Cling Film Packaging Machine: The Complete Buying Guide In 2024

Cling Film Packaging Machine: The Complete Buying Guide In 2024

Sometimes you need to pack different items in a visible form, it may look hard to do so but there are some packaging techniques that can help you with this.

Cling film packaging machine is used to give visible packaging to your product in such a way that your product look fresh and visible to your customers.

You do not have to think much or remain curious about because this article will explain everything regarding to Cling film packaging machine & it’s different aspects in modern life.

1.What is Cling Film and what is Cling Film Packaging machine?

Cling Film

A cling film is a very thin surface plastic wrap made of polyethylene in such a way that it can wrap around any type of product to give it a visible form.

Cling film usually, sticks to the product when you wrap it around it without any heat. Because during the wrapping the upper layer when comes out from the roll it contains active electrons that can help the film to stick.

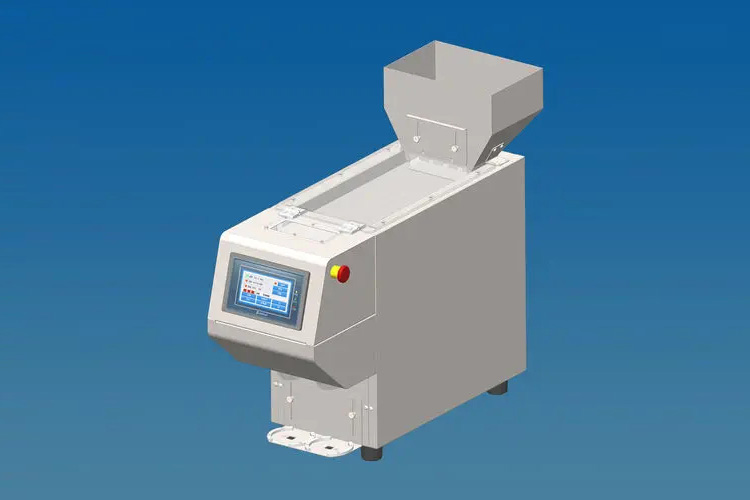

Cling Film Packaging Machine

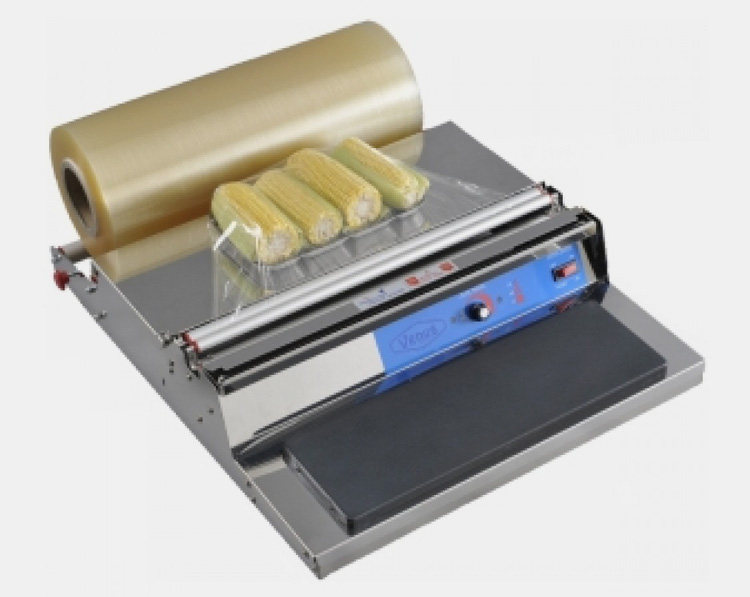

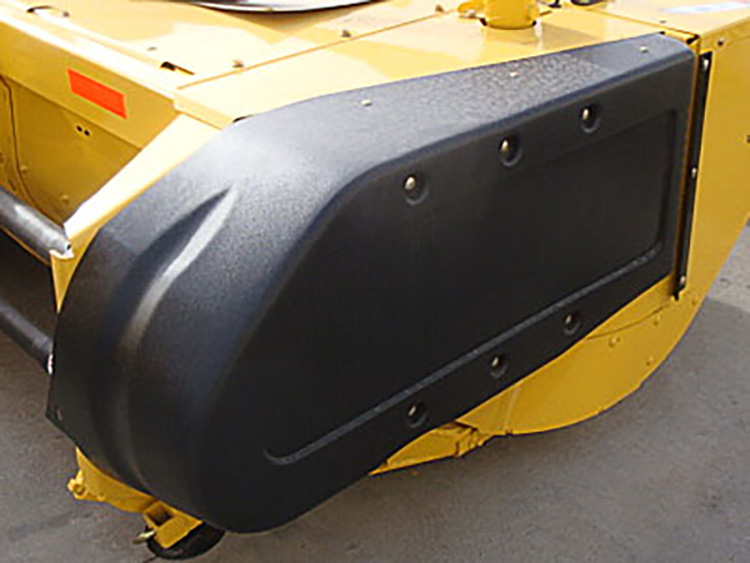

Cling Film Packaging Machine

The idea to introduce cling film packaging machine is to give quick wrapping and packaging solution to different vegetable and fruits production companies.

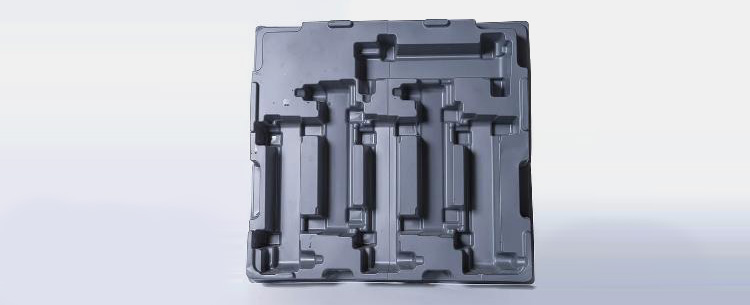

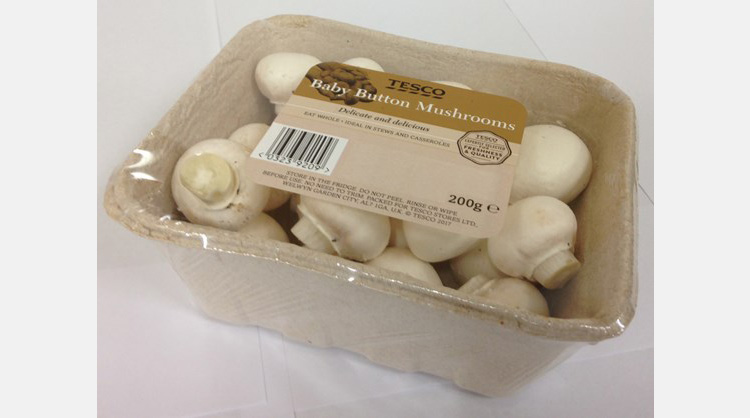

Basically, a cling film packaging machine or Shrink packaging machine is used to automatically pack multiple food items such as fruits, vegetables and other items. It keeps the food items fresh when packed in a tray.

A cling film packaging machine is an easy access equipment used to pack different food items and other items in a small tray or box with a visible sheet called cling film.

When we look around most of food dealers such as buffets, superstores, Hotels and vegetable farms they use this machine quite regularly.

All of the different steps that a person have to perform manually such as cutting the wrapped sheet and shrinking, cling film machine can help you with these steps.

2.Cling Film How a Cling film is made & why it is called Cling?

Cling Film Packages

A typical cling film is made with PVC called polyvinyl Chloride when you heat this element at a specific temperature it will melt down in a liquid form.

When you get the liquid form of polyvinyl Chloride then specific amount of water is added into it. The addition of water will help the PVC to stretch up to a specific limit.

After the water reaches to its boiling point the water bubbles will help the PVC plastic to extend its property that will later help you for packaging purpose.

Metal bars present inside a boiling tube will catch the boiling bubbles onto them in this way a roll of a cling plastic will be obtained. Later on after these cling films are made then you have to cool down them for packaging purpose.

Cling film is a stretchable plastic that provide you stretchable and sticky property to cover a food item. It is very safe to pack & wrap multiple food items safely because it will not make any reaction to these items that can cause degradation to their freshness.

On the other hand, cling means sticky and extendable so just like that, cling film contain both of these properties that will help you for packaging.

The sticking ability of the cling film is made it unique as compared to other packaging elements beside it is not reactive when wrapped around any element.

3.What features Cling film packaging machine holds?

A cling film packaging machine is a useful equipment that can facilitate you in many different ways with its multiple features.

Excellent Packaging

Cling Film packaging of fruits

A cling film packaging machine can give your product a proper packaging look which is hard to get manually. Cling film machine can help you to brand your product in a better package.

Cling film packager will give gentle and authentic look to your product tray.

Multiple Tasking

Packaging is not the only thing that you are going to get working with cling film packaging machine. it can provide you weighing ability along with auto packaging of different size trays and in terms of branding it can print your companies logo on the sheet.

Comfortable and Efficient

Comfortable & Efficient packaging

The speed of packaging of a cling packaging machine is approximately 15 to 20 packages in a minute which is very decent value as compared to manual packaging.

Your cling film packaging machine is designed in such a simple way that it can be operated in a comfortable manner providing different technical abilities such as, noise free working, fast and smooth operation, and contact free packaging.

Production Material

The stainless steel high end material used in the production of cling film packaging machine make it corrosive free so that your machine remain up to its maximum life cycle.

All of the cling film packaging machine parts are made with stainless steel material for quality assurance.

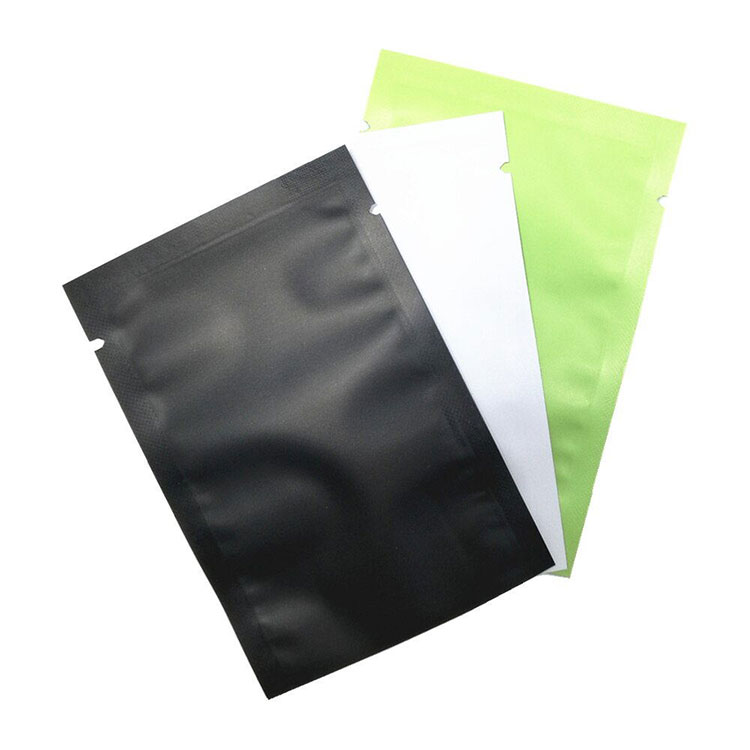

Multiple Film Choice

Multiple Color Cling Films

Cling film packaging machine will give you multiple choices to use a plastic film for packaging purpose such as you can use polyvinyl Chloride or Polyethylene.

So, you will not be restricted to use only a single packaging film.

4.Explain different types of Cling packaging machine?

Semi-Automatic Cling Film Packaging Machine

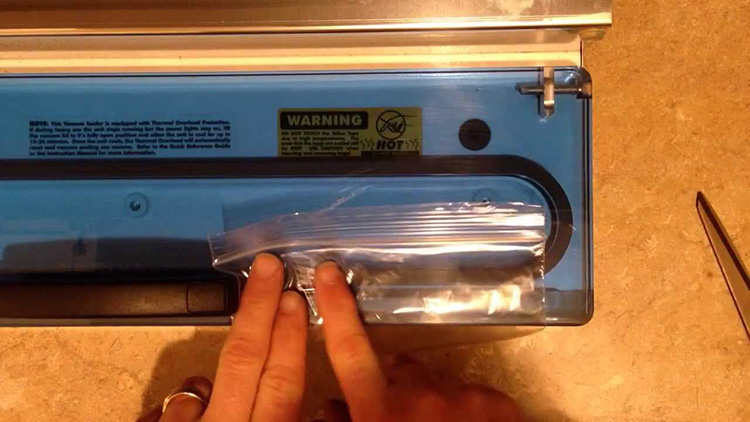

An ordinary small size cling film machine which is not that much effective as compared to other cling film packaging machines. Mostly used for small purposes such as houses and small vegetable or fruit stores.

Only the packaging is done automatically in this cling film machine and all other operations need to be performed manually by a person.

Working:

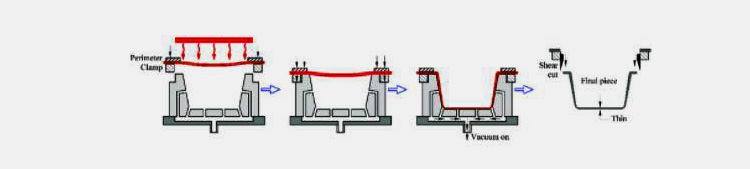

This machine is suited for packaging fruit, vegetables, meat, and bakery items, the end result is a wrapped product that maintains freshness, looks attractive and maintains a shelf life. After being wrapped in Venetian cling film, the film is pressed against a protective guard.

Advantages:

- This machine is used to pack small things.

- Reliable enough to be used in small industries or home.

- This machine is not expensive.

Disadvantages:

- This machine is not ideal to pack different size objects.

- Its speed is low as compare to other machines.

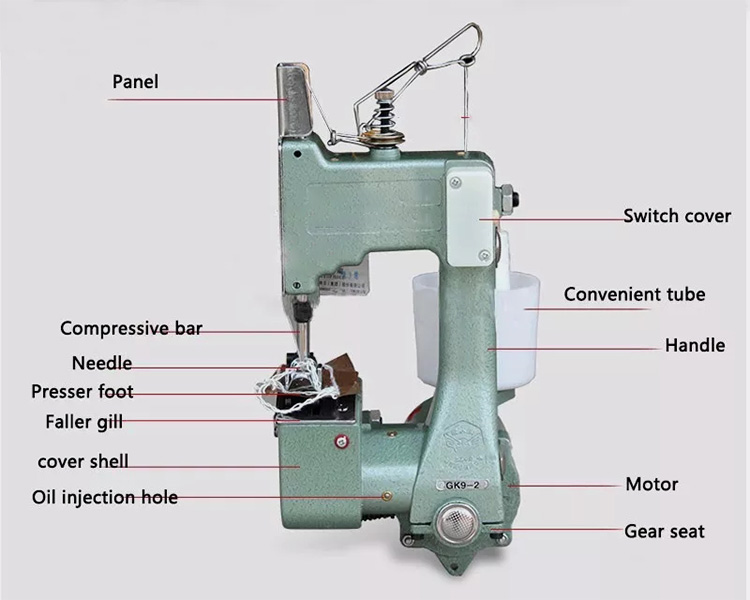

Components

In semi-automatic cling film packaging machine there are some differently working parts as compared to

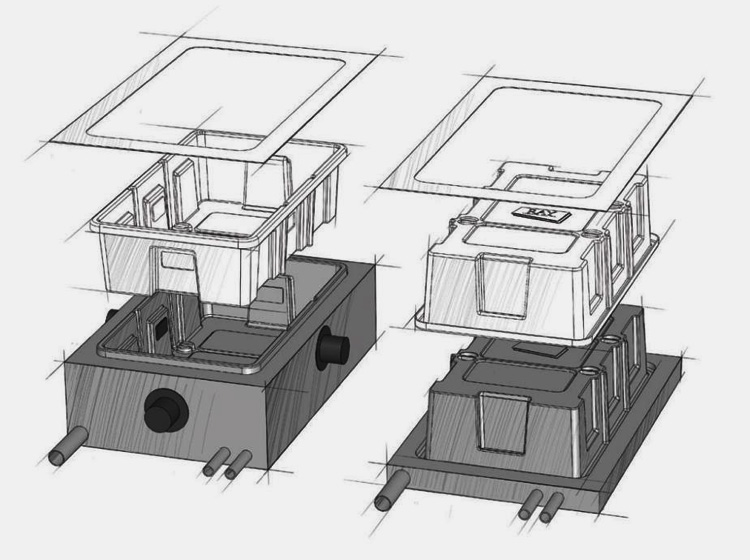

Wrapping Bracket

Once the product is loaded onto the assembly it interacts with the wrapping bracket in which according to the measurements of the product the cling film is wrapped around it.

Wrapping bracket carefully inspect the elements and wrap it perfectly.

Temperature Plate

Cling film is completely based on heating and stretching so for this purpose a hot metal plate is placed inside the cling film packaging machine to control the inner temperature of the machine for secure packaging.

Holding Casters

Holding caster acts like a baseline in the semi-automatic cling film wrapping machine. Basically, these are present along with bottom wheels to make sure your machine stand still while perform packaging.

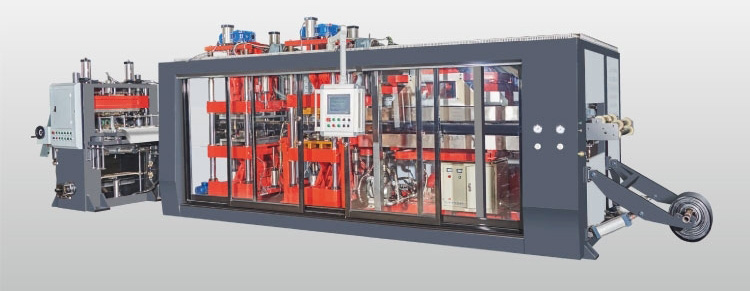

Fully Automatic Cling Film Packaging Machine

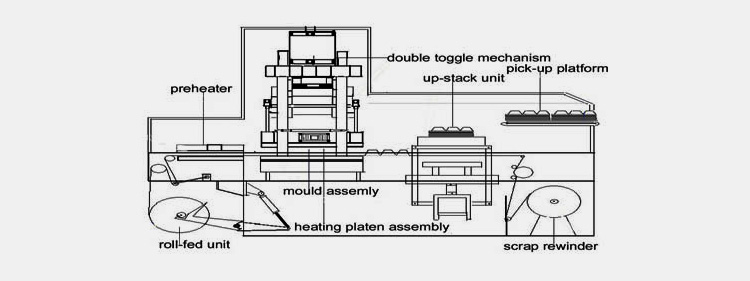

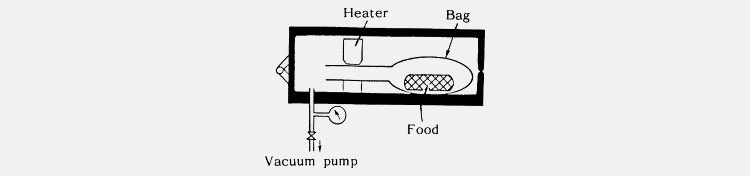

Fully automatic cling film packing machine comes in a big size. All of the operations from packaging to printing made automatically in this fully automatic cling film packaging machine.

In this cling film packaging machine, you have to put your packaging product into a feeder or collector and put the PVC roller on the hook.

After that fully automatic cling film packaging machine will fetch these elements and perform the required operation automatically for packaging.

Working:

After product placement, the cards (or other backing media) are automatically placed on blisters and sealed. Finally, the completed blister pack is removed from the delivery.

Advantages:

- Contact heat to ensure rapid and precise heating

- Automatic card feed(s) or reel feed of film media

- Automatic removal of the completed pack

Disadvantage:

- It is very expensive & will consume a lot more electricity as compared to other machines.

Components

Here are some important cling film packaging components that you need to know.

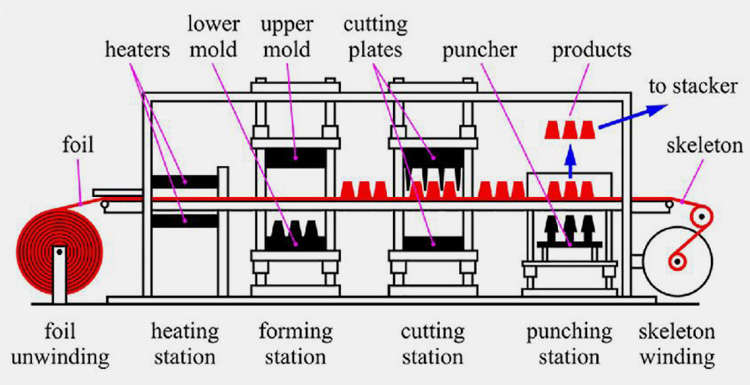

Conveyor Line

From the beginning to the end conveyor line is assembled in the whole machine by making it appropriate that your packaging products goes step by step.

At the end of the conveyor line a metal controls the packed items and move them towards the collector for final check in.

Transparent Glass Cover

A glass cover on a fully automatic cling film packaging machine works like a protector that keep your packaging items as well as inner parts of your machines dust free.

So, it can perform its actions fluently and effectively.

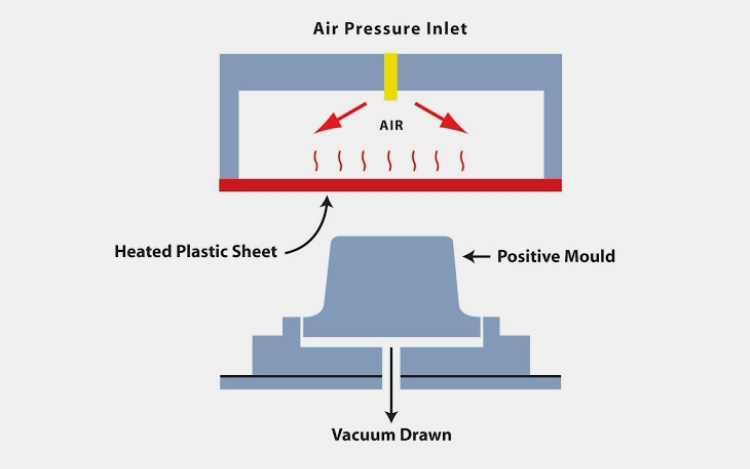

Heaters

Small size heaters usually blows the hot air onto the cling film so that it can expand properly on top of your product by covering the edges.

These heaters came very handy when you work with tray packaging of food items.

5.Why Cling film packaging machine is different from other packaging machines?

Cling film packaging machine is quite different from other packaging machines because of some reasons.

Working with Cling Film

Cling film packaging machine is very effective while packaging multiple products because it is specially designed and structured to work with cling film material which is hard to use with other machines.

Ability to Stretch & Shrink

Cling film packaging

A cling film is a stretchable & shrinkable plastic which can be done while working with a cling film packaging machine as other machines use hard plastic material for packaging purpose.

Heat Ability

The heat inside a cling film packaging machine is used to shrink it. This heat ability lets the cling film to adjust and shrink according to the packaging product type.

A Good Insulator

A cling film not only keeps your product fresh it can also act as an insulator between your product and outer environment. It works as a wall boundary to keep your products safe.

6.In which industries Cling film packaging machine is widely used?

A cling film packaging machine is used in many modern industries that are working on different packaging materials & here are these industries.

Food Industry

Cling Film packages

It is the most common industry in which a cling film packaging machine is used. As I explained earlier many of the vegetable items and food items are packed with cling film packaging machine.

However, meat is another type of food item that you can pack in a box or tray using a cling film packaging machine.

While going into store you look into a refrigerator you will see different boxes of freezed food items these are packed with the help of cling film machine.

Baking Industry

Cling Film package

Cling Film package

When you visit a bakery you often see different cookies packed in a visible tray that is also done by using a cling film packaging machine.

Bakery items need protection from outer environment and they need to be isolated inside a box. So for these reasons a cling film packaging machine is used.

Pharmaceutical Industry

Cling film packages

Most of the cartoons and small boxes that contain medicine inside them are also wrapped and packed with cling film packaging machine.

Bulk amount of capsules or tablets inside a tray with a visible cover on top is also another example of cling film packaging machine.

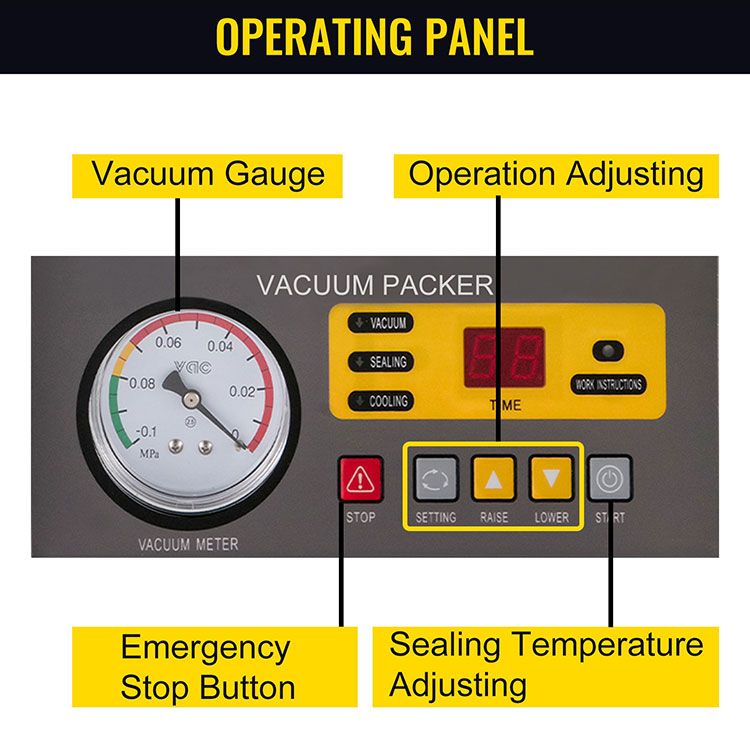

7.Explain the operational procedure of Cling film packaging machine?

Cling Film Packaging machine

The working operation of a cling film packaging machine is very simple. Here is the explanation about the cling film packaging machine working.

Basic working principle of a cling film packaging machine is same just like other packaging machines but it is different in some operations.

It begins with a tray filled with different items. When you place the filled tray on a packaging assembly it will dive in towards the packaging unit.

In the packaging unit the cling film will roll over from the hooks and the rolling rods will pack the item inside the cling film.

The cling film packaging machine contains different controlling jaws to control the extension of a cling film and also the movement of packaging tray during the working.

Cling film machine also uses the heat up to some extent to make sure the products are sealed and packed perfectly without any error.

8.Is it safe to use cling film for different food items?

Different items packed in Cling film packages

The simple answer to this question is yes, it is well safe for you to pack any kind of food item while using a cling film.

It is a normal PVC plastic but in a thin shape that will help your food to remain fresh, bacteria free and pollution free from outer environment.

Many supermarkets that you visit in your daily life routine they use cling film to wrap and pack different vegetables, fruits and other items. The main purpose of a cling film is to give a visible look to your product so your customers can see if the product is fresh or not.

You do not have to worry while using a cling film for packaging different food items because it will not react when get in touch with any of the product that is the best thing about it.

9.What types of cling films you can use in cling film packaging machine?

The film can be applied manually or mechanically, and so can wrapping.

The machine is offered in wrapping wrap sizes to meet any requirement.

Killing Wrap equipment is designed to quickly cut and distribute Killing Wrap.

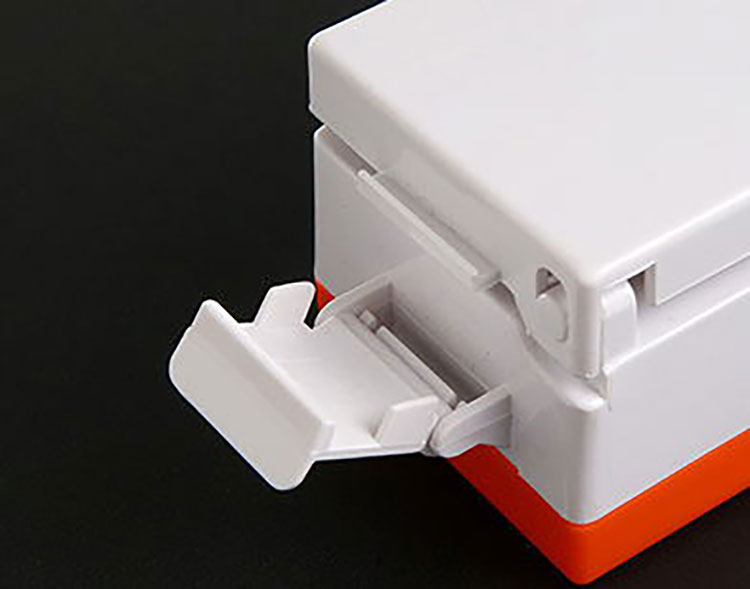

Cling Wrap with Cutter Box

The most common type of cling wrap is a plastic wrap with a cutter box. Wrap with cutter box is perfect for use in delis, bakeries, and kitchens. It has a cutter box with metal teeth across the width of the box to facilitate pulling and tear cutting.

Cling Wrap with Sliding Cutter

These roll cutters from cling wrap are like wraps with box cutters. The sliding cutter design is very easy and safe to use. Sliding cutter wraps are more expensive. The advantage of Cling Wrap with Sliding Cutter is efficiency and safety. With the help of a cutter, it is very easy to cut the film easily and to the desired length.

Pre-Perforated Cling Wrap

This type of cling wrap allows you to remove pre-cut sheets of cling wrap quickly and easily. It is most widely used in the food and medical industry. It is also used by printing companies, hair salons, etc.

Machine Cling Wrap

Stretch film can be applied manually or mechanically. The wrapped wrap is the same. The Killing Wrap equipment is designed to cut and dispense Killing Wrap quickly and easily. This machine is offered in wrapping wrap sizes to meet any requirement.

10.How to solve common problems while working with cling film packaging machine?

These are some common problems faced while working with the cling film machine and their solutions.

Problem 1: Cutting position or wrong sealing

Solution: This problem can be solved by checking the height of the conveyor belt and adjusting it to the right position. Make sure that the wrap cling is not too large nor too small. Ideal size is the best to make a right sealing.

Problem 2: Swelling

Solution: The indication of this problem is that there is air inside the film. To remove the swelling or air increase the number of vents so that air is leaked from the cling film. We can also slow the speed of conveyor belt so that the air has a long time to leak from the film

Problem 3: Fisheye like wrinkles

Solution: The problem can be solved by multiple solutions. The circulating wind force of the machine is too low that the wrinkles are being formed on the film we just need to maintain the speed of the circulating wind force of the machine.

Problem 4: Dog ears

Solution: The shrink bag size should be made smaller its large enough that the dog ears are being made. The speed of the conveyor belt must not be very fast if it is then it needs to be slowed down to solve this problem.

11.How to select appropriate cling film packaging machine?

The key points to remember to select an appropriate cling film machine

Speed: The speed is a major factor while selecting a cling film machine because its obvious that we want our work to be complete without wasting any time.

Flexibility: The machine should be flexible enough to wrap different type of products like vegetables, medicines, and other products.

Size: Size of the machine must be kept in mind because sometimes you need to warp large number of vegetables together so it should be large enough to warp multiple items or a large item like watermelon.

12.Is it all right to use cling film for food products packaging?

Many people think that cling film is not safe to use for food items packaging but it is a myth define by people and those who do not know about the benefits of cling film packaging.

Cling film is very much safe as compared to other plastic wraps because it is not made with any kind of dangerous chemicals. It is a simple visible plastic wrap that keeps your product safe and healthy in terms of ingredient properties for longer period.

So, you can use cling film for food items packaging in any industry because it is not reactive and made up with simple and basic elements.

Conclusion

At the end, a cling film packaging machine is a powerful tool with unique working ability to give you reliable packaging for different items. Less human effort will require with ability to perform powerful operations automatically. Allpack is providing best Cling Film Packaging machine to all its customers around the globe. Please feel free to contact us, Happy shopping!

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide

Tell us your material or budget, we'll reply you ASAP within 24 hours

Cling Film Packaging Machine: The Complete Buying Guide In 2024 Read More »

Double Chambers Vacuum Packaging Machine

Double Chambers Vacuum Packaging Machine

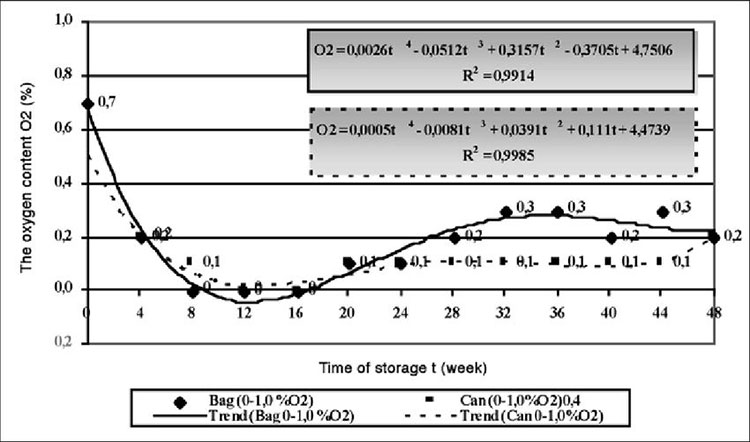

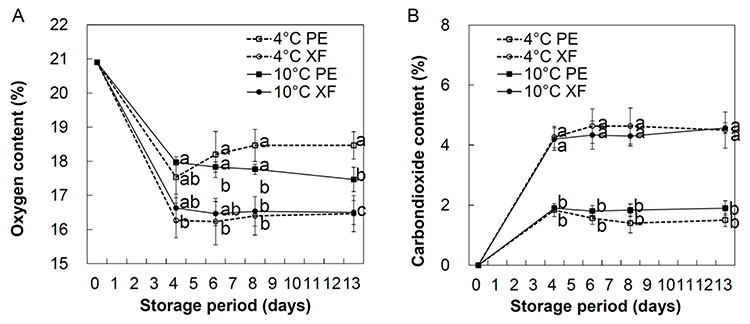

Storage Time Table

Storage Time Table

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours