Carton Sealing Machine: The Complete Buying Guide in 2024

In our daily routine you may face some problems to seal carton’s & boxes manually all by yourself but why don’t you consider to have a machine that can work for you.

Yes, carton sealing machine is especially designed to perform this kind of task for you in a reliable and quick manner to increase your productivity.

So, if you have not made up your mind to purchase a carton sealing machine come on then, what are you waiting for? This relative guide is going to explain all about the carton sealing machine & how you can use it in what circumstances and many more.

1.What is a carton sealing machine?

A carton sealing machine is a device that is used to seal cartons. It uses an adhesive tape to seal the flaps of the carton. This machine is also known as a case sealer or box sealer.

It is also a cardboard sealer. The equipment helps in sealing the cardboard carton easily. Carton sealing machines are also used in commercial and industrial areas to seal cartons for shipment purposes.

You can also seal the large container products with the carton sealer. The equipment also helps in protecting from damaging the sealed product.

You can also use the carton sealing machine for printing purposes just as expiry and manufacturing dates.

2.Can you explain the advantages of a carton sealing machine?

A carton sealer is a machine that is used to seal corrugated boxes. There are many benefits of using a carton sealing machine. These benefits include:

Increased Efficiency

A carton sealing machine can dramatically increase the efficiency of your packaging line. These machines can quickly and easily seal boxes, which can save you time and money.

Improved Quality

A carton sealing machine can also improve the quality of your packaging. These machines can help to ensure that your products are properly protected during shipping and storage.

Reduced Costs

A carton sealing machine can also help to reduce your packaging costs. These machines can help you to use less tape and paper when sealing boxes, which can save you money.

Fast to Use

The carton sealing machine is very fast to use. It seals many products in very less time. So, you can pack a lot of products quickly by using this equipment. If you are packaging the products for shipping purposes then this equipment will be greatly advantageous for you.

Simple to Use

Another advantage of having a carton sealing machine in your industry is that it is very simple and easy to use. You can simply install the machine in your industry and start working on it.

Easy to Maintain

The maintenance of the carton sealing machine is very easy. The design of the machine is very simple and you can easily clean all the parts of the machine. You just have to clean the machine daily to maintain the working level of the equipment.

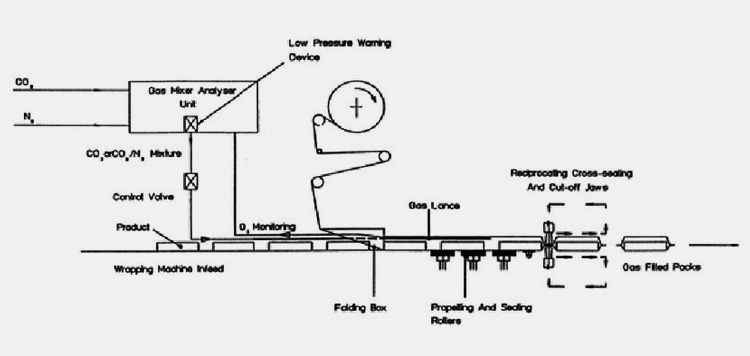

3.How does a carton sealing machine works?

Working of Carton Sealing Machine

A carton sealing machine is a device that is used to seal cartons. The machine works by using a hot melt adhesive to seal the edges of the carton. The process is simple and can be completed in a matter of minutes.

To start, the machine will need to be turned on and the carton will need to be placed onto the platform.

Once the carton is in place, the operator will need to select the correct settings for the size and type of carton that is sealed.

After the settings have been chosen, the machine will begin to heat up the adhesive. Once the adhesive has been heated, it will be dispensed onto the edges of the carton. The operator will then need to use a roller to ensure that the adhesive is evenly distributed.

Once the adhesive has been applied, the operator will need to press down on the lid of the carton in order to seal it shut. The operator may need to apply pressure for several seconds in order for the seal to be secure.

After a few seconds have passed, the operator can release pressure and remove their hand from the lid.

The final step is to allow time for the adhesive to cool and set. Depending on how hot the adhesive was when it was applied, this could take anywhere from a few seconds to a few minutes.

Once cooled, your carton should now be securely sealed!

4.What are the different kinds of carton sealing machine?

A carton sealing machine is a device that is used to seal cardboard boxes. There are different types of machines available on the market, each designed for a specific type of box. These types of cartons sealing machines are as follows:

Automatic Uniform Carton Sealing Machine

The automatic uniform carton sealing machine does not require any operator to work. This machine does everything fully automatically. They are also best for sealing the same size cartons.

Components

Its structure can be described as a combination of various parts like guide rail, casters, main frame, tape holder, cutting blades, tape dispenser, conveyor motor, uniform case loader, control system, upper stand adjustment lever and transparent glass windows.

Working Principles

The process starts when carton is placed over conveyor belt. As, it is uniform carton sealer, so only same size boxes are processed. Tape is dispensed from upper and lower cartridges as the case passed through guiding rail. It gets completed when cutting blades cut the tape ends and discharged by conveyor belt.

Application

Those manufacturing firms which use uniform shape cases mostly look for this type of machine which includes glassware industry, pharmaceutical industry and chemical industry etc.

Uniform Semi-Automatic Carton Sealing Machines

Uniform semi-automatic carton sealing is the next type of carton sealing machine. This machine needs the operator for adjusting the width and height of the cartons. This carton sealing machine is considered the ideal and best for sealing the same size cartons.

Components

Major parts include movable wheels, conveyor belt, height and width adjustment handle, tape roller, cutters and control system.

Working Principles

Operator manually load uniform cases after adjusting the suitable upper and lower frame position. Machine then starts sticking tape over both upper and lower sides of case. When guide rail push it forward, user pick up the carton by hands.

Application

It is often applied in grocery markets and baking industries etc.

Automatic Random Carton Sealing Machine

The automatic random carton sealing machine is best for sealing the different size cartons. It automatically seals the cartons. This machine is best for large-scale industries. It can seal many packages in very less time.

Components

It consists of self-centering guide rail, compression rollers, drive belts, control system, flap folders, top and bottom drive, power light, circuit breaker, tape releaser, lubrication system etc.

Working Principles

Its working procedure is quite simple as whole operation is automatic. The random size boxes are loaded in machine and sealer adapt itself according to that box. At same time, adhesive tape adheres to the upper and lower sides of box. Just after realizing that function is performed, case is discharged aside and machine grabs another carton for sealing.

Application

Due to its excessive production rate and random size boxes, it is used in beverage industries, cosmetic industries, electronic industries and food Industries.

Semi-Automatic Random Carton Sealing Machine

The semi-automatic carton sealing machine provides an easy way to seal the cartons. It also seals the cartons of different size cartons smoothly and easily. The operator is needed here that helps in folding the top of the boxes.

Components

Its structure is made up of standard quality parts including main frame, casters, emergency stop, double tape holders, changeable side driving belts, flap folder and controlling system.

Working Principles

Set suitable height and width required for your case manually and load the box on conveyor belt. Press start button, carton would be carried by driving belts from sides, while as tape dispenser would dispense the tape from dual sides. You can hold the box after tape is separated through blades.

Application

Usually, small scale plastic, kitchen-ware and beverage industries admire this machine on large extent.

5.Is there any kind of carton sealing machine in manual form?

Yes, there is a manual form of carton sealing machine. In fact, most of the gift packaging industries use manual carton sealing machine. It is also known as handheld carton sealing machine as you can hold it in hand and simply pass through the carton. It has a tape holder, handle and cutting blades. Except cartons, this manual or handheld carton sealing machine can be also utilized for other things like film sealing, paper sticking or abnormal shape of boxes.

6.How uniform carton sealing machine is distinguished from random carton sealing machine?

The words uniform and random strongly express their meanings, but in case of carton sealing machine you should not be ambiguous. For that consider the underlying factors:

| No | Features | Uniform Carton Sealing Machine | Random Carton Sealing Machine |

| 1 | Nature | Uniform carton sealing machine is static in nature, and it can only process boxes with same size | Random carton sealing machine is dynamic in nature and is capable of processing boxes with different shapes and sizes |

| 2 | Process | Its process remains same | Its process changes for various cartons |

| 3 | Versatility | It is not versatile but limited | It is more versatile and adaptable |

| 4 | Application | Its application is particular | Its application is vast and diverse |

| 5 | Example |  |

|

7.Differentiate between fully automatic and semi-automatic carton sealing machine?

For your better understanding of distinctions between fully automatic and semi-automatic carton sealing machines, we have elaborated both in different aspects:

| No | Features | Fully Automatic Carton Sealing Machine | Semi-Automatic Carton Sealing Machine |

| 1 | Nature | It is continuous and self reliant | It is dependent upon user, thus operation is non-continuous |

| 2 | Process | The operation is smooth and simple | Its process is irregular and remains demanding due to constant handling |

| 3 | Structure | Its structure is complex and mostly large due to additional parts | It is precise and compact in formation |

| 4 | Speed & Capacity | It has high speed and capacity | Its capacity and performance is slower than fully automatic carton sealing machine |

| 5 | Application | Huge industrial firms like food, beverage, pharmaceutical etc. | Limited industrial sectors like markets and selling stores etc. |

| 6 | Machines |  |

|

8.What are the key parts of a carton sealing machine?

The carton sealing machine is commonly used in many industries for sealing different kinds of products. The carton sealing machine consists of some key parts. These key parts are as follows:

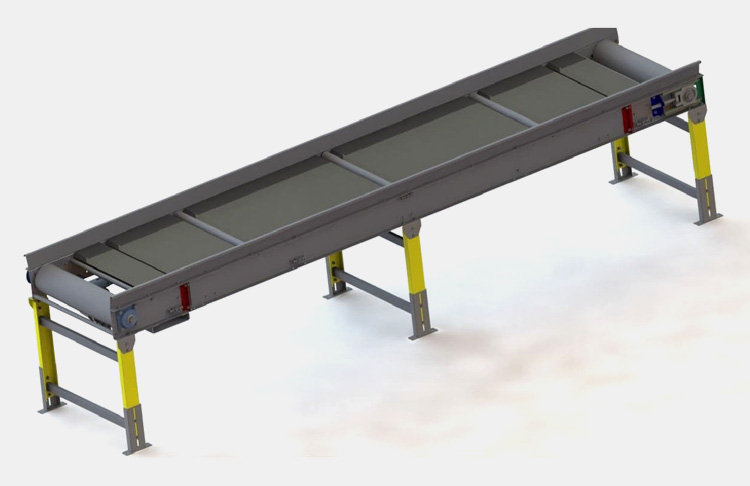

The Conveyor Belt

The very first part of the carton sealing machine is a conveyor belt. A conveyor helps the belt to move the boxes through the machine. All the movement of the boxes is controlled by this conveyor belt.

The Tape Head

The second important part of the carton sealing machine is the tape head. The function of the tape head is that it applies adhesive tape to the box.

Cutting Device

A cutting device is the next key part of a carton sealing machine. This part mainly trims the excess tape.

Operator Interface

An operator interfaces for controlling the machine’s settings and functions. You can change the settings easily according to the needs of your industry.

9.What are the different applications of carton sealing machine?

Carton Sealing machines is considered very versatile machine and are used in many industries. The machine is an expert in sealing and keeping the products remains fresh and protected from any kind of damage and contamination. There are some applications of carton sealing machines. These include:

Food and Beverage Industries

Carton sealing machines can be used to seal cartons containing food and beverage products. This helps to keep the contents of the carton fresh and uncontaminated.

Pharmaceuticals Industry

Carton sealing machines can also be used to seal cartons containing pharmaceutical products. This helps to ensure that the contents of the carton remain sterile and free from contamination.

ElectronicsIndustry

Carton sealing machines can also be used to seal cartons containing electronic products. This helps to protect the contents of the carton from damage during shipping and handling.

CosmeticIndustry

The carton sealing machines are also used to seal cartons in the cosmetic industry. You can pack different types of skin care products from the carton sealing machine. Moreover, hair care products are also packed with this equipment.

10.How many types of cartons you can seal using a carton sealer?

The carton sealing machine seals different types of cartons. These are as follows:

Solid Fiber Cartons

The first type of carton that is sealed by a carton sealing machine is a solid fiber carton. These cartons are basically made up of solid paperboard. A single layer of paper is used to produce solid paperboard.

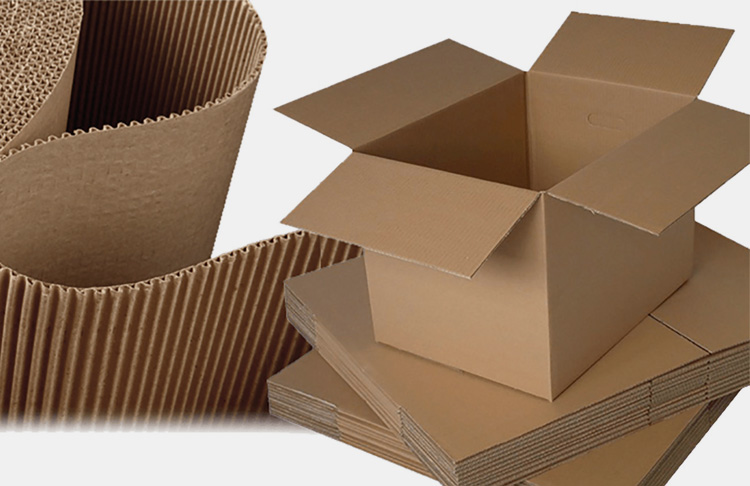

Corrugated Cartons

The next type of carton that is used to seal carton sealing machines is corrugated cartons. Corrugated paperboard is used to make corrugated cartons. The multiple layers of paper that stick together with the help of glue are used to make corrugated paperboard.

Carton Sealing machines can easily seal the above types of cartons. But if you want to know the best then corrugated cartons can be the best choice for sealing them with the help of carton sealing machines. As the machine used many methods to seal these cartons like the heating method and hot glue and tape.

11.Can we directly integrate a carton sealing machine to our production line?

You might be busy in thinking, that whether a carton sealing machine can be directly connected to your exiting production line? Or is it should be used separately?

The exact answer to your question is, that you can definitely integrate a carton sealing machine to your current production line. Even, by doing so, you would be relieved in much better way. Because, all the filled cartons would directly come for sealing through conveyor belt. It will make your operation more smooth, consistent and efficient.

12.What type of material a carton sealing machine uses for sealing purpose?

A carton sealing machine typically uses pressure-sensitive adhesive tape, glue, or heat to seal cartons.

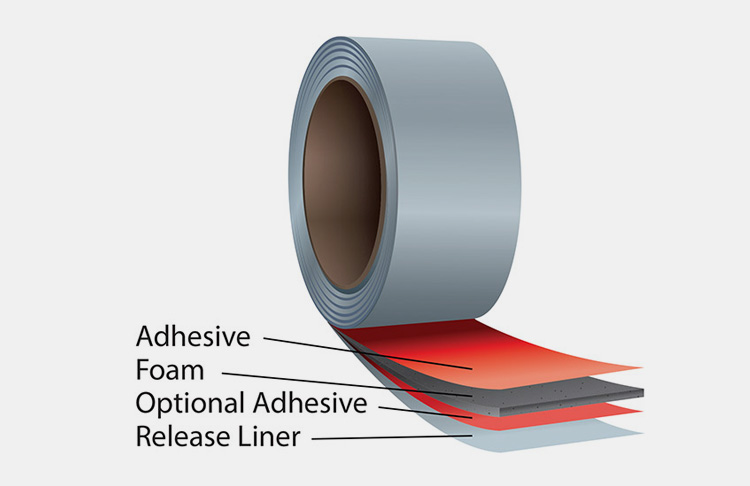

Pressure Sensitive Adhesive Tape

Pressure-sensitive adhesive tape is applied to the top and bottom flaps of a carton and then run through the machine. The machine uses rollers to apply pressure and create a seal.

Glue

Glue is applied to the top and bottom flaps of the carton and then run through the machine. The machine has paddles that spread the glue evenly over the surface before it seals the carton shut.

Heat to Seal Cartons

Heat is used to seal plastic or laminated bags. A heating element in the machine melts the material, which bonds the two surfaces together when cooled.

13.What is the daily preventive maintenance required for a carton sealing machine?

Here are few tips for you to adopt for daily maintenance of your carton sealing machine. They are:

- Always use heavy-duty switches because using weak wires or switches can cause electric shocks.

- Lubricate the parts of machine on weekly basis especially the conveyor belt and shafts where rollers are attached. It will help in smooth running of guide rail.

- Another aspect which we often ignore is the assembling and dismantling of machine. It should be done by professionals because inaccurate assembling can cause serious damage.

- Clean the tape cutting blades on regular basis as most of the time, tape adhesive get stick to the blades which result in tape folding.

- Try to stay away from the hot parts of machine during operation like driving belts and conveyor motor etc.

14.Highlight major problems, their possible causes and countermeasures for a carton sealing machine?

To enable you in managing the minor issues during your operation, we have enlisted few problems with possible causes and countermeasures. Just keep reading for good understanding:

| No | Problem | Possible Causes | Countermeasures |

| 1 | Belts are not pushing cartons | Either size of box is too narrow, the drive belts are damaged or flap folder is too high | Use a bit larger boxes, replace the belts in case also adjust the flap folder height |

| 2 | Tape is applied on side instead of center | Position of tape drum, compressor rollers and case flaps are unequal | Make sure that tape dispenser is in center, parallelize compression rollers and check the case flaps are equal in size |

| 3 | Cutter is not cutting tape | The blade is contaminated with adhesive of tap or becomes less sharp due to constant use | Clean the blades and remove out glue. Replace cutters if dull |

| 4 | Tape breakage or improper sticking | The quality of tape is not good and the adhesive on tape is not sufficient | Replace the tape with one having good quality and strong sticking glue |

| 5 | Tape is dispensed in zigzag or curved shape | Too much pressure on tap dispensing wheel or inaccurate cutting of tape | Reduce pressure on mandrel wheel and also clean the blades |

15.What should be considered before purchasing the best carton sealing machine?

This is the most significant question every buyer should think about at least once before purchasing any carton sealing machine. Some factors which are necessary to look for are as under:

Type of Cartons

The first and foremost thing is the type of cartons you have to seal. Are they uniform or random size? For uniform cartons you will need uniform carton sealing machines while as for various and random size boxes random carton sealing machine is recommended.

Production Volume

What is the rate of packing boxes per hour? If you are packing ordinary level of cartons then semi automatic carton sealing machine is a good choice with reasonable price. On the other hand, for high volume of production fully automatic carton sealing machine will effectively fulfill your demands.

Sides of Sealing

Now comes the question, that whether the case you are intending to seal is requiring upper and lower seal or parallel sides seal. After examining this factor, you would come to conclusion for picking up right carton sealing solution.

Additional Devices

Along with main sealer, you may require some additional equipment like shrink wrapper, stretch wrapper, ink jet printer for carton identification or conveyors etc. It would be much better to think in advance about these devices.

Carton Weight

The content you place in case also matters because it would show how much load your box is carrying. For instance, fragile items like medicines have less weight than beverages or glass wares. Thus, determining your product’s nature can also assist you in choosing good option.

Conclusion

As you can see, the Carton Sealing Machine is a versatile and reliable tool that can help you save time and money. This machine is perfect for businesses of all sizes and can handle any type of packaging material. Plus, it’s surprisingly affordable given its features and performance. So, if you’re looking for a way to improve your packaging process, the Carton Sealing Machine is the perfect solution. I highly recommend you the Allpack carton sealing machine. As they produce the best equipment in the market. If you have any queries regarding this machine, you can contact us.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide

Tell us your material or budget, we'll reply you ASAP within 24 hours