Chilli Powder Packing: The Complete FAQ Guide In 2024

Chilli Powder Packing: The Complete FAQ Guide In 2024

Chilli powders are an integral part of every cuisine to spice up the culinary experience. Do you know what preserves the flavour of chilli powders? Chilli powder packing preserves flavour but also the nutritional quality of chilli powder.

Due to the demand for spicy and delicious culinary dishes, the demand for chilli powder packing has been on the rise. Chilli powder packing is a foolproof method to provide superior quality chilli powders in the market.

Numerous people use chilli powder packing but are unaware of what machine and elements make it chilli powder packing. This blog is designed for people, who want to know more about the evolving world of chilli powder packing.

1.What is Chilli Powder Packing?

Chilli Powder Packing- Picture Courtesy: 99Design

Chilli powder packing is a protective covering that encloses chilli powders from all sides. It surrounds and contains chilli powders for handling, transportation and delivery. It is a beautiful covering that showcases the brands' value on the retail shelves and engages customers for buying.

Chilli powder packing is functional and flexible in its use. The primary purpose of the chilli powder packing is to protect chilli powders against environmental culprits that may spoil them. It is a strong and durable container that safeguards chilli throughout the supply chain and logistics. Chilli powder packing includes pouches, sachets, and bottles.

2.Why Chilli Powder Packing is Significant?

Chilli powder packing is significant because of its protective and branding purposes. Some useful benefits that contribute to its significance are:

Transportation

Transportation of Chilli Powder Packing- Picture Courtesy: Urban Spice Shop

Chilli powder packing is stackable and is placed over one other to easily transported over long hauls. Without chilli powder packing, its transportation journey will be a messy and difficult exercise. Chilli powder packing contains chilli powders and reduces the money spent on transportation.

Protection

Protection by Chilli Powder Packing- Picture Courtesy: Dribble

Chilli powder packing is a protective barrier that provides resistance and prevents the entry of harmful physical and biological agents like air, moisture, temperature, microbes, and pests that spoil chilli powders. Chilli powder packing reduces interaction between the environment and chilli powders and it extends the shelf-life of chilli powders.

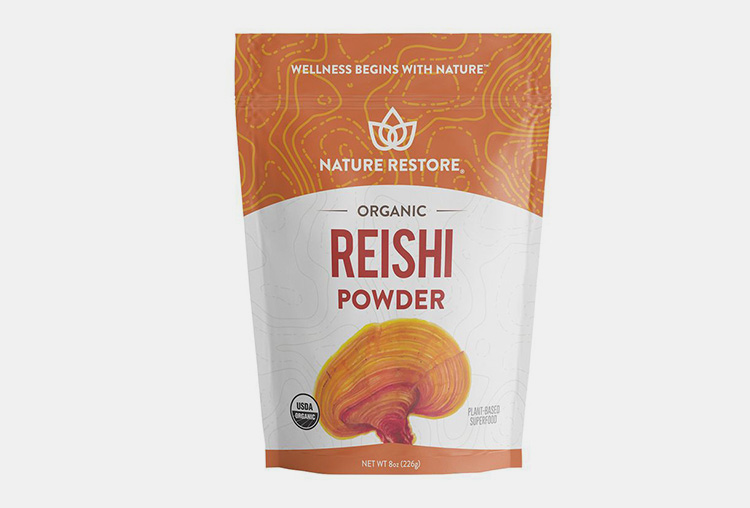

Communication

Product Information- Picture Courtesy: Vedic Spices

Consumers of today need to know what they are buying. It is where chilli powder packing comes into play. Brands conspicuously label their chilli powder packing to inform and communicate with users about the advantages and uses of their chilli powder products. It communicates expiry dates, brand values, nutritional value, and ingredients.

Branding and Advertisement

Branding by Chilli Powder Packing- Picture Courtesy: mishry.com

For brand awareness purposes, the brand designs its chilli powder packing in colourful and attractive design elements. These bold patterns and stylish artwork attract customers and build their memory. Thus, users recognize this chilli packing at first glance on retail shelves and increasing chances of buying.

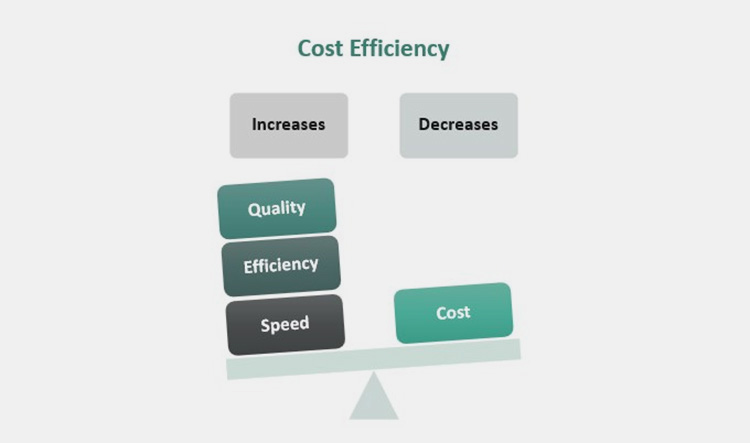

Cost-Reduction

Cost Reduction by Chilli Powder Packing- Picture Courtesy: designerpeople

With chilli powder packing, brands can earn huge profits. This is because the manufacturers can decrease chilli powder wastage, saving costs. Tough chilli powder packing reduces the mechanical damage to the chilli powders, meaning more and more chilli powder packing in the market. More products in shops means more profit.

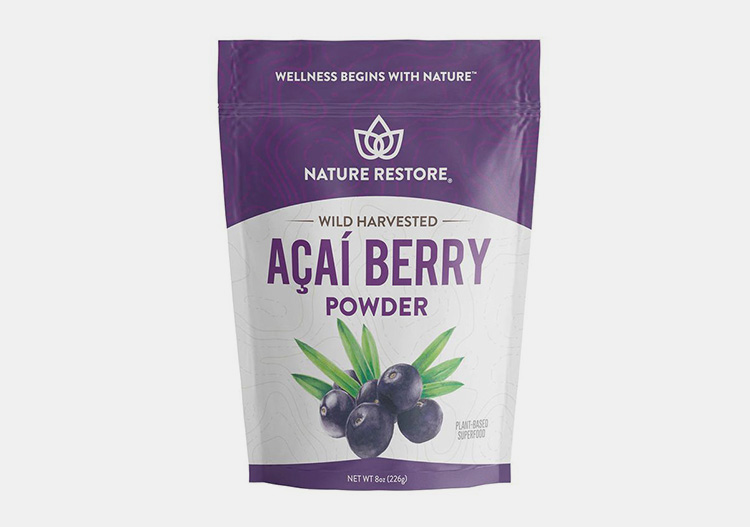

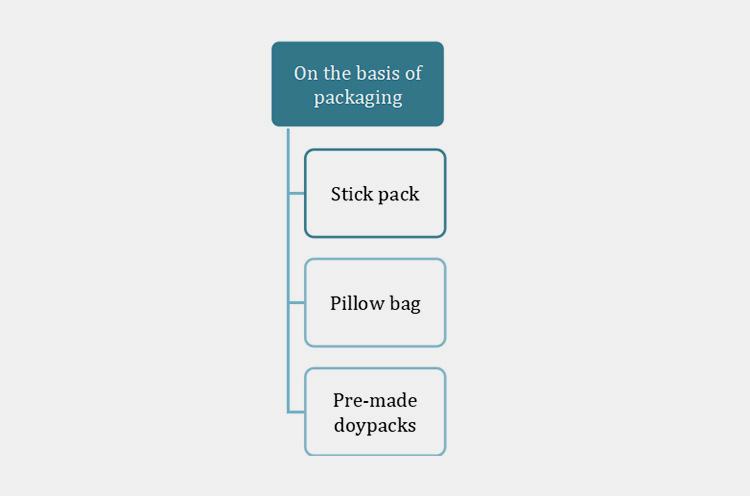

3.What Packing Formats Are Included in Chilli Powder Packing?

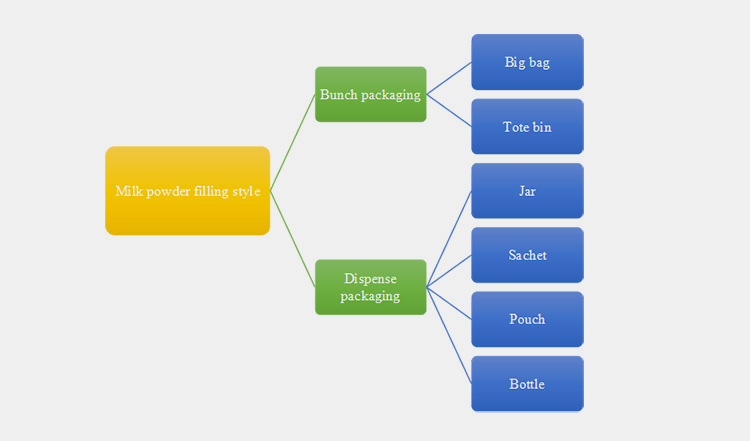

Chilli powder packing is versatile and different packing formats are included in this packing. A detailed description of these chilli powder packing is penned below:

Bottle

Chilli Powder Bottle Packing- Picture Courtesy: McCormick

The bottle is a cylindrical container and is sealed with a cap on the top. It is formed of clear glass or plastic that allows users to check the quality of chilli powders. Bottle chilli packing attracts high-end users.

Tins

Chilli Powder Tin Packing

It is made with metals and is a cylindrical container that has lids fitted on the top. It is sturdy and robust chilli powder packing that maintains the fieriness of chilli powders.

Pouch Chilli Powder Packing

Chilli powders are packed in a variety of pouch styles like:

| Standup Pouch

It has a flat round base with sharp edges. It has traction due to its standability and cost-effectiveness. It captivates customers because of its uniqueness. |

Standup Pouch- Picture Courtesy: Behance.net |

| Flat Lay Pouch

As the name indicates, these chilli powder pouches do not stand upright but instead lay flat on the retail shelves. It is sealed on four sides and is economical in retail chilli powder packing. |

Flat Lay Pouch- Picture Courtesy: Packaging of the World |

| Pillow Pouch

It is another distinct chilli powder packing style with its pillow-like shape. It has a distinct back seal, due to which, it has a different design than other chilli powder packing styles. |

Pillow Pouch- Picture Courtesy: Packaging of the World |

| Sachet

It is a popular single-serving style featuring three or four side seals. It is a portable and lightweight chilli powder packing style and usually comes with ready-made meals. |

Chilli Powder Sachet- Picture Courtesy: Spice Rush |

4.What are the Steps in Chilli Collections to Chilli Powder Packing?

Have you ever wondered how chilli powders are packed? Chilli powder passes different stages to reach customers. The steps from chilli collection to chilli powder packing are listed below:

Harvesting

Harvesting of Chillies- Picture Courtesy: Plantura Magazine

Ripened chillies are harvested by the farmers by hand. These chillies have a desired red or green colour. For large-scale harvesting, chillies are mechanically picked by the harvesting machines.

Cleaning and Sorting

Cleaning and Sorting of Chillies- Picture Courtesy: freeplants.com

In the next steps, chillies are cleaned and sorted by colour, size, and quality. Cleaning of chillies involves the removal of dust, soil, leaves, and other contaminants by water. Metal debris is also removed at the cleaning step.

Drying

Allpack Hot Air Circulating Dryer

The washed chillies are air-dried or dried with a machine such as a hot air dryer or vacuum dryer. This machine dehumidifies chillies by removing their water content. Chillies are placed in the oven and hot air is circulated in this machine for drying.

Grinding

Allpack Chilli Grinding Machine

The dried chillies are powdered using a grinding machine. This machine applies crushing force to ground chillies. This step is carefully controlled to acquire chillies powders with the desired particle size.

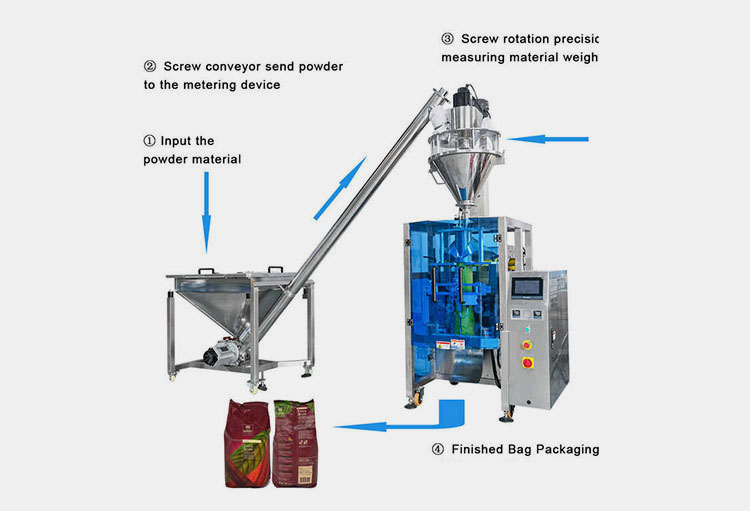

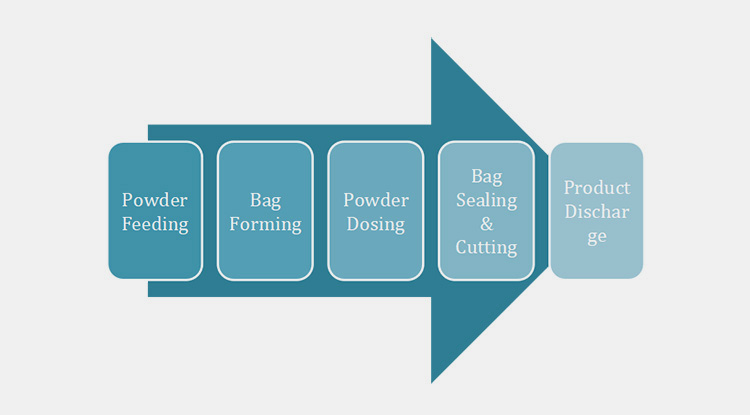

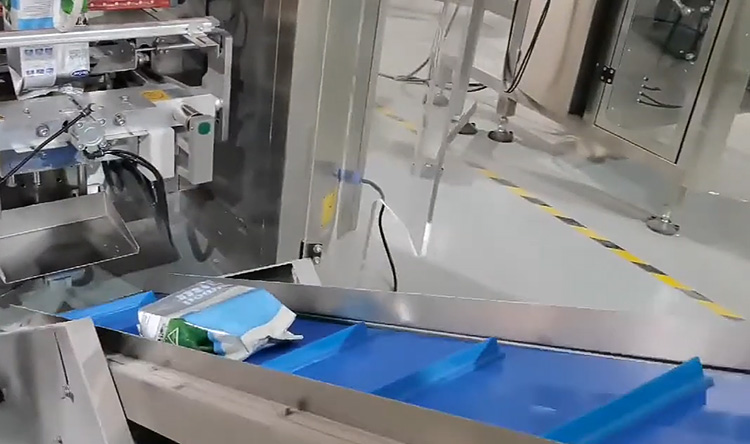

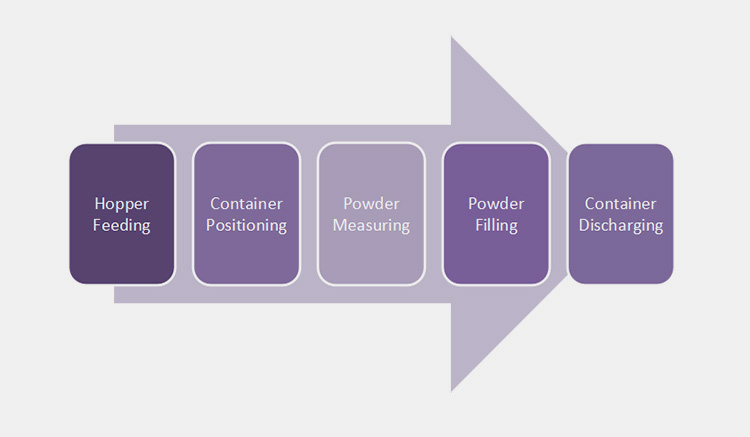

Filling and Sealing

Filling and Sealing Machine

After grinding, the chillies powders are packed using different machines depending upon the packing style. After filling, these packing containers are airtightly sealed to preserve chillies powder.

Labelling

Allpack Labeling Machine

It is an optional step, carried out by the labelling machine that labels the barcode, expiry dates, ingredient list, and nutritional value on the information panel of the chilli powder packing container.

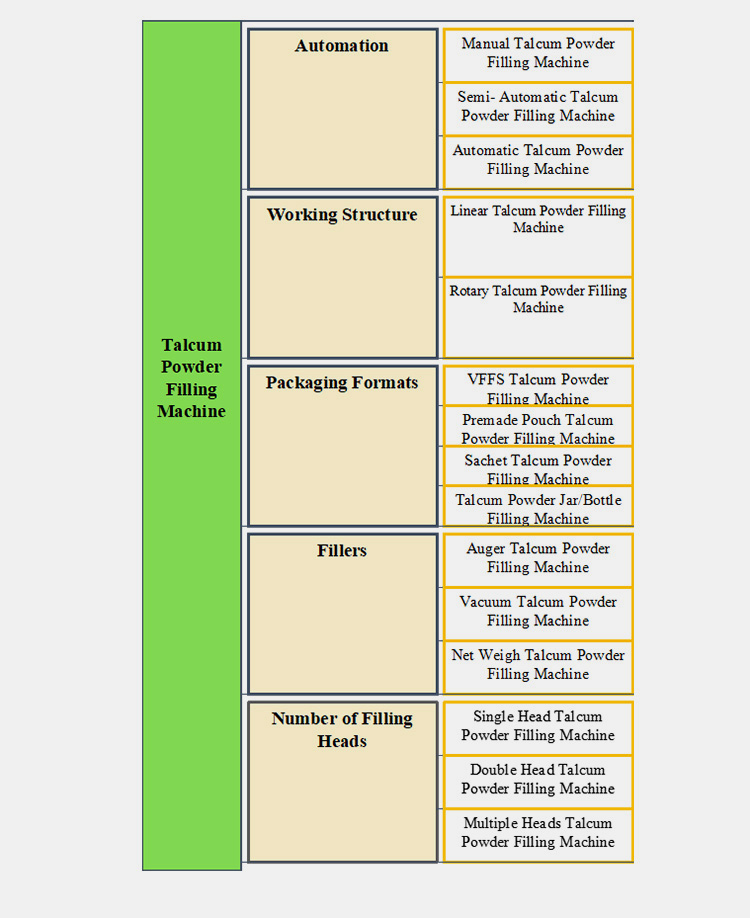

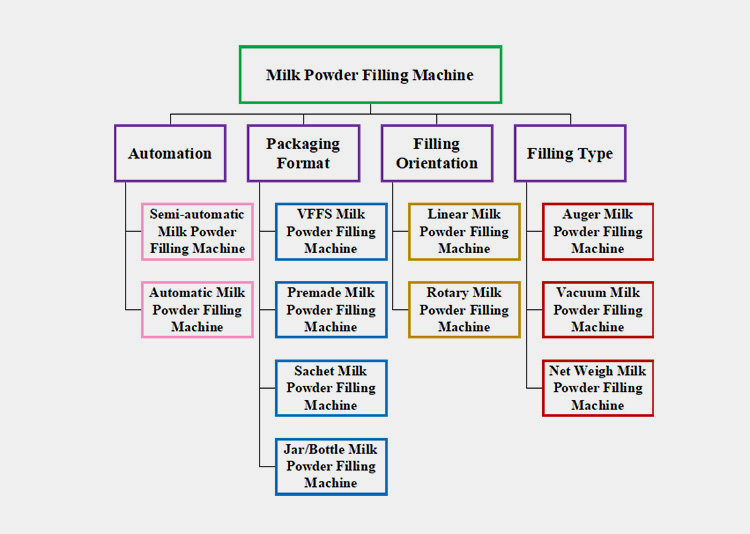

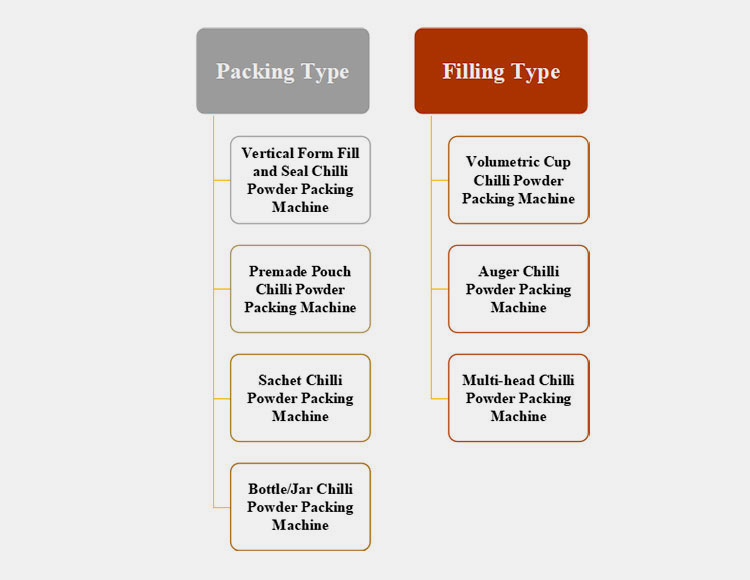

5.What Are Chilli Powder Packing Machine?

As mentioned above, chilli powders are available in different packing containers. So, there are different machines to pack chillis powders like:

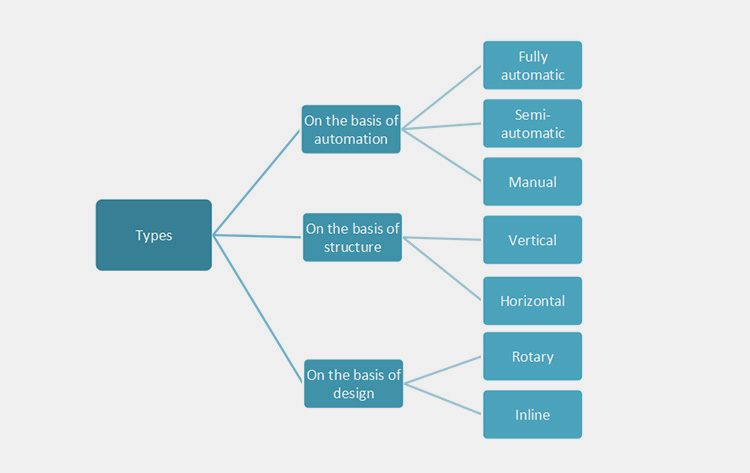

According to the Packing Type

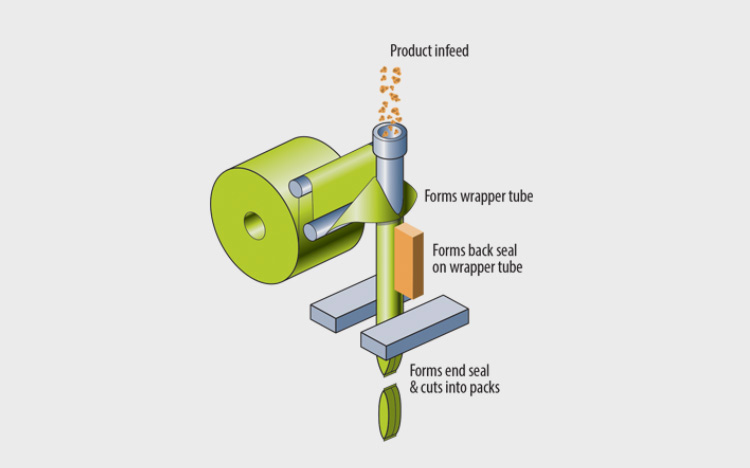

Vertical Form Fill and Seal Chilli Powder Packing Machine

Vertical Form Fill and Seal Chilli Powder Packing Machine

It is one of the most commonly found chilli powder packing machines. Vertical form, fill, and seal chilli powder packing machine is a fast and reliable manufacturing unit that comes with a smaller footprint. Its vertical orientation is essential for the delicate packing of chilli powders.

It forms packing containers using packing film via forming tube and sealing jaws. The chilli powders are filled into the pouches and afterwards, top edge sealing takes place by the horizontal sealers.

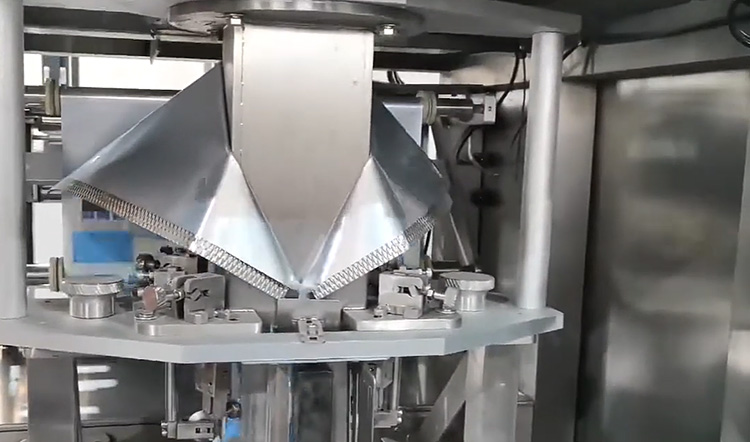

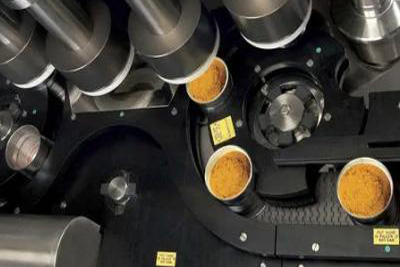

Premade Pouch Chilli Powder Packing Machine

Premade Pouch Chilli Powder Packing Machine

It processes already-made pouches. It has a rotary table with numerous inflating, filling, and sealing stations. Simultaneously processing of chilli pouches increases its production efficiency.

The preformed pouches are loaded inside the bag magazine and are taken to the inflating area for inflation. Next, the bags are loaded with chilli powders. Finally, the top edges are joined by the horizontal sealers.

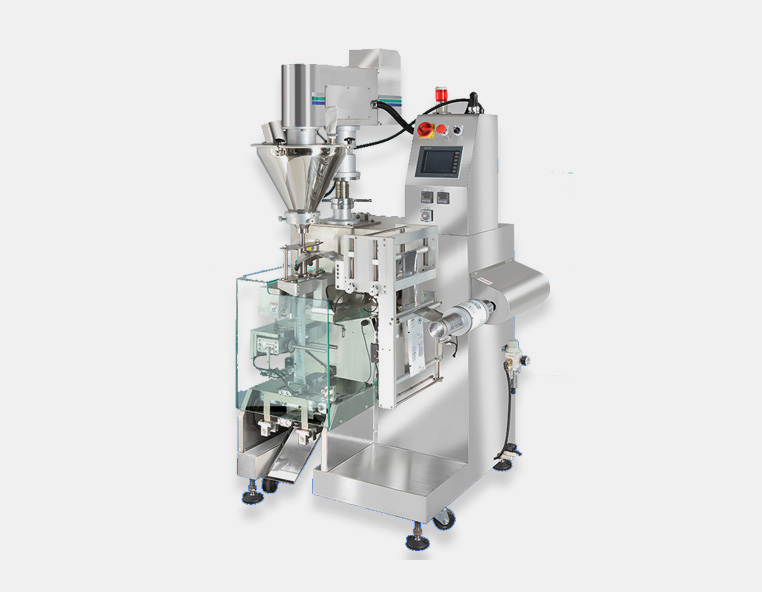

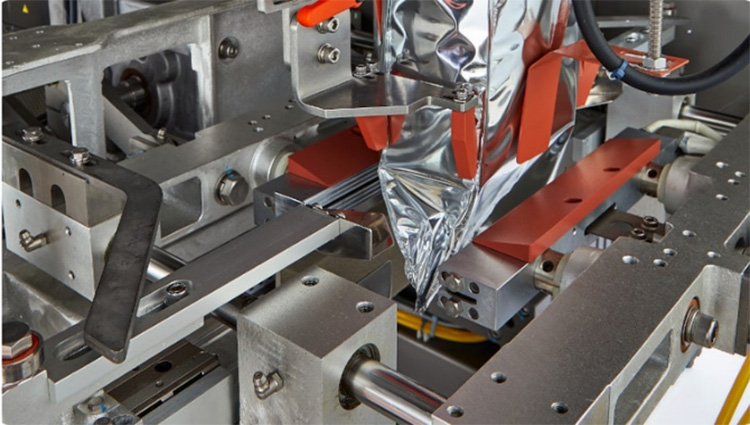

Sachet Chilli Powder Packing Machine

Allpack Sachet Chilli Powder Packing Machine

This machine is routinely employed in the industries for making single-serve sachets. This machine has a small footprint and its mode of working is quite similar to that of a vertical form fill, and seal machine.

The sachet chilli powder packing machine uses packing film to create the sachet. The packing film travels to the forming tube, where this film is doubled and enclosed around the forming tube for fabricating sachets. Filling in the sachet takes place by the filling devices and ultimately sealing occurs by the sealing jaws.

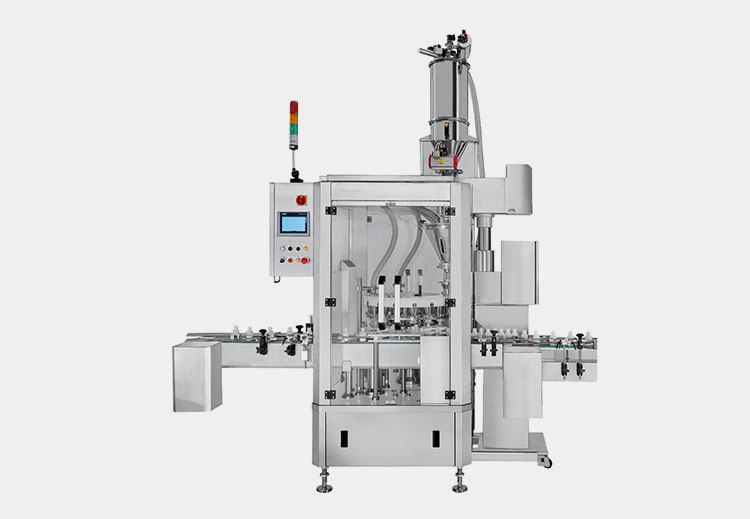

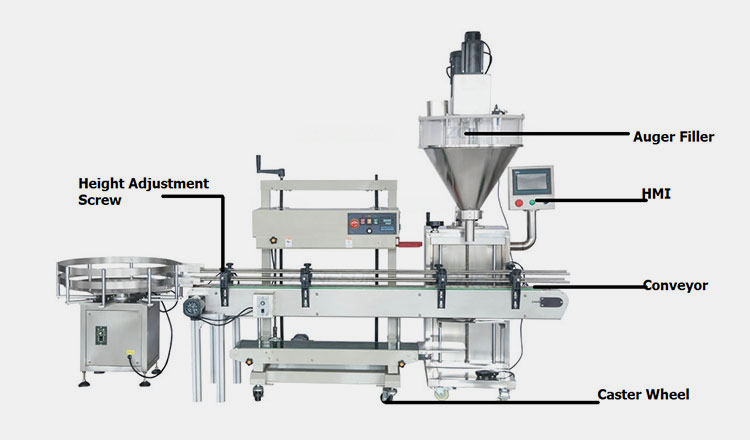

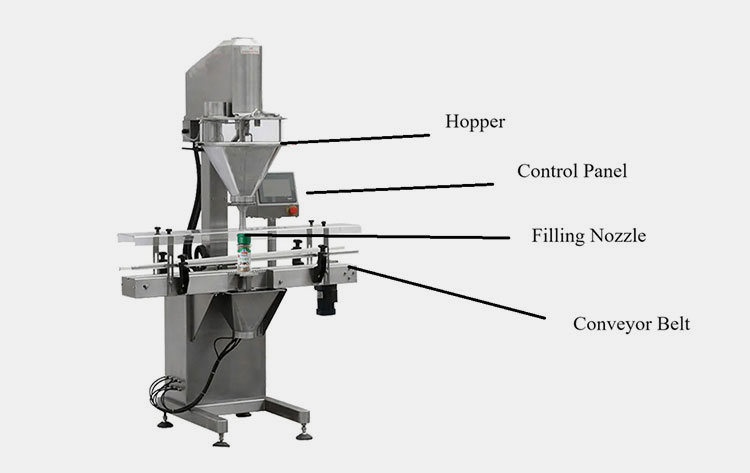

Bottle/Jar Chilli Powder Packing Machine

Bottle/Jar Chilli Powder Packing Machine

It is the machine in which a long conveyor or rotary star wheel is present for processing the chilli powders. This machine is found in both linear and rotary configurations. It has multiple filling nozzles for filling numerous bottles, jars, or tins in one go. Its automation and speed boosts its traction among industrial sectors.

Bottles unscrambler loads the bottles or jar in a standing position on the conveyor. These containers travel to the filling station by conveyors, where the filling nozzle dispenses the required quantities of chilli powders in the container. After that, they are moved to a sealing machine, where these containers are capped or lidded.

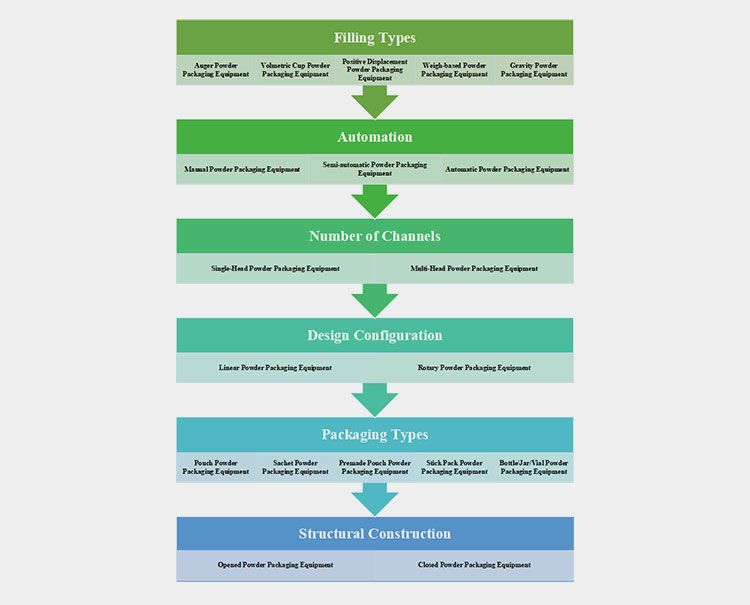

According to the Filling Type

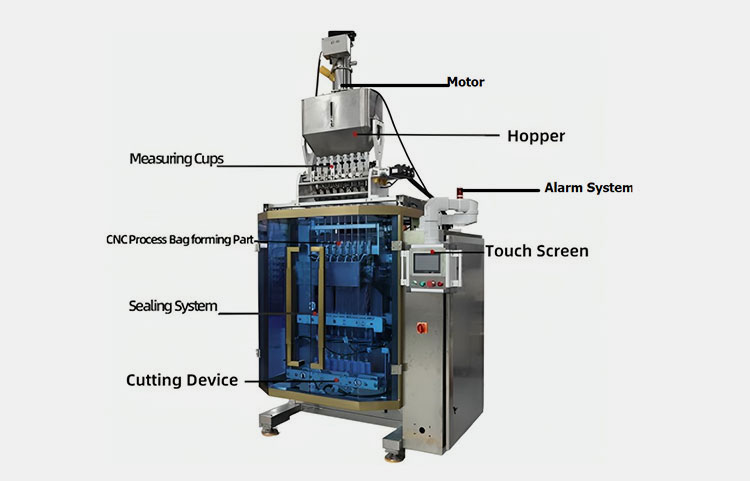

Volumetric Cup Chilli Powder Packing Machine

Volumetric Cup Chilli Powder Packing Machine

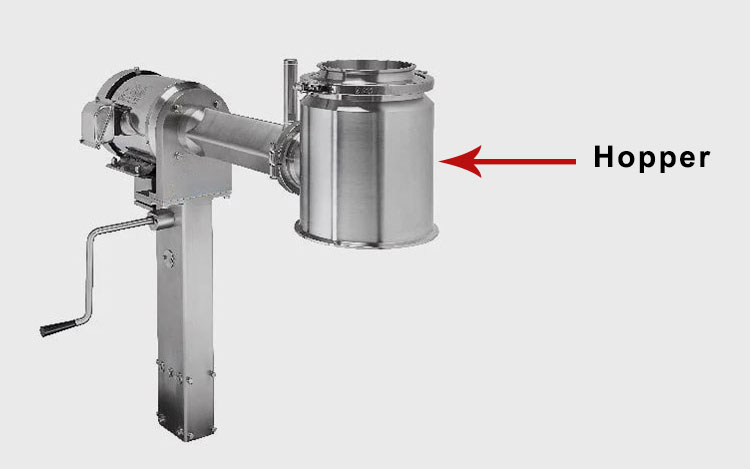

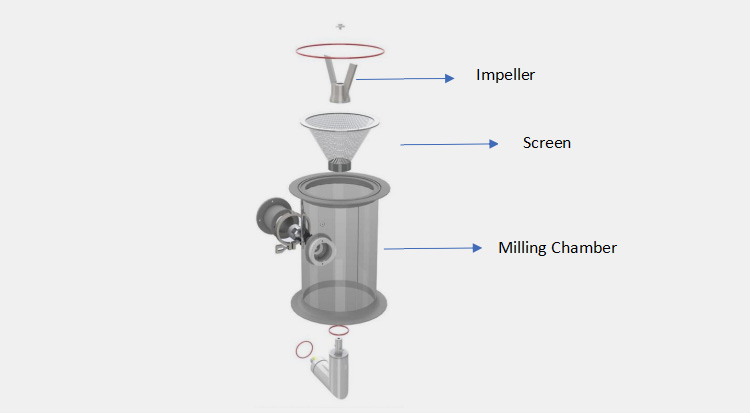

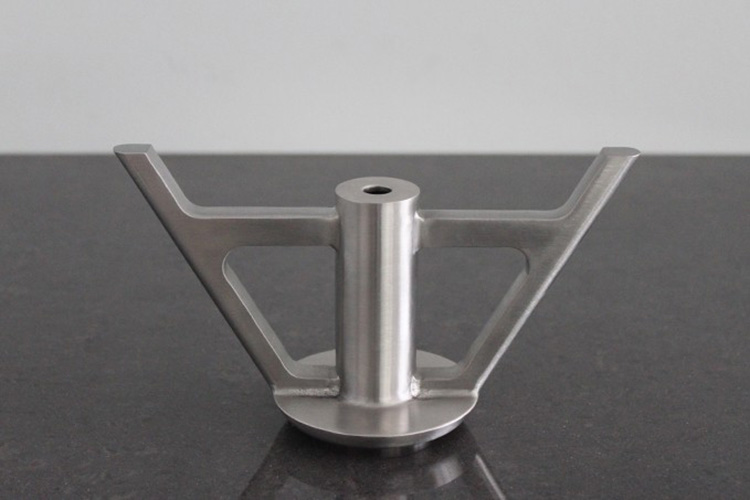

This machine is utilized for the loading of free-flowing chilli powders in packing pouches or jars. The volumetric cup chilli powder packing machine consists of dispensing cups, holding plates, hoppers, and servo-drives.

It is equipped with different cups in which a measured amount of chilli powder is dispensed from the hopper. These volumetric cups gradually load the said quantities of chilli powders inside the containers.

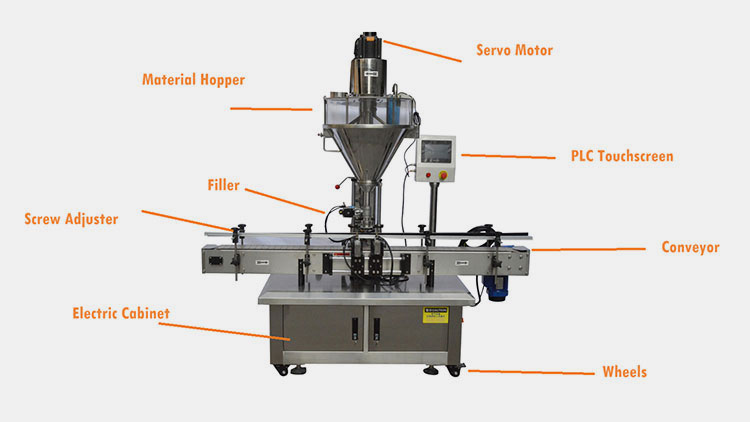

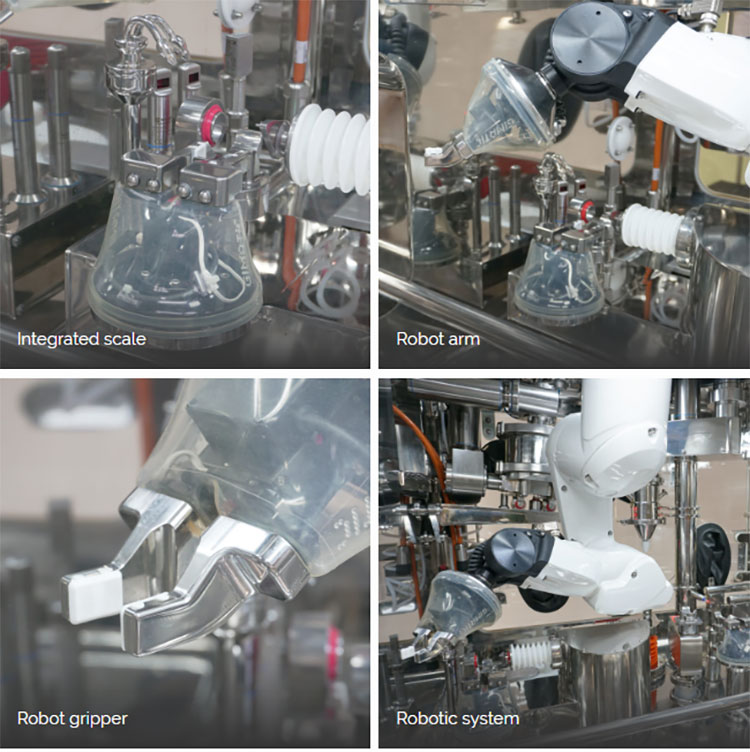

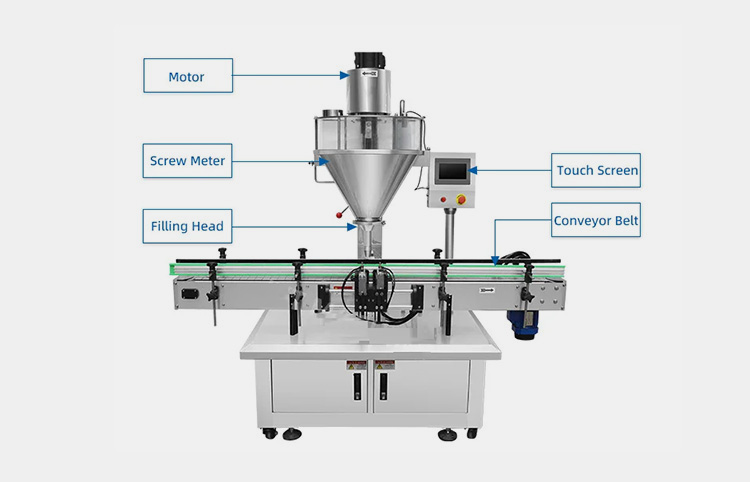

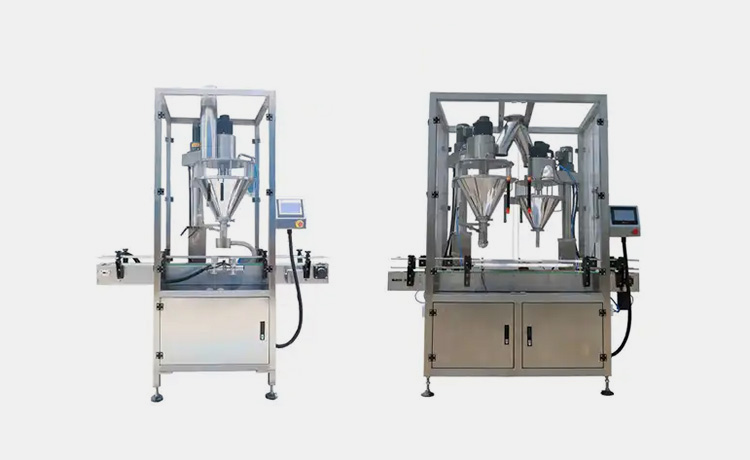

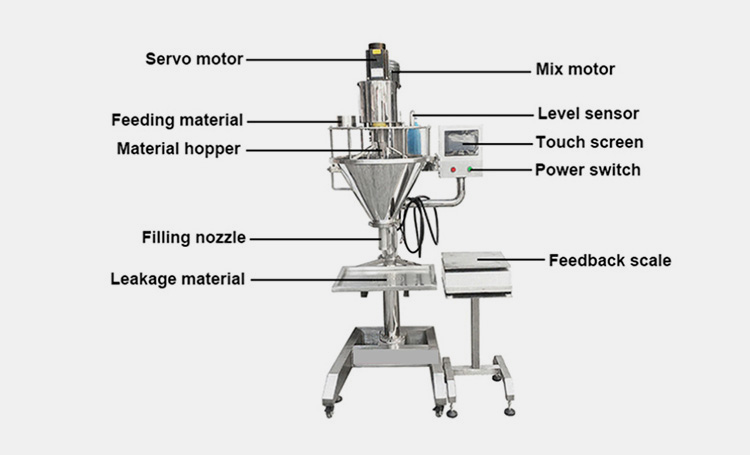

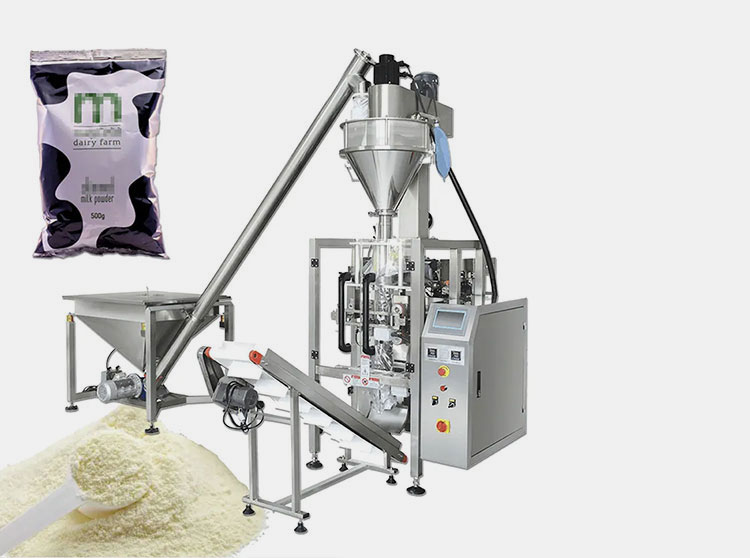

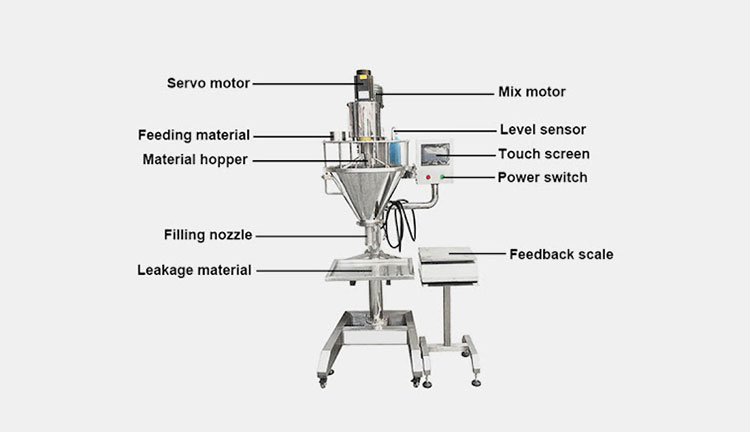

Auger Chilli Powder Packing Machine

Auger Chilli Powder Packing Machine

It is one of the most frequently utilized machines for loading dry chilli powder in packing containers. This machine is equipped with a hopper, auger plates, and a rotating screw. It is known for its accuracy and precision.

