Top 10 Global Bottle Labeling Machine Manufacturers: The Complete Guide In 2024

Top 10 Global Bottle Labeling Machine Manufacturers: The Complete Guide In 2024

Bottle labeling machines are an important part of the bottle filling and packaging process. After all the bottles are sterilized, cleaned, filled, and packaged, they need to complete labeling and printing. Therefore, do you know who are the well-known bottle labeling machine manufacturers in the world?

Do you know the models and designs of their corresponding well-known bottle labeling machines? This top 10 global labeling machine manufacturers can provide you with the most detailed company and bottle labeling machine information. Let's start reading!

Top 10 manufactures of bottle labeling machines in the world

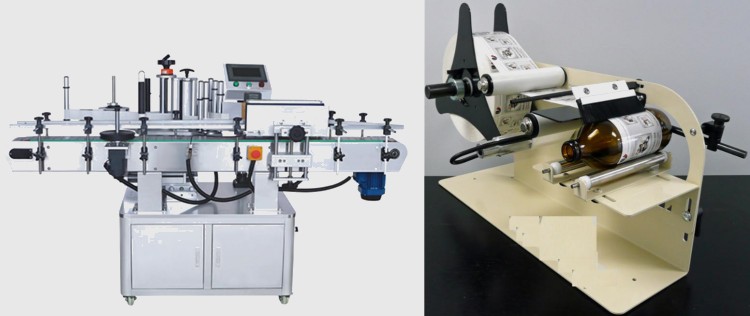

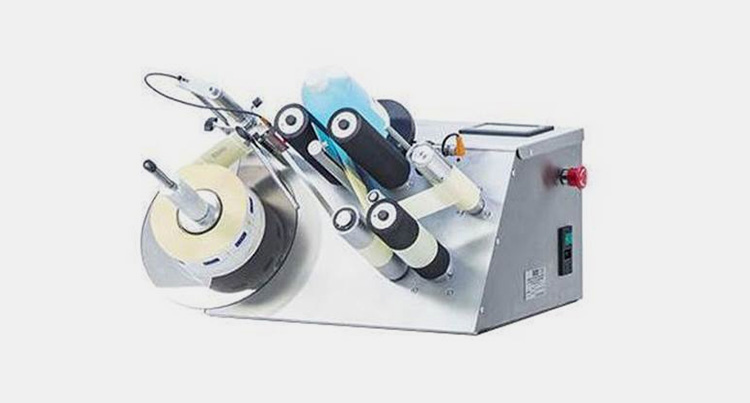

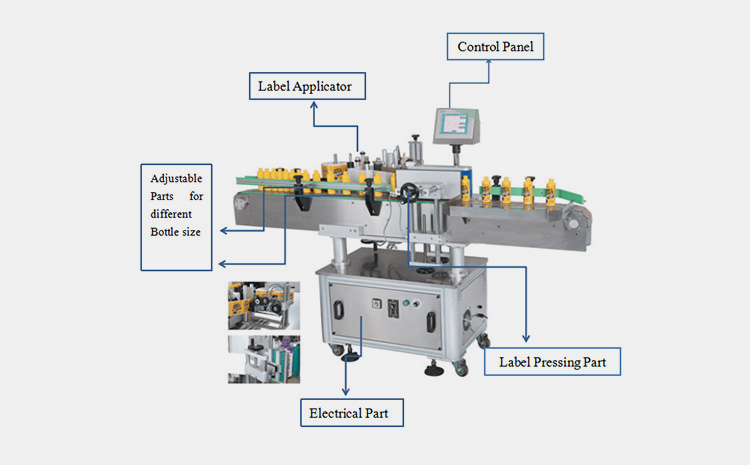

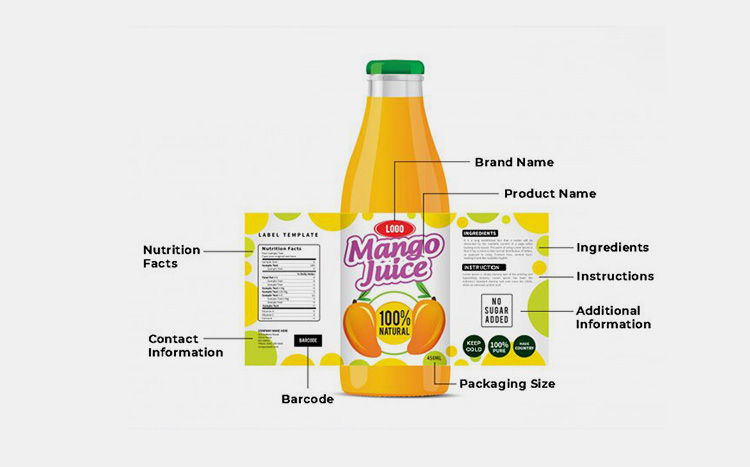

Bottle labeling machines are specially designed for applying different labels to your bottles with different methods. They include all semi-automatic types and fully automatic types.

The labeling machines are suitable for various bottles such as cosmetic bottles, shampoo bottles, shower gel bottles, medicine bottles, jam bottles, essential oil bottles, sauce bottles, wine bottles, mineral water bottles, beverage bottles, glue bottles, etc. with high efficiency and high quality.

Here are the top list of manufacturers:

| RANK | MANUFACTURES OF BOTTLE LABELING MACHINE | HEADQUARTERS |

| 1 | Sidel | Italy |

| 2 | Krones | Germany |

| 3 | Marchesini Group | Italy |

| 4 | ALLPACK | China |

| 5 | Fuji Seal | Japan |

| 6 | HERMA | Germany |

| 7 | SACMI | Italy |

| 8 | Accraply | USA |

| 9 | Accutek Packaging | USA |

| 10 | PE Labellers | USA |

1. Sidel

Company Background & Information

Sidel is a leading manufacturing company providing equipment and services for packaging and labeling liquids such as water; carbonated and non-carbonated soft drinks; sensitive beverages such as milk, liquid dairy products, juices, tea, coffee, isotonic and beer; food and home and personal care.

With more than 40 years of industry packaging and labeling experience, they are well aware of the need for attractive packaging and labeling, as well as the need for sustainable and cost-efficient production in order to meet increasing regulations and consumer demands.

Key Products

RollQUATTRO Evo

EvoDECO Roll-Fed

EvoDECO Adhesive

Recommend Reason

- Labeling PET containers, especially for soft drinks and water, primarily uses wraparound roll-fed technology, applying either paper or plastic labels with hot glue.

- Sidel Roll-fed labeling solutions deliver the flexibility needed to match all your needs.

- Furthermore, they are able to meet a fast-growing market trend that calls for efficient, high-speed machines able to handle lightweight containers with extremely thin labels.

- Using hot glue to apply wrap-around plastic labels and fully brush-less motorization, it can handle lightweight containers and ultra-thin labels, yet allowing for better glue control and distribution, together with reduced consumption.

2. Krones

Company Background & Information

Krones is a German packaging and bottling labeling machine manufacturer. It produces lines for filling and labeling beverages in plastic and glass bottles or beverage cans. With labelers from Krones, you can be sure that your product is an eye-catcher. Whether it's hot-melt, cold-glue, pressure-sensitive labels, or sleeves.

Key Products

Sleevematic TS

Sleevematic M

Sleevematic ES

Recommend Reason

- Thanks to rotary cutters which perforate the film sleeve continuously instead of in cycles, the Sleevematic TS can process 50,000 containers per hour.

- The higher the stretching rate, the lower the material consumption.

- The infeed worms are stored directly in the machine and therefore ready for use at any time.

- Sleevematic TS requires significantly fewer handling parts than all other sleeving systems.

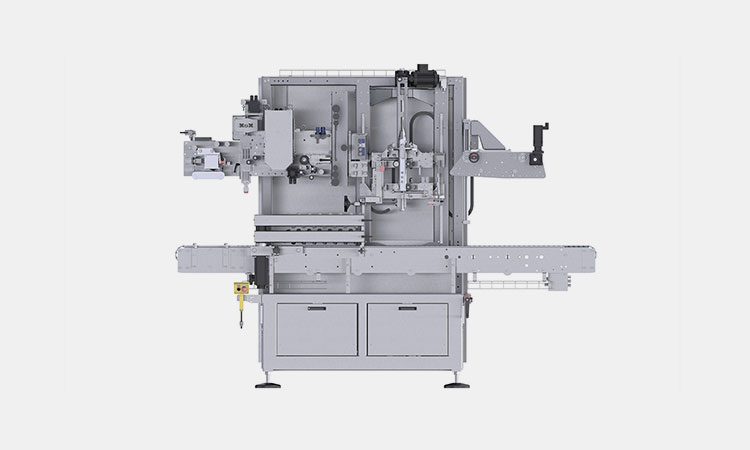

3. Marchesini Group

Company Background & Information

Marchesini Group was established in Pianoro in 1974 by virtue of the shrewd intuition of Massimo Marchesini. They package and label bottles of every shape - oval, square, round, and rectangular - in different materials ranging from plastic to glass, and of all sizes, from small to larger-sized bottles.

Key Products

CL-F Series

SL SERIES

BL-H235

Recommend Reason

- CL-F Series automatic labeling machine suitable to apply one or two labels on oval, rectangular, and round containers and vials, and cylindrical bottles at low and medium speeds.

- Flexibility and versatility; it's possible to integrate on board different types of printing and camera systems.

- SL SERIES rotary labelers for the jar and specially cosmetic products with positive transport.

- Stabilizing the upper belt when labeling flat and oval products.

- High accessibility for easy maintenance and cleaning.

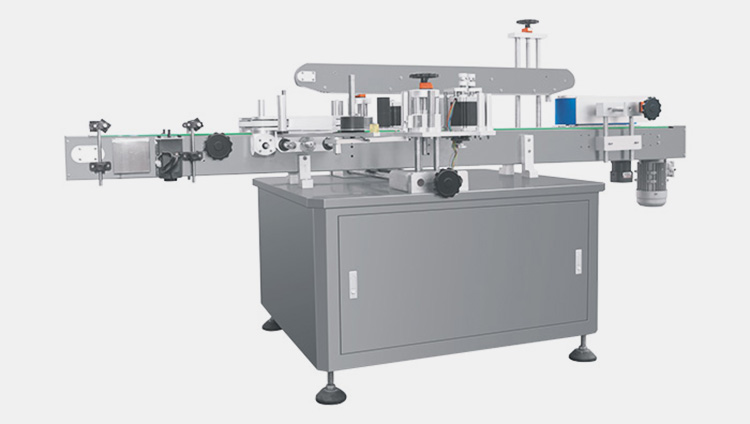

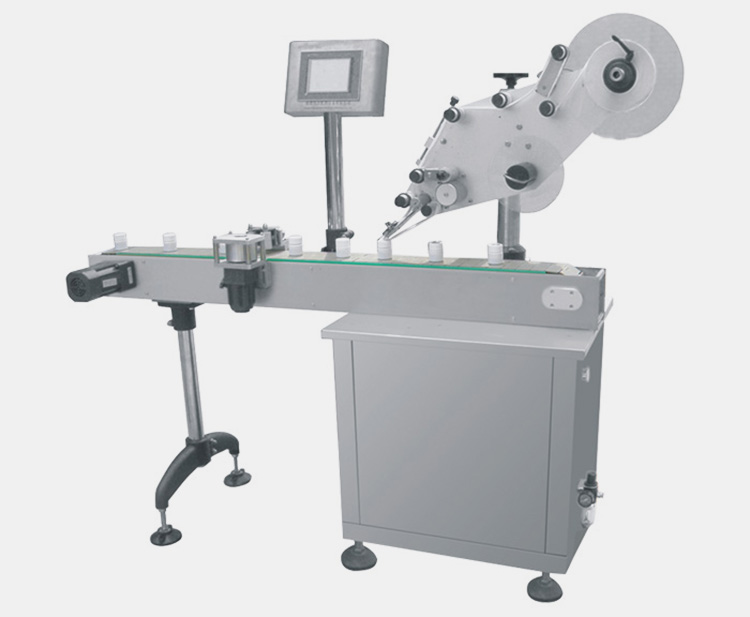

4. ALLPACK

Company Background & Information

ALLPACK is a professional food packaging & nutrition equipment manufacturer with 11 years of experience in packing machine labeling, and they focus on round bottles. The wide range of labeling machines and techniques in food packaging and nutrition by Allpack can offer you multiple assistance in different industries.

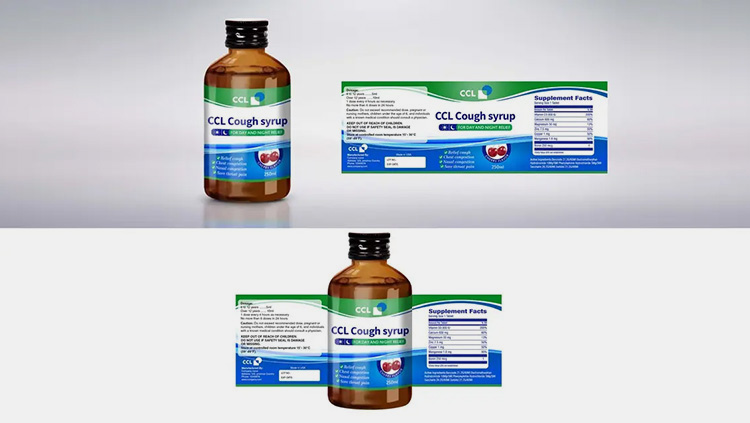

Allpack labeling machines are applicable to circumferential labeling of various cylindrical products. Such as cosmetic bottles, shampoo bottles, shower gel bottles, medicine bottles, jam bottles, essential oil bottles, sauce bottles, wine bottles, mineral water bottles, beverage bottles, glue bottles, etc.

Key Products

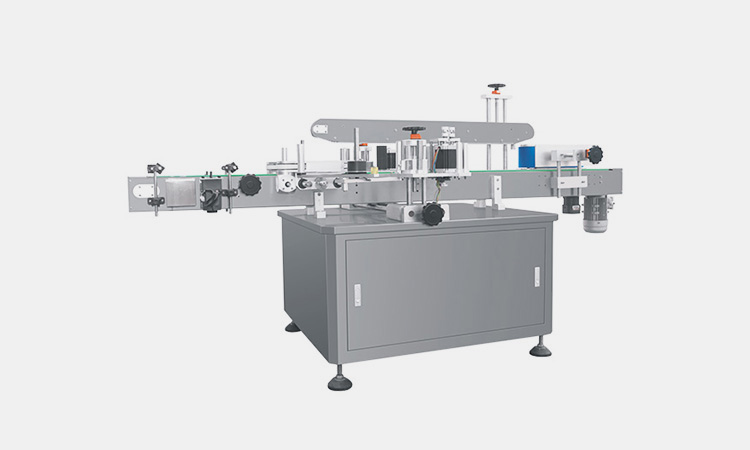

APC-T1 Round Bottle Side Face Labeler

APC-T2 Multi-function labeler

APC-T3 Top Face Labeler machine

Recommend Reason

- APC-T1 round bottle side face labeling machines adopt tension design to ensure the coding quality, and can accurately control the length and uniformity of the label.

- APC-T2 multi-function labeling machines adopt mature PLC control system technology that can make the whole machine stable and high-speed while you are handling and operating.

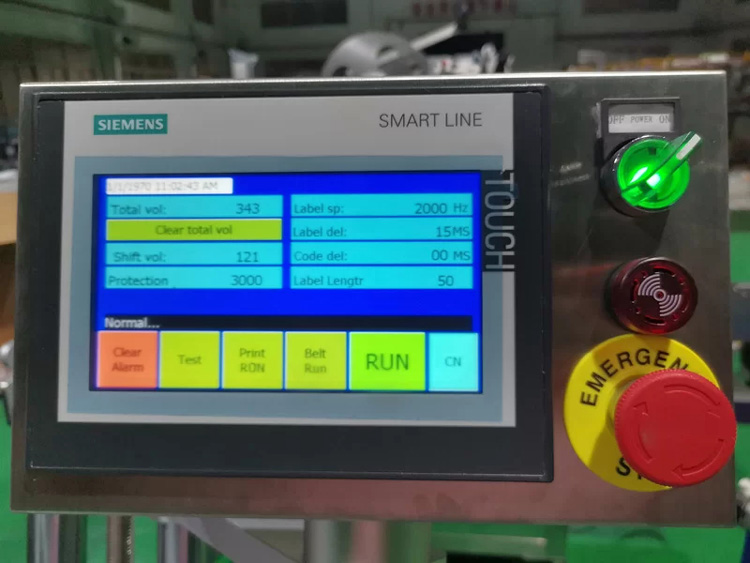

- APC-T3 top face labeling machines apply the SIEMENS brand PLC control system that can offer you a highly stable labeling operation and an extremely low failure rate.

5. Fuji Seal

Company Background & Information

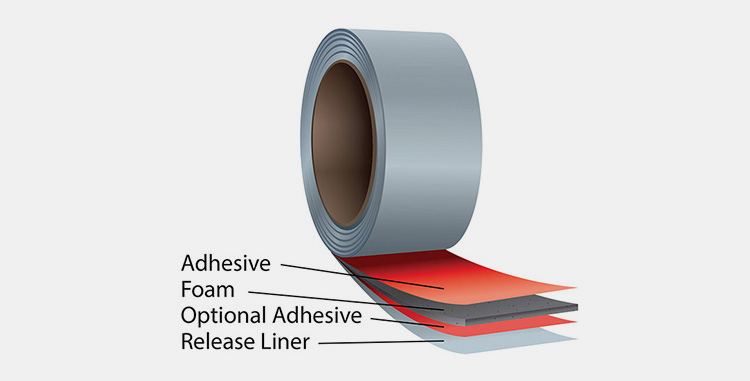

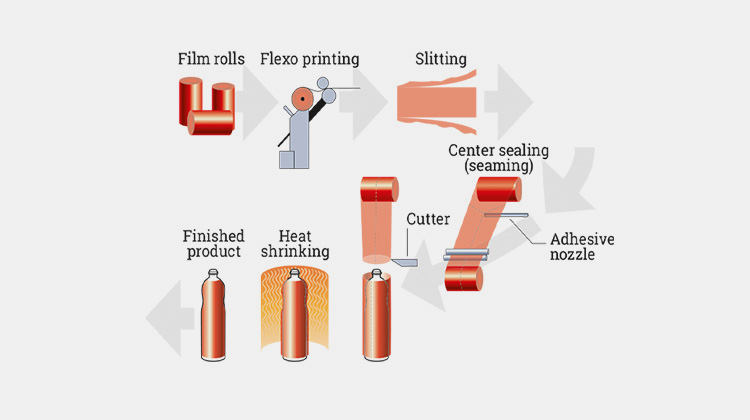

Fuji Seal is a provider of packaging and labeling solutions. The company's product portfolio includes shrink sleeve labels, self-adhesive labels, pressure-sensitive labels, spouted pouches, insulating labels, contour pak carriers, and in-mold labels (IML).

It involves developing, designing, and manufacturing labeling machines and machinery systems such as shrink labelers, stretch labelers, self-adhesive labelers, thermo-shield labelers, heat-activated labelers, spouted pouch equipment, and label-application machines.

Key Products

FujiSeal 200 SERIES

TLS-1000 SERIES

Fuji Seal 9000 SERIES

Recommend Reason

- The new sleeve applicator "TLS series" has been developed for handling thinner film, and is realized with one of the strong points of Fuji Seal Group.

- FUJI SEAL 9000 series shrink sleeve label applicators are intended for high-speed production lines.

- Fuji Seal 200 series is a linear shrink sleeve label application machine for medium and low-speed lines.

- It can handle several packaging materials and container shapes and simplifies mold change work.

6. HERMA

Company Background & Information

HERMA is one of Europe's leading manufacturers of self-adhesive technology, especially in labeling machines. As Europe's leading manufacturer of self-adhesive technology, they inspire with quality made in Germany and the UK - with consistent know-how from self-adhesive labels and material to labeling machines.

HERMA stands for strong self-adhesive material, high-quality labels, and precise modular labeling machines.

Key Products

Two-side labeler HERMA 362C

Wrap-around labeler HERMA 132M HC

HERMA Wrap-around labeler 152C

Recommend Reason

- Compact and stable labeling machine that works virtually without format parts and yet covers a very wide range of product formats.

- Flexible, quick, and easy to retool for precise side labeling.

- Its compact design makes it suitable even for difficult installation situations.

- Equipped with the high-performance labeler HERMA 500, it is suitable for up to 200 cylindrical products per minute.

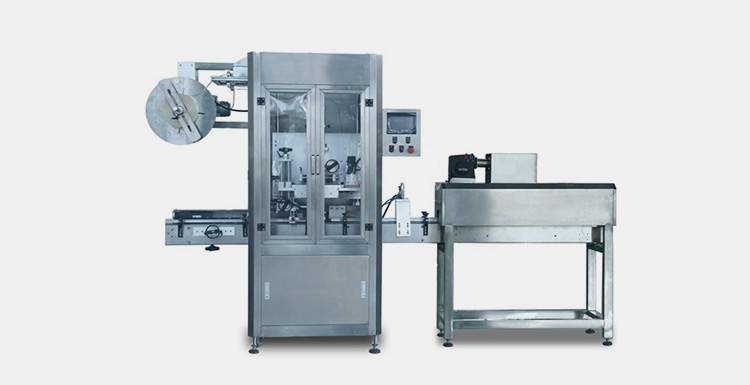

7. SACMI

Company Background & Information

SACMI is a supplier of machines and complete plants for the ceramics, metals, packaging, and plastic container manufacturing industries. SACMI designs and manufactures bottle filling and labeling machines and complete plants, developed on the basis of the specific needs of each individual customer, sector, and market.

SACMI covers a complete range of automatic and modular labelers for glass, plastic, and metal containers and bottles.

Key Products

ROLL-FED LABELING STATION

COLD-GLUE LABELING STATION

SELF-ADHESIVE LABELING STATION

Recommend Reason

- Possibility to decorate the same container with one or more labels of the same technology or with a combination of different labeling

- The operating parameters of the labeling unit can be changed directly from the control panel.

- Double profiled cam to obtain smooth, precise glue segment movements.

- Unwinding speed controlled by servomotors for increased performance and better control of label tension.

8. Accraply

Company Background & Information

As a member of the Barry-Wehmiller Family of companies, Accraply is the leading manufacturer of plastic bottle packaging and labeling machines. Accraply's unique plastic bottle labeling machines are the perfect solution for bottles of all shapes and sizes like the honey bear plastic bottle, dropper bottles, shampoo and conditioner, condiments, and more.

Each product has a specific shape that customers associate with the contents when they are browsing the store.

Key Products

Trine 4400 Roll-fed Labeling System

Trine 4450 Roll-fed Labeling System

Trine 4600 Roll-fed Labeling System

Recommend Reason

- The 4400 roll fed wraparound system has been designed with a 30% smaller footprint than previous machine while providing labeling speeds up to 200 cpm.

- The 4450 roll fed wraparound system has been designed with an extended conveyor and feed screw change parts standard for smooth high-speed container handling.

- The 4600 roll fed wraparound labeler is based off the industry standard Model 4500. With advanced technology, quicker changeovers, and affordable change parts.

9. Accutek Packaging

Company Background & Information

Accutek Packaging Equipment Companies, Inc. is one of the largest privately held packaging and labeling machinery manufacturers in the United States. They are a leading developer and manufacturer of complete turnkey packaging and labeling solutions.

Accutek packaging makes a variety of labeling machine equipment that can automatically place and secure most label types on a variety of containers. Accutek packaging offers three different labeling systems, all of which use cutting-edge technology to achieve the highest speed and accuracy in the labeling machine market.

Key Products

APS-134

APS 208

RL-720

Recommend Reason

- Labelette's APS-134 is an easy-to-operate automatic horizontal wrap labeler.

- The APS-134 is designed to label unwieldy round containers horizontally oriented with full or partial wrap labels.

- The APS-208 is economical, self-contained, and easy to operate. This automatic labeling system comes equipped with a 7 ft. variable speed conveyor.

- The RL Rotary Labeling Systems are designed with the needs of the contract packaging and demanding end user in mind.

10. PE Labellers

Company Background & Information

As a member of the Pro Mach Family of companies, P.E. Labellers offers high-performance, flexible, and customizable automatic labeling machines, inspired by Design Innovation. For 50 years PE Labellers has been adding value to your offering with their flexible and modular automated bottle labeling solutions.

They offer combined labeling technology, pressure sensitivity labeling machines and stations, cold glue labeling machines and solutions, roll-fed labeling machines and solutions, shrink labeling solutions, etc.

Key Products

Futura SL

Roll-Line

Rollmatic

Recommend Reason

- Futura SL is an extremely reliable, versatile and customizable automatic labeling machine.

- Linear labeling machine using hot melt technology for roll-fed labels. It represents the ideal solution for the application of wrap-around OPP labels on cylindrical containers, both full and empty.

- Roll-fed rotary labeling machine for the application of wrap-around labels with hot melt.

- Depending on the drive type, the machine is able to label cylindrical and/or shaped containers.

Conclusion

This top 10 global bottle labeling machine manufacturers covers a wide range and detailed information about the bottle labeling machine manufacturer backgrounds and their corresponding products. If you have anything to add to these manufacturers or want to know more, you are welcome to browse our official website: https://www.allpackchina.com/ or consult our customer service staff.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide

Top 10 Global Bottle Labeling Machine Manufacturers: The Complete Guide In 2024 Read More »