Shrink Wrapper: The Complete FAQ Guide In 2025

Whether you are a manufacturer, retailer or a wholesaler, you cannot deny the role of a shrink wrapper which it plays in helping your packaging perfection reach the highest mark!

Do you familiar with a shrink wrapper? Or is it your first experience to look for a precise packaging solution? If yes! You are few steps away from knowing into the extensive information about a shrink wrapper. For your convenience, Allpack is always there to bring you amazing packaging solutions with detailed information so you may never be mistaken by any false assumption. This comprehensive review is going to display the structure, uses, applications and many other aspects of a shrink wrapper. Just keep reading it!

1.What Is A Shrink Wrapper?

A shrink wrapper is an automatic machine employed to cover variety of products in plastic film. It uses heat source to apply it on the scaffold plastic material in order to tightly seal the object. It comes in many types although their basic function is to maintain the integrity of product.

Shrink wrapping is undertaken both as a primary sealing and as a protective cover to combine several items in a single form. It is now an inevitable part of almost every industry including food, pharmaceutical, automotive, chemical and cosmetic industries etc.

2.How You Can Get Benefited By Using A Shrink Wrapper?

There may be a question raising in your mind that why should you use a shrink wrapper? For this we have explained the essential features of a shrink wrapper which can bestow you lots of advantages. They are as follows:

Versatile

One of the essential attribute of a shrink wrapper is the degree of versatility it possesses. Its processing is not confined to any particular object rather it is capable to shrink wrap every type of material wether it is food or non food, dry or wet items. It shows the adaptability of machine to different products.

Extend Shelf life

Most of the food products like vegetables, fruits and meat are passed through this mechanism to ensure full safety against debris and bacteria eventually enhancing their span of life on shelves.

Maintain Product integrity

It maintains the integrity of your products by keeping them unite under a single wrap so they cannot be damaged during transit and shipping. It also reduces the risk of product spillage by tight sealing.

Effective Presentation

Using this machine for packaging of your products can give them appealing and aesthetic look which consequently make them eye catching and grab the attention of people.

Sustainability

One of the greatest advantages of a shrink wrapper is the sustainability of shrink film like POF and PE. Both of them are 100% recyclable and best for consumer packaged goods. Moreover, POF does not release dangerous gases thus complying sustainability standards.

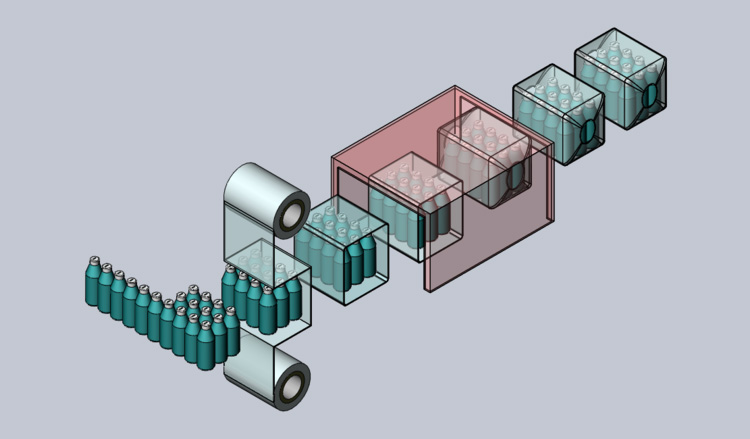

3.Elaborate The Major Steps Involved In Operating AShrink Wrapper?

To understand the working mechanism of a shrink wrapper, you should know the underlying principles such as:

This machine can be brought into operation by first setting the measurements required for material processing via human touch interface such as size of film, temperature intensity and time of stay for each product.

In second step, the machine is switched on and a layer of plastic film is loosely dispensed around the products. These products are then carried by conveyor belt towards heating tunnel.

During the time when these objects are passed through the tunnel, heat is applied over them resulting in the close shrinking of film around the product. Finally they appear in form of finished products with protective barrier.

4.What Type Of Food Products Are The Most Suitable To Be Directly Processed By A Shrink Wrapper?

The range of products processed by a shrink wrapper is vast enough that every type of material whether it is liquid or solid, food or non-food can be easily shrinked by this machine. So, few of these products are described below:

Fresh Food

Most of the hydrated food like fresh vegetables and fruits etc are sensitive by nature. They quickly get spoiled if not packed properly. To retain their freshness for longer period they are shrink wrapped in trays covered with plastic film.

Ready Made Meal

Most of the people prefer to use readymade meal as it save the time that can be consumed in kitchen for preparing meal by oneself. That’s why restaurants and other sectors sell their prepared food in trays that are processed by a shrink wrapper.

Sweets

Research has shown that sweets get contaminated by the chemicals that are present in the cardboard boxes in which they are packed. Thus, to keep them fresh and give traditional look with beautiful opaque films a shrink wrapper is employed.

Snacks

This machine can also process snacks in film wrappers such as peanuts, potato chips, chocolates, popcorn and other products as well.

Dairy Products

Products that come under the category of diary sectors are ideally recommended to be shrink wrapped like cheese, butter, yogurt etc.

Baked Products

Bread, pastries, cakes and biscuits are the things that we use on daily basis. In this way, they need proper packaging for save delivery and quality preservation that can be easily done by a shrink wrapper.

Fast Food

Like other goods fast food including burger, pizza and nuggets are directly shrink wrapped this machine.

Meat& Seafood

All type of meat, chicken and sea food can be easily packed by this machine both in raw and cooked form.

5.What Are The Major Components Of A Shrink Wrapper?

Just like human body, a shrink wrapper is the combination of many parts each performing particular function. These components are separately described as under:

Main Frame

It consists of the overall structure of machine like table, the design of machine, moving area, conveyor belt etc. The main frame of machine is made up of rigid stainless steel that is corrosion resistant and anti-acidic.

Material Handling System

This part of machine basically deals with the movement of objects and comprised of conveyor belt, collation mechanism and support rails. The smooth packaging of machine entirely depends upon the stability as well as ability of conveyor belt to stand up to the workload.

Electrical and Control Systems

Here is another system of a shrink wrapper that provides you with human machine interface and PLC control system. Both of them directly affect your packaging process. The former facilitate you in setting the parameters while as later controls the motion of all electric, pneumatic and servo parts of machine.

Sensors

Sensors help in detecting the presence of objects and send the message to machine for performing the action accordingly.

Film Reel

It is also known as film cradle or accumulator on which film is wounded in the form of layers so it can be easily dispensed over the products.

Film Feeder

Film feeder ensures the consistent flow of delivering film to items. Its flow time is always kept low to reduce film waste.

Cutting Blades

This part of machine cuts the film when it is dispensed by the reel. The accurate and proper cutting of film reduces waste and assists the beautiful shape of products after shrinking.

Shrink Tunnel

The actual process of shrinking occurs here when products along with covered wrap enters the tunnel and machine heat the wrapping in order to integrate them in form of precise packed item.

6.What Type Of Films Are Used By A Shrink Wrapper?

To secure and protect the products from external environment various types of films are utilized. These films are basically consists of three types which are explained below:

Polyvinyl Chloride (PVC)

Polyvinyl Chloride film is made up of chlorine, carbon and hydrogen. Once it remains the most common shrink film popularly used around the world due to its light weight, inexpensive and multi-purpose processing capabilities. However, it is by nature sensitive due to which its ability of resistance becomes feeble after getting shrinked. It also releases harmful odors when heated. Most of the industries like construction, automobile, healthcare and electronics use polyvinyl chloride film for packaging of wires, pipes and blood bags etc.

Polyolefin (POF)

This type of shrink film is extremely durable and comes with high flexibility ratio which eventually makes it a premium choice. It is prepared with 100% recyclable material and does not emit harmful effects after being heated. It is puncture resistant and even shows propagation in case of tear. Such type of films is also available in perforated form in order to fully eliminate the air that might be left in case of flat film. Its use has been appreciated by many sectors for packaging of toys, food items, books and condiments etc.

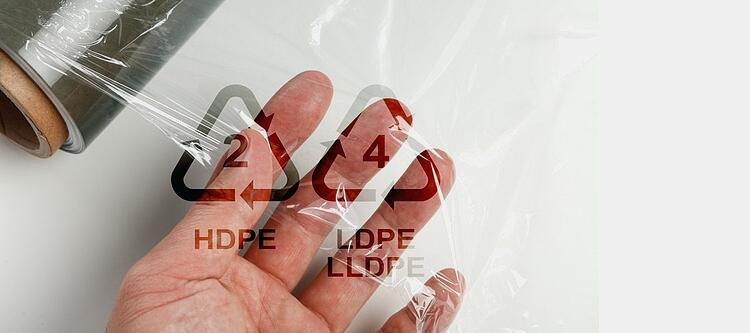

Polyethylene (PE)

Polyethylene film is formed by the combination of monomer and ethylene. It can be further categorized into three types including high-density polyethylene, low-density polyethylene and linear low-density polyethylene. It effectively makes a strong barrier against moisture and chemicals also prohibit air inclusion. With exceptional versatility it is most commonly used plastic film among others. Thus it can be applied to wide spectrum of goods such as shampoo bottles, beverages, cereal box and personal care products.

7.Explain The Different Types Of A Shrink Wrapper?

There are many types of a shrink wrapper which can be divided into two fundamental categories. They are:

On The Basis Of Automation

Fully Automatic Shrink Wrapper

Fully automatic shrink wrapper is innovative machine that comes with certain benefits in order to give your business optimum production. This model of shrink wrapper eliminate the involvement of an operator in handling machine thus save your time and hassle of direct contacting. This machine is directly connected to a production line. It is capable of processing 100 packs per minute in a smooth consistent manner. Whilst keeping in view the demand of various firms, it can handle the objects with different shapes, sizes and volume.

Working Principles

Process of this machine is automatic and gets started after completing the initial phase of fixing parameters. Products directly come from production line via conveyor belt towards machine where plastic film it put down by the roller and objects are surrounded with loose cover. They are then moved ahead for getting heat and finally shrinked by the machine for final outlet.

Components

This machine is constructed with stainless steel and parts including main frame, transporting system, human machine interface, PLC control system, servo motor, sensors, fail-shut down components, film roll, cutting knife and temperature sealing system.

Application

Due to its high capacity and fast performance most of the large scale industrial sectors with excessive workload preferred to incorporate this automatic equipment into their production line. These include beverage industry, chemical, cosmetic, automotive and hardware industries.

Semi-Automatic Shrink Wrapper

Another type of shrink wrapper is semi-automatic which carry the operator fed items. This is also efficient in its yielding capacity and used as a separate machinery without any direct link with manufacturing line. Range of models can be found in semi automatic shrink wrapper. Moreover, these machines have good availability for customization and usually reach the speed of packing 10 cartons in a single minute.

Working Principles

Machine initiates processing after objects are manually placed in machine. Film is released onto a platform where products are positioned. Blades cut the film and items are transferred to the shrink tunnel. Inside thermal energy lead to the contraction of film around the product after which they come out of the tunnel in ready form.

Components

Formation of a semi automatic shrink wrapper is the result of various components such as shrink tunnel, roller conveyor, adjustable plastic reel, cooling system, film feeding, control board, emergency stop switch and film cutters.

Application

Such type of machine is most suitable for medium to large production volume. That’s why number of companies including dairy, pharmaceutical, chemical, fresh food and toys industries are looking for its services.

Manual Shrink Wrapper

This machine is entirely dependent upon user for its execution. It efficiency is directly linked with the performance of an operator engage with machine. However, it is inexpensive, consume less power and occupy less space compare to automatic and semi automatic models. Using this machine is not a difficult task but your correct understanding is necessary.

Working Principles

Operator feed the machine with placing objects separately or collectively. Products are pushed forward with the help of hands and button of machine is powered on where a gate type device quickly fall downward and cut the film. These packs are then picked up by user and placed in another machine having tunnel system. Here they get shrinked.

Components

Some of the major components of this machine includes film roller, shrink tunnel, control system and hot knife temperature cutter.

Application

It is useful for small business start-ups like household products, confectionaries packaging, books, gifts and processed food etc.

On The Basis Of Structure

Chamber Shrink Wrapper

This type of shrink wrapper has structure like table over which chamber with transparent cover is located. It can be found in fully automatic, semi automatic and manual model. Moreover, its structure is straight forward so cost is also reasonable. Along with that its performance is fast enough to deal with medium to large volume.

Working Principles

Film is pulled out from roller and laid down over table. Material is placed inside the film and grabbed towards heating area where transparent dome is pulled downward over the object in order to create environment free from air. At that time, button for starting heating fan is turned on which shrink the plastic closely around the object. Product is finally ready for outlet.

Components

The main parts of machine are high straight transparent dome, control panel, packaging film holder, flat surface, heating device with blower motor, film cutters and wheels etc.

Application

For wrapping of books, households and products on medium level this machine is good choice. For example, markets, gift shops and utility stores have trust over the machine.

Shrink Sleeve Wrapper

A shrink sleeve wrapper is an automatic machine that is employed to cover the bottles by creating 360° degree wrapping around the containers. It provide you an opportunity to label your goods with different shapes and design so your products would be recognized by those labels. It can be directly linked to production line.

Working Principles

Bottles continuously come from bottom line via conveyor belt. Here round shape films are dispensed over bottle one after another. These bottles are pushed towards heat tunnel where film shrink around the bottle and transform into containers shape.

Components

The structure of machine is complicated with parts including conveyor, bottle separator, sensors, frame , table blade, touch screen etc.

Application

Its use can be traced in beverage industries like bottle containing juices, cold drinks and milk etc.

Heat gun for shrink wrapping

This small size heating device is integrated with high power of heating. It can give you optimum result along with easy usability, maintenance and low cost.

Working Principles

It can be brought into operation by putting plug into electric board. Right after getting current the fans inside machine started and pulls the air inside equipment which join together with the heat and come out of the nozzle. This consequently creates shrinking of film surrounded by object.

Components

It consists of wire, plug, two speed switch, power cord, heating core and electroplated iron air duct.

Application

It is perfect for professional use and mostly use in automotive, shipping and automobile Industries for covering cars, helicopters and other objects.

8.Differentiate Between An Automatic Shrink Wrapper And Manual Shrink Wrapper?

Both automatic and manual shrink wrapper are associated with similar task of wrapping objects, although their cost, performance and capacity vary. You should be well aware of these differences before choosing for any one. For knowing distinction look into the table below:

| No | Factors | Automatic Shrink Wrapper | Manual Shrink Wrapper |

| 1 | Definition | An automatic shrink wrapper refers to the standalone machine that uses heat to shrink the wrapper placed around the objects. | Manual shrink wrapper on the other hand entirely depends upon manual intervention of an operator to shrink wrap the products. |

| 2 | Working Procedure | Its working procedure is based on certain steps like loading of goods, film feeding, cutting, and shrinking after getting passed through the heat tunnel. | Method of executing a manual shrink is quite simple because it does not follow predetermined steps rather operator put the object in film and places it inside heating area where it is shrunk in few moments. |

| 3 | Structure | Structure of an automatic shrink wrapper is complex with many parts like sealing system, temperature control system, material handling, guarding and safety system etc. | It has uncomplicated texture with small foot print that can be easily adjusted with less |

|

4 |

Speed & Capacity |

Due to its high degree of automation the machine give you extremely high output with fast performance. | This type of machine has low capacity because of its small design only one item can be packed in a single time. Subsequently, it affects the speed of machine to lowest level. |

| 5 | Cost | Its cost is high due to large number of components and heating mechanism. | In contrast, manual shrink wrapper is more economical with less cost. |

| 6 | Application | It is the first choice of large manufacturing firms like that of beverage, dairy, cosmetic, pharmaceutical and lubricant industries. | Due to its low capacity and cheap price its sphere of usability is confined to few sectors like book shops, grocery stores and houses etc. |

| 7 | Machine |  |

|

9.Compare And Contrast Between A Shrink Wrapper And Stretch Wrapper?

Both the shrink wrapper and stretch wrapper has similar purpose of packaging however, they are different in their structure, functions and operation. To understand these distinctions look into the table below.

| No | Factors | Shrink Wrapper | Stretch Wrapper |

| 1 | Definition | Shrink wrapper refers to the packaging equipment that is used to cover any type of product with a film wrap which get shrinked after getting heat. | Stretch wrapper is an automatic machine employed to bind the cartons with stretchable film without using heat. |

| 2 | Working Procedure | Products are loaded on flat surface; film is dispensed over these objects which are further taken by a conveyor belt. After passing through shrink tunnel the film is shrinked around the objects. | Cases are loaded on the turntable of machine in organized form which constantly rotates the weight. The stretch wrap holder starts releasing film on the load and completes process by moving upward through tower in straight direction. |

| 3 | Structure | The structure of a shrink wrapper is complicated compare to stretch wrap and consist of shrink tunnel, conveyor belt, heat system, cutting blades and film reel etc. | It has simple and precise structure with few components including lifting track, stretch wrap holder, cut clamp brush mechanism and turn-table. |

| 4 | Packaging Type | Shrink wrapper is frequently preferable as a primary packaging device. | Stretch wrapper on the other hand cannot be used for primary packaging rather it is only good for secondary packaging. |

| 5 | Cost | Shrink wrapper is expensive as it come with various complex components and heating system. | While as stretch wrapper is cost effective with simple structure. |

| 6 | Application | Shrink wrapper is used in every industry whether small, medium or large scale including food processing, chemical, medical, automotive and cosmetic industries etc. | Contrary to shrink wrapper, stretch wrapper is mostly utilized for bundling and shipping purposes so large industrial sectors prefer its usage like wholesale markets and shipping companies etc. |

| 7 | Machine |  |

|

10.What Are The Disadvantages Of Using A Shrink Wrapper?

Despite having lots of benefits a shrink wrapper has some cons which are described below:

Expensive

A shrink wrapper is expensive due to its various complex components and use of high quality film which adds into its cost.

Limitation of film

There are many types of films used for shrink wrapping products among which PVC is also included with reasonable price. However, has poor resistance to pressure and also gets brittle when heated. This indicates that only limited types of films are used for shrink wrapping.

Environmental Impact

As a shrink wrapper use plastic films that are made up of various chemicals which sometime emit harmful gases and strong odors. In this way it is detrimental for environment.

11.Highlight The Prominent Entities Who Are Keen To Incorporate The Shrink Wrapper Into Their Production?

There is no industrial sector left from the use of a shrink wrapper. To prove this, we have described different industries that are using this machine:

Medical Industry

For labeling and bundling the bottles of syrups, tablets and capsules this machine is always the first choice of pharmaceutical companies. In addition, for safety of surgical instruments and bandages a shrink wrapper is used to pack them in films via heat shrinking.

Food and Beverage Industry

Shrink wrapper is one of the most popular machines extensively used in food and beverage industry. Enormous goods of bakery, restaurants, dairy firms, confectionary industry like juices, milk, sweets and vegetables etc are processed by this machine on large extent.

Cosmetic Industry

Cosmetic and health care products are often sealed in multi color labels by this machine to give them proper recognition.

Chemical Industry

Various forms of organic, inorganic, solid and liquid chemicals are processed by this machine. Furthermore insecticides, pesticides and dyes are also among these objects.

Automotive Industry

You may have never seen the vehicles covered in plastic wrap but it is commonly practiced in particular areas like that of airport. Helicopters, containers and vehicles are sealed by this machine.

Oil & Lubricant Industry

Lubrication and oil industries are engaged in day to day activities of producing and supplying their customers with these essential products. To accomplish these tasks, services of a shrink wrapper is taken.

Shipping Industry

From small products to large commodities, every item is now transported from one place of the world to another. Subsequently they need proper packaging for which shrink wrapper is one in all solution.

Hardware Industry

Manufacturers from hardware sectors like plastic, electronics, metal and glassware are effectively utilizing this machine on broad range to secure their goods from dust, dust and damage.

12.Describe The Common Problems Faced When Using A Shrink Wrapper? Also Highlight The Causes Behind And Give Solutions For Resolving Them?

Despite being the most famous and versatile solution, a shrink wrapper may cause challenging situation during processing due to improper handling of shrink wraps or heating devices. To counter such problems you should be well aware of their troubleshooting which are described below:

| No | Problems | Causes | Solution |

|

1 |

Tunnel is not generating heat |

There may be a voltage problem | Correct it by checking the power infeed for proper electric supply delivery |

| Tunnel heat setting is incorrect | Turn up the tunnel temperature | ||

| Wires around the heating coil are loose | Well tight the wires manually | ||

|

2 |

Shrink wrapping display problem |

Insufficient shrinking of film cause the film look like dog’s ears | It can be solved by using quality films and applying sufficient heat to shrink film |

| Direct contact to hot air right after sealing leads to ballooning of shrink wrapping | It can be avoided by using pre-perforated films | ||

| Too much heat result in burn holes | Temperature should be reduced to moderate level | ||

|

3 |

Conveyor does not work properly |

Conveyor speed might be on zero | Inspect the speed and set it to desired level |

| Chain of roller is out of the sprockets | Check and correct the chain for smooth running of conveyor belt | ||

| There may be fuse damage or inappropriate connection of wires | Be sure that all wires are accurately connected and replace the fuse in case of damage | ||

|

4 |

Blower motor is not blowing heat | It occurs when blowers get static and wires are loose | Check for continuity of blower motor in case of inconsistency replace it |

|

5 |

Jagged and incomplete sealing | It happens when seal temperature is too low | Increase the film sealing temperature for sharp cut-off |

13.Explain The Top Tips For Proper Maintenance Of A Shrink Wrapper?

Regardless of the perfection of your machine, it would always require you to look for its proper maintenance in order to run it smoothly and long lasting. In this regard we have enlisted few tips to assist you in machine handling:

- The initial step any operator should do is to train the staff before coming into direct contact with machine.

- Regularly check your machine and look if heating tunnel has an issue or of conveyor belt.

- Clean machine with wet clothe and wipe out before you start the machine.

- Lubricate the areas of machine for smooth running.

- An operator should wear his mask during the process as the emission of gases may occur when film is heated.

14.What Factors Should Be Considered Before Purchasing A Shrink Wrapper?

Buying new packaging equipment for your business is something that needs your full consideration and attention because it would ultimately shape the production of your bottom line. For this, we have highlighted some of the crucial factor for your ease just go through them:

Frequency of Usage

It is necessary to know the machine’s frequency of usage. If you are going to use it on daily basis then heavy duty shrink wrapper with automatic functioning would be a good choice. While as, for low volume production light duty or semi automatic machine is suitable.

The Product Packaging

Never overlooked the factor about packaging type your product looked for. For instance, if you are supposing to pack beverages or cosmetic items as a primary packaging then shrink sleeve wrapper is best machine but if your area of interest is delivering items in bulk form then shrink tunnel machine is the perfect answer for secondary packaging.

Type of Film

Various kinds of shrink wrap films are available in single or multi colors like polyvinyl chloride, polyolefin or polyethylene. However, each of them is having different specifications so you have to select the one that best suit your material nature.

Pick Manufacturing Wisely

Purchasing a shrink wrapper is like adding a major part to your production line. The machine parts, warranty and safety system should be your first priority. So, always choose a vendor that assures you full remote support and customer case services.

Conclusion

Shrink wrapper has influenced every sector and its significance is undeniable. It has gripped every industry in its area of applicability. Allpack in this regard, is providing you with models of your choice. If you are interested to get the best shrink wrapper or you want to know more about it just click on the link given below.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide