Stick Pack Packaging Machine: The Complete FAQ Guide In 2025

Stick Pack Packaging Machine: The Complete FAQ Guide In 2025

What if the sleek machine form, fill and sealed the packs and pouches with zero mess and high precision. This is the marvel of automation and that lies in a stick pack packaging machine.

With fast-paced packaging industry and the increasing demands of the consumers, this machine is used in many industries like pharmaceutical, food and beverage, and cosmetics etc. due to the smarter, faster and precise performance of it.

In 2025, if you are investing on this machine or wants to you how actually they work? What benefits you can get by using it or what makes them so popular in every industry? This complete guide will answers you all your questions and helps you to choose the right machine for your business. Keep reading!

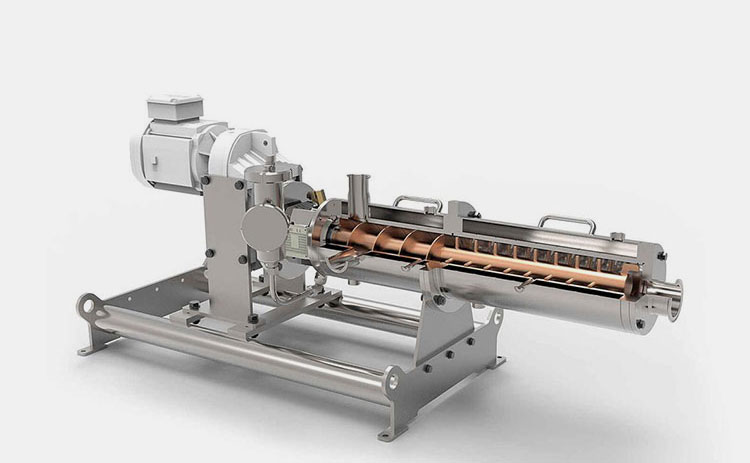

1.What is stick pack packaging machine?

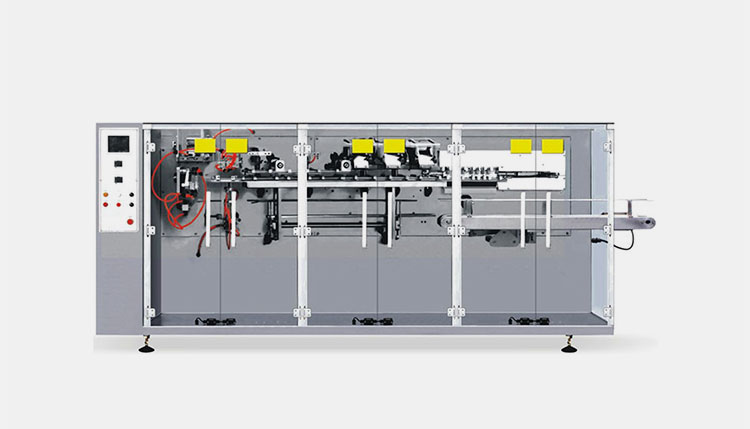

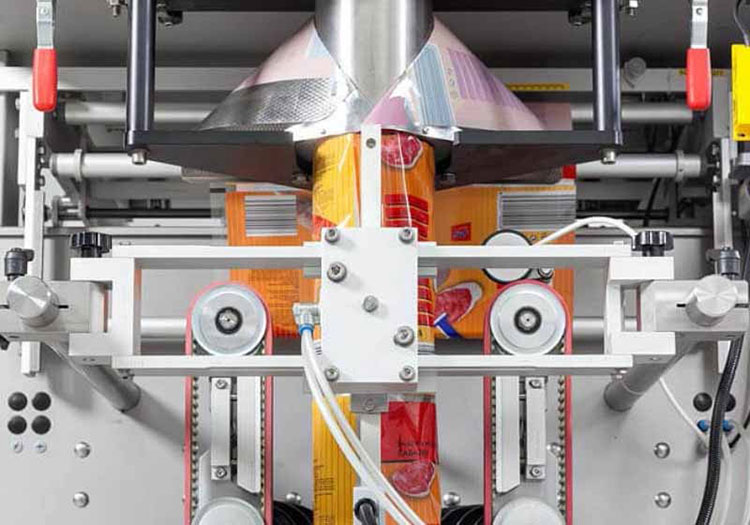

Stick pack packaging machine-Picture courtesy: Allpack

A stick pack packaging machine is a modern automation packaging machine that forms a film into a stick shaped packs, fills it with the products like powders, granules, gels and liquids and then seal them.

It works in multi-lane operation that can handle and produce many stick packs instantly for high precision and accuracy. These packs or pouches commonly used in pharmaceutical, food, cosmetics and chemicals etc. industries for the packaging of nutritional supplements, sugar and coffee, shampoos and creams and surfactants etc.

2.What benefits can you get by using stick pack packaging machine?

Have you ever wondered how your favorite creams and coffee are packaged in these aesthetic and easy-to-carry stick packs and what benefits you can get by using it? How can you get advantages by using this machine for running your businesses? Let’s enlighten the benefits you can get:

Material efficiency

Material efficiency-Picture courtesy: tkqlhce.com

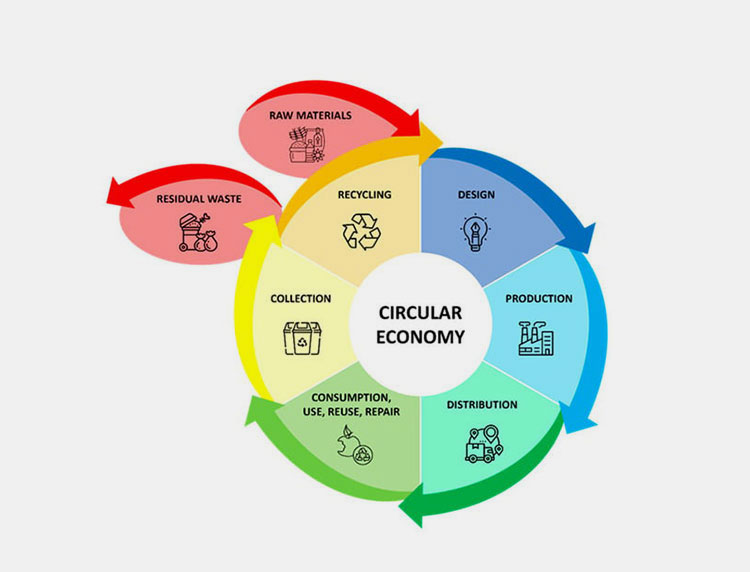

The stick packs need less quantity of materials for the packaging of products as compared to other packaging styles like pouches or sachets. If you will use less material for the packaging then the cost as well as your time will preserve. Also you can get benefit of less material wastage to the environment, making your environment and atmosphere a safe and eco-friendly.

High speed output

High speed output

As the stick pack packaging machine can run on multi-lanes so, it means you can get hundreds of stick packs immediately per minute without compromising on the quality. Due to its high production capacity, you can elevate your business by getting high quality and speedy products. In this way, your products demand in the market and satisfaction of the consumers ensures.

Space saving

Space saving

Do you want to pack a large quantity of products in the warehouse? Well, the stick pack packaging machine packs your products in slim, elongated tubes. Then these tubes can be packed in cartons. You can pack these stick packs tightly in to the cartons making saving space during its storage. In this way, you can packs a lots of stick pack in less space.

Products freshness and protection

Stick honey packaging as a product freshness and protection-Picture courtesy: dribbble.com

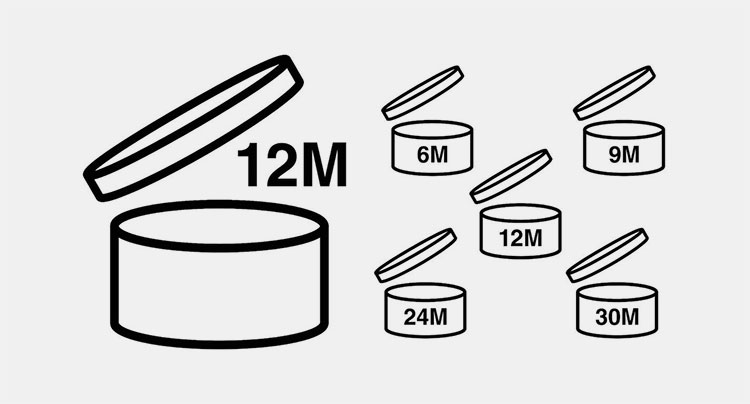

This machine has the amazing feature of tight sealing of stick packs. It can seal your products inside the pack tightly, making sure your products protect from external agents like contamination, exposure to air and moisture. Due to this reason, no microbial growth or oxidation of the products occur and your products remain fresh and protected for a long time.

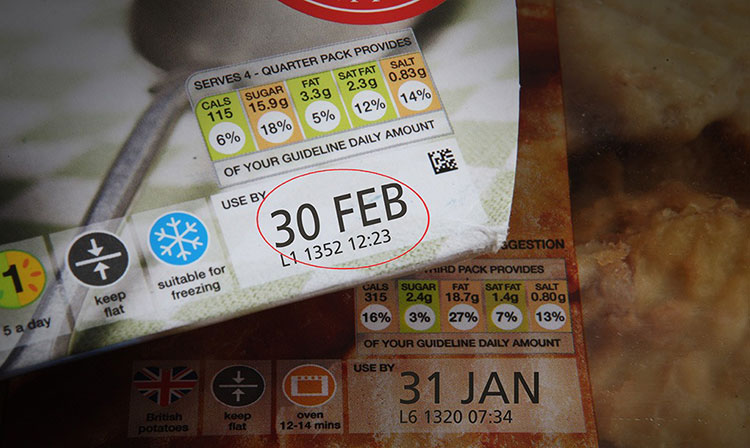

Accurate dosing

Accurate dosing-Picture courtesy: designcrowd.com

The accurate dosing plays a crucial role for health products and supplements. Do you want to satisfy with accurate dosing? This machine can be helpful. It has precise filling system, ensures that every packs has the exact amount of dose, which reduce the wastage of products and enhance the satisfaction of the consumers.

Budget- friendly production

Budget friendly production

Do you want budge friendly production? You can get benefit from this machine, as it has automated system of forming, filling and sealing so, you don’t need to hire workers for the operation of this machine. By this feature, you can save the need of manual labor. Also, the human contact with the products also minimize and helping your business.

Versatility across the industries

As this machine can handle every type of products either it is powder, granules, gels or liquids. These products are packaged in a very stylish and well-sealed stick packs making tit suitable for using in every type of industry. Due to its unique packaging styles and good labelling, this machine can highly be helpful in every industry.

Attractive branding

Attractive branding

In the modern world, consumers are attractive towards the stylish and well-sealed package products that can be seen in the shelf. This machine make slim, and unique styled stick packs that are visual appealing and eye-catchy designs. So, in this way, this machine can make an attractive branding towards the customers.

3.What types of products can be packed by using stick pack packaging machine?

Have you ever wondered how the tiny packs you see in the shelf hold different materials like instant coffee, skincare gel, and sugar in a restaurants? And every packs have perfectly dosing? This machine is working hard to pack every products in these slim packs with high precision and with zero mess. Let’s discuss the expertise of this machine in handling the various products in various industries:

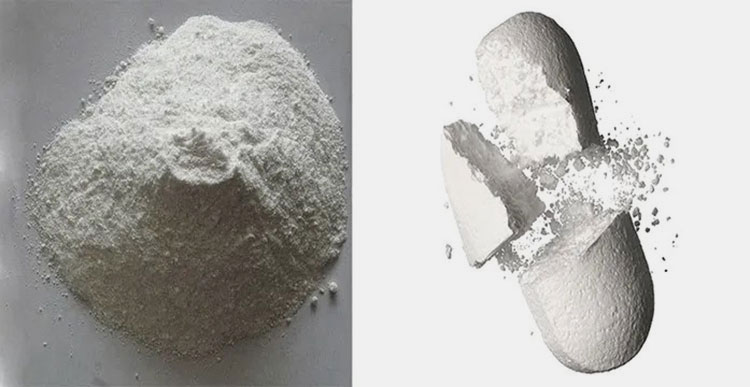

Powders

Powder in stick pack-Picture courtesy: anthropologie.com

The powder materials can be packaged in these slim packs. The accurate dosage of fine and high flowability powders are fill in the formed stick packs and then sealed them, ensuring to prevent the products from exposure to moisture and other contamination.

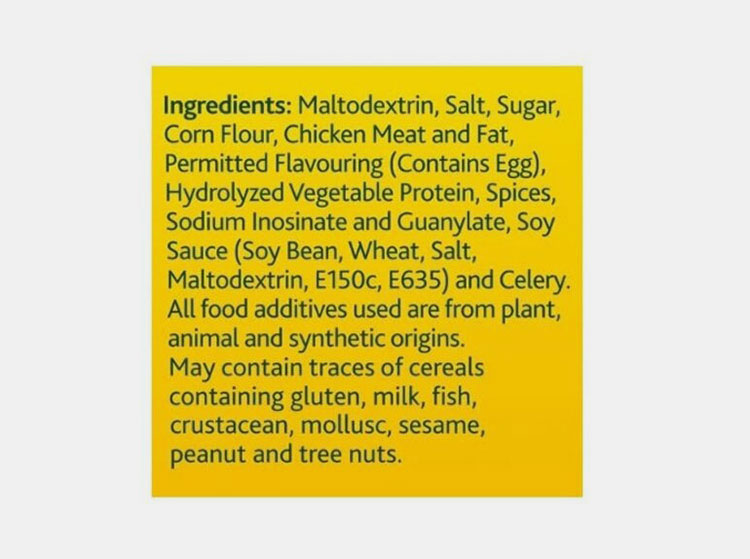

The powder materials such as vitamins and supplies, instant tea and coffee, cocoa powder and spices are packed in these stick pack to ensure its freshness.

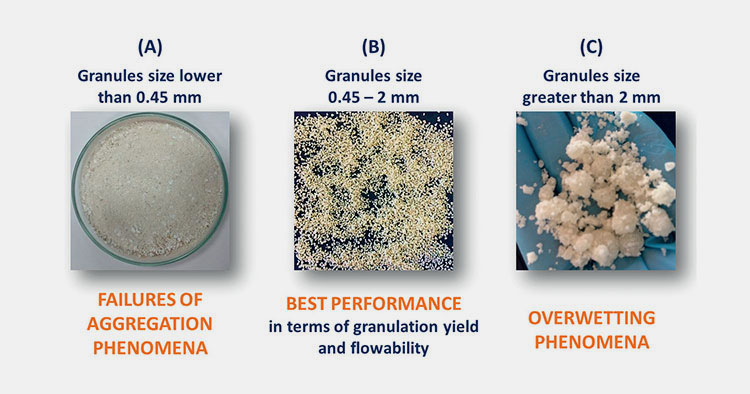

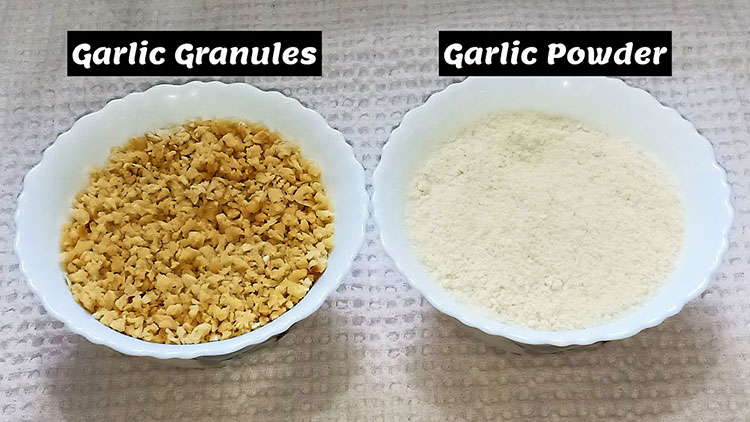

Granules

Granules in stick packs

Granules have larger particles as compared to the powder but it has good flowability. The examples of granules are herbal granules, oral dehydration salts and flavored drink crystals. These granules are packed in stick pack with accurate dosage and excellent for portable usage.

You can get benefit from packing these granules in stick pack by reducing the clumping as compared to the bulk packaging of these granules.

Gels and pastes

Gel as an aloe vera in stick pack-Picture courtesy: remedium.co

If you are running your pharmaceutical industry or skincare industry, then you can pack the gels and pastes in stick packs for sampling as well. This machine has the capacity to store semi-solid products like aloe Vera gel, toothpaste samples, and medicinal gels in the stick packs. This ensures the products integrity and offers hygienic environment to the products.

Liquids

Liquid in stick pack

This machine can also pack viscous as well as free-flowing liquids in a unique and stylish stick packs to ensure its safety and takes accountability for providing the hygiene products. You can pack honey, vitamin C shots, and mayonnaise and energy gels for athletes by using this machine. This machine is highly expert in sealing which ensures you that your products will not leak.

4.Enlist the industries that get most benefits by using stick pack packaging machine?

The use of stick pack packaging machine is not a choice for industries but it is a necessity. In every industry, you can use this machine and can get benefited by using it in various way. Some of the industries that get most benefited by using this machine are as follows:

Pharmaceutical industry

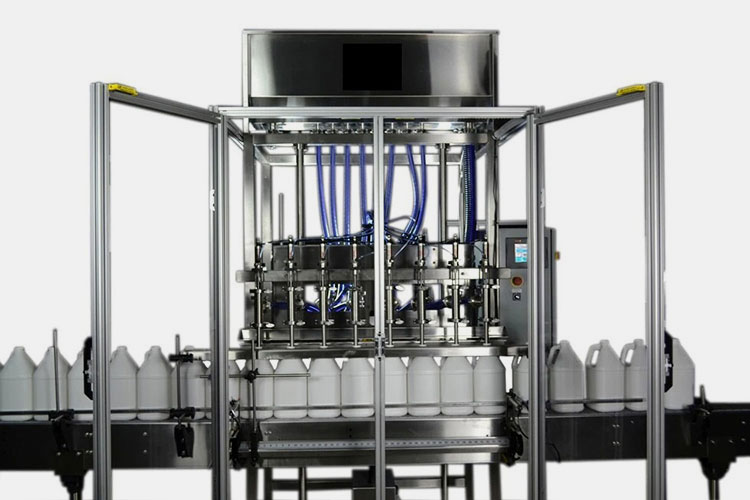

Pharmaceutical industry-Picture courtesy: unither-pharma.us

If you are owning a pharmaceutical industry, surely you will want a correct dose for the safety and treatment of the patients.

Pharmaceutical industry use a stick pack packaging machine for the packaging of gels and medicinal ointments, oral rehydration salts, and nutritional supplements in a sealed packs to ensure to maintain the hygienic and protect against the contamination. Also, the consumers get benefits from such packaging as a portable for emergency.

Food and beverage industry

Food and beverage industry

In food and beverage industry, as the demands for single serve, and portable food and drink products are increasing day by day. So, this industry is leading in using the stick pack packaging machine.

This industry can pack sugar and salts, spices, soup mixes and ketchup etc. in stick packs to ensure the freshness and convenient for easy-to-handle and travel.

Nutraceutical and health supplement industry

Collagen powder stick in neutraceutical and health supplement industry

In today fast-paced world, everyone is conscious about the wellness and fitness. This industry promotes the packaging of the dietary supplements, to maintain the supplements potency and offer single use samples. The most common products that can pack are collagen mixes, protein powders and herbal gels in a stick packs.

By using this machine, clean and eye-catchy presentation improves brand appeal.

Cosmetics and personal care industry

Cosmetic and personal care industry-Picture courtesy: prom.ua

Some customers used trial-sized cosmetics or skincare products or if someone wants to travel with small packs of creams then the demand for such stick packs increases. Cosmetics and personal care industry packs face creams, shampoos etc. packed in stick packs to ensure its intact chemical formulas and its effectiveness. If well-packed stick packs are available, then your products can resonate in the market.

Pet and veterinary industry

Pet and veterinary industry

Pet and veterinary industry used stick packs for packaging of pet vitamins and supplements, skin treatment gels for pets, and deworming powders etc. The stick pack packaging machine is used for making accurate dosing for pet treatment and making easier for pet owner to store the supplements at home or convenient during travelling.

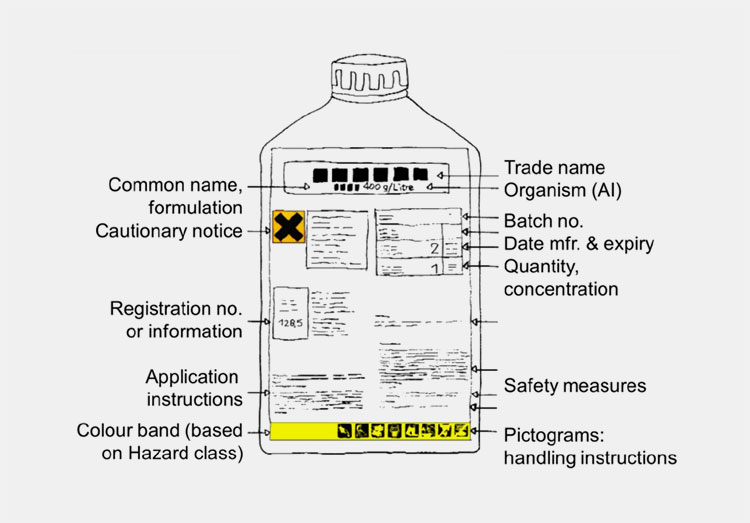

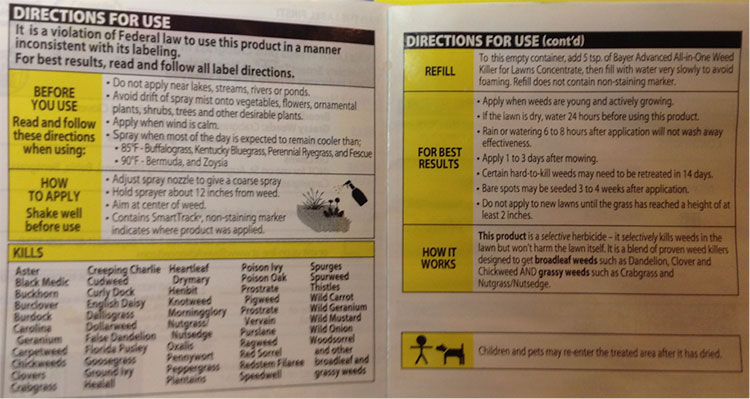

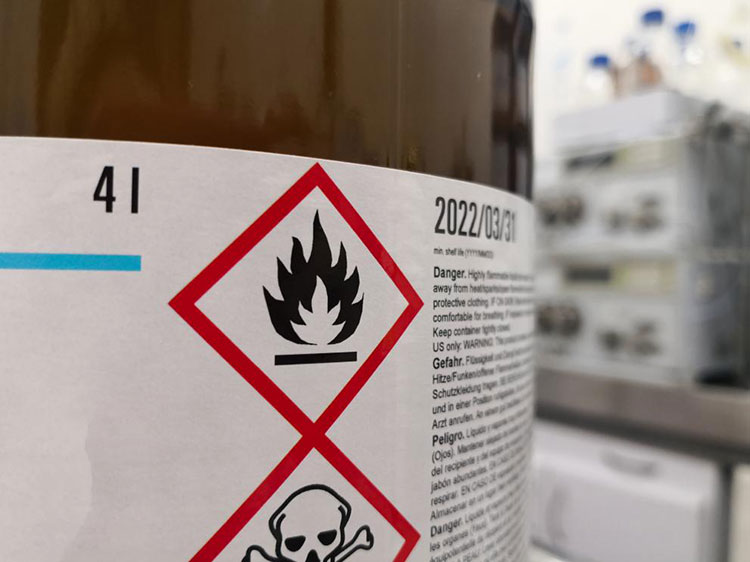

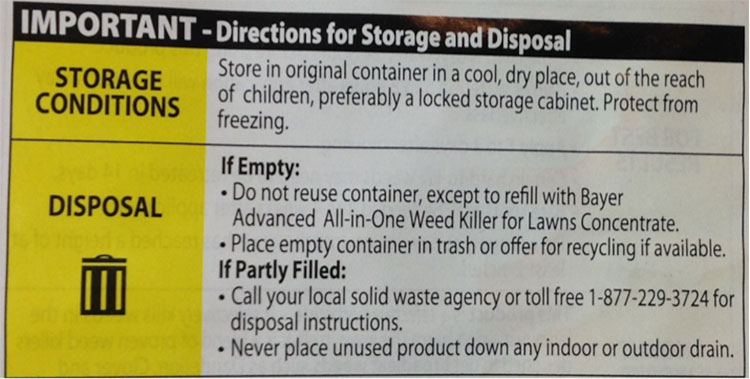

Chemical industry

Chemical industry-Picture courtesy: canadiantire.ca

Chemical industry pack certain non-toxic chemicals and cleaning agents in stick packs to reduce the exposure to air and moisture. The most common products packed in stick packs are industrial additives, water purification powders and detergents.

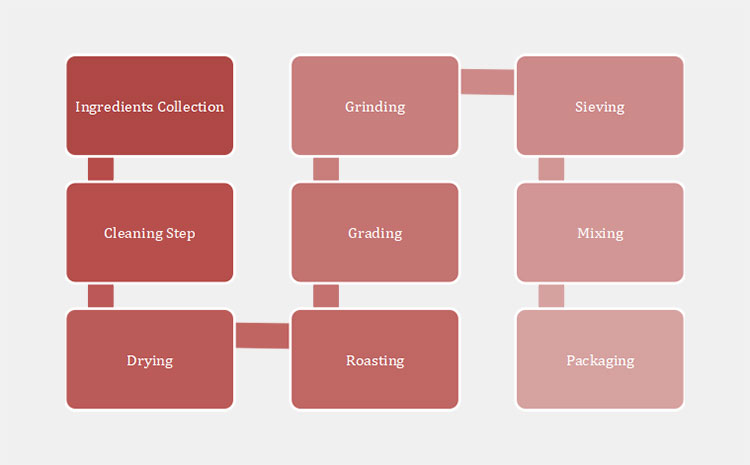

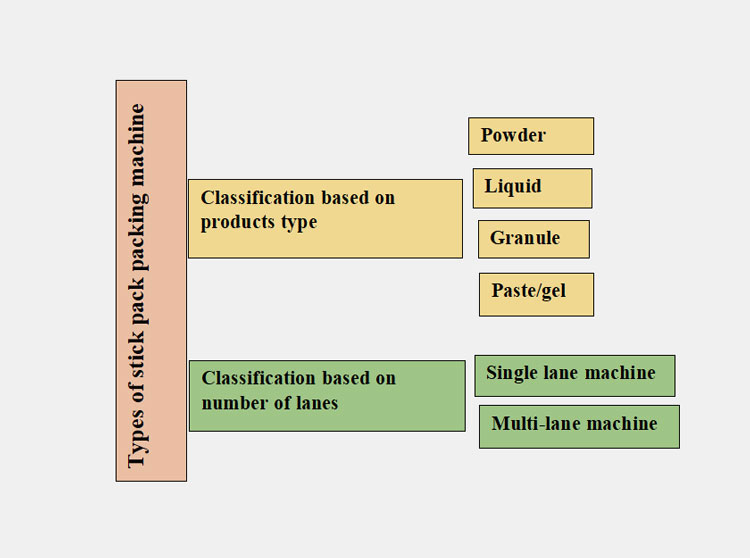

5.How to classify the types of stick pack packaging machine?

Flowchart of the types of stick pack packaging machines

There are many types of stick pack packaging machines are available, depends on the product type and number of lanes. Let’s discuss each of them:

Classification based on products type

The products to be packed in stick packs are divided into following types.

Powder stick pack packaging machine

Allpack APK 2-220 powder stick pack packaging machine

This machine is used to package of fine and semi-fine powders into the stick packs. The products to be packed by this machine are milk powder, protein powder and spices. This machine has unique feature that prevent the clumping of sticky powders and has also dust extraction system to make dust-free and hygienic products.

Granule stick pack packaging machine

Allpack granule stick pack packaging machine

This machine is used for the packaging of coarse granules in the stick packs. The free flowing granules such as sugar, salt and herbal blends are package in the stick packs. It ensures you the accurate dosing for granules.

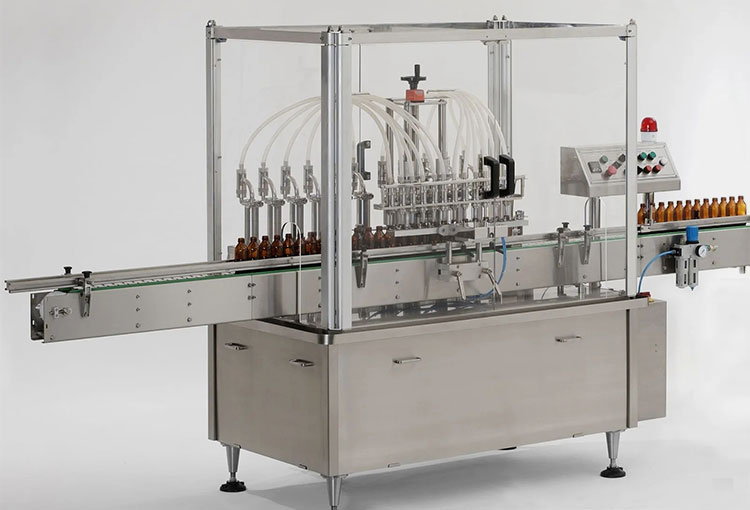

Liquid stick pack packaging machine

Allpack APK 8-480 Multilane stick packing machine for liquid

The liquid and semi-liquid products are fill and seal by using this machine. It is ideal for both viscous and non-viscous liquid products packaging in the stick packs. The examples of such type of products are honey, energy gels and medicated liquids.

The machine has easy to clean components to ensure safety of the products.

Paste/ gel stick pack packaging machine

Allpack paste/gel stick pack packaging machine

This machine is used for the high viscous products filling in the stick packs. Skincare gels, ointments and skincare creams are packaged by using this machine.

Classification based on number of lanes

On the basis of the number of lanes, these machines are divided into following types:

Single lane machine

Allpack single lane machine

The single lane machine is used by small businesses or those who wants startups. It operates on low speed and produce several hundred packs per hour.

It can automatically form, fills, seals and discharge the stick packs but at slow speed. It has many advantages like high precise production, easy to operate and having low noise.

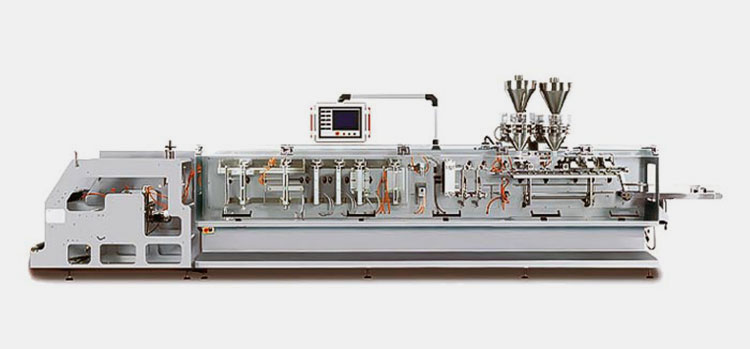

Multi-lane machine

Allpack multi-lane stick pack packaging machine

This machine is used by large scale manufacturer or used in industries because it can produce thousands of packs per hour. This machine operates automatically and don’t need an operator for operating the machine. As it operates automatically, so it reduced the labor cost.

It produces a lot of stick packs with high precision, fast speed and high quality stick packs production. So, if you are running your own industry, then go for the investment in this machine.

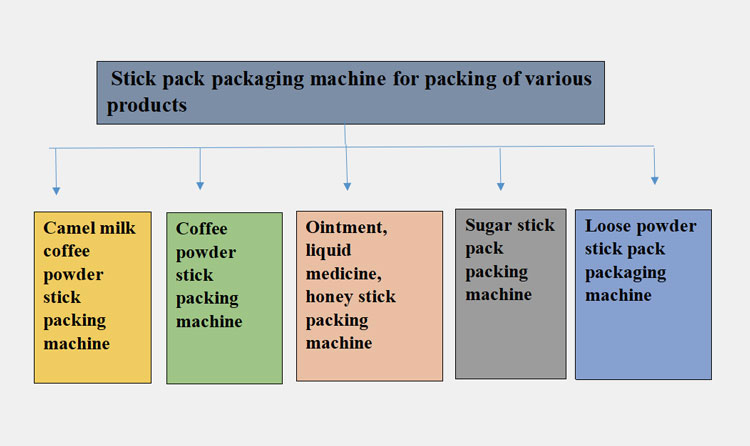

Various stick pack packaging machine for different products:

Stick pack packaging machines for various products

According to the physical nature of the products to be packaged in stick packs, various stick pack packaging devices are used. These are as follows:

Camel milk coffee powder stick packing machine

Camel milk coffee powder stick packing machine-Picture courtesy: coretamp.com

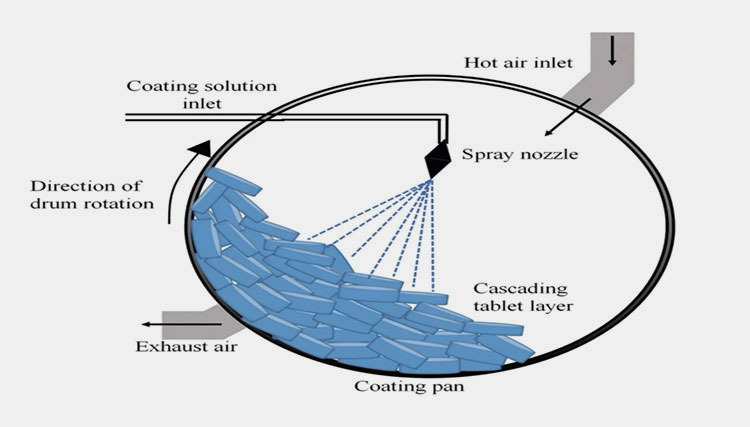

This machine is used for the efficient and hygienic packaging of powder in the stick packs to ensure the consumers satisfaction in single-serve. This device is usually associated with an auger filler. Both vertical and horizontal sealing of the stick packs are done to ensure that the product is safe from moisture and increase the shelf life of the products.

Coffee powder stick packing machine

Coffee powder stick packing machine-Picture courtesy: ft-pack.com

This machine is used for the packaging of coffee into stick packs to maintain its freshness. It can handle multilayer films that protects the coffee from oxidation, moisture and air and protect its aroma. If you want to elevate your coffee brand, then you can choose this stick pack packaging machine.

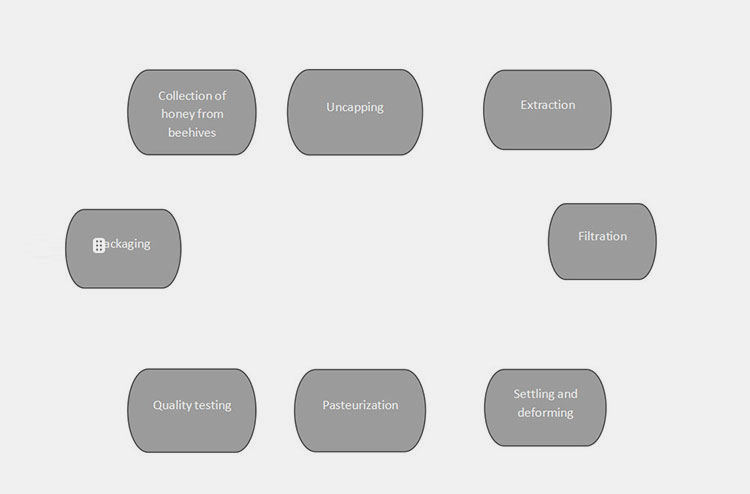

Ointment, liquid medicine, honey stick packing machine

Ointment, liquid medicine, honey stick packing machine

Ointment, liquid medicine and honey stick packaging machine pack these products into stick packs for easy-to-carry purpose or for single-serve purpose. This equipment has liquid pump filler that uses a pump to transfer the products in to the packaging container in the stick packaging machine. Different medicinal ointment, liquid medicine and honey are packed in sticks by this machine. It can handle thick and sticky materials.

Sugar stick pack packing machine

Sugar stick pack packaging machine-Picture courtesy: landpack.com

Sugar stick pack packing machine is used to package sugar in the stick packs for use in cafeteria or in hotel for single serving. This machine is equipped with a filling system usually, volumetric cup filler for the filling of granules and consistent sized particles into fixed volume cups and stick packs.

Grains and small granules like sugar is filled in measured cups or sticks. This system allows to pack the consistent and non-sticky granules in stick packs.

Loose powder stick pack packaging machine

Loose powder stick pack packaging machine-Picture courtesy: samfull.net

A loose powder stick packaging machine is an automated machine used to fill, seal and discharge the narrow and well-sealed stick packs for portable and single dose purpose. It is associated with vertical form sealing. It is usually used in food industry, pharmaceutical and cosmetic industry.

6.Do you know the components of stick pack packaging machine?

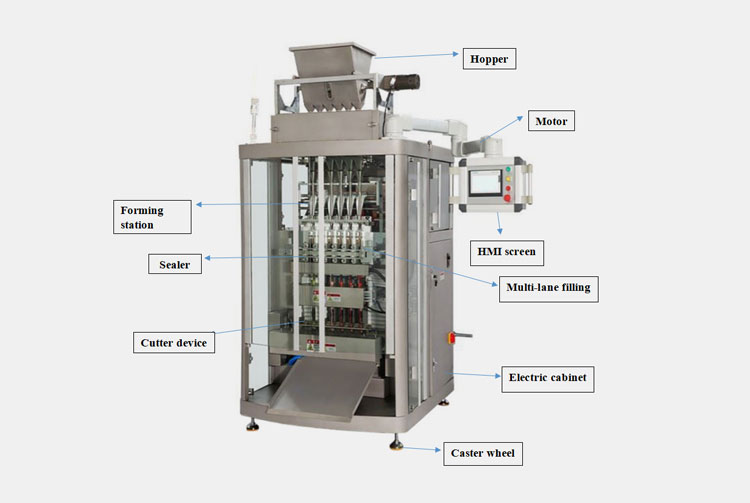

Allpack stick pack packaging machine parts

The detailed components of the stick pack packaging machine are as follows:

| Parts | Function |

| Hopper | The hopper is the part of machine where storage of products occur. It is at the top of the machine and usually square in shape. It feed the products for the filling purpose. |

| Motor | Motor is used for the smooth operation of each station across the machine. It drives the movement of film forming, filling system and movement jaws for precise task like filling and sealing. |

| HMI screen | HMI screen is the surface which allows the operator to set the operation parameters like stick pack length, filling dose, sealing temperature and number of lanes. You can get benefit from this by diagnosing the fault and machine control. |

| Electric cabinet | Electric cabinet contains wiring, PLC, breakers and emergency button. It coordinates communication between sensors and motors. |

| Forming station | The forming station is designed for forming the multiple narrow tubes. |

| Multi-lane filling | Once the film tubes are formed and vertically sealed, the product from the hopper fills in these tubes. The filling is done through the multi-lane filling device. |

| Sealer | After the products filled, the horizontal sealing jaws are used for the sealing of the top and bottom end of the stick packs. |

| Cutter device | The continuous strip of the horizontal sealed stick packs are then cut into individual units by using cutter device. |

| Caster wheel | Caster wheel is used for the moving purpose of the machine. You can easily move the equipment by using caster wheel. |

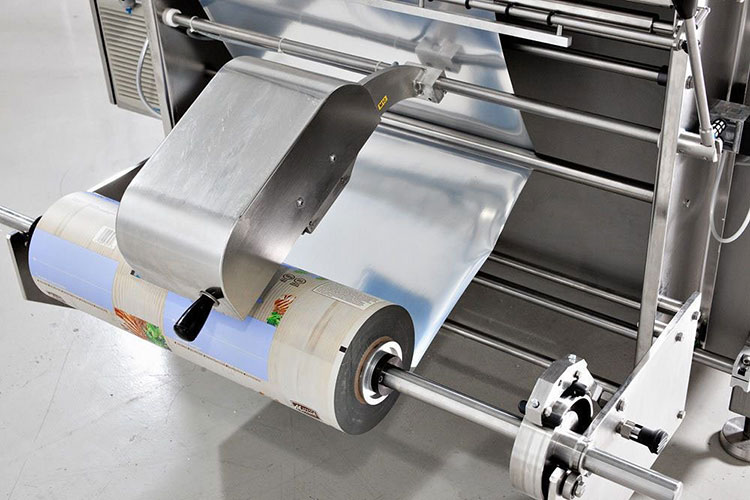

7.What are the working steps of the stick pack packaging machine?

Stick pack packaging machine production line

The working steps of the stick pack packaging machine are automatic and sequential to form roll films into individual stick filled packs. The detailed steps are as follows:

| Steps | Explanation |

| 1. Film unwinding

|

A roll of packaging material like foil, laminated foil or paper is placed on the unwinding unit. The feeding of this foil into the machine is done by the rollers guide. |

| 2. Film slitting

|

The film is then cut into various film sticks by using rotatory or stationary blades. |

| 3. Forming

|

Each film stick are converted into narrow tubes by using forming collar. The stick packs are formed when the film is fold or wrapped into tube shaped. The edges of the stick packs are also ready for the sealing. |

| 4. Vertical sealing

|

For the continuous longitudinal tube formation, the edges are sealed by using heated vertical sealing jaws. |

| 5. Filling | The sticks are then filled with powders, liquid and granules from the hopper. |

| 6. Horizontal sealing | After the filling, the top and bottom edges are done by using horizontal sealing jaws. |

| 7. Cutting | Then the cutter device is used for the cutting of individual units in secure, clear and accurate cutting. It also ensures each sealing of the stick pack is intact. |

| 8. Discharge | The finishes stick packs are then discharge through conveyor outside the machine. The stick packs are collected into the trays and further proceed for packaging or for cartoning. |

8.What kind of seal preformation’s are available in stick pack packaging machine?

You often find your favorite chocolates in different styled preformation or the way, the stick pack formed and sealed. This is due to the magic of stick pack packaging machine. The key difference in every type of seal preformation lies on the product types, desired aesthetic and packaging film. Let’s unravel the main types in detail:

Fin seal preformation

Fin seal preformation

As the name suggested, in fin seal, the fin like structure created which bulge from the back side. The packs are formed when the two inner surfaces of the film are sealed together. This sealing type is very strong and suitable for liquid or greasy products.

Three side seal

Three side seal

As the name suggested, the three sides are sealed before filling the products in to stick packs. The sealed sides are two vertical sealing and one horizontal sealing occur. After filling the products into stick packs, the top sealing is created. This create a smooth appearance and you can easily tear it down.

Small dose products are packed in such kind of sealing. This is suitable for the packaging of powder and granules in stick packs.

Contour seal

Contour seal-Picture courtesy: cardomax.com

In contour seal, instead of getting straight edges of the packs, uniquely shaped sealing patterns are created. This seal provide tight sealing and good grip for the consumers. As the sealing is strong so, suitable for child resistant. The industries that get most benefited by using contour seal are cosmetic and luxury food industry.

Ultrasonic seal preformation

Ultrasonic seal preformation-Picture courtesy: honorpack.com

For sealing of films, usually heat sealing is done but in ultrasonic seal preformation, ultrasonic vibration fell on the film and seal it. This type of sealing is done if temperature sensitive products like enzymes, are desired to be packaged because if heat-sealing procedure is created, then it may affect the products. You can get strong sealed stick packs by using this preformation.

9.How many stick pack styles are available in stick pack packaging machine?

There are various types of stick pack styles are available in stick pack packaging machine depend on the product type, machine configuration and branding type. The detailed explanation is given as follows:

Standard stick pack

Standard stick packs

This is the most common stick pack style in which three sides are sealed, you can say fin sealing procedure is done in this style. The most common products packed in this stick packs are sugar, dietary supplements and flavoring. You can apply this standard stick pack style in pharmaceutical, food, neutraceutical and beverage industry.

The consumers can get advantages by this styled packs are the products remains safe in these packs and customers can easily tear the seals as well.

Tapered stick pack

Tapered stick pack-Picture courtesy: allure.com

You most encountered the packs in which one end is narrow as compared to the other end. This type of sealed packs are usually can be seen in pharmacy shelf and cosmetic and skincare stores. Creams, lotion, drinks or single-use dosage pharma products are usually packed in tapered stick packs. You can easily pour the products without creating mess.

Rounded end stick pack

Rounded end stick packs

If your customers are conscious about the eye-catchy products or packing, then you can create a stick packs in which the top and bottom ends are round in shaped instead of flat ends. You should handle it carefully by cutting and sealing the film. The products usually packed in round end stick packs are collagen powder and beauty drinks for giving them premium look.

Notched stick pack

Notched stick packs

This type of stick pack is similar to standard stick pack but here, small cut or notch is added near to the seal to make the tearing procedure easy for a consumers. The consumers can easily tear the pack without error and wastage of products. You may also don’t need scissor for cutting purpose. All the industries can adopt this styled stick packs especially food and skincare industry.

Custom shaped stick pack

Custom shaped stick pack-Picture courtesy: us.revivecollagen.com

In this styled stick packs, various shapes like heart, wave and petals are created by using professional die-cut tools. If you are making children products, luxury cosmetics and if you are promoting your products then custom shaped stick packs is suitable for your products packing. But you have to carefully handle the whole mechanism of forming and sealing procedure of the packs.

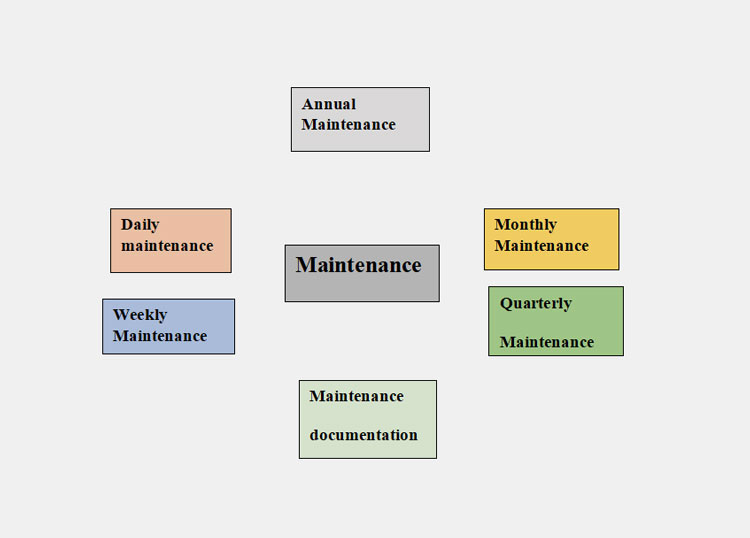

10.What are the maintenance required for stick pack packaging machine?

Behind every perfectly packaging machine, the high precision and high quality products creating lies in the care of the machine. For the efficient and smoothly operation of stick pack packaging machine, you have to take care of this machine in the following ways:

Daily Maintenance

Cleaning and inspection of machine parts-Picture courtesy- canadianmetalworking.com

Before and after the operation, you have to clean and visual inspect the machine parts.

Cleaning:

Before start the machine, you must make sure every part is dust free. Clean the hopper, filling tubes, and sealing jaws etc. to avoid any contamination. Clean the cutting blades and conveyor also to make them free of germs.

Visual inspection:

You must ensure that there is no cracked, or wear or tear parts in the machine. Also, look for any leaks in the hopper or any other parts. Emergency button plays a crucial role for controlling the machine in case of emergency, so also inspect it.

Weekly Maintenance

Weekly maintenance-Picture courtesy: advancedtech.com

Once in a week, you have to inspect the sealing jaws, belts, chains etc. for proper and smoothly working of the machine parts. You can also lubricate the machine joints and moving parts with food-grade lubricants to ensure the smooth operation of the machine.

Monthly Maintenance

In a month, calibrate the sensors, PLC and load cells for proper working of the machine. Also, you should inspect the wires, gears and motor response for accuracy.

Quarterly Maintainenace

You should inspect the machine parts, if you observe wearing then replace them. You can also replace the cutting blades for neat and clean cutting of stick packs. You can also diagnose the full system of machine for filling, sealing etc. procedure.

Annual maintenance

Annual maintenance-Picture courtesy: choongngaiengineering.com

In a year, you should disassemble all the parts of the machine, clean, lubricate them. If you want to replace any part, then you have to replace them as well.

Maintenance documentation

You have a complete documentation of machine parts being replaced, calibration setting, and service date of the machine and downtime records for the machine.

11.What are the safety measures you should consider while investing in stick pack packaging machine?

Safety measures while investing in stick pack packaging machine

While investing on the stick pack packaging machine, safety is as important as the production, precision and smooth operation of the machine. Here are some of the tips you should consider while investing in stick pack packaging machine.

| Tips | Explanation |

| 1. Certification | The machine must be abide by the international safety standards or you can say, you must invest on the certified machine. |

| 2. Emergency stop button | For the safety of machine as well as the surrounding, emergency button plays a crucial role. For this purpose, always inspect the emergency button so that the operator should stop the machine in case of emergency.

Always look for the emergency button that is easily accessible from all the direction. |

| 3. Overload and overheat protection | Always look for the heat sensors and circuit breakers. The purpose of these is to detect the overheating and overloading if occurred.

The sensors and breakers prevent the electric wires from getting fire and also avoiding the mechanical failure. |

| 4. Interlock safety guards and covers | The covers on different parts like blades, filling station and sealing jaws should be inspected. If the covers are opened, then the machine automatically stops.

The purpose of interlock safety guards are to provide safety to the moving parts during processes. |

| 5. Operator training | If you wants to get high precise and risk free packaging, then the supplier must train the operators. The operator must should have the information about the machine parts, processing it and handling the emergency situation. |

| 6. Noise and vibration control | Your machine must also have anti-noise and anti-vibrational mounts. For the safety of machine and for the operator, these functions incorporation into the machine are very important. |

| 7. Automatic fault detection | Sensors and audio and visual alarm should be incorporated into the machine. In case of any emergency, alarm alert the operator to stop the machine via emergency button. |

Conclusion

In 2025, different industries like pharmaceutical, chemical, cosmetic and food industries packed various powder, granules and liquid products in the stick packs. These industries also ensuring the good quality, same quantity dose and well-sealed package for the consumers’ safety and satisfaction. So, for this purpose stick pack packaging machine is not an optional equipment but it is necessity in every industry. Allpack is providing you a certified stick pack packaging machine and also ensuring you, a good quality products production by the machine and consumers’ satisfaction. I hope you like our blog and if still you have any query, feel free to ask have!

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide

Tell us your material or budget, we'll reply you ASAP within 24 hours

Stick Pack Packaging Machine: The Complete FAQ Guide In 2025 Read More »

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply to you ASAP within 24 hours

Tell us your material or budget, we'll reply to you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours