Shrink Wrapping VS Stretch Wrapping

Packaging of your laboursomely produced goods is somehow difficult task when it comes to retain their quality, appearance and structure by keeping them well organized especially during transit because improper packaging can ruin your products.

Thus to counter this obstacle, the packaging industry is constantly striving to introduce best technology for solving it which eventually results in presenting the two distinct but essential ways of packaging, namely; shrink wrapping and stretch wrapping.

However, these both have certain qualities in their respective structural and functional spheres. What are these? Can be perfectly understood by thoroughly examining the article explained below!

1.What Is Shrink Wrapping?

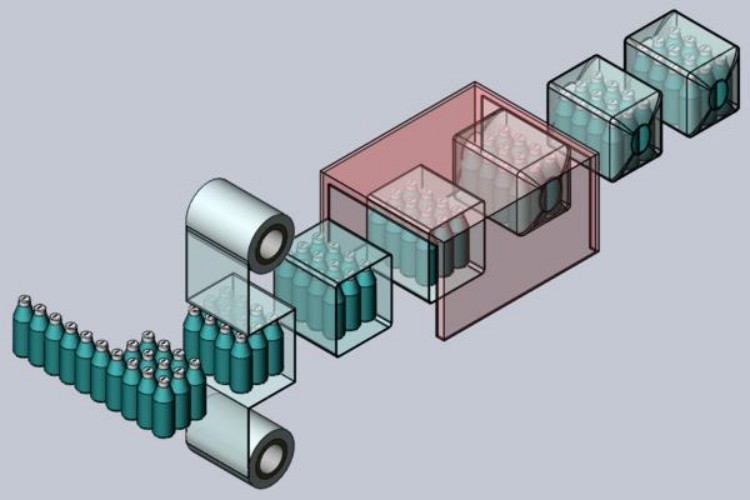

Shrink wrapping refers to the packaging of goods by covering them loosely with plastic film so that it can be shrinked after getting heat. In this type of packaging, heat is applied and it works as a main source for the purpose of tightening film around the products.

Shrink wrapping not only pack the bulk products rather it is the most popular way of primary packaging for enormous goods that’s why it is an essential packaging equipment every manufacturer looks for. There are various machines utilized for shrink wrapping. All of them are designed with particular characteristics.

2.What Is Stretch Wrapping?

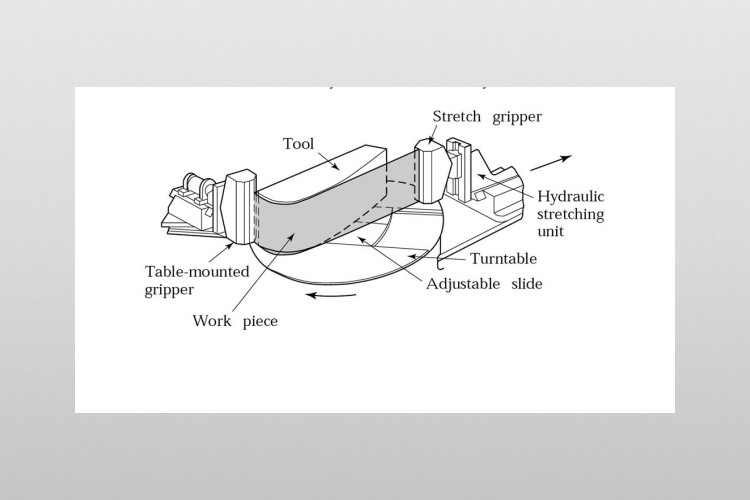

Stretch Wrapping can be defined as the way of packaging in which large number of cartons are tightly joined together by flexible plastic film through stretching. This type of packaging is performed by special machines known as stretch wrapping machines.

Unlike shrink wrapping machines, they do not use heat for wrapping instead the constant movement of turntable leads to the hermetic packaging. In addition, need for stretch wrapping becomes inevitable when it comes to transportation of large volume commodities.

3.Whose Structure Is More Complex Between Shrink Wrapping Vs Stretch Wrapping?

- Components

The structure of shrink wrapping machine and stretch wrapping machine is totally different which can be analyzed by looking into their components:

Shrink Wrapping

Shrink wrapping machine is highly complex integrated with so many parts. They are:

Control Panel

Control panel is the key component of shrink wrapping machine through which you would be able to communicate your commands into it. It mainly comprised of conveyor belt speed along with separate system for temperature control due to integrated heat system.

Conveyor Belt

Another element which works as a road for all your goods to pass through the shrinking phase is conveyor belt. Increasing its speed is used when your products require less heat while it is decelerated when nature of plastic used is hard to get shrinked.

Conveyor Motor

Conveyor motor is usually located beneath the conveyor belt and indicates its speed when alteration is done via control panel.

Heating System

The core part of any shrink wrapping is obviously the heating source which can be found in so many forms like that of heater bank, steam tubes or electromagnetic force. This heat source shrinks the surrounding film of products.

Tunnel

Most of the fully automatic and semi automatic shrink wrapping machines have enclosed area which is called shrink tunnel. Heating system is fitted here, products come out in final shrink form when passed through this area.

Curtains

Silicone coated polytetra fluoroethylene curtains are hanged outside both the openings of shrink tunnel for reducing heat loss.

Film Rollers

An essential component of shrink wrapping is film rollers which are fixed in particular areas of machines for dispensing over the products.

Stretch Wrapping

Structure of stretch wrapping machine is quite simple with few parts. These are:

Lifting Track

Lifting track can be also referred as tower which works as a tall stand having separate space for control panel and film frame.

Film Frame

It is situated in the lifting track in such a way that it easily moves towards upward and downward direction while dispensing the film which is placed inside the frame.

Turntable

It is the place where bulk containers are placed in arrange form. The circulatory movement of turntable is the main step when cartons get wrapped collectively.

Control System

Like other machines, stretch wrapping also has proper controlling system but unlike shrink wrapping, here the speed of turntable and direction of film frame is adjusted.

Cut-Clamp-Brush Mechanism

These are two parts which combinely named as cut clamp brush. Clamp is a metal device located on table that holds the film so it can be stretched around load. Cutter and brush are carried out by the frame which comes into action when process becomes completed, cutter cuts the film and brush stick the film end on load.

- Auxiliary Devices

Auxiliary devices are that equipment which are not necessary for running the process shrink wrapping or stretch wrapping but they add into the existing efficiency of machine.

Shrink Wrapping

Supportive equipment for shrink wrapping are more in number than stretch wrapping. They are:

- Liquid filling machine

- Bottle inspection machine

- Shrink sleeve labeling machine

- Bottle capping machine

- Induction sealing machine

Stretch Wrapping

Contrary to shrink wrapping, stretch wrapping mechanism is done by single machine and there is no such need for additional accessories. However, few are described below:

- Conveyor belt

- Pallet weighing system

- Low profile access ramp

4.Differentiate Between Shrink Wrapping And Stretch Wrapping?

- Material Used

Shrink Wrapping

Films used for shrink wrapping are often hard and rigid in nature eventually do not possess flexibility. They are mostly made up of polyvinyl chloride and polyolefin. The reason behind to choose such type of films is to fully assure that products are covered with firm protective plastic so that external elements would not damage inner quality of materials.

Stretch Wrapping

As a matter of fact, stretch wrapping film is the result of lean stretchable plastic usually prepared from polyethylene plastic. It contains high degree of elasticity and has the ability to expend its existing length up to 300%. That’s why; regardless of the extreme pressure it shows flexibility and is split-resistant.

- Working Process

Shrink Wrapping

Working process of shrink wrapping is little bit convoluted to understand and has to be performed by certain fixed steps such as:

Initially, the machine provides you with an integrated set of graphics in form of control panel and let you enable to set parameters according to your requirements. Once you are done with this step, there is no need to bother in form of manual intervention.

Machine will take the commands and dispense dual layers of transparent or printed film to loosely but completely cover the bulk products. In case of individual item film is delivered as per desired like half, full or neck sleeve etc.

These items are then passed through heating phase mostly under heating tunnel where film around them get shrinked and adopt the shape of objects.

Stretch Wrapping

Process of stretch wrapping is extremely easy that any layman can understand it and consequently operate without any need for experts. Its mechanism of action is given below in few steps:

The machine can be executed by simply loading material over turntable in sequence. Switch is turned on, and machine follows the directives set in control panel.

Stretchable plastic film is held by clamp after which the motion of table starts in rotary form. Film is constantly released by roller and tightly binds around the bundle.

Once bundle gets wrapped, cutter cuts down the film end and brush press the film so that it would properly attached to the load. The operation gets finished here.

- Classification

Both shrink wrapping and stretch wrapping can be divided into the types of ways they are done. However, all of them vary from one type of wrapping method to another type of wrapping. Below table clearly demonstrates the real picture of these differences like:

| No | Types | Shrink Wrapping | Stretch Wrapping |

| 1 | Fully Automatic | Fully automatic shrink wrapping is done independently by machine where load is conveyed through conveyor belt, covered with plastic and passed through heating phase. | Here load is delivered by guiding rail on turntable whose consistent rotation leads the flexible plastic to surround the bundle tightly. |

| 2 | Semi Automatic | Objects are manually placed by operator and rest process is achieved by machine itself. | Cartons are placed in arrange form over turning table and machine then do its operation automatically. |

| 3 | Manual | Here a heat gun is used with hands which exhale heat to get the plastic over objects shrinked around them. | While as, in stretch wrapping manual means that operator just take the roll of stretchable film and starts surrounding the load with it. There is no machine present here. |

- Advantages

Shrink Wrapping

Versatile

Shrink wrapping is comprehensive in its application and can be used for primary as well as secondary packaging.

Adaptable

Shrink wrapping is known due to its quality of adaptability because it transformed into the manifestation of object.

Stretch Wrapping

Cheap

Shrink wrapping method is cheap in price due to simple machinery and thin stretchable plastic.

Flexible

Material which stretches wrapping uses is quite flexible.

User-Friendly

It is user friendly as it can be easily understand and operated by ordinary user.

Heat Sensitive Objects

There is no where a step in stretch wrapping where heat is used thus it is best for packaging of heat sensitive items like explosives or chemicals etc.

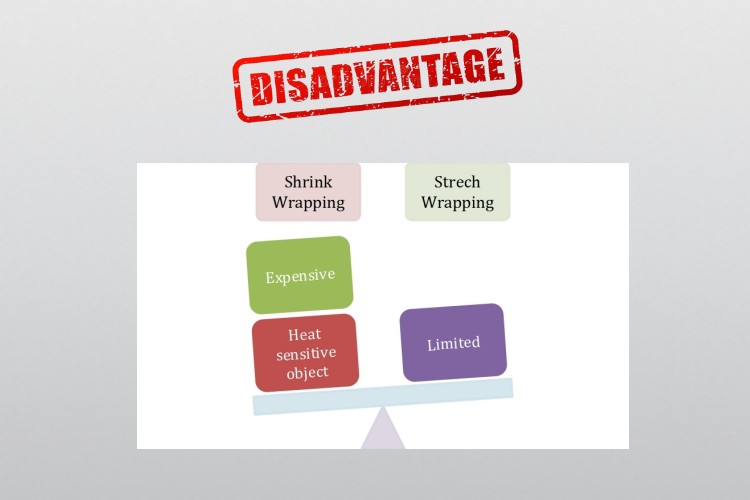

- Disadvantages

Shrink Wrapping

Expensive

Shrink wrapping is expensive method from every angle.

Heat Sensitive Objects

It is not suitable for heat sensitive objects like chemicals or explosives etc.

Stretch Wrapping

Limited

Stretch wrapping is limited process due to its applicability to only large industries so it cannot be used as primary packaging.

5.Which Is More Cost Effective- Shrink Wrapping Vs Stretch Wrapping?

From below explanation, it would be clear to you which method between shrink wrapping and stretch wrapping is more cost effective:

Shrink Wrapping

Shrink wrapping is expensive due to hard film it uses. Moreover, machinery used for it has high price and complicated using method which would definitely require team of experts for installation.

Stretch Wrapping

While as, stretch wrapping is cost effective because it does not have complex components in main machinery. Its method of usage is too easy that can be done alone without need for experts assistance.

6.Which Has Greater Applicability- Shrink Wrapping Vs Stretch Wrapping? Highlight The Major Areas?

Shrink Wrapping- Small to large scale industries

Shrink wrapping is the most utilized method undertaken by small to large industries due to its characteristic of being adoptable to both individual item as a primary packaging and bulk products as secondary packaging. Its application is vast as discussed below:

Food Industry

In food industry shrink wrapping is playing significant character for wrapping uncountable products like bottles of condiments, tea, ketchup, pickles, oil and candies etc.

Beverage Industry

Discussing this sector becomes obligatory when talking about scope of shrink wrapping because the beverage industry has recognition through this method. From our daily used water bottles to soft drink cans and wine, shrink wrapping is applied both as a separate and collective packaging.

Pharmaceutical Industry

Most of the tablets, pills and medicinal syrups can be seen in shrink wrapped labels. This method is generally employed to deal with the excessive production as well as their security by covering them with leak and moisture-proof shell.

Chemical Industry

Mostly powder or liquid chemicals are often packed in strong plastic bottles after which they are passed through shrink wrapping phase in order to give them identity and display necessary precautions over them. Insecticides and pesticides can be also used under this category.

Hardware Industry

Hardware industry carries products with diverse nature like plastic, metal and glassware etc. Manufacturers who are engaged in producing toys, electric gadgets and glass items are constantly using shrink wrapping.

Automotive Industry

Here the word automotive can be expanded into two categories on the basis of its usage of shrink wrapping. Oil and lubricants required for engines are individually packed through shrink wrapping on one hand and all these vehicles are completely shrinked wrapped by heat gun on the other.

Shipping Industry

Shrink wrapping has also good demand on large scale areas like that of shipping sector. Whether goods or cartons, vehicles or large containers everything can be perfectly shrink wrapped.

Aerospace Industry

This is the area where stretch wrapping is not applicable but only shrink wrapping is ideally recommended for covering helicopters or similar other parts of aerospace engineering.

Stretch Wrapping- Large scale industries

In contrast to shrink wrapping, stretch wrapping is only utilized in large scale industries and is confined to limited areas which are as follows:

Shipping Industry

Stretch wrapping is employed when there is need for securing bundles of cases by tightening them together so their integrity could be maintained until they reach final destination.

Wholesale Distributors

Wholesale market is the area where goods can be purchased in large quantity in discount so it can be further sell to buyers on exact amount. In such areas stretch wrapping is the most favorable.

Conclusion

From above discussion we may conclude that you have gotten the clear picture of what shrink and stretch wrapping are. Also the differences between both are well clarified. Both have their own importance in their respective fields which cannot be ignored. Besides, if you are among one of them and want to go for any one or both of them, Allpack is the best seller of these packaging solutions with outstanding performance. Don’t waste time, just click on the given link to approach us.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide

Tell us your material or budget, we'll reply you ASAP within 24 hours