Strip Packing Machine: The Complete Buying Guide In 2024

Strip Packing Machine: The Complete Buying Guide In 2024

Strips are the flexible and thin packaging mostly made up of plastic, aluminum or paper. The packing provides protection to these products and save them from environmental impacts like bacteria, fungi and other microbes. Packing of these strips is done using strip packing machines is most of the part of world. These machines perform efficient and quick packing of strips of either tablets or capsules.

But there is always confusion in selecting the right type of strip packing machine. Allpack in this regard has variety of strip packing machine options and is providing you this complete buying guide to answer all your queries. It will also help you selecting the right type of machine. So, let’s go!

1. What Is Strip Packing Machine?

Strip packing machines are mostly used in pharmaceutical industry for performing packing of pills, tablets and capsules. These medications required high level of care as entrance of contamination can effect their composition and purity. Pre-formed material is inserted into a strip packing machine and packaging films are filled with tablets or capsules in small intervals of packets or blister to create efficient packaging.

Other than pharmaceutical industry, strip packing machines are also used in confectionary, cosmetic and chemical industry. Strip packing machines are mostly available in manual, semi-automatic and automatic type according to their working and have an ability to pack hundreds of strip in a short interval of time.

2.What Is Strip Packing? How Many Types Of Strip Packing Are There?

Strip Packing

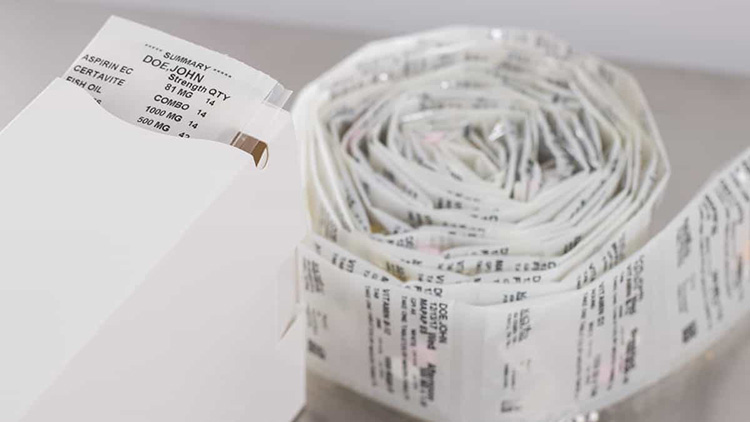

Strip packing is a technique to pack variety of products into a single strip. The arrangements of these products in done after a complete research and ensures no overlapping occurs. Strip packing medication dosages to be enclosed between two sheets forming mostly of plastic or aluminum. The packing foil helps the dosage to resist from being contaminated and secures its purity. Strip packing also makes the logistics and transportation of these products easier and reliable as it consumes less space.

Types Of Strip Packing

Cold Form Foil Strip Packing

Blisters of material are form in a single sheet and with desired shape using a cold formed foil strip packing. In this type of strip packing cavity is formed in packaging material for the placement of product using stamping tool or pressure. Both of these are used for creating cavity to ensure complete protection to the product from environmental factors.

Single Strip Packing

In a single strip packing, the pharmaceutical dosages are packed in a single row or strip. Single type of dosage is packed in a single strip packing with individual product covered with its lid of material. The strip is folded from both the ends onto the material.

Multi Strip Packing

Unlike a single strip packing, the pharmaceutical dosages are packed in more than one strip and of fixed width. Multi strip packing consumes less packing material as compare to other single strip packing.

3.What Are Mostly Packed By Using A Strip Packing Machine?

Capsules

Capsules are a type of oral medication that is available in different sizes and shapes. These capsules may vary in their sizes and that is why strip packing machine are ideal for their packing. Strip packing machine provides each of the capsule with separate covering so that it may be used according to the prescribed dosage.

Pills

Pills are the other type of material that is packed using a strip packing machine. These pills are usually hard from outer shell and made up of different chemical compositions. Pills also include tablets and other micro capsules.

Confectionary

Confectioneries including gums, mints, toffees, candies and other eatables can be packed using a strip packing machine. As confectionary items offer contamination easily, this packing provides shield and prohibits their entrance.

4.What Materials Can Be Applied For Packing By Strip Packing Machines?

Some of these materials are

Regenerated Cellulose

Regenerated cellulose is highly resistive to moisture contents and that is why it can be ideally used as packaging material in a strip packing machine. It is made up of natural cellulose from plant fiber and then treated chemically for created impermeable films of gases and liquids. These films are then used for creating barrier to moisture content.

Paper

Papers are also one of the most popular packaging materials that are used by a strip packing machine. Papers remain environment friendly ad can be recycled easily. The only con in using a paper is that it cannot resist the moisture at a greater level.

Plastics

Plastics like polyethylene, polyvinyl chloride and polypropylene are widely used by a strip packing machine and are good in providing barrier to moisture.

Heat Sealable Cellophane

It is a cellophane film that is generally present with a heat sealable coating. The heat sealable coating in heat sealable cellophane usually allows it is sealed easily using heat.

Heat Sealable Polyester

Heat sealable polyester films are made up of synthetic material and are suitable for a strip packing machine. They can be kept at any atmospheric temperature and the quality of material will remain the same even after years.

Foil

Foils are ideal for strip packing as it provides resistance against the entrance of oxygen and moisture content. Foils are flexible in nature and can either provide single or double layer to the product that can assure its freshness for a longer period.

5.What Are The Applications Of A Strip Packing Machine?

Pharmaceutical Industry

The most common application of a strip packing machine is in pharmaceutical industry. As medications required strong packing that’s why strip packing ensure that the tablets remains airtight and moisture proof when sealed. The packing doesn’t allow any type of environmental factor entering affecting the materials purity.

Food Industry

Products like jellies, bubbles, toffees and other are efficiently packed using a strip packing machine in food industry. For attracting the young ones, many of the food manufacturing industries are using strip packing machine in their process lines. The food product is sealed using different types of packing materials that keeps it airtight for prevention of contamination.

Cosmetics Industry

Cosmetic industry uses a strip packing machine as it can delicately pack products with individual identity that are small in size. The quality of packing required for cosmetic products remains a concern as it can directly affect human life, which is why strip packing machines are used for providing efficient packing to cosmetic products like balm, cream, shadow and etc.

Chemical Industry

The first and foremost benefit of using a strip packing machine in a chemical industry is that is can be designed according to a clean room process area. Here chemical material can be packed in a way that no dust or other microbe from the atmosphere may enter into the packaging material. It also reduces the risk of contamination and and helps chemical material to survive for a longer period of time.

6. What Are The Advantages Of A Strip Packing Machine?

Advantages of a strip packing machine are

Product Life

Strips that are packaged using a strip packing machines can live for a much longer period as they remain airtight and moisture free. These features reduce chances of product contamination to a greater level and allow the consumer to consume products without any fear. As medicines are directly related to human life, it is always necessary to maintain their quality do that no reverse reaction may take place.

Quality Products

The quality and quantity of medical products require high level of sensitiveness that’s why strip packing machine are ideal to be used for this purpose.

Waste Reduction

Due to the presence of sharp edge cutter in sealing station, less amount of waste is produces during the process of a strip packing machine. It cuts the edges of strips in a decent manner for making it look pleasant to the customer.

7. What Is The Working Principle Of Strip Packing Machine?

The working principle of a strip packing machine can be easily understood by any operator without any prior expertise.

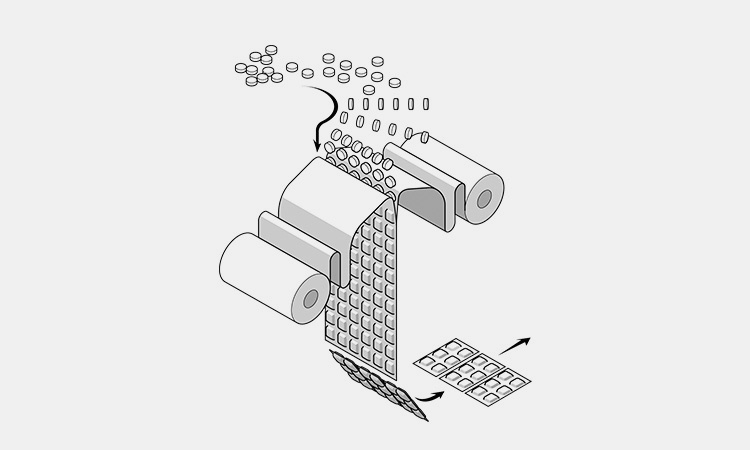

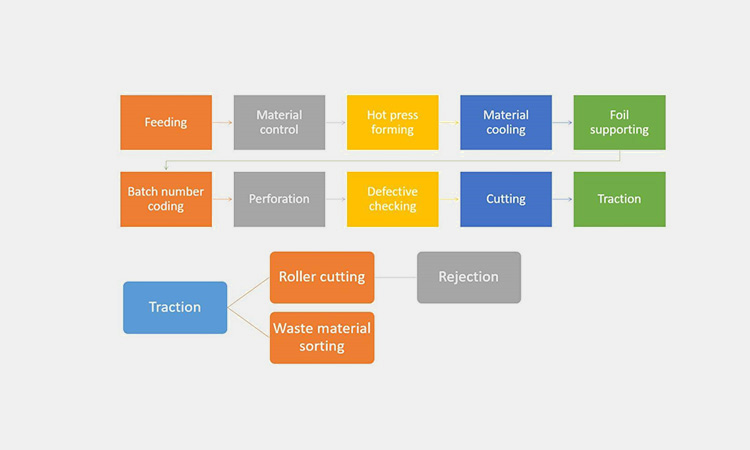

- Initially the packaging material is fed into the system through a hopper chamber or an installed vibratory chamber. This material can be a raw material or a readymade one. From here the material is then moved for packaging.

- On the other hand, a film roll is attached to the machines body which contains the packaging material. This material is pulled out to the system once the strip is filled with the product.

- Once both of the factors i.e. packaging material and product are fed to the system, the process gets started. The capsule or tablet travels through the filling system and is poured into the desired shape using dies or shapes.

- Once these prepared products are aligned in a position that film can easily be applied on it. The roller releases the packaging material and covers the back of plastic strips.

- The machine then seals the applied film around the capsule or tablets by applying head on it. This seal is done for providing each on a separate and individual pocket.

- Finally the process of cutting takes place at the end. The film is cut between the pockets of strips to produce multiple strips. These steps are then moved to the final step and packaged there for customer usage.

8. What Are The Main Components In Strip Packing Machines?

Some of the main components of a strip packing machines are

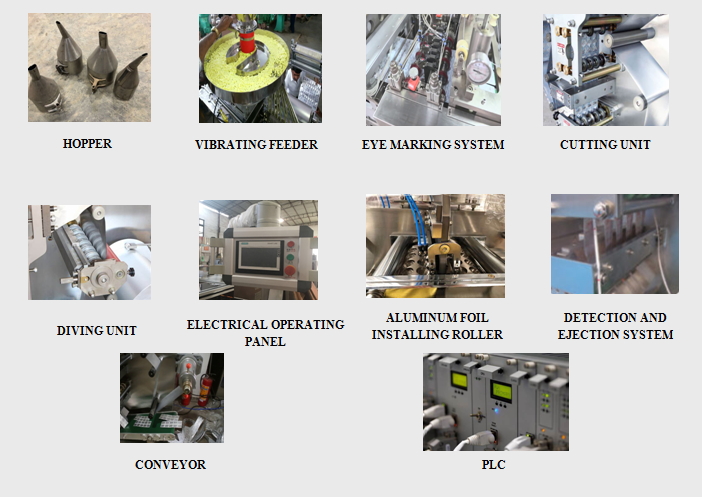

Hopper

This material can either be a ready product or sometimes raw material if the machine is associated with a tablet making machine.

Vibrating Feeder

Vibrating feeder is a type of feeder that continuously vibrates and segregates the solid material like tablet, capsules and etc. The vibration helps even placement of tablets or capsules with maintaining the quality. This vibrating feeder is used to move the material from hopper to the packaging system.

Eye Marking System

An eye marking system has a sensor or camera that detects the presence of packaging material. Before packaging of material this system ensures that the placement of material is done properly and all the pills are aligned. If the pills are not aligned properly, the eye marking system stops the process and makes sure no material is wasted.

Cutting Unit

A cutting unit is responsible for cutting of the packaging material filled with capsules, tablets or pills. The temperature of a sealing cutting head in maintained at different levels for ensuring clean and efficient cutting. Also pressure is to be monitored every time so that the system remains even.

Diving Unit

A diving unit ensures accurate positioned packaging around the product with covering all the corners. This is a mechanical component that helps the material to be positioned in a correct way so that sealing may be performed efficiently.

Electrical Operating Panel

An electrical panel is responsible for complete monitoring and controlling of machines components. This allows the operator to directly contact with the machine and monitor all the working programs.

PLC

Programmable logic controllers are used to ensure that all of the parts of a trip packing machine and packaging line are performing their operations in a correct manner. If any of the component shows malfunction. The PLC directly shuts that part off.

Aluminum Foil Installing Roller

The packaging material is fed into this aluminum foil installing roller. The material is then supplied to the system through this roller.

Detection And Ejection System

Detection and ejection system of a strip packing machine identifies the defected solid material and removes it from the system. Sensors are used for detection of those particles while mechanism is installed in the machine for ejection of those materials.

Conveyors

As the product enters the discharge port it provides option for manual and automatic discharge at the same time. Numbers of products are collected ant the discharge port and then delivered further using these conveyors. Product alignment can also be maintained in these moveable conveyors.

9. What Are The Types Of Strip Packing Machines?

Some of the types of strip packing machines available are

Alu-Alu Strip Packing Machine

The word Alu-Alu refers to the packing of material into multiple layers of aluminum and a layer of PVC. An Alu-Alu strip packing machine packs capsules and tablets in rolls of packaging layer with accuracy and precision. The machine itself holds both packing and sealing feature of desired sized medications that are not easy to be tear.

Mostly pharmaceutical industry uses an Alu-Alu strip packing machine in their process line for packing of solid dosages. The machine are easy to move and also convenient while using.

High-Speed Tablet Strip Packing Machine

Frequency controllers along with conveyers are present in the machine for maximizing machine output. The structure of machine is mostly made up of stainless steel that ensures long life and durability. More than 1100 pieces of strips can be produced in an hour by a high speed strip packing machine.

Foil Strip Packing Machine

Foil strip packing machines uses foil as the packaging material for preservation of products. The advanced segregation and blind pocket detectors in a foil strip packing machine allows uniform packaging throughout the process. Its packing is easy and convenient to open when they are used. Tablets and capsules from 36ooo to 72000 in an hour can be produced using a foil strip packing machine.

Semi-automatic Strip Packing Machine

A semi-automatic strip packing machine is mostly used in small and medium scale industries. The machine has involvement of both operator and machine that are responsible for maintaining the operation in a smooth manner. In a semi-automatic strip packing machine the dosages are fed by the operator and then the machine perform the packing process.

Along with this, the machine also requires high level of skills. The operator should be fully aware of all the process so that he can stop the process in any uncertain situation. A semi-automatic strip packing machine is not feasible for high scale production setups.

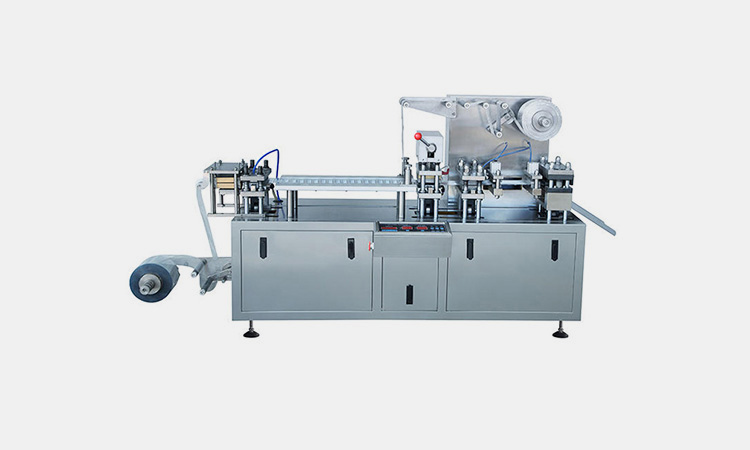

Fully Automatic Strip Packing Machine

In a fully automatic strip packing machine, from material flow to sealing and then packaging all the processes are carried out by machine itself. Less human intervention is required in this type of machine and it is mostly based on automation.

Fully automatic strip packing machine are ideal for large scale industries where large quantity of strips are produced in a short interval of time. The material flows through the feeding system to the packing area where uniform strips are produced and then sealed through diving units.

Capsule Strip Packing Machine

A capsule strip packing machine offers precisely control of high scale production is directly controlled process. Pharmaceutical industry is the most commonly application of capsule strip packing as they are simple tear off and also it allows individual packing to each of the capsule.

PP Strip Packing Machine

Polypropylene or PP strip packing machines can create strips of different types of products like pens, brushes and sticks. A PP strip packing machine involves a hopper in its top from which the product is loaded into the system along with a strip forming unit. Usually the strips are filled through filling pockets present at the center of a PP strip packing machine.

At the end of the process, uniform sealing and cutting of strips are performed in a synchronies manner which turns the product look great to the customers.

10. What Are The Differences Between Strip Packing And Blister Packing?

Working Method

The strips are basically made up of plastic or aluminum foils that can easily be sealed around the product. A uniform pressure and heat is applied on the packaging material once it wraps the product.

Blister packing involves placing of packaging products into pockets known as blisters of a plastic sheet. The blister of product is then sealed with an additional material most likely of a foil or paper.

Applications

Blister packing on the other hand is used in industries like electronics, pharmaceutical industry, food industry, medical devices, electronics and chemical industry. These materials use safe packaging so that they might not get affected during transportation.

Conclusion

Strip packing machines can be used according to their applications and different sizes. Allpack is also providing the world with variety of strip packing machine options to world and always there to guide its customers. Please feel free to us if you still have any query or visit our website http://www.allpackchina.com/.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours

Strip Packing Machine: The Complete Buying Guide In 2024 Read More »