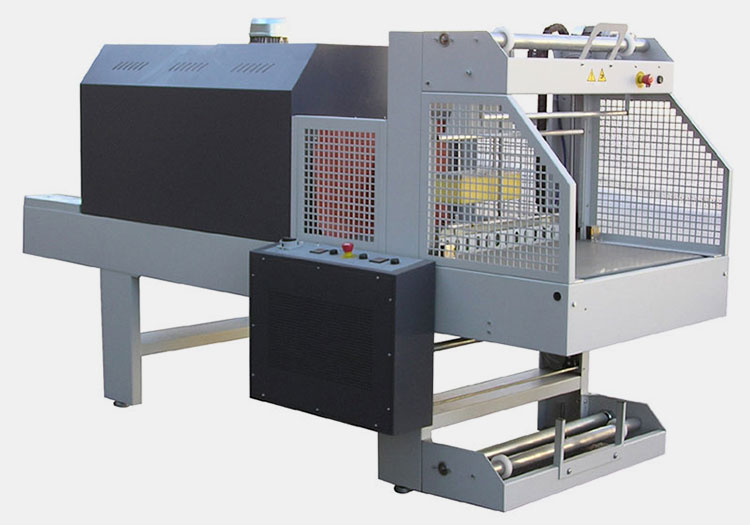

1.What Is An Automatic Shrink Wrap Machine?

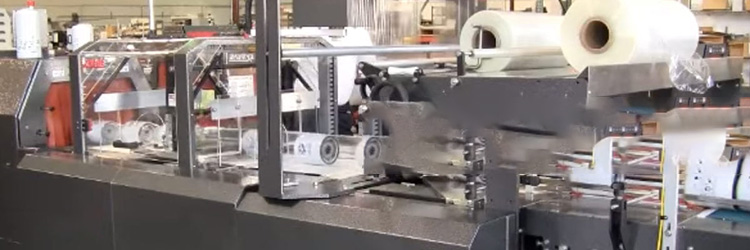

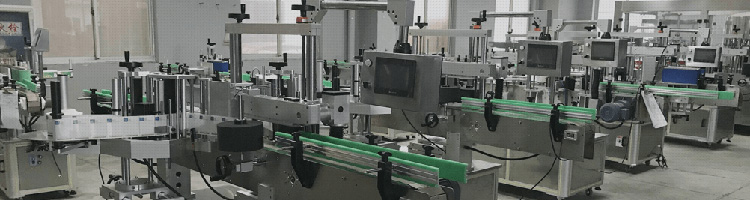

An automatic shrink wrap machine is a device used to package products using plastic film. It typically involves the automatic feeding of the product into the wrapping area, followed by automatic sealing and cutting of the film around it.

The heat from an external heating element causes the material to shrink tightly around the product providing secure packaging that also helps protect against moisture, dust, and tampering.

Also, this machine is ideal for high-volume production and efficiency. It can be configured to work with various materials such as PVC, polyethylene (PE), polypropylene (PP), and more. It also saves production costs by a great percentage.

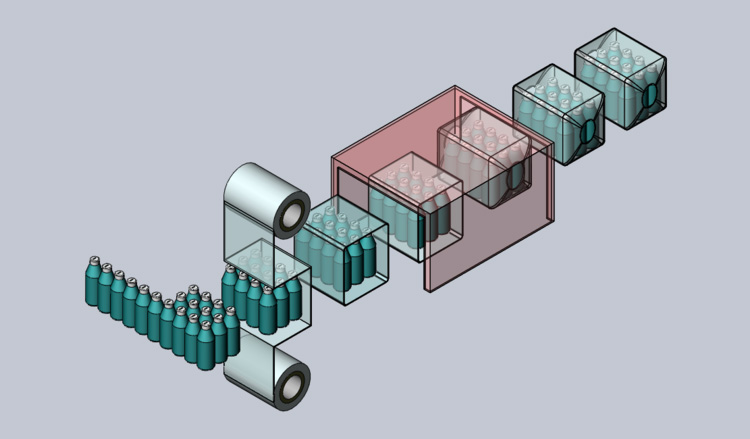

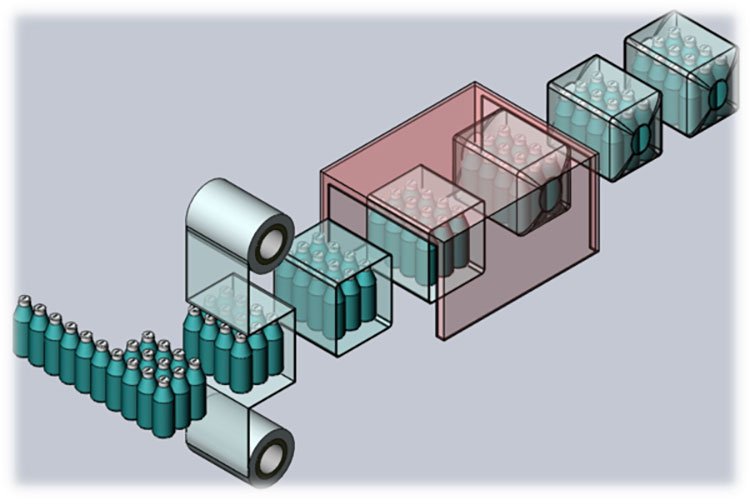

2.How Does An Automatic Shrink Wrap Machine Work?

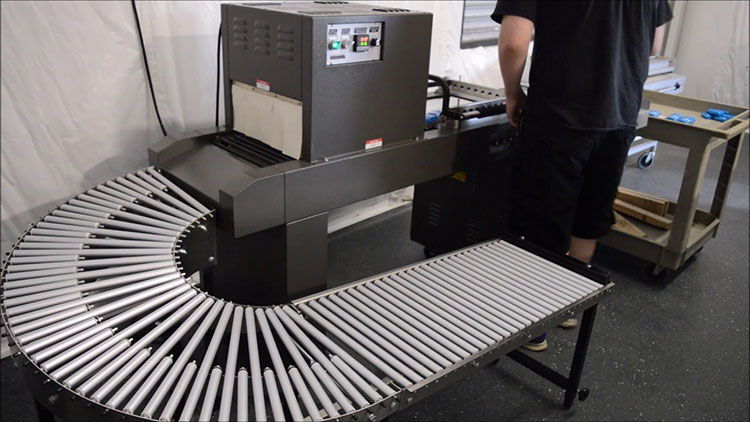

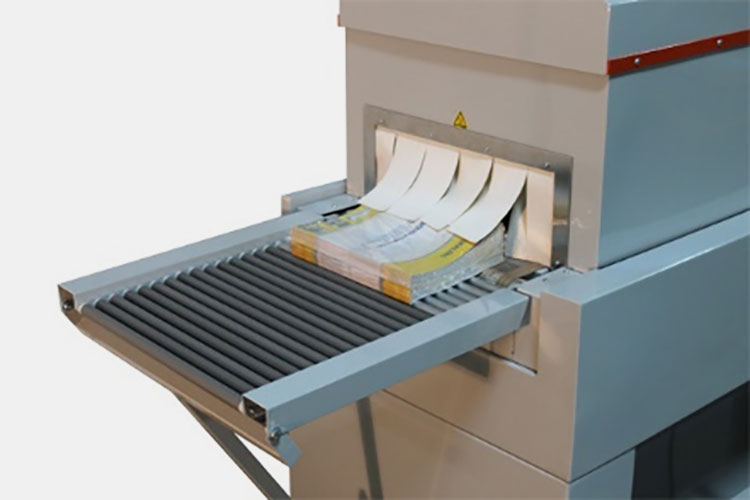

Automatic Shrink wrap machine works by automatically feeding the pre-cut film into the chamber before it is heated and sealed. The machine will then move the product on a conveyor belt, allowing it to pass through the heated chamber.

Once inside, the shrinking tunnel uses infrared heaters to shrink the film around the product and seal it. Then, the conveyor belt movement ensures that each product is evenly wrapped and sealed with minimal assistance from human operators.

3.What Are The Working Principles of An Automatic Shrink Wrap Machine?

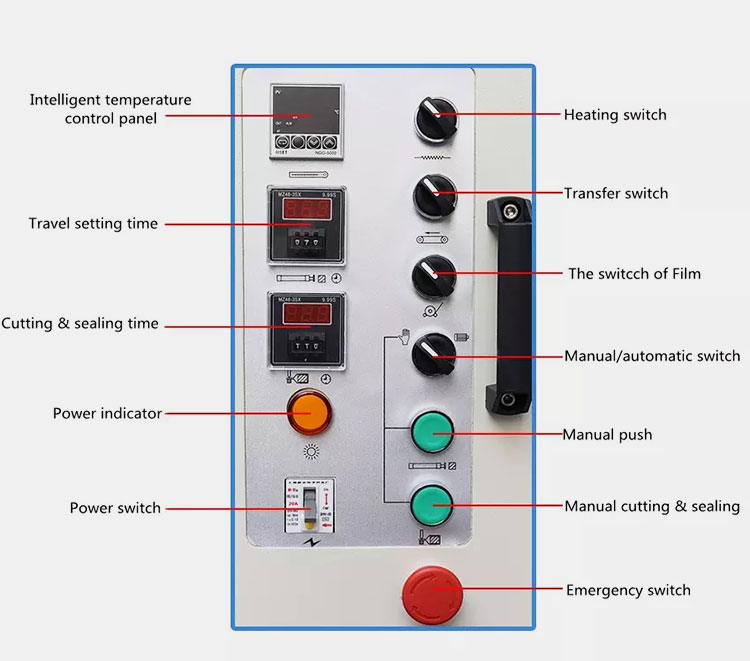

Automatic and manual feeding modes. In automatic mode, this device can automatically package items quickly and efficiently with pre-programmed settings and operators can manually adjust the parameters for each item as required in manual mode. These modes provide flexibility and make automatic shrink-wrap machines more efficient.

This machine uses a combination of heat and shrink-wrap film which activates when it detects an item passing through the internal chamber to package items. This heats the shrink-wrap film causing it to form a tight seal around the item. Once sealed, the automatic shrink wrap machine then cools the film, which shrinks it tightly around the item.

4. Which Kind Of Foodstuffs Can Be Packed By An Automatic Shrink Wrap Machine?

Automatic shrink-wrap machines are a great choice for food product packaging. This equipment can be used to package different types of foodstuffs such as vegetables, fruits, meat, fish and prepared meals.

Vegetables

Automatic shrink wrap machines are capable of quickly wrapping vegetables in a protective film that keeps them safe from dirt, moisture, and other contaminants. This machine also helps to retain the freshness of the product for a longer period of time.

Fruits

Just like vegetables, fruits normally have high moisture content. The water lost by fruits through transpiration causes them to dry, shrink and soften. However, using an automatic shrink wrap machine to cover fresh fruits helps to reduce the transpiration rate, thus maintaining the firmness of fruits.

Meat

Automatic shrink wrap machine can pack cured and uncured meats such as bacon, ham, steak, poultry, sausages, or jerky. It provides an airtight seal that prevents moisture loss during transport and storage ensuring they remain fresh longer than if stored in the open air or a refrigerator.

Fish

As such, automatic shrink wrap machines are a valuable tool for organizations dealing with fish preservation. By using this machine, businesses can ensure that their fish products are safe to consume while extending their shelf life.

Readymade Food

Automatic Shrink wrap machine is used to seal readymade foodstuffs. It packages food like sandwiches, burgers, pre-cooked meals, and other food items that are ready to eat. The foodstuffs are sealed airtight which helps to preserve the food for longer periods and also helps protect it from any external contamination or spoilage.

5.What Type Of Materials Does An Automatic Shrink Wrap Machine Use For Packaging Products?

Food packaging materials come in many different forms. Common types of food packaging materials include paper, plastic, metal, and glass. These materials are used to store and protect food products from contamination, spoilage, and damage.

Paper

This material is often used for wrapping food items such as sandwiches or slices of cheese. It can also be printed with branding graphics that help make the product look attractive on shelves at grocery stores. Paper bags can also be used for cereal or other dry goods.

Plastic

It is a versatile material that can be used in many different ways when it comes to food packaging. Plastic containers are great for storing liquids and soups.

Metal Cans

Metal packaging is used to store canned goods like vegetables, fruits, and soups. The metal containers generally have waterproof labels that allow consumers to know what’s inside the can without opening it. Metal lids also provide a good seal so that foods remain fresh regardless of temperature changes.

Glass Jars

They are widely used to package jams, honey, pickles and many other types of preserves. Glass is impermeable, meaning oxygen cannot pass through it which helps keep the contents fresh over time. It also provides an attractive presentation for products on store shelves.

6.How Can Waste Minimization Be Achieved When Using An Automatic Shrink Wrap Machine?

Using an automatic shrink wrap machine can help to reduce the amount of waste produced and increase efficiency. To minimize waste, it is important to ensure that the correct size and type of shrink wrap film is being used for the product or items being wrapped.

Additionally, careful placement of the item or product in the automatic shrink wrap machine can maximize usage of shrink wrap film. Also, the automatic shrink wrap machine should be maintained regularly to ensure that it is working properly and not causing excess waste.

Ultimately, the automatic shrink wrap machine should be set to the correct temperature and speed for the product or items being wrapped in order to minimize film usage

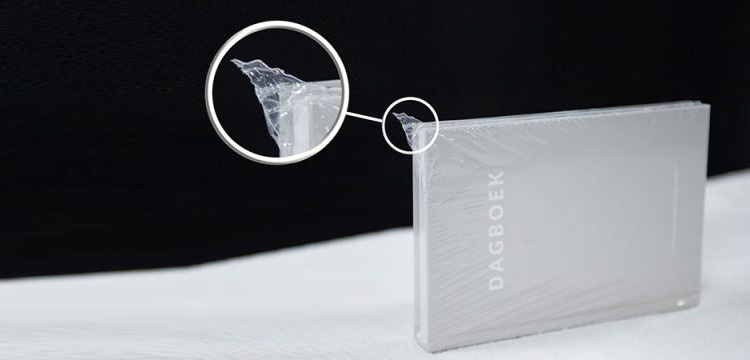

7.How Can The Quality Of Packaging Be Improved Using An Automatic Shrink Wrap Machine?

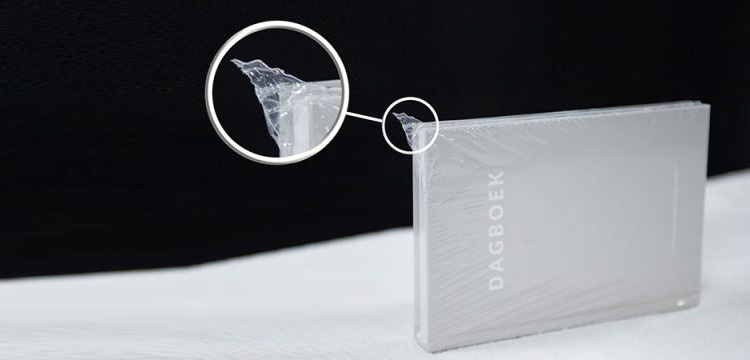

Using an automatic shrink wrap machine is a great way to improve the quality of packaging. This machine can quickly package products with high precision and accuracy. An automatic shrink wrap machine seals the product in a polyolefin film creating an airtight seal that keeps moisture, dust, dirt and other contaminants out while protecting it from scratches and damage.

Also, the automatic shrink wrap machine can be used to add additional features like labels, barcodes and logos, which helps increase the product’s appeal. Additionally, automatic shrink wrap machines are designed to save time and money by streamlining your packaging process.

All in all, an automatic shrink wrap machine is an invaluable asset to any business looking to improve the quality of their packaging. It allows businesses to achieve a higher level of quality, faster turnarounds and increased efficiency at a lower cost. Therefore, with the automatic shrink wrap machine, you can ensure that your products are packaged perfectly every time.

8.Why Does An Automatic Shrink Wrap Machine Leak Air During Packaging?

Automatic shrink-wrap machines consist of conveyors, rollers, heating elements, cutting tools, and automatic controls that work together to package items. If any of these components are not properly aligned or there are loose parts, it can cause air to leak from the automatic shrink wrap machine when packaging items.

Air leakage can also be caused by the type of shrink-wrap material used. The wrong thickness or quality of shrink-wrap material may not provide a proper seal when wrapping items, leading to air leakage. A good automatic shrink wrap machine should be designed with the correct size and shape of heating elements to properly heat the plastic film for sealing.

Solutions

- If any part of the automatic shrink wrap machine is blocked or clogged up with dirt or debris, it is important to inspect all components regularly and clean out any blockages so as to avoid air leakages. This will also help to attain optimal performance from an automatic shrink wrap machine.

- Regular maintenance, proper alignment, and selecting the right shrink-wrap material are also important steps to avoid air leakage when packaging items. With the right care and attention, automatic shrink-wrap machines can provide reliable performance and efficient sealing of products.

- Regular inspection on shrink-wrap machine parts can also be one of the solutions to prevent air leakages when using an automatic shrink wrap machine.

- Finally, lubrication of moving parts for reduction of friction, wear and tear at large.

9.Explain The Major Advantages Of An Automatic Shrink Wrap Machine?

Automatic shrink wrap machines offer a wide range of advantages over manual and semi-automatic shrink wrap systems. The most significant advantages include:

Speed and Efficiency

This is the most important advantage of an automatic shrink wrapping machine. This equipment can quickly and consistently package large numbers of items hence reducing labor costs and increasing production speed.

Precise Application of Film

Automatic shrink wrap machines provide more precise application of the film than manual or semi-automatic machines, resulting in better product protection from dust, moisture, and other environmental conditions.

User Friendly

Moreover, automatic equipment offers user-friendly features like automatic feeding systems for easy loading of products and automatic cutting for a clean finish on each package.

Durability

Also, automatic shrink wrap machines are designed to be more durable than their manual counterparts, making them a long-term investment that will save time and money in the long run.

Reduces Waste and Labor Costs

The automatic sealing process by automatic shrink wrap machines eliminates the need for excess material that would otherwise be used in manual packaging.

Maintains Quality

The automatic shrink-wrap machine ensures that food stays fresh and safe for consumption by protecting it from outside elements.

Protects Products from Damage

This type of machine allows for precise sealing of the packages, ensuring that the product is protected against air or moisture damage during transport.

Increases Marketing of Products

Automatic Shrink-wrap machines used to package products not only properly seal products but also prolongs their life. Ultimately, Proper sealing of items attracts more customers because of easy transportation and good labelling.

The Products Are Visible

The machine uses transparent polythene papers in packaging to ensure products are visible for easier identification and marketing.

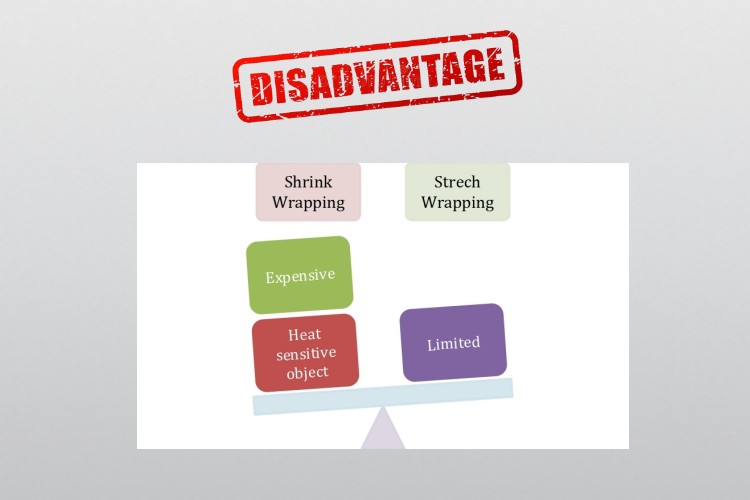

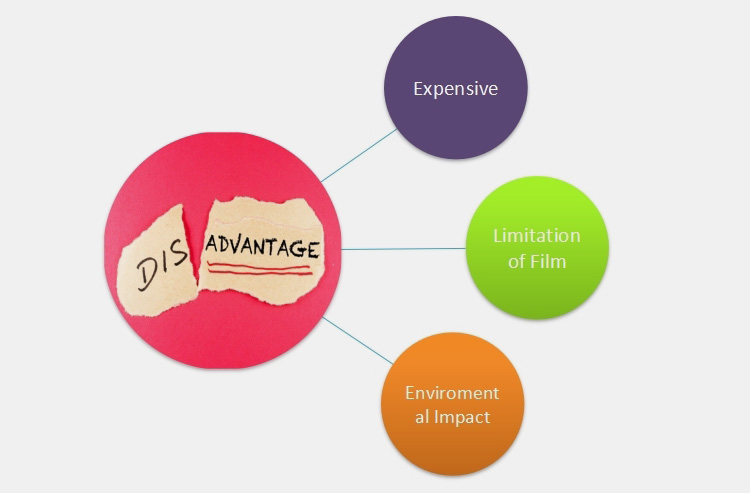

10.What Are The Disadvantage S Of Automatic Shrink Wrap Machines?

Automatic shrink wrap machines are associated with certain drawbacks that should be considered before investing in them. They include:

Cost

Automatic shrink wrap machines are much more expensive than manual ones. This makes them out of reach for many businesses that don’t have the budget to afford them.

Regular Maintenance

Additionally, automatic shrink wrap machines require regular maintenance and often use specialized parts that can be hard to find or costly to replace.

Size

Also, automatic shrink wrap machines tend to be large and bulky, meaning they take up a lot of space in a facility and may not fit in certain areas where smaller manual wrappers could easily fit.

Require Trained Personnel

Finally, automatic shrink wrap machines usually require a trained operator who is familiar with the system’s functions and operation

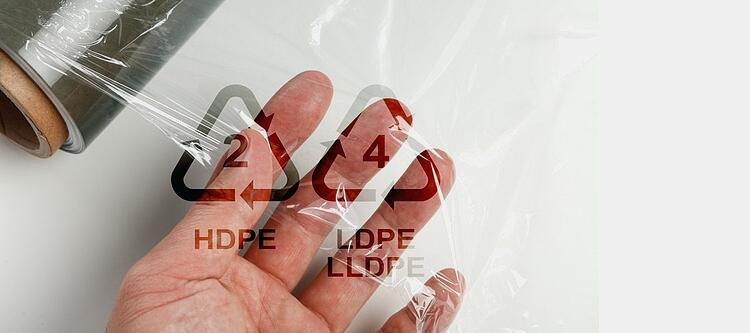

11.What Type Of Material Does An Automatic Shrink-Wrap Machine Use For The Packaging Of Products?

Choosing the right shrink film for packaging products is very important. Polyolefin is one of the most preferred shrink films and is widely used because it is stronger and more flexible. In addition, it has no odors and is environmentally friendly when sealing products. It can be used to seal both edible and non-edible items.

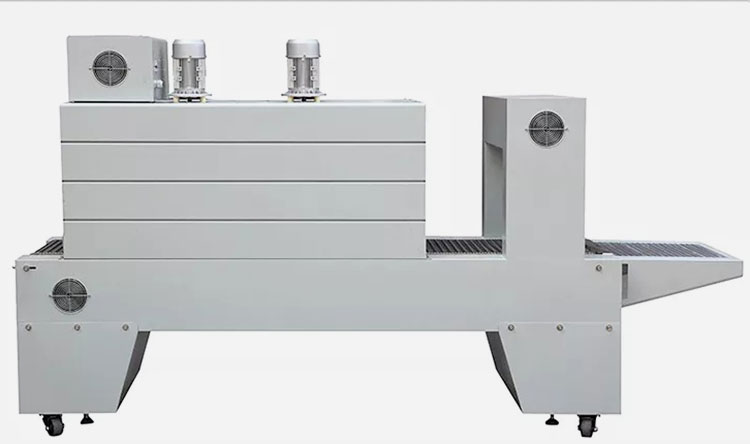

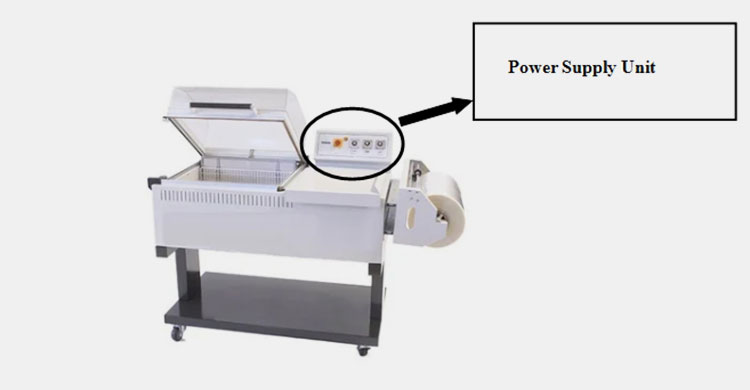

12.Describe The Core Components Of An Automatic Shrink Wrap Machine?

An automatic shrink wrap machine consists of different components that enable it to work effectively. These components of this machine are discussed below;

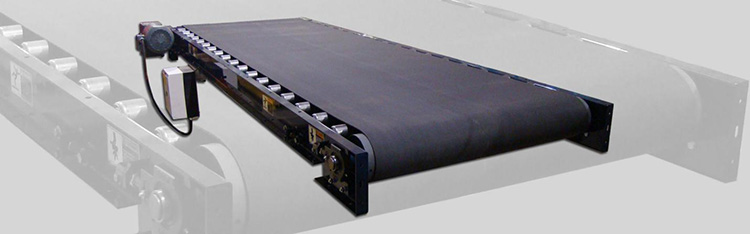

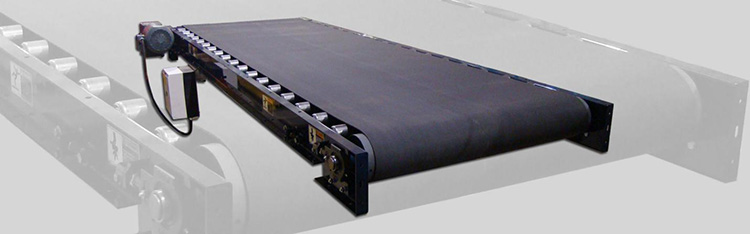

Conveyor Belt

The conveyor belt is responsible for bringing the product to the automatic shrink-wrap machine and allowing it to move through the system. It also helps ensure that the product is properly aligned before entering the system.

Pre-shrinking Oven

The pre-shrinking oven heats the material to be easily formed around the product without causing damage. This part of the automatic shrink-wrap machine will help keep products from wrinkled or damaged during transportation or storage.

Shrinking Tunnel

The shrinking tunnel creates the seal around the product and ensures it stays securely wrapped. This portion of the automatic shrink-wrap machine uses hot air to shrink the material tightly around the product so that it can be handled without causing any damage.

Cutting Device

Finally, the automatic shrink-wrap machine usually has a cutting device that helps cut off excess material once the product is sealed and securely packaged. This helps ensure that only enough plastic or other packaging material is used to fit around the item, reducing waste and cost.

13.What Factors Determine The Shelf Life Of Goods Packed By An Automatic Shrink Wrap Machine?

In general, automatic shrink-wrap machines can provide extended shelf life for many types of products compared to other forms of packaging. As such, properly packed items can often enjoy a shelf life of several months or even years.

The shelf life of goods packed by an automatic shrink-wrap machine depends on various factors. Some of these factors include:

Quality and Type of Packaging Materials Used

The material used for creating a wrapper should be chosen based on its quality, durability, and thermal properties. In this case, PVC or polyethylene can offer excellent protection from moisture.

Size And Shape of Items

The size and shape of items being wrapped need to be considered when selecting packaging materials since some materials may only work with certain sizes or shapes.

Environment

Environmental conditions in which a product is stored as well as any contaminants that may come into contact can play a big role in determining its shelf life.

Climate

climate control capabilities of automatic shrink wrap machines should also be considered when calculating estimated shelf life. For instance, high humidity levels can affect the integrity of packaging over time.

So, it is important to ensure that a shrink wrap machine is being used in an environment with low humidity.

14.Explain The Different Types Of Automatic Shrink-Wrap Machines.

A wide range of automatic shrink-wrap machines are available to suit different production requirements. The types vary in terms of size, features, and capabilities. The most common ones are:

Automatic Heat Shrink Wrap Machines

This is the most common type of automatic shrink-wrap machine and is ideal for products that can withstand moderate heat levels, such as CD cases or food items. It uses hot air to cause polymer plastic film to shrink around a product or bundle of products. Heat is applied via heated plates or tubes, and the plastic film shrinks tightly around the product to form a secure seal.

Automatic Banding Machine

This automatic shrink-wrap machine is typically used for items that cannot withstand heat, such as paper products or textiles. It utilizes thin plastic bands to secure bundles together. Also, it uses a tensioner to apply pressure as the band wraps tightly around the bundle.

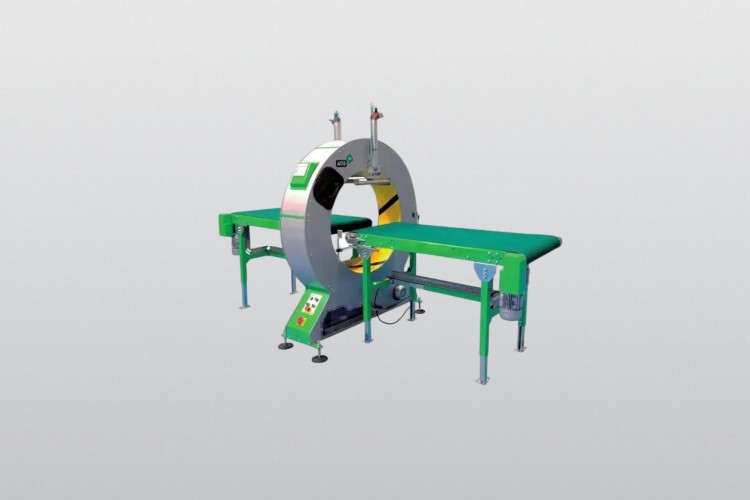

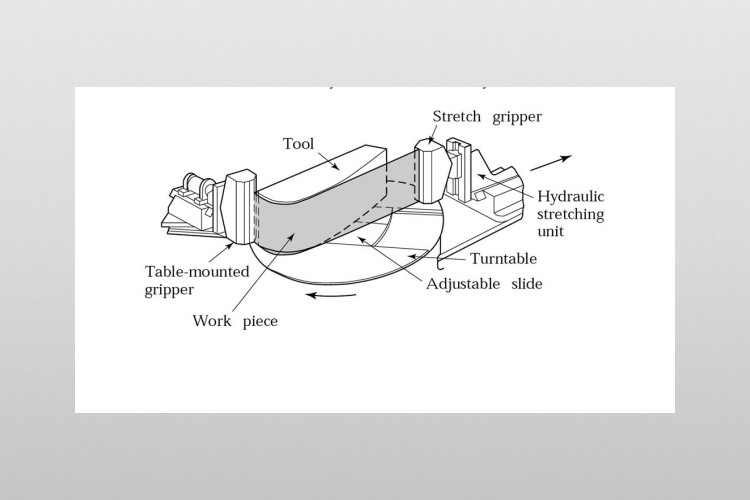

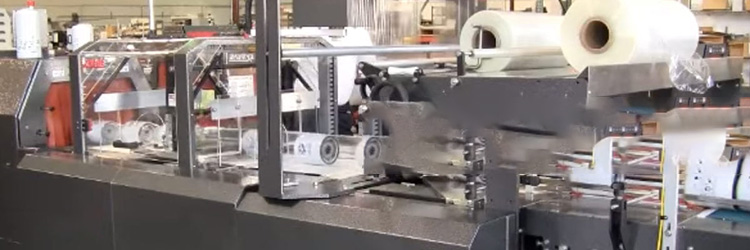

Automatic Stretch Wrap Machine

This machine is suitable for various packaging applications, including encasing products in shrink wrap. It uses a plastic film stretched and wrapped around a product or bundle. Also, it features a conveyor system, film roll holder, and wrapping arms that move around the product being wrapped, thus improving efficiency and convenience.

High-Speed Stretch Wrapper

These machines feature advanced technology that allows them to wrap large loads or even multiple products at once quickly. They are often used in production lines where speed and precision are essential.

Thermal Shrink Packaging Machine

This machine is used to package the product with shrink film which is heated by the machine. The fine packing not only pleases to the eye of customers, but also has the features of seal, damp-proof and prevent dirty.

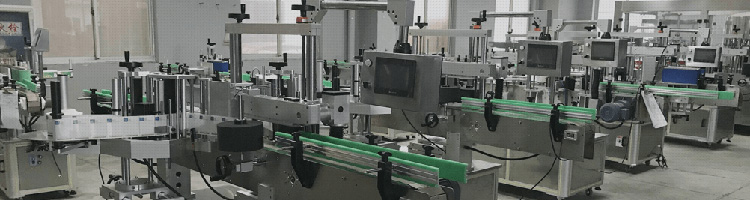

Label Shrink Packaging Machine

These label shrink machines are mainly used to shrink label of product in bottle shape, can shape or barrel shape with glass bottle, plastic bottle or paper cup.

15.In Which Industries Can Automatic Shrink Wrap Machine Be Used?

Automatic shrink-wrap machines are highly versatile and can be used in various industries. They can be used in packaging items of various sizes and shapes.

Food Industry

The application of automatic shrink-wrap machines is a popular option in the food industry. This application helps keep products such as boxes of snacks, bottles of sauces, jars of pickles, or cases of frozen fruit safe from damage during transit, as well as preserving freshness and extending shelf life.

Also, by using this application in the food industry, producers can ensure that their products reach consumers in perfect condition

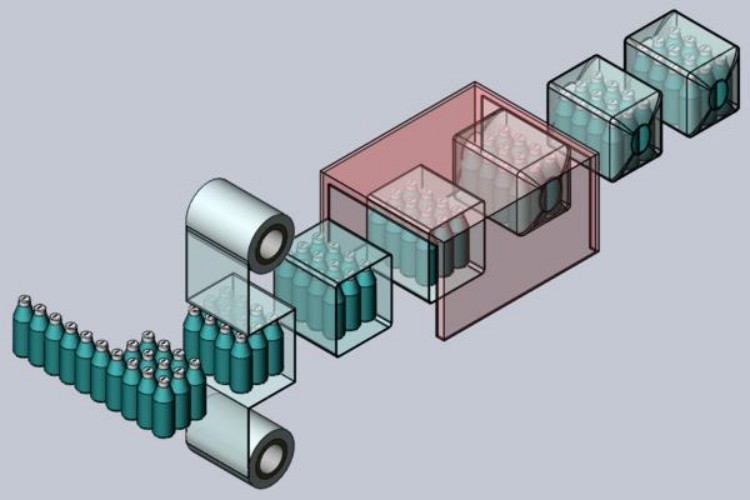

Beverage Industry

Automatic shrink-wrap machines can be used in the beverage industry to package bottles and cans in pairs or multiple units. It is a quick, efficient, and cost-effective way to package products of various sizes.

The machines use special plastic film (shrink wrap) to wrap around the containers with heat application which causes the film to shrink tightly against the product, forming a tight protective seal. This application ensures that the products remain safe during transport and storage, providing tamper-evident seals that are difficult to break open without detection.

Pharmaceutical Sector

The usage of automatic shrink-wrap machines in the pharmaceutical sector has become increasingly popular in recent years. This technology allows companies to safely and efficiently package products, including medicines, for distribution.

The machine’s application helps ensure a secure seal on the product’s packaging. Additionally, shrink-wrap machines offer improved control over the application of labels and other information on the packaging, which helps to ensure accuracy and uniformity across all packages

Cosmetic Industry

In the cosmetic industry, automatic shrink-wrap machines are essential to ensure product safety and preservation. The application of such machines can help keep products in pristine condition for longer by preventing contamination through air and water infiltration. Shrink-wrapping also helps protect cosmetics from damage due to external conditions such as sunlight or humidity.

16.What Are The Common Faults Associated With Using An Automatic Shrink Wrap Machine And Their Possible Solutions?

Common faults associated with automatic shrink-wrap machines include frequent jamming, poor packaging quality, and slow speed. Nonetheless, there are possible solutions to each fault, as discussed below.

Jamming

Jamming occurs when the machine cannot properly feed the materials due to excess debris or incorrect adjustment settings.

Solution

To address frequent jamming, clearing away any debris that may be stuck in the machine’s components and ensuring all settings are correctly adjusted for optimal Performance.

Also, a software update may be needed to mitigate any compatibility issues if this doesn’t resolve the issue.

Poor Packaging Quality

This fault can result from inadequate heat application or improper film tension.

Solution

To address poor packaging quality, the heaters and sensors should be checked to ensure they are working properly and not damaged. If the problem persists, the film tension needs to adjust for better contact with the wrapped product.

Slow Speeds

Automatic shrink-wrap machines can be slow due to weak motors or misaligned belts and pulleys.

Solution

To address this issue, it is important to always double check and ensure that all the parts are correctly installed and that the proper film thickness is being used. This will help ensure optimal efficiency of the automatic shrink wrap machine.

Also, regular lubricating moving parts can help prevent breakdowns from occurring due to wear and tear.

17.Factors That Should Be Considered Before Purchasing An Automatic Shrink Wrap Machine.

There are several factors that a company should consider before purchasing a shrink-wrap machine. They include:

Size

Automatic shrink-wrap machines come in various sizes to accommodate different types of products. Therefore, it’s important to consider the size and type of products you need to pack before purchasing this machine.

Luckily, most of these machines offer adjustable settings that allow producers to adjust the thickness of the wraps according to their needs. This ensures that the products are securely and tightly sealed, making them safe for transport or storage.

Speed

The speed of an automatic shrink-wrap machine is a major factor in determining its cost. The faster the machine, the more expensive it is likely to be.

Automatic shrink-wrap machines are designed for mass production, but not all models offer the same level of performance and some may be too slow if you plan on using them for large-scale production.

Therefore, it’s important to ask yourself how quickly you need the automatic shrink wrapper to produce products, so you can select a machine that meets your needs.

Cost

Depending on the size and complexity of the machine, prices can vary widely. Therefore, the cost of an automatic shrink wrap machine should be a major factor when purchasing one.

Energy Consumption

Automatic shrink-wrap machines consume energy for their operation, and it’s important to consider this before making your purchase decision. The amount of power consumed will vary depending on the size of the machine and its features.

Maintenance

Automatic shrink-wrap machines are complex and require regular maintenance to function correctly. Make sure you factor this into your decision when considering whether or not to purchase an automatic shrink-wrapping machine.

Ease Of Use

Automatic shrink-wrap machines should be simple to operate so that anyone can quickly learn how to package products properly. Therefore, one should consider the user-friendliness of the automatic shrink-wrap machine before making a purchase.

Material Recommended for Use with The Machine

Different shrink-wrap machines use different materials in packaging items since the goods are of different in size, shape and weight. Companies should ensure that the packaging materials the machine should use are readily available and from many different sources so as to avoid stock outs.

Conclusion

Automatic shrink wrap machines are an innovative and reliable way to quickly and cost-effectively package products for transport or storage. Also, these machines have many advantages such as their fast packaging speed, automated technology, energy efficiency, and the low maintenance requirements. Therefore, if you need to package your products in a timely manner without sacrificing quality, Allpack is an ideal solution. Don’t wait any longer, contact us for more information and watch your productivity soar!

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours