What is the Best Shrink Wrap Machine for Your Business: The Ultimate Guide in 2025

What is the Best Shrink Wrap Machine for Your Business: The Ultimate Guide in 2025

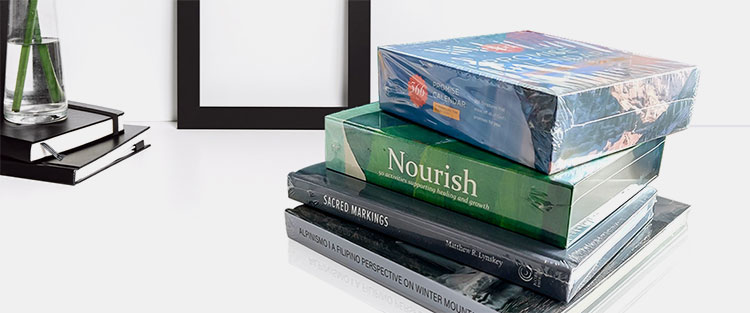

If you are strolling through a bustling contemporary manufacturing facility or shopping at a store, you may miss a crucial element: shrink-wrap. This clear sheet securely holds products, protecting items from the manufacturing line to the consumer’s hands. Shrink wrapping is a great packaging solution for businesses in several sectors and is a popular packaging option for various reasons.

If you are an entrepreneur or a facility manager looking to expedite your packaging process, selecting the right shrink wrap machine is critical for your business. It can save you time, funds, and effort in the long run.

Since each packaging line is distinctive, the ideal shrink wrap machine varies for each line. While many firms highly value uniformity and pace, you also need to think about the safety and labor features of the device and its integration compatibility with the rest of your line.

This blog post will be a perfect place for you to learn about shrink wrap machines and select the best one for your company.

1.What do you mean by shrink wrapping?

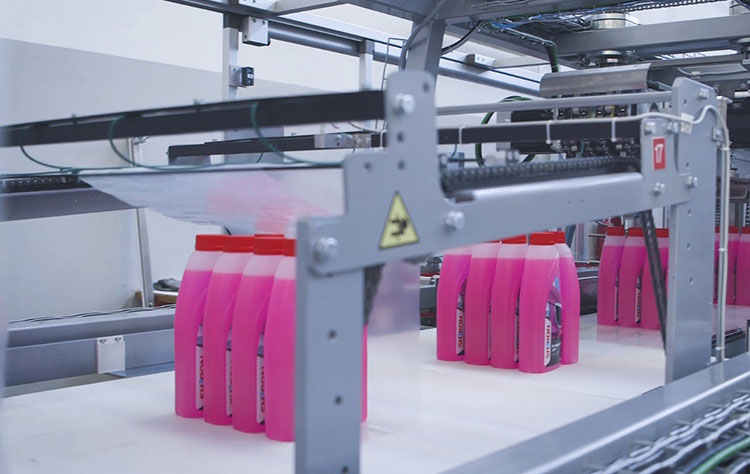

Shrink Wrapped Bottles

Shrink wrapping is a technique of covering materials in shrink films by applying heat. Shrink wrap is a plastic film made of polymers. The film contracts by the application of heat and firmly enfolds the material.

The shrink wrapping process can be performed through several methods. Heat may be applied using manual operation via handheld heat guns or an automatic shrink wrap machine where the film and material pass through a heat chamber. Shrink wrapping keeps the products secure during storage, handling, transportation, and distribution.

2.Which films are used for shrink wrapping?

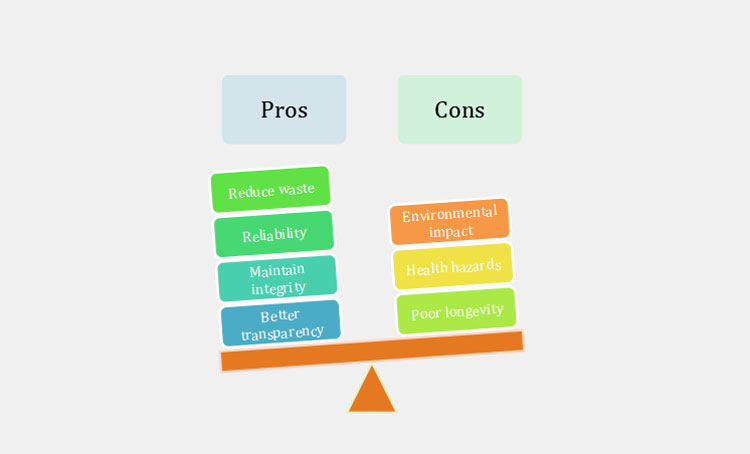

Shrink film is a multipurpose and indispensable substance employed in many sectors to package and secure goods. There exist several varieties of it, each possessing distinct characteristics and uses. Selecting the appropriate shrink film may greatly influence the operational efficacy and the product’s finished look.

Some commonly used shrink films are discussed below:

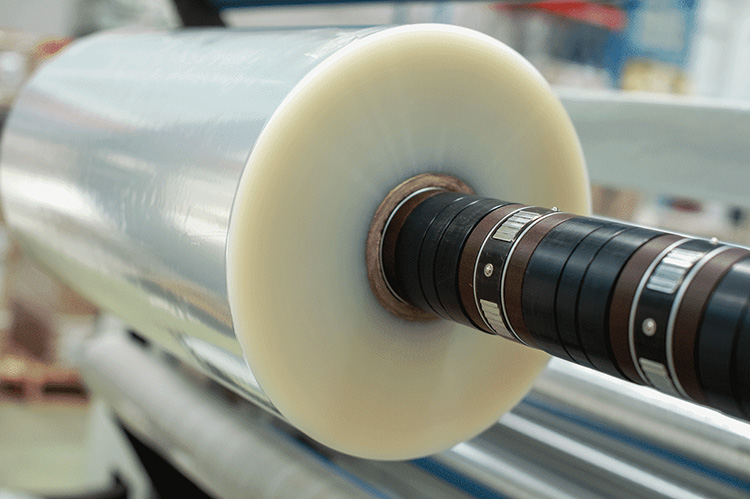

Polyolefin Shrink Film

Polyolefin Shrink Film

It is the most frequently employed film for both edible and non-edible materials. It offers a stronger seal, less smell, and more adaptable storage while sealing. It is utilized for almost all product categories, such as food, office supplies, playthings, athletic goods, and more.

The polyolefin shrink film comes in various forms, such as low-temperature and crosslinked. The former shrinks at reduced temperatures while the latter needs high temperatures but offers better seals.

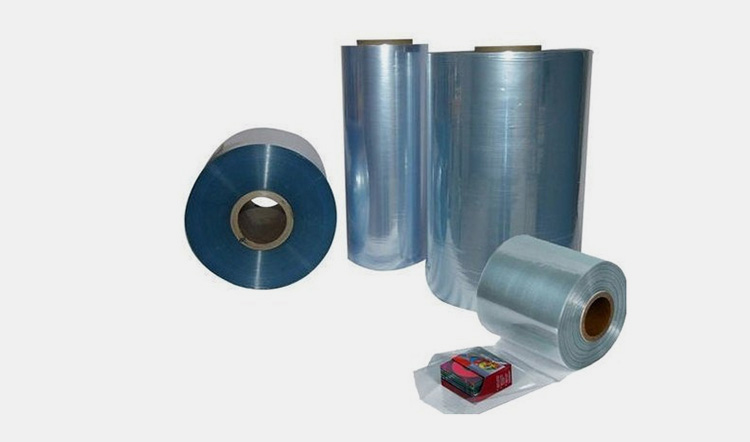

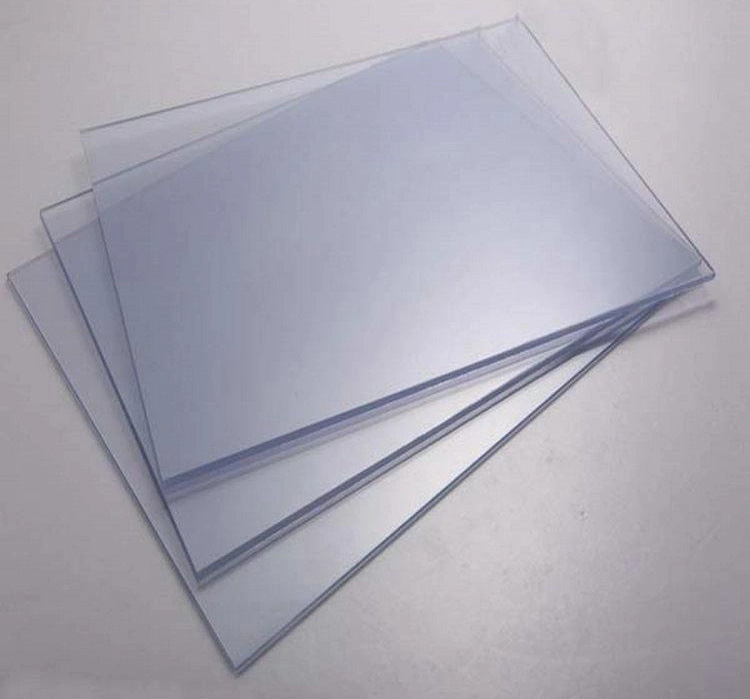

Polyvinyl Chloride (PVC) Shrink Film

Polyvinyl Chloride (PVC) Shrink Film – Picture Courtesy: Darnel Group

Polyvinyl chloride (PVC) ranked third among the most manufactured plastics. It is utilized for packaging containers/boxes, DVDs, compact disks, hardware items, and other inedible goods. The cons with this type of film include the sensitivity to extreme temperatures and the production of HCl gas.

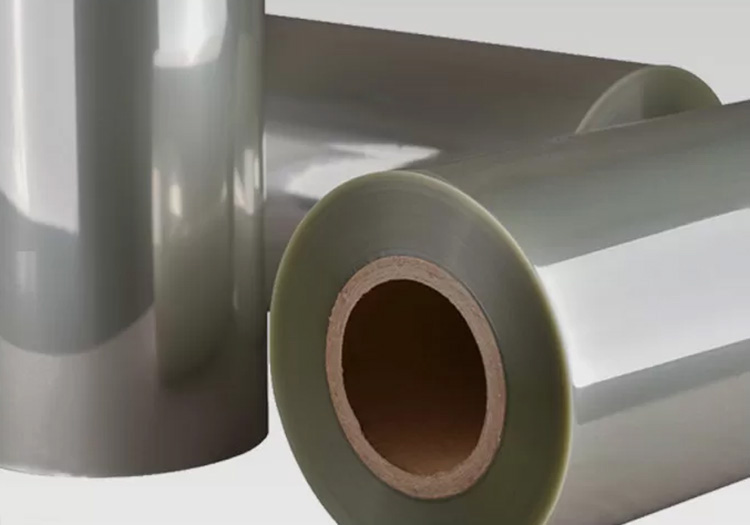

Polyethylene

Polyethylene

The PE shrink film is renowned for its firmness and durability. It is employed for large and heavier commercial goods. It exists in several forms, the common ones being the LDPE and HDPE.

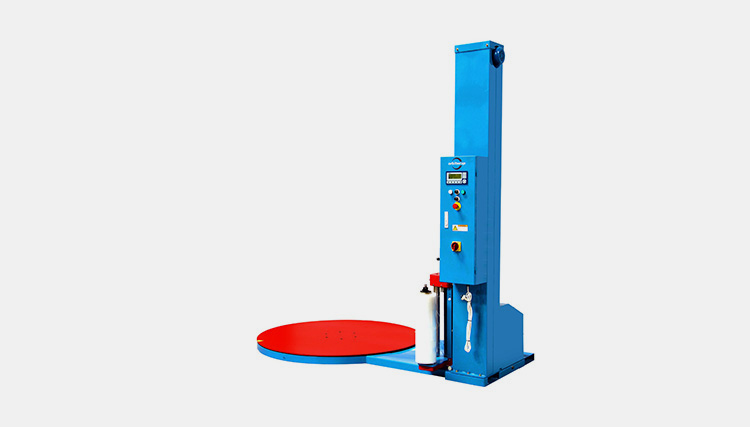

3.What is a shrink wrap machine?

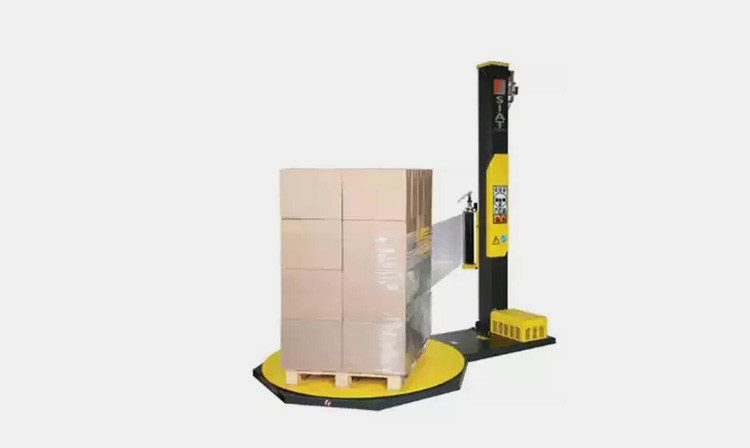

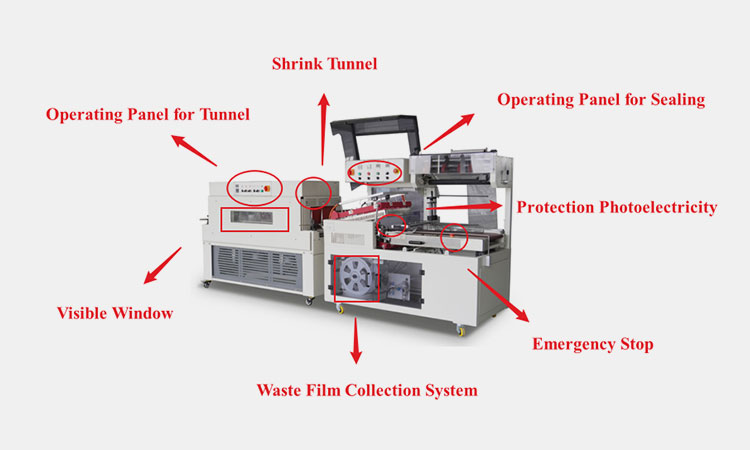

Shrink Wrap Machine – Picture Courtesy: Enoline Solutions

It is an indispensable device of the packaging industry designed to wrap materials in a transparent, plastic film, followed by heating the film and firmly attaching it around the material.

The shrink wrapping implementation is diverse across different industries. The process benefits in assembling of bundles of smaller items like jars, tins, cartons, and bags and shielding hefty industrial tools during conveyance and depot.

4.Why do businesses use shrink wrapping?

The reasons behind its utilization in your businesses are:

High-level Protection of the Materials

High-level Protection of the Materials

The polymer film serves as a shield to protect items from impurities including humidity, dirt, and grime. It extends the life expectancy of nutritional products. This also helps in protecting metal parts from corroding.

Secure and tamper-proof packaging

Secure and tamper-proof packaging

Shrink-wrapped objects are extremely challenging to remove from the plastic covering without breaking them. Hence it not only prevents the item theft but also alerts the owner/buyer in case of unwanted access.

Conservation of Resources

Conservation of Resources

Given that to the toughness and thinness of the shrink film, its usage instead of bulky boxes and crates allows you to the best protection of goods at lower expenses and resource consumption.

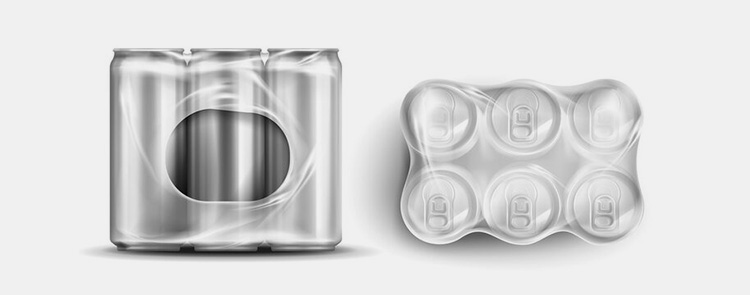

Assorting and Condensing of Materials

Assorting and Condensing of Materials

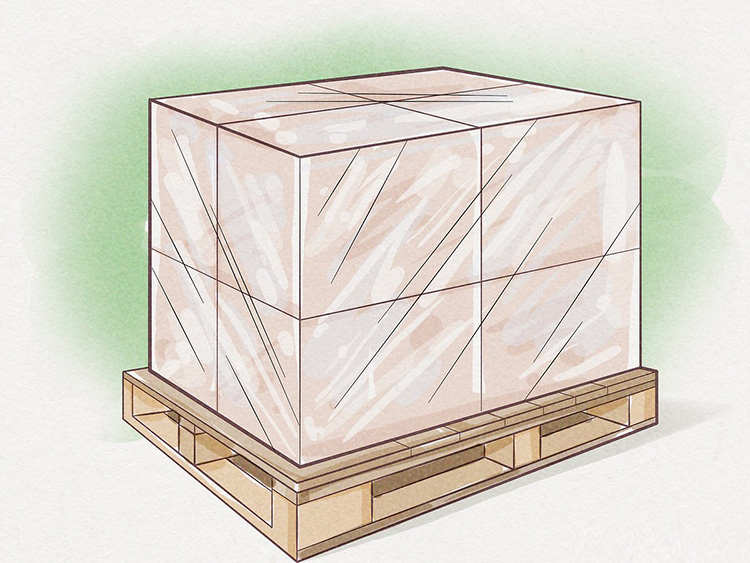

Shrink wrapping allows the materials to be firmly condensed from the corners. Items are sealed together securely, keeping them intact and protecting them from damage during transit.

Operational Flexibility

Operational Flexibility

Shrink wrap offers flexibility and can be used for numerous items, like hardware, food items, and large boxes. It protects these items from the external environment and makes them secure during storage and transportation.

Improved Branding and Advertising

Improved Branding and Advertising

Products that gain advantage from visual attractiveness may find it easier to sell to customers when they are wrapped in clear shrink wrap.

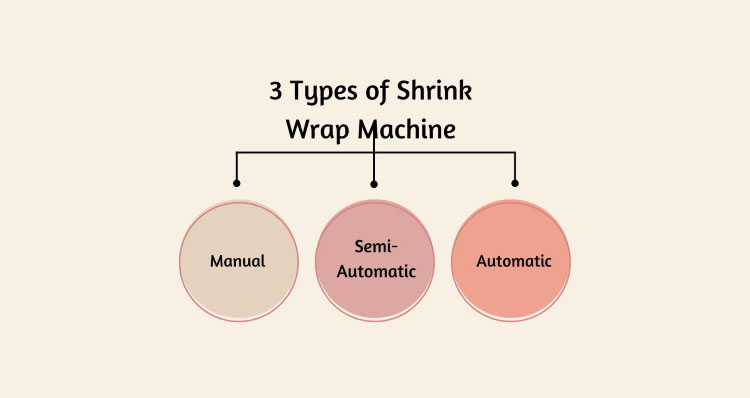

5.What different types are available for a shrink wrap machine?

The three major types are as follows:

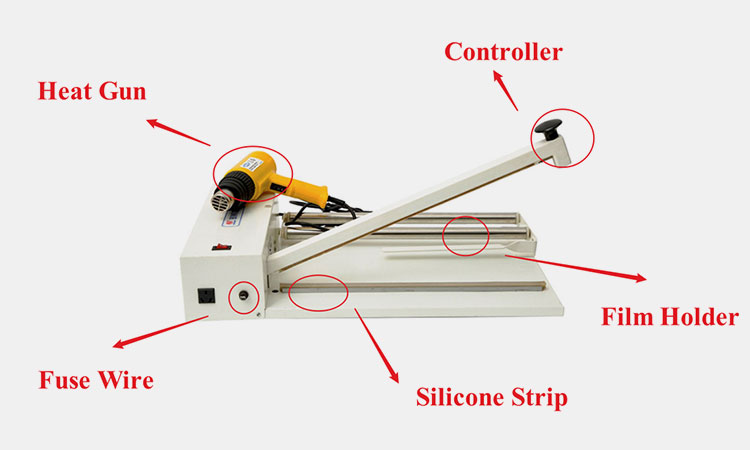

Manual-Shrink Wrap Machine

Manual Shrink Wrap Machine

A manual shrink wrap machine has the simplest design and affordable price and therefore is an ideal device for small enterprises and low-production sectors. This entails manual operational procedures including supplying and releasing items, wrapping them with film, and using heat cannons to seal and shrink them.

However, this device is economical but impedes huge manufacturing volume as it needs a lot of effort (labor intensive). This kind of device usually includes I-bar sealers and is suitable for encasing single materials or small packs.

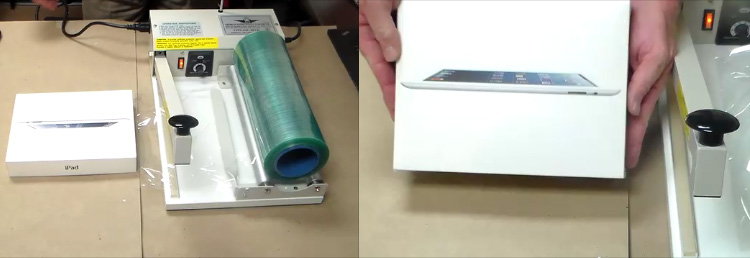

Semi-Automatic Shrink Wrap Machine

Semi-Automatic Shrink Wrap Machine

It is working in combination with automatic and human intervention. Although it reduces the need for manual involvement and frequently can mechanically compact and seal the products but still requires workers to feed and discharge the goods.

Companies that produce considerable volumes of goods with varying sizes may want to think about semi-automated machinery.

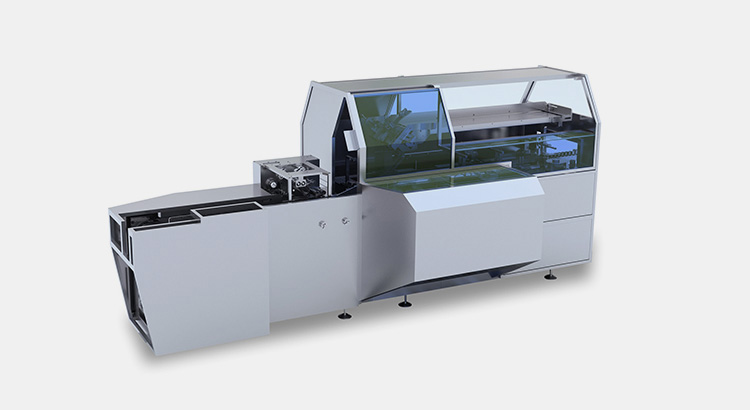

Automatic Shrink Wrap Machine

Automatic Shrink Wrap Machine

The automatic shrink wrap machine is designed to manage constant and extensive processes. It automates the whole shrink wrapping operation, including material loading, sealing, shrinking, and unloading of finished products.

This device is ideal for achieving the best productivity and operational efficiency but also needs the largest initial investment.

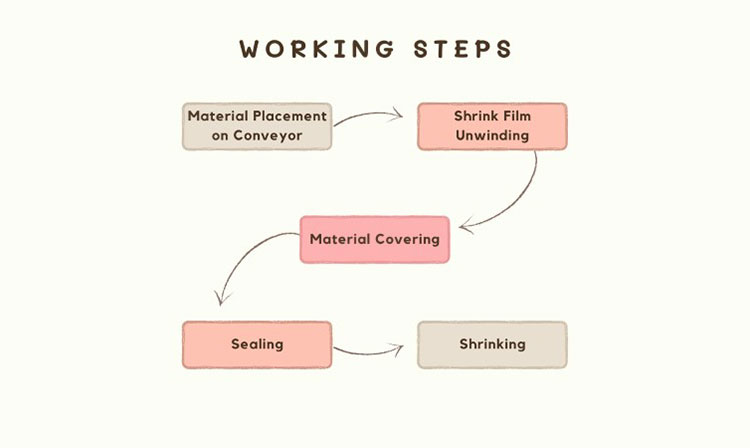

6.How does a shrink wrap machine work?

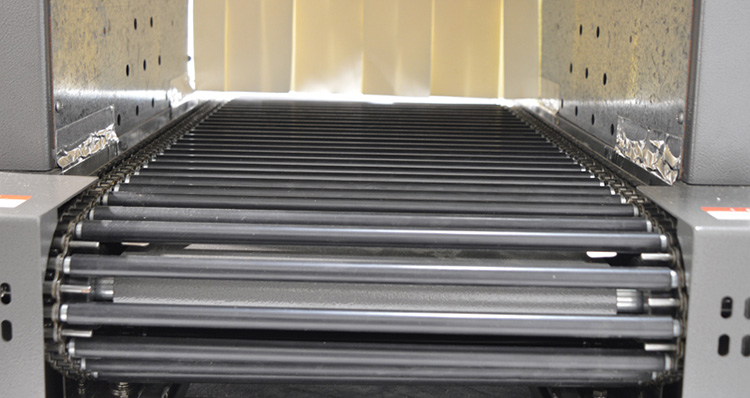

The shrink wrap machine has an easy and efficient functioning procedure. The process is initiated by placing the material on the device’s conveyor. After that, a shrink film ream is unwound, covering the material, and sealing it through a sealing bar.

Once the material gets covered, it is directed to the shrink tunnel for the application of heat, causing the film to compact and firmly wrap the material. This whole process results in a safe and elegant-looking package.

7.Can temperature-sensitive items be wrapped using a shrink wrap machine?

Shrink Wrapping of Temperature-Sensitive Goods

Yes, temperature-sensitive items may be wrapped using a shrink wrap machine. Certain machines include temperature controls, so you may reduce the heat for delicate things, for example, medicines, food, and chemicals. Additionally, there are low-temperature shrink films made for objects that are susceptible to variations in temperature.

8.What is the difference between I-bar sealers and L-bar sealers?

Every shrink wrap device has a core component, the sealing network, which is liable for producing a compact, firm seal around the materials. The two most common sealer configurations are I-bar and L-bar, each having certain advantages.

I-Bar Sealers

I-Bar Sealer

I-bar sealers have a heated sealing bar that is horizontal and straight, shaped like an "I." I-bar versions' straightforward, durable construction makes them perfect for sealing smooth, consistently shaped objects such as:

- Flat packs or bags.

- Rectangular products up to 20 inches tall.

- Packets or casings of cans, jars, or bottles.

- Boxed goods.

The horizontal sealing bar can produce a smooth, wrinkle-free seal since it easily seals over the top surface. Additionally, I-bar apparatus are often more cost-effective with faster working rates of about 35 packages/min.

L-Bar Sealers

L-Bar Sealer

L bar sealers is excellent for an asymmetrical structural items. The film may be sealed on both the top and side surfaces concurrently thanks to the L-shaped sealing device. L-bar systems are therefore perfect for:

- Multiple packets of standup receptacles or bottles

- Tall, tubular goods, such as reams of paper

- Objects with unusual shapes, such as shovels or car components

- Any item that is taller than twenty inches

The created “L-shaped” seal can effectively cover the arcs, projections, and junctions with uniform tightness. But this adaptability arrives at the expense of a little reduced speed—about 25 packages/min on average.

Though both techniques provide reliable seals, the decision is based on the particular material sizes, shapes, and productivity needed. L-bars provide the flexibility needed for intricate or higher-end product features, but I-bars are difficult to beat when it comes to the affordable speed wrap of packaged goods.

9.How to improve the efficiency of shrink wrap machine?

Here are some key aspects to optimize for the improvement of the packaging process efficiency:

Optimize the material loading systems to guarantee organized and uninterrupted supply by integrating solutions like timed conveyors and feed augers.

Harmonize the device specifications with the product’s size, shape, and volume to avoid bottlenecks.

Integrating the device with automated equipment in the production line will result in a flawless process without manual inaccuracies.

Establishing a strict schedule of preventive maintenance and technical services keeps the optimum equipment performance and reduces detrimental breakdowns.

10.How do you maintain a shrink wrap machine?

Regular maintenance of the shrink wrap machine is essential for optimum performance and efficient results. Some of the key steps to follow to maintain your shrink wrap machine are:

Regularly examine the sealing section and thoroughly clean it.

Monitor the temperature in the shrink channel and regulate it according to the film and material characteristics.

Ensure the streamlined functioning of the conveyor by regular inspection of conveyor belts and immediate replacement (if damaged) and lubricating the moving parts.

Observe the condition of the shrink wrap regularly and consider replacement as needed.

11.What to consider when buying the right shrink wrap machine?

For procurement a shrink wrap machine, with so many options, combinations, and levels of automation available, making an informed decision is very tricky. These crucial considerations include:

Volume of Production

Volume of Production

No matter how many things are wrapped every day—hundreds or thousands—having the right device capacity is essential to achieving maximum efficiency and economy. A lower capacity device will cause problems while an oversized machine is a wasteful expenditure.

Handheld device variants may usually handle up to 5 packets each minute. That works out to 24 hundred packets in a shift of 8 hours. A manual device could work for a small enterprise with limited production demands.

However, if you have a huge volume of production, such as a medicine or food business, you might need a semi-automated or completely automated shrink wrap machine.

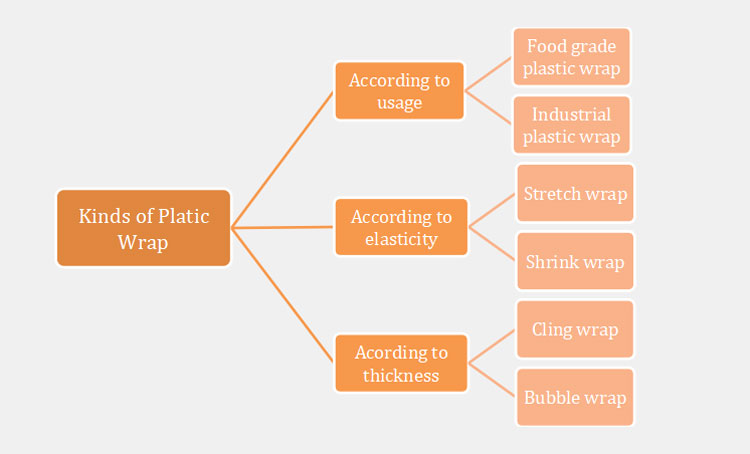

Types of Shrink Film

Type of Shrink Film

The type of shrink film used greatly influences the performance of the shrink wrap machine. Therefore, it is crucial to opt for the device compatible with your desired film. The most used types shrink films used are:

Polypropylene films (a type of polyolefin film) have properties, like excellent lucidity, humidity resilience, and broad limits of heat shrink, which make them ideal for covering several objects, like food, beauty care, and medicines.

Apart from the composition of the film, other elements that affect efficiency include its thickness, slip properties, and heat shrink limits. More heat is needed for thick films to shrink, but they are more durable. Films that include slip enhancers lower friction and facilitate shrinkage and closure.

Safety Elements

Safety Elements

Shrink channels can have temperatures of more than 200°C. Therefore, opt for the device with excellent cooling mechanisms to minimize surface temperatures and lower the risks of burning during the process. Additionally, the device should have a guarding element to avoid contact with the moving components, such as wrappers and sealers.

An immediate cessation mechanism is also crucial to cease the entire process in case of any incident.

Budget

Budget

Budget plays a significant role in the ultimate decision of selecting a specific device for your business. It is recommended to consider the initial investment as well as the required operating and maintenance expenses.

An efficient and easy to maintain device with a significant initial cost could prove cost-effective in the long run by requiring less utility and maintenance expenditures. A wise shrink wrapping purchase necessitates carefully weighing both the present and future financial implications.

Conclusion

Selecting the ideal shrink wrap machine for your company's requirements is a crucial choice that will have a big impact on the effectiveness of your packaging, the safety of your products, and your bottom line. By careful consideration of the factors discussed in the blog, you may able to get your desired shrink wrap machine that could satisfy your unique needs and advances your company. Always remember that selecting the best shrink wrap machine is an investment in your organization’s future growth and success. To remain on top of things, don't hesitate to ask packaging specialists, such as the Allpack team, for further guidance and investigation of the newest developments in shrink wrapping technology.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide

What is the Best Shrink Wrap Machine for Your Business: The Ultimate Guide in 2025 Read More »

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours