Syrup Cartoning Production Line: The Complete Buying Guide In 2024

Mere packing your syrups into bottles is not enough for ensuring their safety especially during transit. Infact, it is also very crucial to have properly displayed the product information over package for which secondary packaging of syrup bottles is significant. Therefore, to encase syrup packages into cardboard cartons, you will require a sophisticated machine which is the one and only a Syrup Cartoning Production Line.

It can perfectly carry out multiple tasks to provide error free syrup cartoning. But the question is, how can it be brought into operation? What are its essential features? Does it support multiple syrup bottles? How to conduct its regular maintenance? These all with many other questions will be answered in this detailed buying guide. So, be ready to explore it!

1.What Is Syrup Cartoning Production Line?

Allpack- Syrup Cartoning Production Line

Syrups are often delivered in durable bottles such as plastic or glass bottles to ensure their safety until they reach consumer. Similarly, these syrup bottles are further protected by the introduction of a cardboard box around them. For this, a specialized equipment is being made which is known as syrup cartoning production line.

This packaging solution is tailored with advanced features due to which it carries out the task of encasing syrup bottles into cartons automatically. During this process, it performs multiple operations such as carton forming, loading, closing, and printing etc. That's why, it is termed as a production line for syrup cartoning.

2.Explain The Benefits Of A Syrup Cartoning Production Line?

A syrup cartoning production line is extremely beneficial with highly updated design and sophisticated technology which is enough for accomplishing multitude of tasks independently and give you utmost production output. Some of these advantages are enlisted below:

Multi Tasking

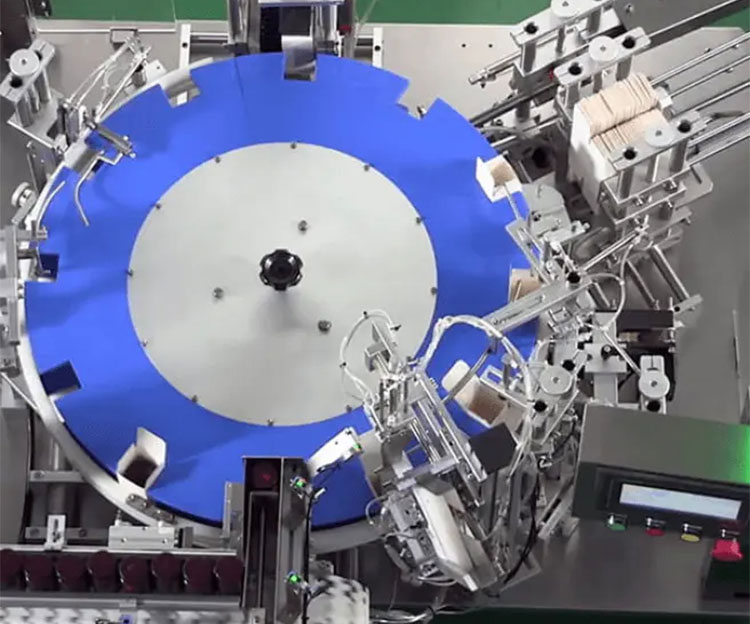

Multi tasking worktable of a syrup cartoning production line- Picture Courtesy: sirosilo.com

One of the top benefits of a syrup cartoning production line is its multi tasking ability with higher automation level. It can be better understand by seeing it to form the carton from flat cardboard, loading it with a syrup bottle and then closing it tightly by using different methods of flap folding or glue sealing. Moreover, it imprint the necessary data about syrup on carton for secure drug usage.

Quality Performance

Quality cartoning- Picture Courtesy: sirosilo.com

This production line ensures that the syrup bottles are packed precisely and efficiently by eliminating packaging errors. For instance, it automatically rejects the syrup bottles with lacking carton or instruction manual before output and maintain the quality of product as well as packaging throughout operation.

Customizable

Cartons of different sizes- packagingoftheworld.com

Another key attribute of a syrup cartoning production line is its adaptability to process syrup bottles of different shapes, sizes, and material. In addition to it, the equipment offers multiple ways of sealing as per your requirements, such as hot melt glue sealing, ultrasonic sealing, and flap insertion etc.

High Level Automation

Automatic carton forming- Picture Courtesy: sirosilo.com

This production line falls under the category of fully automatic solutions and give you production output of 100 cartons per minute. It can be integrated with a syrup bottle feeding machine, labeling machine, bundling machine, and case packing machine. And all these units are dependent upon just a small size human machine interface which controls the regulation of machine.

Durable Construction

Durable Intermittent motion vertical cartoner model "AV"- Picture Courtesy: heal.eng.co.uk

With all the components being made from quality stainless steel, it is highly safe to process syrup bottles. For final cartoning section, there is a protection window to restrict product contact with environmental elements and formulate a precise finished package.

3.What Are The Working Principles Of A Syrup Cartoning Production Line?

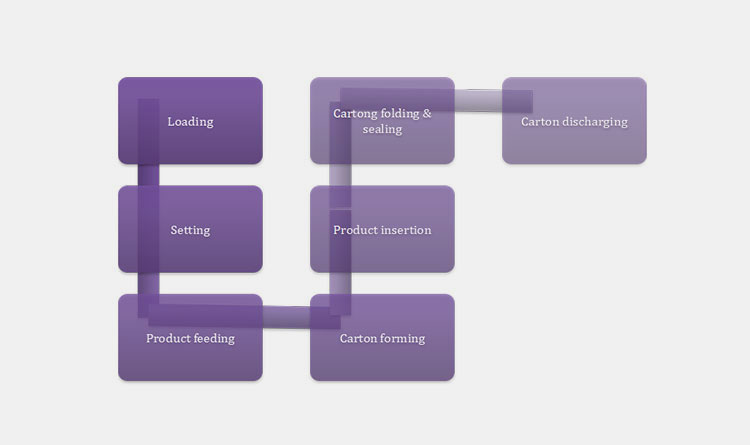

As there are multiple types of syrup cartoning production line, so, you may notice a bit difference in the way it is brought into operation. However, the general working principles for all these types are similar. You can easily get it by looking into the underlying steps:

Loading

Magazine loading

The very first step of the working principles of a syrup cartoning production line include its loading with a stack of unformed flat cartons and manual instructions. These cartons and leaflets are fed to the separate magazine of equipment from where the pick and place assembly take it and process for formation.

Setting

Secondly, the operator will adjust the setting of machine as per the requirement of packaging. It includes setting the speed of machine, conveyor belt, and data for printing on carton such as manufacturing date, expiration date, and price etc.

Product Feeding

Syrup bottles feeding- Picture Courtesy: Chengxiang

A syrup cartoning production line has an integrated unit for syrup bottle feeding which is known as bottle turntable. It helps in the product feeding into production line once machine gets started.

Carton Forming

Carton forming

Now, the machine will be switched on for functioning. The bag pick and place assembly start taking the empty flat cartons from magazine and placing it over conveyor belt one by one. During this phase, the cartons are opened with the help of the stainless steel edge and after its opening, the product insertion takes place.

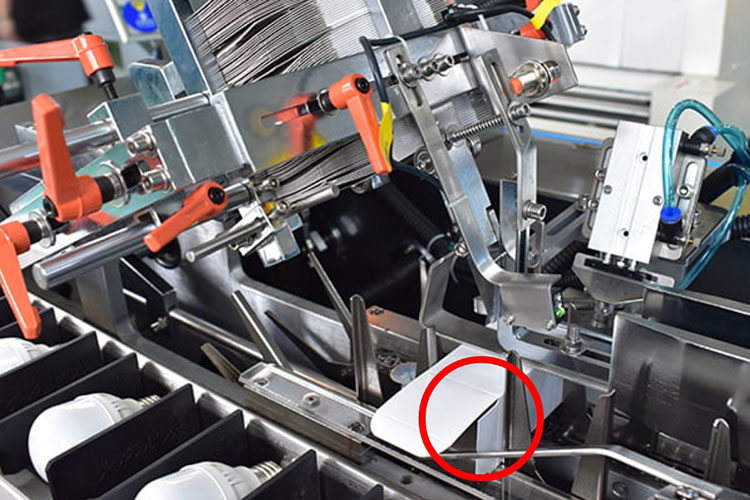

Product Insertion

Syrup bottles & leaflets insertion- Chengxiang

As the carton is opened and moved through conveyor belt, syrup bottle move in same corresponding path and when they reach a specific station, a flapper insert the bottle into carton. Along with it, a leaflet is also inserted into each passing carton being loaded with syrup bottle.

Carton Folding & Sealing

Carton folding- Picture Courtesy: Chengxiang

Moving forward, the filled cartons are pushed ahead where the ears of carton are folded through the pushing plate and cam-coupled motors. Depending upon the type of sealing method being used, the use of glue can also be undertaken during this phase to enhance the carton additional security against opening.

Carton Discharging

Carton discharging- Picture Courtesy: Chengxiang

At last, the finished cartons are passed through optional printing step and with the help of parallel conveyor belts, these cartons are discharged from the machine for further packaging.

4.Describe The Structure Of A Syrup Cartoning Production Line?

Syrup cartoning production line has simple structure with several components. Each component perform particular task to carry out the syrup cartoning function. A brief detail of each part is given below:

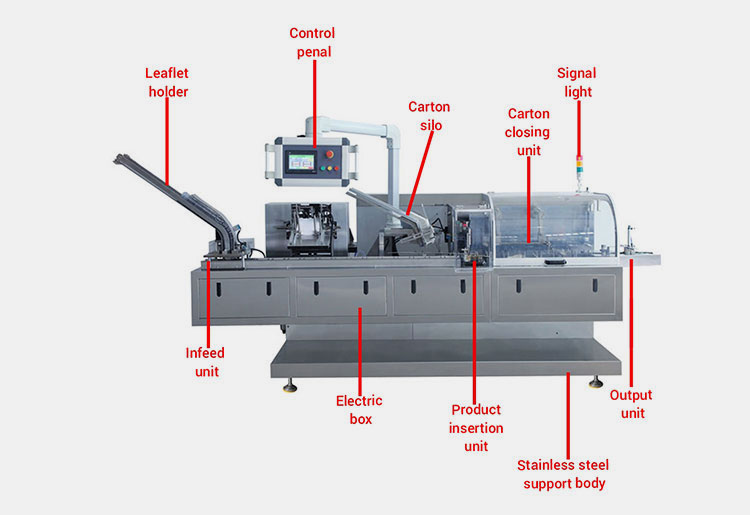

Structure of Allpack Full Automatic Bottle Cartoning Machine

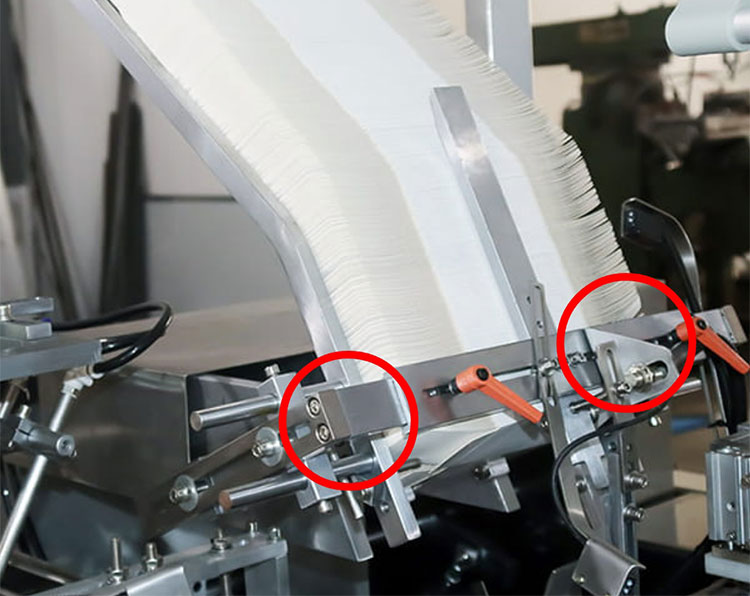

Leaflet Holder

Leaflet holder is a sort of magazine located in the syrup cartoning production line for holding stack of flat leaflets or instruction manuals. From here, the leaflets are taken and fixed into passing drive belt.

Control Panel

It is one of the primary and most important part of the equipment which is also referred as the brain of machine. It has a small human machine interface which display over it multiple parameters to set commands in machine and regulate the machine as per fixed commands. Along with it, several knobs are also placed near the interface which include emergency stop, power button, and reset button etc.

Carton Silo

Carton silo is a magazine which is responsible for holding the stack of unformed flat cartons. It is made in such a way that cartons cannot fall over the conveyor until the picking assembly automatically pick carton from it.

Carton Closing Unit

It refers to the integral unit of a syrup cartoning production line where the final closing of cartons is carried out. Therefore, it has multiple tools on both sides of the conveyor which helps in the closing of cartons flappers. In case of melted glue sealing, this unit will have a heated gun which will inject the melted glue between two flaps and after cooling the flaps will be tightly closed to each other.

Signal Light

Signal light is also called alarm light which indicates the working condition of machine. It provides visual and audible indicators of the equipment status in form of colors and sounds. For instance, red light indicates the emergency caused by any part breakdown or malfunction, green light shows the normal condition of machine, while as, blue light means that external help from operator is required. It can be feeding of product or maintenance etc.

Infeed Unit

Infeed unit is the product feeding inlet from where the syrup bottles are introduced into a syrup cartoning production line. For this, a turntable is attached to the equipment for non-stop smooth feeding during operation.

Electric Box

This is another important part which encases all the electrical components like wires, switches, and fuses etc., for protection. It also has motors inside it which are significant for providing the mechanical energy to various parts of the production line such as guide rail, conveyor belt, and bag forming assembly.

Product Insertion Unit

It is another section which is used to insert syrup bottles along with leaflets, each at one bottle, into carton.

Stainless Steel Body

This solution is made from durable stainless steel which is fully protected against corrosion and bacteria. The support body is what all the other components of machine are attached for stable functioning of machine.

Output Unit

It is the discharge station which is located at the end of machine. It has a parallel pair of conveyor belts which holds the finished syrup carton till its safe discharge into a collection container or adjoined machine.

5.Explain The Types Of A Syrup Cartoning Production Line?

A syrup cartoning production line can be divided into two different types which are explained below:

Horizontal Syrup Cartoning Production Line

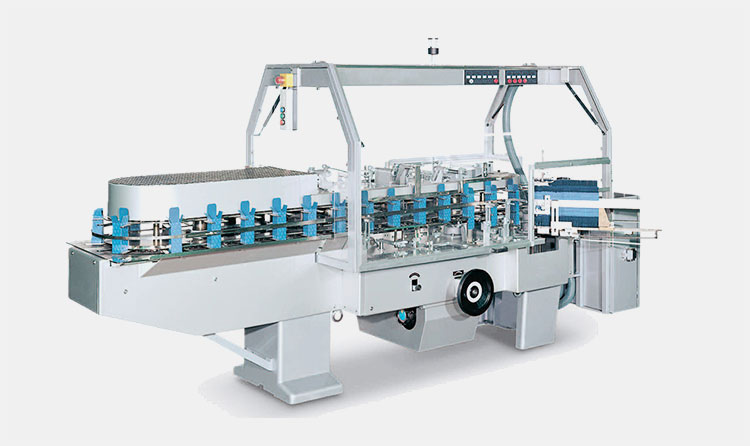

Allpack- Horizontal Syrup Cartoning Production Line

Horizontal syrup cartoning production line is an efficient machine which can perfectly pack your different sizes syrup bottles into cartons. It can be linked with other machines including bottle feeding machine, labeling machine, bundling machine, and case sealing machine etc. Its speed frequency stood at finishing 100 packs per minute.

Structure

The structure of production line is horizontal with all the components being arranged in horizontal manner. So, it may take a bit larger surface than the vertical machine. Its major parts include a carton magazine, leaflet silo, control panel, protection window, electrical system, and carton closure unit etc.

Working Principles

It functions by processing the product in a horizontal way over guide rail where leaflet is placed along each passing syrup bottle and after a small interval carton box is dropped by the magazine. Similarly, it is accurately formed and the syrup bottle along with leaflet is inserted inside the carton. After this, carton is closed and ready for output.

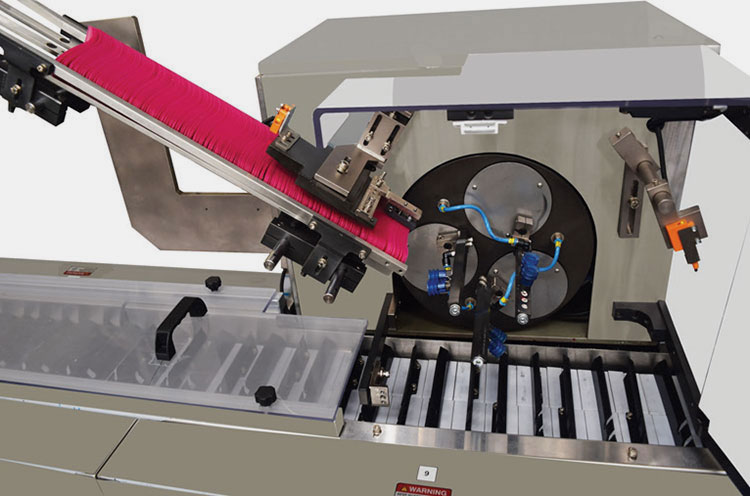

Vertical Syrup Cartoning Production Line

Vertical cartoning machine- Picture Courtesy: endflex.com

As the name indicates, it is a vertical syrup cartoning production line with comparatively precise longitudinal body. It is centrifugal for supporting several sizes and styles of cartons. Compared to horizontal syrup cartoning production line, it has slow speed with finishing up to 60 cartons in a minute. However, it requires less space and is perfect for medium to large scale industries. It is available in both rotary and linear form.

Structure

The structure of machine is compact with all the components being adjusted in a vertical structure. It consists of transparent window on all the sides for safe operation. Moreover, it is made up of stainless steel body with proper control system, carton feeder, carton closure, and coding device etc.

Working Principles

It starts functioning when syrup bottles are fed onto the machine's rotary star wheel. The movement of wheel results in the mobilization of bottle towards cartoning. While at the same time, carton is formed, and bottles are sequentially inserted into these cartons from upside down. Similarly, the closing and sealing phase takes place after which they are discharged from the machine.

6.Highlight The Applications Of A Syrup Cartoning Production Line?

A syrup cartoning production line can be extensively used in small to large and extra-large industries in different fields encompassing fields beyond food, medical, and cosmetic. Some of its prominent applications are highlighted below:

Pharmaceutical Industry

Pharmaceutical industry drugs- Picture Courtesy: packagingoftheworld.com

Pharmaceutical industry is one of the top industries where the use of a syrup cartoning production line is inevitable. It is because this industry is engaged in manufacturing and packaging of large number of medication in which cough syrup, flavored kids syrups, vials, and ampoules are the most notable.

Herbal Industry

Various herbal syrup bottles- Picture Courtesy: homohacerpara.com

Another important application of this production line is herbal industry. Despite the growing advancements in technology and medical fields, most of the people still prefer using herbal products for their treatment. Hence, a syrup cartoning production line is brought into operation to carry out the cartoning of herbal syrups and pastes.

Veterinary Industry

Veterinary syrup bottle cartoning- Picture Courtesy: shakehands.co.in

Well, animals also require proper care and medical treatment during illness or in case of injury. That's why, most of the veterinary industry find it easy to make liquid drugs for esy drug administration as it can be easily mixed in food for animals and pets. Hence, this production line become applicable here to process these drugs.

Food Industry

Biscuits carton packing- Picture Courtesy: carrefour.be

Food industry is a large field where multitude of products including sauces, spices, jams, confectioneries, and snacks are packed in flexible to rigid packages. These packages are then further secured by enclosing into cartons for which a syrup cartoning production line can be used.

Cosmetic Industry

Soap packaging- Picture Courtesy: beingbeautifulandpretty.com

Beauty case industry has also witnessed outstanding surge in demand for daily care products like facial kits, hair colors, serum, shampoo, soap, lotion, and make-up foundation etc. Similarly, manufacturers aim to promote their brand for which effective packaging is the key. Hence, they can take advantage of a syrup cartoning production line.

Chemical Industry

Insecticide spray with carton

In addition to cosmetic industry, chemical industry can also be included in the list which aspire to use a cartoning production line for their vary products. These include liquid chemicals, pesticides, insecticides, detergents, and other cleaning agents.

Hardware Industry

Cartoning of electric bulbs- Picture Courtesy: grafmag.pl

The use of a syrup cartoning production line also extends to hardware industry where multiple items are being packed in cartons such as electrical bulbs, stationary items, toys, and chargers etc.

7.How To Maintain A Syrup Cartoning Production Line?

Maintaining a syrup cartoning production line can prolong its working life, efficiency, as well as working flow by restricting barriers like breakdowns, friction, and blockage etc. Therefore, we have explained some of the valuable tips for you to conduct a regular maintenance schedule for your cartoning solution. These are as follows:

Operator tightening screw- Picture Courtesy: justdial.con

Cleaning:It is necessary to conduct daily cleaning routine for your syrup cartoning production line. For this, you need to use the recommended method as well as cleaning materials, like water, brush, and compressed air, for the cleaning of different parts. During cleaning, pay attention to remove debris and accumulated dirt. Make sure to accurately clean the conveyor, guide rails, and glue nozzles etc.

Setting:Setting of machines is also very important. You should check the internal parameters of machine each time after begining operation. It can be done by contacting control panel. Moreover, structural adjustment of different parts is also crucial to avoid any loose or wrongly placed part from malfunctioning.

Lubrication:Lack of lubrication causes sudden squeak and stagnation during operation. Due to this, the belts and conveyor may also show friction. Therefore, use proper oil and grade to lubricate the transmission and movable parts of the production line.

Parts Changeover:It is for sure, that after a period of time, your syrup cartoning production line may face parts damage or breakdown. In such case, you need to be vigilant to take notice of the affected component and take measures for their correction or replacement.

8.What Are The Quality Standards Which A Syrup Cartoning Production Line Should Adhere?

There are several quality standards established for developing standards for machines and production lines for safety purpose. These include:

Standard icon- in puzzle

ISO:A syrup cartoning production line should comply the rules and regulations set by International Organization for Standardization.

GMP:Good Manufacturing Practices is another important platform which thoroughly assess the equipment construction material and its safety for processing different kinds of goods and products.

FDA:Food and Drug Administration is a primary institution that aims at promoting the production and processing of items which are fulfilling all the prerequisites for public health safety. Thus, the production line should meet with FDA's principles.

CE:Equipment which are meant to be created or sold in European Union countries should comply CE regulations.

9.How To Diagnose The Spontaneous Faults Of A Syrup Cartoning Production Line?

A syrup cartoning production line is an effective solution that works remarkably; however, a sudden issue can create hindrance in the way for smooth functioning of the production line. These are highlighted below to enable you in advance and take relevant measures to counter these problems:

The cartons cannot be sucked down

Carton sucking mechanism- Picture Courtesy: sirosilo.com

Cause:

The air circuit to carton suction cup is blocked or air is released due to pipe leakage.

The vacuum pressure for sucking is low.

Carton stacking magazine is wrongly positioned.

Solution:

Check the air circuit for blockage, remove possible barrier and replace pipe if damaged.

Increase the vacuum pressure for effective sucking.

Adjust the position of carton feeding silo.

Misaligned carton

Misaligned carton- Picture Courtesy: sirosilo.com

Cause:

The gears, conveyor, or transmission belts over which carton is placed are defective.

The carton may lack indentation which result in the exertion of force when picked up by assembly.

Solution:

Repair or replace the damaged conveyor belts and guide rails.

Make sure to use the cartons of good quality and with proper indentation for accurate formation.

Inaccurate carton formation

Wrongly formed carton

Cause:

The carton formation mechanism is not properly set in accordance with carton size.

The folding flappers may have something stuck in their way.

The adjustment moving parts are showing friction due to lack of lubrication.

Solution:

Properly set the carton forming and folding mechanism.

Check and remove the possible barrier in way of folding flappers.

Lubricate the movable parts for smooth and sound working.

Inconsistent application of glue for sealing

Inconsistent application of glue- Picture Courtesy: fmtmagazine.in

Cause:

The glue spraying nozzle may be blocked with accumulation of residues.

In case of melted glue, the temperature of glue gun may be inadequate.

Solution:

Clean the spraying nozzle and remove out dried glue.

Adjust the temperature of glue gun for uniform flow of glue.

10.Factors Essential For Selecting The Right Syrup Cartoning Production Line?

Range of factors are responsible for selecting the right syrup cartoning production line. That's why, most of the manufacturers get confused to consider which one. So, we have provided a list of the most significant and effective factors which will definitely help you in making a sound purchase. Let's start exploring these all!

Production Output

Various syrup cartons

The foremost aim of every entrepreneur is to maximize profits. In such a case, it is very essential to know the production capacity and output ratio of a syrup cartoning production line which meet you need. You can easily check it by looking into your current production volume and then opting for the right production line.

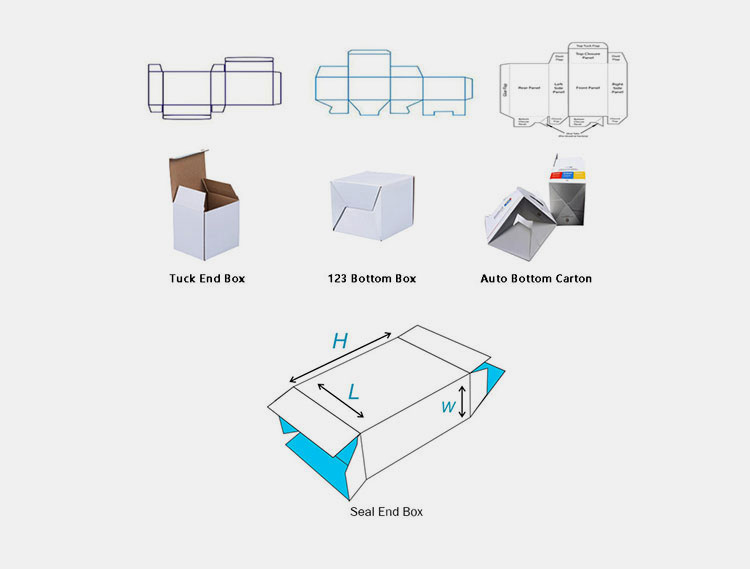

Carton Design

Various types of carton boxes- Picture Courtesy: sirosilo.com

Cartons are of numerous designs with different sizes and shapes. Therefore, it is important to determine what type of carton do you want to process. Although, a syrup cartoning production line is adaptable and can be easily modified to process wide range of cartons, yet it is good to have marked the particular type for your products.

Supplier Reputation

Supplier reputation icon- Picture Courtesy: Freepik

You will find lots of manufacturer's out there producing and supplying syrup cartoning production line. What matters here is that your vendor must have a long term experience and reputation in relevant field. Similarly, it will help you choose the production line that comes with long service life, good quality, and warranty policy.

Expenditure

Expenditure icon- Picture Courtesy: nationalbusinessmirror.com

No one want to increase their spending but everyone desire to extend their earning. That's why, when buying a syrup cartoning production line, you should calculate the overall cost of equipment along with maintenance, spare parts, and installation charge and opt for the one that align your budget.

11.Why Choose Allpack As Your Vendor For Buying A Syrup Cartoning Production Line?

There are many reasons which will compel you to choose Allpack as your vendor for a syrup cartoning production line. These include:

Allpack logo

Experience

Experience is what matters the most on part of every manufacturer. When it comes to talk about Allpack, we are glad to say that the company has over 11 years of experience in manufacturing and successful delivery of packaging machines throughout the world.

Quality

With Allpack, you will get a syrup cartoning production line which is entirely meeting all the regulations of international quality standards such as ISO and GMP. Moreover, all machines and production lines offered by Allpack are made from corrosion resistant and antibacterial stainless steel.

Warranty

Another most fascinating thing about Allpack is that the company give you 1 year of long warranty for every machine. Hence, you can freely use the production line without worrying for its malfunctioning.

Variety

Allpack has wide variety of syrup cartoning production line to meet your specific needs. Therefore, depending upon your production targets, you can opt for multiple machines and combine them together for smooth working flow such as case packing machine and robotic palletizer etc.

Conclusion

Let's sum up this comprehensive buying guide about a Syrup Cartoning Production Line with a reminder that this solution is one of the instrumental ones being used in food, health, and beauty sectors. Bringing it into your production facility can help you raise the output, precision, and charm of your products. You can take best use of it by understanding the structure, working process, and maintenance requirements as discussed above. If you value your business and want to see it growing, then contact Allpack for getting the best Syrup Cartoning Production Line. Our team of experts will contact you ASAP!

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide