Industrial Labeling Machine: The Complete Buying Guide in 2024

Industrial Labeling Machine: The Complete Buying Guide in 2024

Industrial labeling machines have become an integral part of modern manufacturing and packaging processes. They help in streamlining production, ensuring accuracy, and reducing manual labor. In today’s fast-paced and ever-evolving market, choosing the right labeling machine for your business can be a challenge.

This buying guide is designed to help you make an informed decision and find the best industrial labeling machine for your needs in 2024. It covers the latest advancements in technology, key features to look for, and provides a comprehensive overview of the market to help you make a well-informed purchase decision. Read on, so we can help you buy the right industrial labeling machine.

1.What Is An Industrial Labeling Machine?

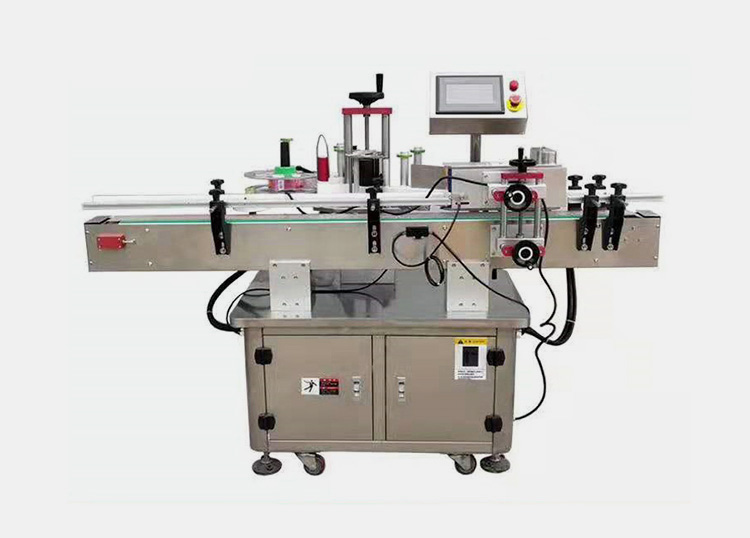

An industrial labeling machine is a device used to apply labels to products, packages, or containers in an automated, efficient and consistent manner. These machines are typically used in manufacturing, packaging and warehousing facilities to label products with important information like barcodes, serial numbers, expiry dates, and other vital data.

Industrial labeling machines come in different types, such as automatic, semi-automatic and manual labeling machines, and are designed to handle a wide range of labeling applications, from small labels to large ones. These machines are essential for improving efficiency, reducing labor costs, and ensuring consistent product labeling.

2.What Are The Different Components Of An Industrial Labeling Machine?

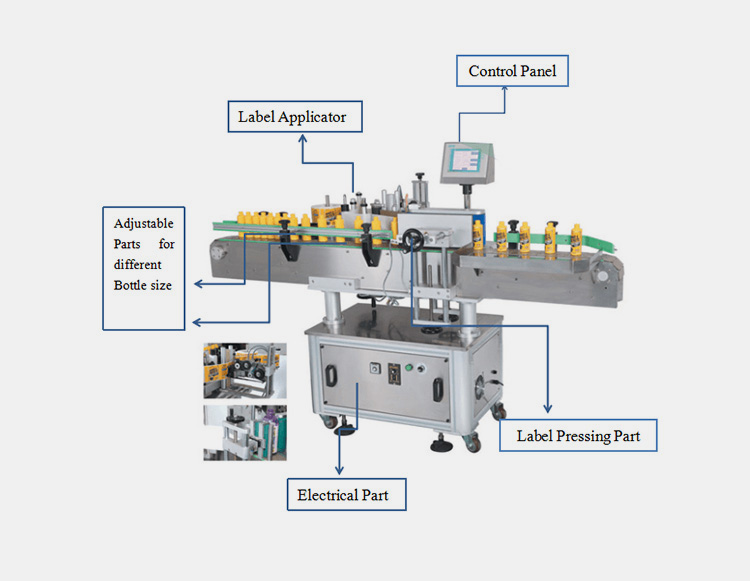

There are different components of an industrial labeling machine, and they include:

Label Roll Holder

This is a spindle that holds the roll of labels to be applied. It is designed to accommodate different label roll sizes and ensures that the label is fed into the machine without wrinkles or other deformities.

Label Dispenser

The label dispenser is a critical component of the labeling machine. It applies a consistent amount of pressure to the label material, ensuring that it is released from the backing paper or liner. The dispenser can also adjust the speed of the labels to match the production line speed.

Applicator Mechanism

This component applies the labels to the product or package. It can use different techniques like pressure-sensitive, heat transfer, or print and apply to apply the labels. The applicator mechanism can be fixed or adjustable, depending on the product or package’s size and shape.

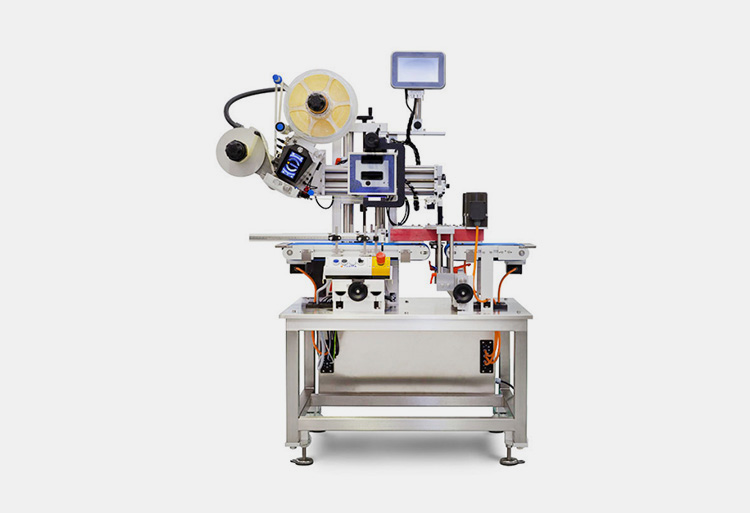

Print engine

The print engine is an optional component that allows the labeling machine to print variable data, such as barcodes, serial numbers, or expiration dates, on the label material before applying it to the product or packaging. It can be a thermal transfer or direct thermal printer, depending on the label material and application requirements.

Control Panel

This component controls the machine’s operation and settings. It includes a display screen, keypad, and buttons that allow the operator to set the label size, print information, and adjust the applicator mechanism. The control panel also displays any error messages or alerts that require attention.

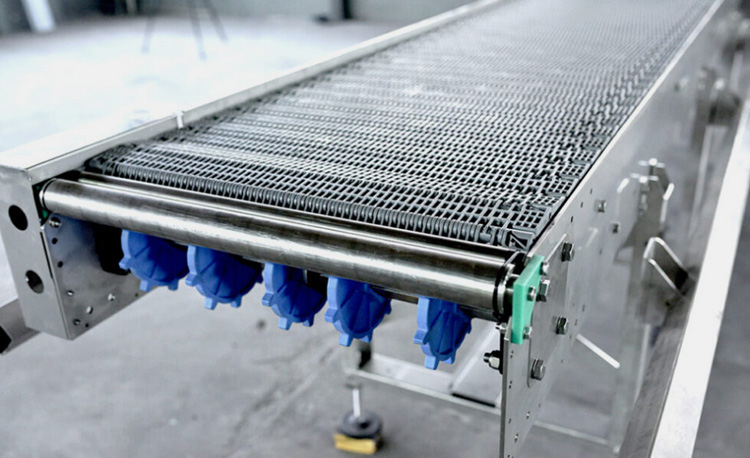

Conveyor system

The conveyor system is the component that moves the product or packaging through the labeling machine. It can be a belt, roller, or chain conveyor, and it usually has an adjustable speed control to match the labeling speed.

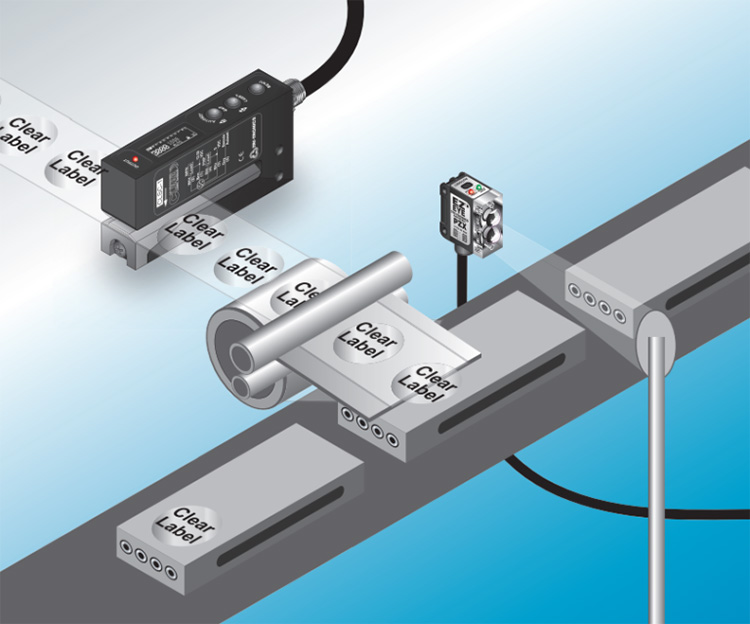

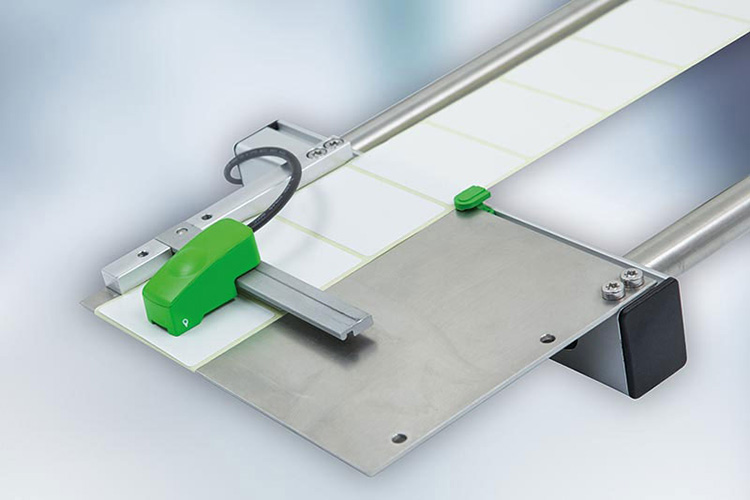

Sensors

This component detects the products or packages and ensures that the labels are applied in the correct position. The sensors can be photoelectric, ultrasonic, or capacitive, depending on the product or package’s characteristics.

3.How Does An Industrial Labeling Machine Work?

An industrial labeling machine is designed to apply labels to various products, packaging, and containers in a fast and efficient manner. The machine works by following a pre-programmed set of instructions that determine the placement, type, and size of the labels to be applied.

The process starts with the operator loading the labeling machine with labels and the products or containers to be labeled. The label dispenser, which holds a roll of labels, feeds the labels onto a roller system. The roller system then separates the labels and applies an adhesive backing to the labels.

The label applicator then picks up the label and positions it over the product or package. The label is then pressed onto the surface with the help of a pressurized system, ensuring that it adheres properly.

The labeling machine is usually controlled by a computer system, which allows operators to customize the labeling process according to the specific requirements of the product or package being labeled. This includes adjusting the label size, the positioning of the label, and the amount of pressure applied during the labeling process.

4.What Are The Applications Of An Industrial Labeling Machine?

Here are some applications of industrial labeling machines in different sectors:

Food and Beverage Industry

The labeling of food and beverage products is an essential part of the industry, and an industrial labeling machine can increase the speed and accuracy of this process. These machines can label product containers, bottles, and cans with critical information such as nutritional values, expiration dates, and barcodes.

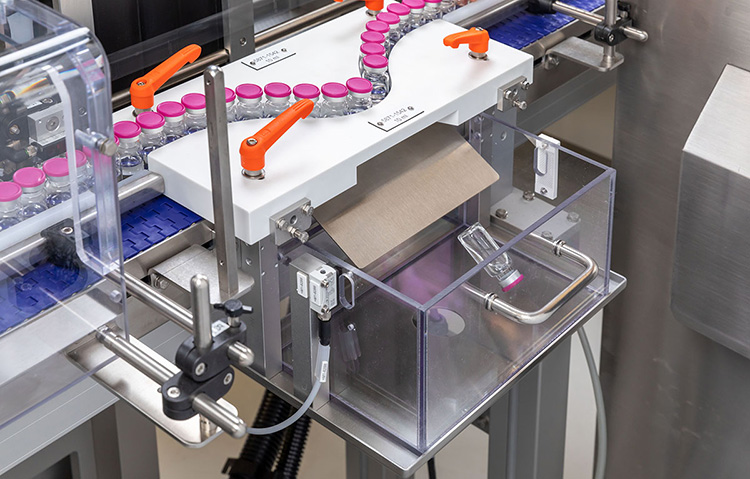

Pharmaceutical Industry

The pharmaceutical industry requires accurate and detailed labeling of products for safety and regulatory compliance. Industrial labeling machines can handle the labeling of small vials and bottles and print information such as dosage, expiry date, and batch numbers.

Chemical Industry

In the chemical industry, labeling machines are used to apply labels to chemical containers and packaging. The labeling machine can be used to apply product information such as warning labels, hazard symbols, and other safety information.

Automotive Industry

The automotive industry requires labeling for parts, components, and finished products. Industrial labeling machines can handle the labeling of automotive parts, such as engines, batteries, and tires, with barcodes, serial numbers, and other identification information.

Textile Industry

In the textile industry, labeling machines are used to apply labels to clothing items such as t-shirts, pants, and jackets. The labeling machine can be used to apply product information such as brand logos, product names, and care instructions.

Electronics Industry

When it comes to the electronics industry, labeling machines are used to apply labels to electronic products such as smartphones, computers, and other devices. The labeling machine can be used to apply product information such as model numbers, serial numbers, and other technical specifications.

5.What Are The Advantages Of Using An Industrial Labeling Machine?

There are several advantages to using an industrial labeling machine, including:

Efficiency

An industrial labeling machine is much faster than applying labels by hand. The machine can apply labels to products at a much higher rate, allowing companies to increase their production speed and output.

Accuracy

With an industrial labeling machine, the labels are applied with precision and consistency. The machine can be programmed to apply labels to specific locations on products, ensuring that every label is placed in the same spot every time.

Cost Savings

An industrial labeling machine can help reduce labor costs, as fewer employees are needed to apply labels manually. Additionally, because the labels are applied with accuracy and consistency, there is less waste due to misapplied or misaligned labels.

Flexibility

Industrial labeling machines can handle a wide range of label sizes and shapes, and can be adapted to work with different types of products and packaging. This flexibility can be useful for companies that produce a variety of products.

Customization

An industrial labeling machine can be programmed to print and apply labels with specific information, such as serial numbers, lot codes, barcodes, or other data. This can be important for traceability and inventory management.

Improved Productivity

By automating the labeling process, an industrial labeling machine allows employees to focus on other tasks, improving overall productivity.

Compliance

An industrial labeling machine can help ensure that products are labeled in compliance with industry and regulatory requirements, reducing the risk of fines and penalties.

6.What Are The Different Types Of Industrial Labeling Machines Available?

There are various types of industrial labeling machines available in the market, each with its specific features and applications. Some of the most common types of industrial labeling machines are:

Manual Industrial Labeling Machines

Manual labeling machines are operated by a person who manually applies labels to the products or packaging material. They are used for small-scale productions, low-volume labeling requirements, and occasional label changes. Manual labeling machines are affordable and easy to operate.

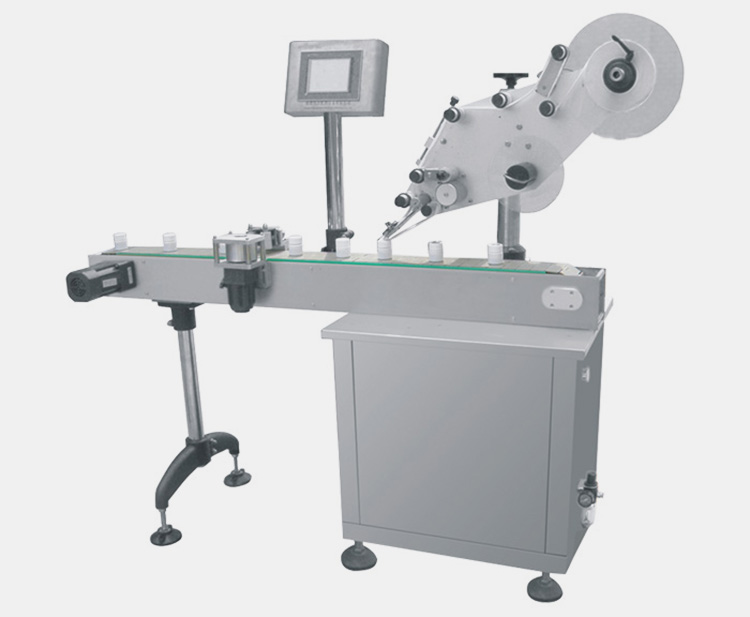

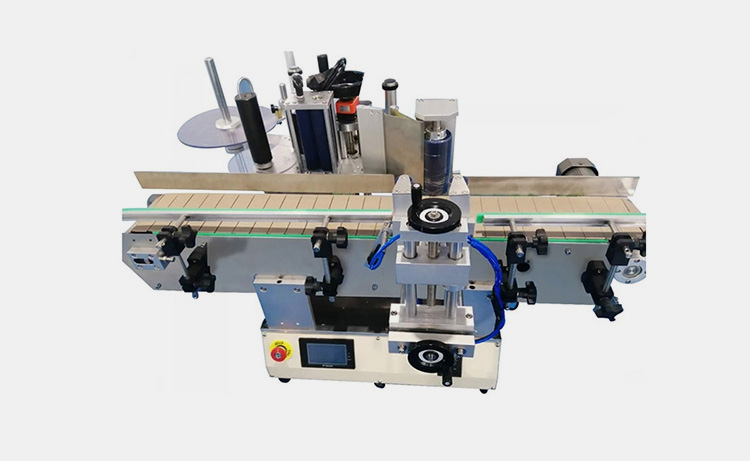

Semi-Automatic Industrial Labeling Machines

Semi-automatic labeling machines require a human operator to load the products or packaging material into the machine. The machine then applies the label automatically. These machines are ideal for small to medium-sized productions and are suitable for a wide range of label sizes and materials.

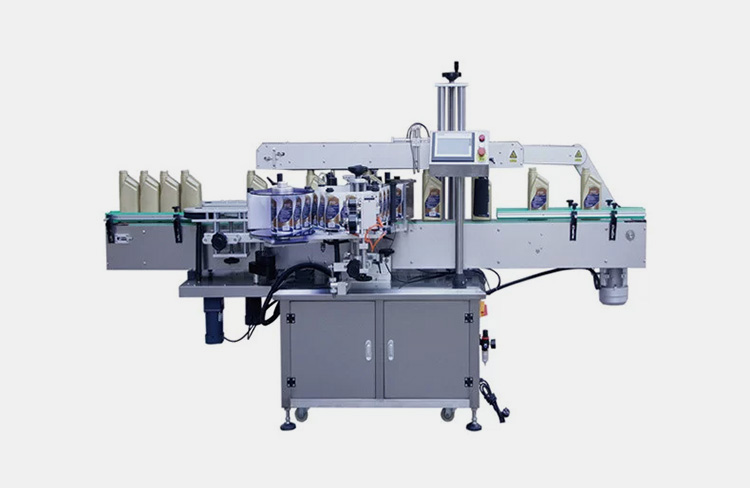

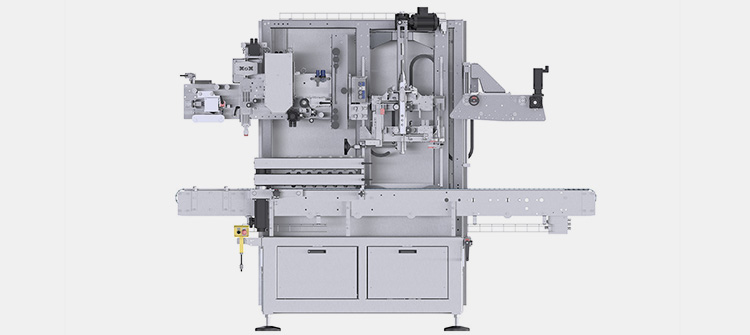

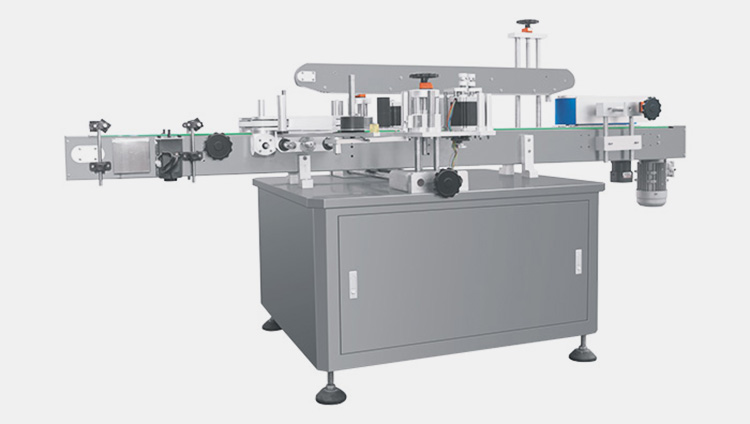

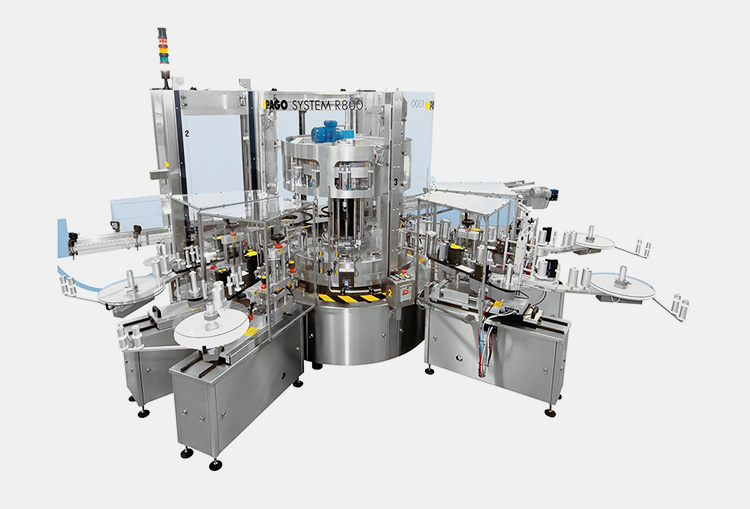

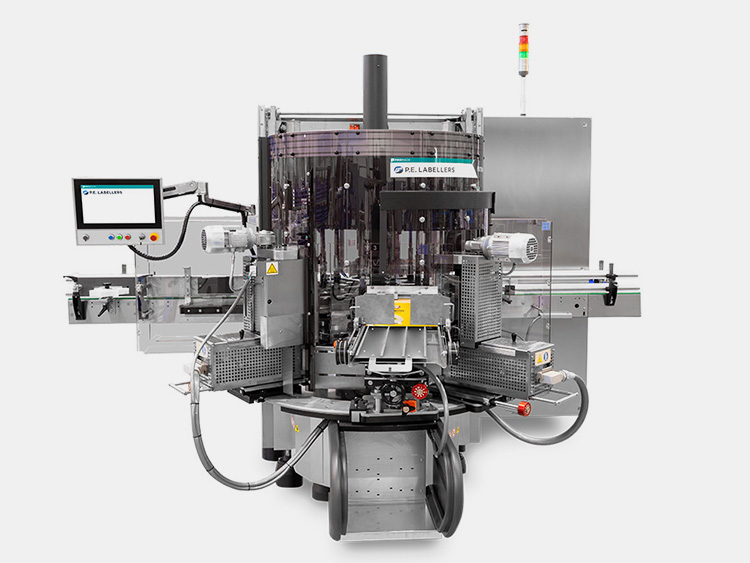

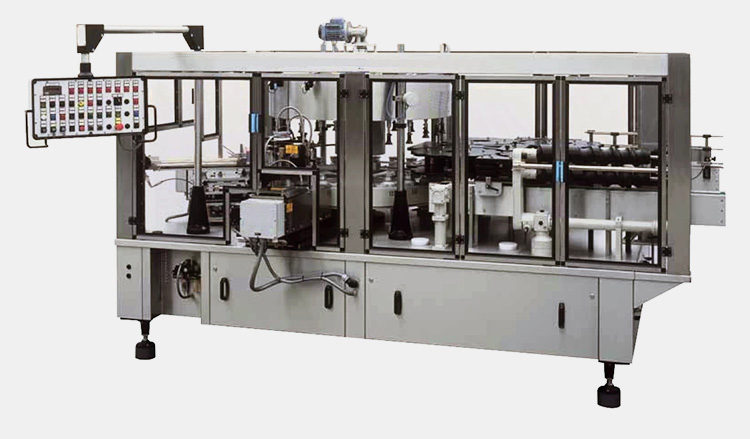

Automatic Industrial Labeling Machines

Automatic labeling machines are fully automated and can handle high-volume productions. They are designed to apply labels to products or packaging materials without any human intervention. These machines are efficient, accurate, and can handle a variety of label sizes and shapes.

Wrap-Around Labeling Machines

These machines are designed to apply labels to the entire circumference of a product, such as bottles or cans. They can be customized to handle different sizes and shapes of products.

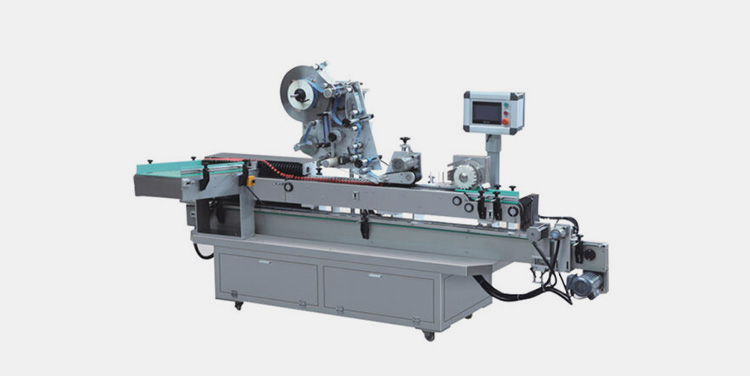

Front and back labeling machines

Front and back labeling machines are used to apply labels to both the front and back of the product simultaneously. These machines are ideal for products such as bottles, jars, and containers, where both sides need labeling. The machine applies the label to one side of the product, and then the product is rotated, and the label is applied to the other side.

7.What Are The Common Materials Used For Labeling On An Industrial Labeling Machine?

An Industrial Labeling Machine requires specific materials for labeling, which can vary depending on the application and the product being labeled. The following are some of the most common materials used for labeling on industrial labeling machines:

Vinyl

Vinyl labels are a popular choice for industrial labeling because they are durable and weather-resistant. They can withstand extreme temperatures, UV exposure, chemicals, and water. They are also easy to apply and come in various colors and sizes.

Polyester

Polyester labels are similar to vinyl labels in terms of durability and resistance to harsh conditions. They are also resistant to abrasion, tearing, and fading. They can be used for outdoor labeling and in environments that require high resistance to chemicals and solvents.

Paper

Paper labels are often used for labeling products that do not require high durability or exposure to harsh conditions. They are easy to print and can be used for indoor labeling, inventory management, and product identification. However, paper labels are not weather-resistant and can tear easily.

Polypropylene

Polypropylene labels are ideal for labeling applications that require high chemical resistance, such as in the chemical industry. They are also resistant to UV exposure, water, and extreme temperatures. They are a good option for labeling products that require long-term identification.

Acetate

Acetate labels are a good option for labeling applications that require high temperature resistance. They can withstand temperatures of up to 300°C and are often used for labeling electronic components and appliances.

Foil Labels

Foil labels are made of metallic material and are commonly used for branding and product identification. These labels are available in a range of colors and finishes, including silver, gold, and holographic. They provide a high-end look and feel to products and are ideal for use in the packaging of luxury goods.

8.Are Industrial Labeling Machines Easy To Use And Operate?

Industrial labeling machines can be easy to use and operate. They are designed to simplify the labeling process and make it more efficient, even for non-technical users. The level of ease of use, however, may depend on the specific type and model of the machine and the user’s experience and training.

Some machines may require more complex setup and maintenance, but many manufacturers offer training and support to ensure the user can operate the machine effectively. Additionally, there are labeling machines with intuitive interfaces and automated features that can simplify the labeling process and minimize errors.

9.What Are The Differences Between An Automatic And Manual Industrial Labeling Machine?

Automatic labeling machines are designed to operate automatically without the need for manual intervention. They use sensors to detect and label products on the production line. They are faster, more accurate, and can handle a larger volume of products than manual labeling machines. Automatic labeling machines also require less maintenance, are easier to operate, and can be integrated with other automated equipment in the production line.

Manual labeling machines, on the other hand, require an operator to load and label the products manually. They are slower, less accurate, and can only handle a limited number of products. However, they are more affordable, versatile, and suitable for smaller production runs or custom labeling requirements. Manual labeling machines also provide more control and flexibility over the labeling process, as the operator can adjust the label placement and alignment as needed.

In summary, the choice between automatic and manual labeling machines depends on the production requirements, budget, and level of automation needed for the labeling process.

10.How Is An Industrial Labeling Machine Different From Standard Labeling Machine?

An industrial labeling machine is specifically designed to meet the requirements of high volume, round-the-clock labeling applications. These machines are built to withstand the demands of industrial environments, such as harsh temperatures, moisture, and dust. The machines can also handle a wide variety of materials, including metal, plastic, and glass. It is typically larger and more robust than a standard labeling machine, and can handle larger volumes of labels and materials.

Industrial labeling machines may also be designed to apply labels to a wider range of surfaces, including curved or irregular surfaces, and may use specialized labeling materials, such as heat-resistant or chemical-resistant labels.

In addition, industrial labeling machines may incorporate features such as automated labeling, barcode scanning, and data tracking and management, which are important for ensuring accurate and efficient labeling in industrial settings.

11.What Type of Products can be Labeled with An Industrial Labeling Machine?

An industrial labeling machine is a versatile piece of equipment that can label a wide range of products. The types of products that can be labeled with an industrial labeling machine include:

Soda

Soda bottles typically feature labels that have been printed on with an industrial labeling machine. This machine is capable of printing large quantities quickly, making it ideal for mass-produced products like soda.

Bottled water

Like soda, bottled water can be labeled using an industrial labeling machine. This method is especially efficient when it comes to printing large quantities of labels, which is beneficial for companies that sell bottled water. The machine can quickly and accurately apply labels to bottles of all shapes and sizes.

Candy Bars

An industrial labeling machine can label candy bars with brand names, nutritional information, and product details. The labels can be applied to different types of packaging, including cardboard boxes, plastic wraps, and foil wrappers.

Milk

Dairy products such as milk, yogurt and cheese are also often labeled with industrial labeling machines. This helps to provide shoppers with accurate information about the product, including its expiration date, nutritional facts and fat content. Labeling machines can also be used to add promotional messages or offers to the packaging of these products.

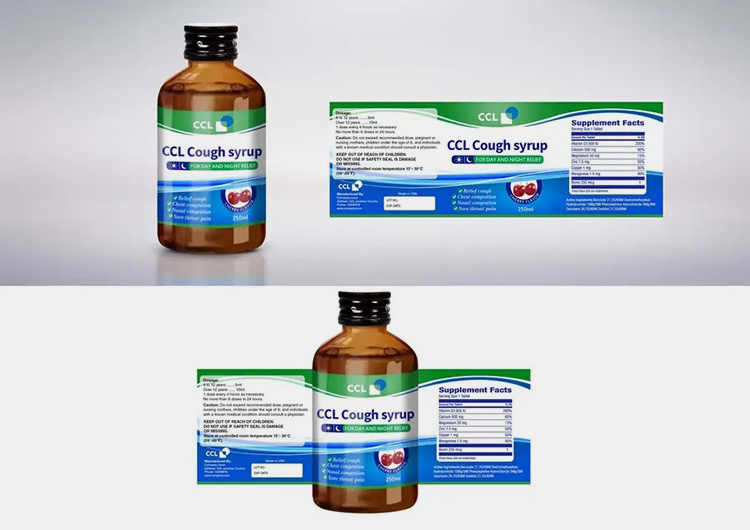

Pharmaceutical Syrup

Industrial labeling machines are frequently used for labeling pharmaceutical syrup bottles due to their accuracy and speed. These labels contain important information about the ingredients in the product and directions for use, as well as warnings and disclaimers.

Clothes

Industrial labeling machines are often used for labeling clothes, such as t-shirts and jeans. Labels can be added to the back of these items, often bearing the company logo or a promotional message. They can also be used to add care instructions and washing symbols to clothing tags.

Automotive Lubricants

Industrial labeling machines are often used to label automotive lubricant containers, ensuring that these products have accurate and detailed labels regarding their contents. This helps consumers to make informed decisions when purchasing these items for use in their vehicle.

Batteries

Industrial labeling machines are often used for labeling batteries and their packaging, ensuring that important information about battery life or power ratings is displayed clearly for consumers.

Lotion/Makeup

Labeling machines are also used for labeling lotions and makeup products, ensuring that all necessary information regarding the product’s ingredients, expiry date and batch number is printed onto the label. This helps to ensure that customers have access to accurate information about these items before they purchase them.

Conclusion

Industrial labeling machines are convenient as they can meet demands of large and small batches, plus they require minimal human resources to operate. So, if you’re looking for a great machine without spending more than necessary then don’t hesitate to reach out to Allpack today and find out why they’re one of the largest suppliers in the world. Contact them now to learn more about their quality Industrial Labeling Machine and see how it could benefit your business.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide

Industrial Labeling Machine: The Complete Buying Guide in 2024 Read More »