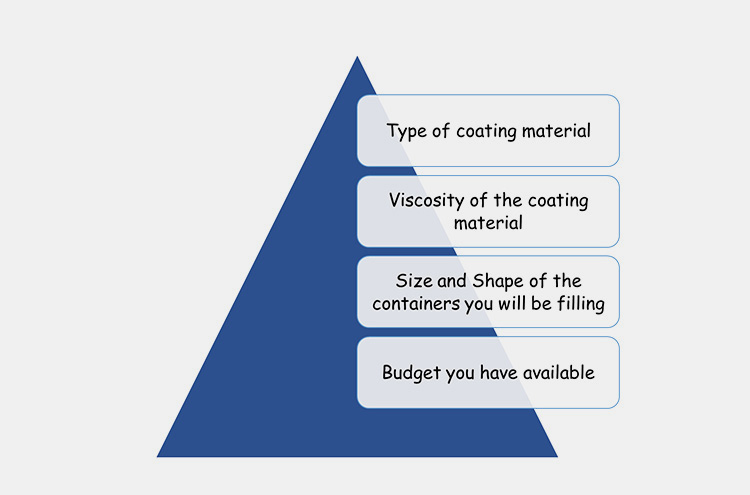

6.What are the Types of Coating Filling Machine?

There are several types of coating filling machine that is categorized based on types of coating materials, flowability, size of containers and budget in your minds.

Upon keeping these factors in mind, you can divide the types in following categories:

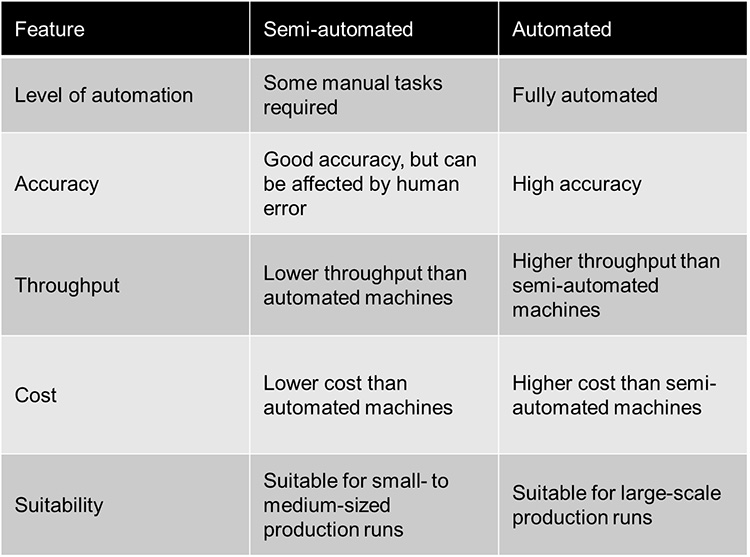

Types Based on Automation

There are two primary types of equipment used for filling solvents: the semi-automatic coating filling machine and the automatic coating filling machine . Each type offers distinct features and levels of automation. Such as:

Semi-Automatic Coating Filling Machine

In a semi-automatic machine, an operator is responsible for placing the containers onto the machine, adjusting filling parameters, and initiating the filling process. While certain aspects of the filling process, such as filling dispensing and volume control, are automated, there are manual steps involved.

This type of machine is commonly used for smaller production volumes or when flexibility is required for different container types.

Semi-automatic machines are often more affordable but require more operator involvement.

Automatic Coating Filling Machine

An automatic coating filling machine is designed to perform the filling process with minimal manual intervention.

These machines are highly automated and capable of handling larger production volumes. They excel in high-speed production lines where efficiency and productivity are crucial.

Automatic machines eliminate the need for significant operator involvement, offering a streamlined and efficient filling process.

Whether you opt for a semi-automatic or automatic coating filling machine depends on your production requirements, volume, and level of automation desired.

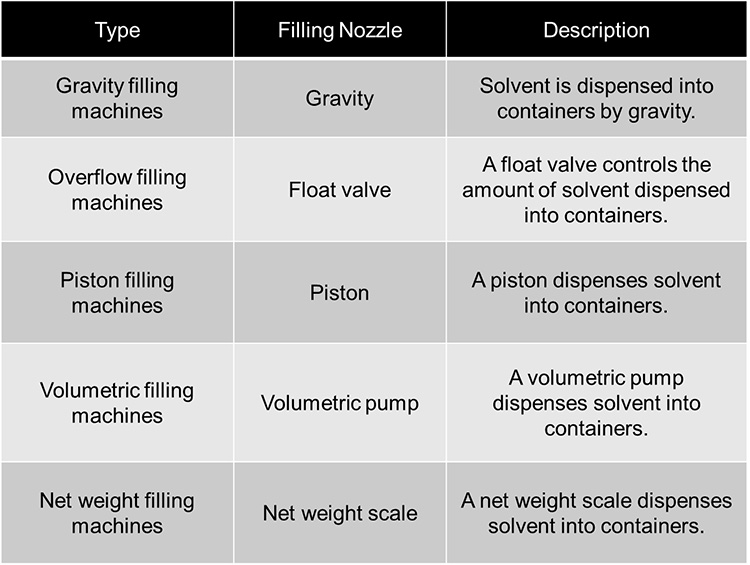

Types Based on Nozzles

Based on nozzle, a coating filling machine can be categorized into the following:

Gravity Coating Filling Machine

Gravity coating filling machines use gravity to fill containers with coating materials.

The liquid flows from a storage tank through a nozzle into the containers.

Gravity coating filling machines are suitable for low-viscosity coating materials and can handle various container sizes and shapes.

Overflow Coating Filling Machine

Overflow coating filling machines are designed for consistent volume filling of coating materials.

The liquid is pumped into a reservoir, and containers are placed under the filling nozzles.

The liquid overflows into a catchment tray, ensuring uniform filling levels in each container.

Piston Coating Filling Machine

Piston coating filling machines use a piston mechanism to accurately measure and dispense coating materials. The piston draws the liquid from a reservoir and pushes it into the containers. Piston coating filling machines are well-suited for filling coating materials with higher viscosity and can provide precise fill volumes, accommodating a wide range of viscosities.

Volumetric Coating Filling Machine

Volumetric coating filling machines measure and dispense coating materials based on predetermined volumes.

They can incorporate various mechanisms like rotary valves, pumps, or flow meters to ensure accurate filling. Volumetric coating filling machines are widely used in pharmaceutical, chemical, and food industries, and can be adapted to different viscosities and flow characteristics.

Net Weight Coating Filling Machine

Net weight coating filling machines focus on precise coating filling based on weight.

Containers are placed on a scale, and the machine dispenses the coating material until the desired weight is achieved.

Net weight coating filling machines are commonly used for filling larger containers or drums, ensuring accurate measurements by weight.

Types Based on Containers

Based on the containers, a coating filling machine divided into the following:

Drum Coating Filling Machine

Drum coating filling machine is used to fill large drums or containers with solvent.

These machines automate the filling process, leading to faster operations and higher production output.

They offer precise control over the volume of solvent, ensuring accurate measurement and minimizing waste.

IBC Coating Filling Machine

IBC (Intermediate Bulk Container) coating filling machine is designed specifically for filling solvents into IBCs.

IBCs are large containers used for transporting and storing bulk liquids.

These machines minimize the risk of human error, which can lead to costly mistakes and material waste.

IBC coating filling machine s are designed to meet industry regulations and safety standards.

They ensure compliance with regards to accurate filling, spill prevention, and proper handling of solvents.

Bucket Coating Filling Machine

Bucket coating filling machine are used to fill buckets with solvent.

These machines streamline the filling process, maintaining accuracy and quality.

They also ensure safety, reduce costs, and facilitate compliance with industry regulations.

Bucket coating filling machine play a crucial role in optimizing operations and enhancing the overall efficiency of filling.

Jerrycan Coating Filling Machine

Jerrycan coating filling machine are used to fill jerrycans with solvent.

These machines are crucial in industries that require efficient and precise filling into jerrycans.

Some of these industries include chemical manufacturing, automotive, and household product industries.

Jerrycan coating filling machine incorporate safety features such as automatic shut-off mechanisms, leak detection systems, and anti-drip mechanisms.

These features minimize the risk of accidents and promote a safer working environment.

Types Based on Filling Mechanism

There two basic filling mechanism of coating filling machine:

Rotary Coating Filling Machine

Rotary filling machines are used for high-volume applications where accuracy is not critical. It has a maximum capacity of 2400 pieces per hour per row, ensuring efficient and high-speed filling operations. The machine filling of a wide range of product sizes. Here, the filling process takes place in a rotational manner, empty and filled containers entered and leave the unit in rotary motion.

Linear Coating Filling Machine

Linear filling machines are a type of filling equipment used in various industries for the precise and efficient filling of containers. Linear filling machines operate with a linear motion, moving containers along a straight line to complete the filling process. This machine is ideal for a diverse range of container sizes, and 1 liter to hundreds of liters, designed for larger containers.

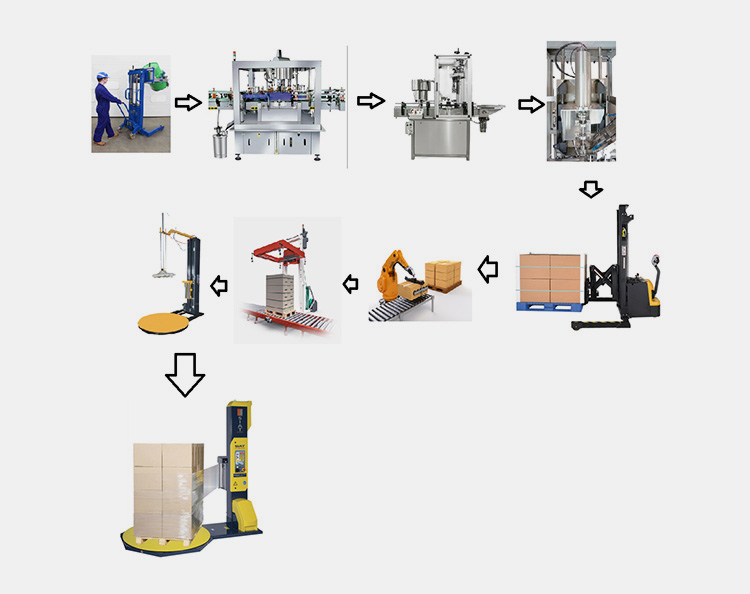

7.What Is the Complete Production Line of The Coating Filling Machine?

There is a full-fledged production line available for coating filling machine. It can be understood by the machines mentioned as follows:

| No | Machine | Description |

| 1 | Manual Barreling Machine | The manual barreling machine is responsible for cleaning and polishing drums like containers before the coating filling process occurs. |

| 2 | Automatic Capping Machine | An automatic capping machine is used to secure different types of caps over containers. By doing so, the coating present inside containers are free of external factors including pollution, moisture and light etc |

| 3 | Servo Track Capping Machine | Servo track capping machine uses fiber optic to cap containers during process without any interruption. It works by following principle of pick and place caps over range of heads from 40b/m to 70b/m sizes. |

| 4 | Automatic Labeling Machine | An automatic labeling machine is integrated with coating filling machine to dispense labels over range of containers for their identification and displaying product information. |

| 5 | Stacker | Stacker loads the filled containers together by rightly positioning them over one another. |

| 6 | Robotic Palletizer | A robotic palletizer is an innovative system adopted to automate the process of stacking products onto palletizer. |

| 7 | Strapping Machine | Strapping machine is crucial equipment utilized for banding loaded containers via straps to avoid dispersion of containers, especially during transit. |

| 8 | Sword Piercing Strapping Machine | Unlike strapping machine, this machine adopts a different way for strapping containers. It carries a sword holding band which is passed over the packed unit of filled containers in order to make it adhere to the palletizer. |

| 9 | Wrapping Machine | Wrapping machine is significant for accomplishing the final unit of coating filled containers packaging. It is either stretch wrapping or shrink wrapping machine which units the large number of containers into a single unit. |

8.What is the Difference between Traditional Filling and Coating Filling Machine?

By looking into table below, you will observe that there are huge differences between traditional filling machine and coating filling machine:

| No | Factors | Traditional Filling Machine | Coating Filling Machine |

| 1 | Process | Its process is hectic as it requires constant manual intervention to complete filling. | It simply works with non-stop operation until user switch the power off. |

| 2 | Structure | The structure of traditional filling machine is complex with congested parts requiring huge space. | It is precise in structure due to composed components which makes it easily portable. |

| 3 | Speed | Its speed depends upon operator and often have low productivity ratio. | It is well known for its fast and effective performance. |

| 4 | Capacity | It is confined to fill limited number of containers due to static nature which never accept scalability. | There is no limitation over the number of containers that has to be filled. |

| 5 | Application | It can be used in small or medium scale industries where productivity and accuracy are not the conditions. | It has vast applications in industries such as coating industry, paint industry and cosmetic industry etc. |

9.What Kinds of Coatings Are Filled Using Coating Filling Machine?

There are several coating materials you can fill using a coating filling machine. For instance:

Oil- Based Coating Solution

A durable and glossy solution that is composed of oil, resins, and some organic solvents commonly used in the manufacturing industry to give a glossy finish to materials.

Emulsion Based Paints

Such paints are manufactured from the combination of water, pigments, and binders e.g., acrylic or vinyl. They are commonly produced in the paint industry using coating filling machine for its packaging.

Watercolor Coating Solution

You can call them thin coating solution which is a mixture of pigments suspended in solvent binders giving semi-transparent color.

Acrylic Coating Solution

The most durable paint solution is commonly prepared by acrylic resins that is best known for its durable and glossy finishing of the walls.

10.What Volume a Coating Filling Machine Can Manage?

Knowing the volume of a coating filling machine is one of the interesting facts to acknowledge its capability. With increasing production, manufacturers are more concerned about the volume of coating that has to be filled in the number of containers.

In this way, a coating filling machine has been upgraded with advancement in technology. Now, it can be used to fill medium to large volume of coating into various containers. Volume ranging from 10 liters to over 200 liters can be dispensed into bottles, jerrycans, drums and intermediate bulk containers while using this machine.

11.Is There Any Device to Guarantee the Safety Of The Coating Filling Machine?

Using the large-scale coating filling machine will no doubt need safety measures for smooth functioning as well as for user and environment preservation. Before installation, it is necessary to carefully read the operational measure for the correct use of the machine.

For safety reasons, the machine is equipped with ‘explosion proof device, which is composed of explosion proof wirings, motors, electric coiling system.

A compact and enclosed structure that is coated with fire retardant material that ensures 100% safety to the operator and your entire production facility. For example steel, polyamide, resins, etc. An explosion proof device strengthens electrical components against high heat up to 700 Fahrenheit to 930 Fahrenheit.

12.How To Deal with Problems and Troubleshooting Of Coating Filling Machine?

To counter the predictable failures of a coating filling machine, consider the table below:

| No | Problems | Causes | Troubleshooting | Picture |

| 2 | Incorrect Filling | Sometimes, the entrance of nozzles into containers creates a seal in their mouths leading to incorrect filling | The operator must check the entry and exit of nozzles by indexing time as well as aligning nozzles to the containers filled |  |

| 3 | Bottle tipping and spreading | The random tips or spills are the result of a damaged, moreover, a conveyor belt which shakes bottles when passed through it | The damaged or missing part of a conveyor belt can be adjusted or replaced to ensure smooth transportation of containers. |  |

| 4 | Pump wheel does not move | The inside roller of pump head is stuck blocking its way to function | The installation of pump head may be needed to resolve this issue |  |

| 5 | Movable parts adopt the difficult motion | Rough gadgets while moving create an obstruction | Lubricate these parts of the machine for smooth running |  |

13.What Buying Consideration For Right Coating Filling Machine?

Isn’t it hectic to delve into the complexities of overthinking for choosing the right coating-filling machine? Definitely it is! That's why, we have underpinned the principal factors that must be considered in this regard:

Production Volume

Every firm has its foremost interest behind purchasing a coating filling machine, which often is the attainment of production efficiency. For this, you need to examine your current production volume and determine to which extent you want it to expand. For instance, machine with upgraded features, diverse specifications and high automation will be more potent for efficacious performance.

Maintenance Requirements

Have you gone through the maintenance requirements of coating filling machine? If not! Make sure to know them, by asking questions about its cleaning procedure, installation and readily available spare parts.

Knowing Nature of Filling Material

Coatings can be distinguished on the basis of their viscosities. Therefore, it is crucial to consider the nature of the coating you are using. In addition, a gravimetric filling machine is suitable for free flowing low viscosity coating, while a volumetric filling machine can easily undertake filling of highly resistant coatings.

Compatibility

If you are planning to use different size containers for coating filling, then it is necessary to check the compatibility of the machine with various sizes of containers. Moreover, a flexible machine is able to withstand scalability and customization.

Conclusion

A coating filling machine is an essential equipment required in manufacturing industries for fast and accurate output. The machine not only improves productivity but helps in ensuring a consistent result of overall production. In this blog, we have discussed all major types of coating filling machine; we assure now you’re able to decide a right machine for you. For machine procurement and queries, please contact us now.

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp:+86 18171018586

Tell us your material or budget, we'll reply you ASAP within 24 hours

Automatic liquid filling line Related Products