The rotating auger screws push the chilli powders from the hopper to the auger plate or funnel. The auger agitators move with the rotation of the screw. From the auger funnel, the chilli powder is loaded into the packing container.

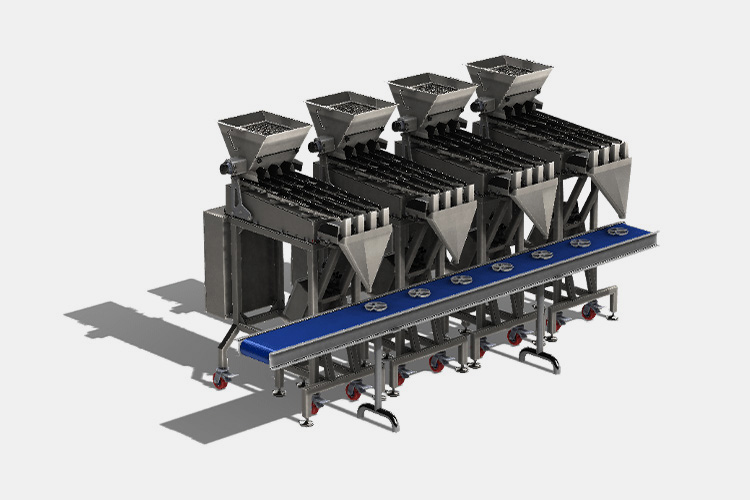

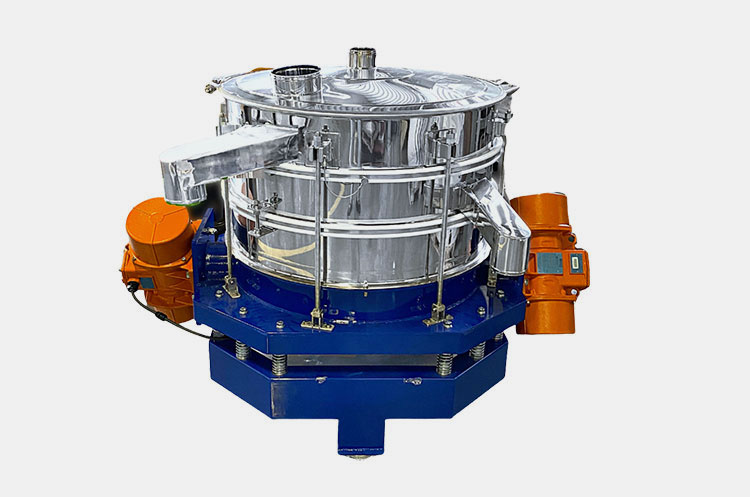

Multi-head Chilli Powder Packing Machine

Multi-head Chilli Powder Packing Machine

This machine has acquired traction over the recent years. It consists of upper and lower hoppers, a vibration plate, load cells, steeping motors and a PLC unit. It is a quick machine that swiftly packs chilli powders into the packing pouches or jars.

The chilli powders from the upper hopper go to weighing powders via vibratory plates. Through the vibration of vibratory plates, the chilli powders fall into the weighing hoppers and are ultimately dispensed into a packing container.

6.What are the Challenges in Chilli Powder Packing?

Chilli powder packing is filled with many challenges, some of which are discussed below:

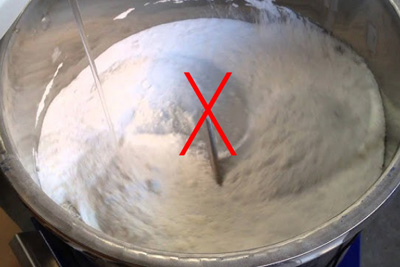

Flowability of Chilli Powders

Flowability of Chilli Powders- Picture Courtesy: Cariyon

It is the most important problem when it comes to chilli powder packing. The chilli powder adheres to the inner surfaces of the hopper and filling devices which leads to hindrance or blockage in the flow of chilli powder.

This problem is resolved by using agitators that move to avoid product buildup.

Dust Generation

Dust Generation

Chilli powder packing often results in dust production. When packing dry and milled chilli powders, dust is produced due to the property of chilli powders to become aerial. These characteristics cause respiratory issues in the workforce due to inhalation of chilli powder dust and this dust gets charged, leading to electric and fire accidents.

This predicament is solved by using a dust hood, enclosed devices, and vacuum suction equipment.

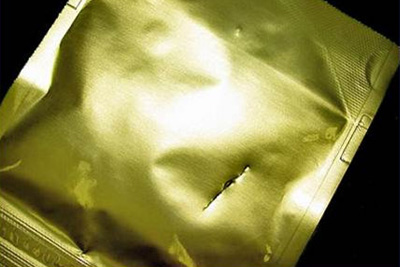

Air in Chilli Powders

Vented Chilli Pouch- Picture Courtesy: Fiver

Huge quantities of air are present in the chilli powders which may lead to bursting and ballooning of chilli powder packing if packed without removing the air. It also creates problems in the stickability of the pouches and lowers the quality of chilli powders.

The air in chilli powders is eliminated using vacuum packing technology and also by vents in the chilli powder packing.

7.What are Resealing Options for Chilli Powder Packing?

Chilli powder packing comes with different resealing options for the convenience of the users. It prevents the chilli powders from getting spoiled. Here is the list of different sealing options.

| Zippers

Standup pouches come with zipper closures that are conveniently closed by pulling zippers. It is a simple yet effective resealing option. |

Zipper Pouch- Picture Courtesy: Packaging of the World |

| Press to Close

After opening, these sealing options are pressed for closing. It creates strong airtight sealing. |

Press to Close Pouch- Picture Courtesy: hunker.com |

| Adhesive Strips or Tapes

It comes with adhesive tapes that are peeled off to expose adhesive which is pressed on the opening of the pouch. |

Adhesive Tapes- Picture Courtesy: Dribble |

| Fold and Close

After use, the pouch is folded and packed using adhesive tape or clip. It creates a secure seal. |

Fold and Close Pouch- Picture Courtesy: Behance.net |

| Caps

Different types of caps like screw caps, flip-top caps, and screw caps provide a strong closure. The caps are opened for pouring out the chilli powders and resealed by turning and snapping shut. |

Caps- Picture Courtesy: Behance.net |

| Lids

The tins and cans are re-closed using resealable lids. It is not an effective option when compared with screw caps. Resealable lids are seldom used. |

Lids- Picture Courtesy: Poetry of Spices |

8.What Is the Used Material for Chilli Powder Packing?

Chilli powder packing is available in different materials to improve the quality of packaging and marketability. The most common methods for chilli powder packing are discussed below:

Metals

Chilli Powder Tin- Picture Courtesy: SIZL Spices

Aluminium and tinplate metals are used to fabricate tins. These metals have superior ductility and formability. These metals are heavier but offer excellent protection.

Aluminium Foil

Aluminum Foil Chilli Powder Packing- Picture Courtesy: Packaging of the World

It is a commonly used material for making pouches. It is easily shaped into different pouch styles because of its highest mouldability. Aluminium foil provides impermeability against moisture, light, and air.

Glass

Glass Chilli Powder Packing- Picture Courtesy: 99Designs

Clear glass is used for fabricating high-end and luxurious chilli powder bottles and jars to attract high-end and sophisticated users. It offers a superior barrier against elements.

Laminate Films

Laminate Film Chilli Powder Packing- Picture Courtesy: Behance.net

These laminate materials are fabricated by combining and bonding aluminium foil and plastics. It has versatile uses and is used for making diverse pouch styles. Laminate films have different finishes so they are popular. These films have excellent toughness and prevent pouches from mechanical damage.

Plastic

Plastic Chilli Powder Packing- Picture Courtesy: Behance.net

It is a frequently employed material for forming flexible chilli pouch packaging. These plastics have resistance against water and air and allow the brands to uphold the aroma and freshness of chillies.

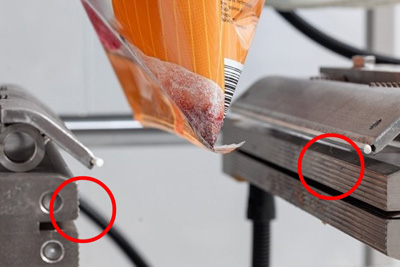

9.What are Seal Strength Tests for Chilli Powder Packing?

Seal Strength Test of Chilli Powder Packing- Picture Courtesy: girorganic

The seal strength test is designed to measure the mechanical strength of bonding between the seals. These tests detect any weakness in the seal. The test for evaluating seal strength chilli powder packing is listed below:

| Compression Test | In this test, the strength of the seal is determined under high-pressure forces by stacking different chilli powder packing containers over one another. It measures the deformity and bursting of seals under compression forces. |

| Dye Penetration Test | In this test, dye is applied at one end of the seal. If it moves towards the other end, it means that there is a weakness and leak in the chilli powder packing. |

| Water Bath Test | The chilli powder packing is emersed under the water surface and air above the surface is removed. If the air bubbles are seen on the water surface, it means there is leakage in the seal or pouch. |

| Vacuum Decay Test | The chilli powder packing is placed in the vacuum area, from which air is removed. The pressure reading is measured by a pressure gauge. If the pressure drops, it means that seal bonding is weak. |

| Gas Leakage Method | Different gases like helium, carbon dioxide, and hydrogen are fed in the chilli powder packing. The sensor is used for determining the number of gases leaking from the hole. If less amount of gases is detected coming out of a hole in chilli powder packing, then seal strength is poor. |

| Peel Test | Maximum force is applied for peeling the two layers of sealed chilli powder packing in the peel test. It measures the effectiveness of seal adhesive. |

10.What are Trends in Chilli Powder Packing?

Chilli powder packing has come a long way from simple and monochrome boxes and jars. It is continuously evolving and has experienced new trends like:

Sustainability

Sustainability of Chilli Powder Packaging- Picture Courtesy: Behance.net

The use of recyclable and biodegradable materials in chilli powder packing has emerged as a new trend because of increasing awareness among users about climate and global warming. Now users demand environment-friendly packaging. So, sustainable chilli powder packing is trendy nowadays. This packaging is easily decomposed by the microbes, decreasing the impact on the environment.

Smart Packaging

QR Codes in Packaging- Picture Courtesy: QR Tiger

Nowadays, the latest and innovative technology is used in the chilli powder packing like sensors and indicators that detect the freshness of chilli powders. It tells users about the quality of chilli powders. Moreover, QR codes and other RFID are included in chilli powder packing to trace and track chilli powder packing.

Minimalist Design

Minimalist Design- Picture Courtesy: designerpeople

These designs including earthy tones and simple patterns and fonts are gaining popularity in chilli powder packing because they appeal to users who demand transparency. Moreover, minimalist design uses less ink and packing materials which in turn contributes towards eco-friendliness.

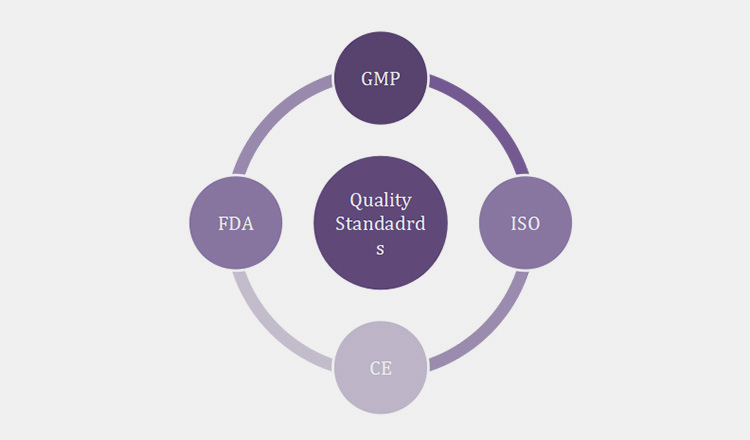

11.Are Chilli Powder Packing Materials Food-Grade?

Food-Grade Materials in Chilli Powder Packaging- Picture Courtesy: Packaging of the World

Chilli packing materials come in direct contact with chilli powder, so these materials must be food-grade. These food-grade materials ascertain the safety of the chilli powders. Different food authorities have ensured guidelines for mandating the fabrication of chilli powder packing with food-grade materials.

It is important as food-grade materials are made with non-toxic materials that do not leach harmful substances into the food. Furthermore, inks, coatings, and other adhesives that make chilli powder packing are also food-grade meaning they do not have harmful chemicals.

To make sure that these materials do not contain harmful chemicals, they are meticulously tested. Otherwise, these chemicals may move to chilli powders, contaminating the latter and deteriorating the health of users.

By using food-grade material in chilli powder packing, manufacturers ensure the health and safety of consumers.

12.How Does Chilli Powder Packing Prevent Clumping of Powders?

Chilli Powder Packing and Clumping of Powder- Picture Courtesy: Behance.net

Chilli powders may clump by absorbing moisture and sticking with each other. So, to ensure that these powders do not clump, chilli powder packing is designed to include round and angled corners that boost the flowability of chilli powders and reduce their chances of clumping.

Moreover, chilli powder packing is made with moisture-proof materials that are impermeable to moisture. It is made from laminated aluminium foils that are not affected by humidity variations and prevent the entry of moisture vapours which may cause clumping.

Some chilli powder packing may come with desiccant packs that contain hygroscopic materials for absorbing water vapours. This protects the inner environment in chilli powder packing and keeps it dry, so inhibits chilli powder clumping.

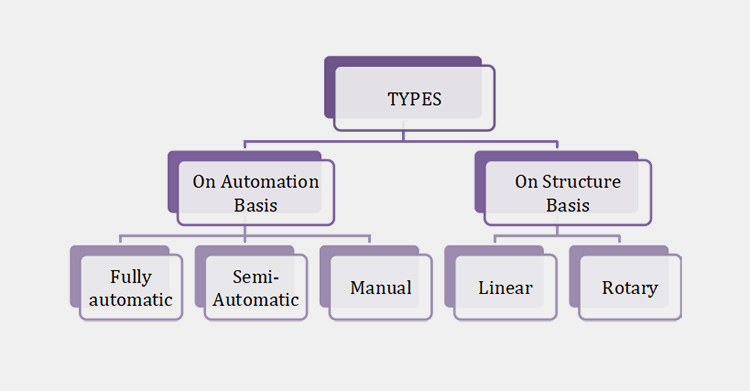

13.What Are the Differences Between Semi-Automatic Chilli Powder Packing Machine and Automatic Chilli Powder Packing Machine?

Allpack Semi-automatic and Automatic Chilli Powder Packing Machine

Semi-automatic and automatic chilli powder packing machines are two essential machines in chilli powder packing that fill and seal the chilli powders. But these machines differ in various aspects that are listed below:

| Feature | Semi-Automatic Chilli Powder Packing Machine | Automatic Chilli Powder Packing Machine |

| Operation | Its functionality is both manual and automatic. Operators manually place and unload chilli powder packages on this machine. Filling and sealing are carried out by the machine itself. | It completely executes various functions like loading and unloading of containers, filling and sealing itself. |

| Foot Print | It has a smaller footprint. | It has a larger footprint due to its complicated design. |

| Labor Cost | It is more labour intensive, requiring more labour for loading and unloading containers. | It does not require much labour force. One or two operators are required to program an automatic chilli powder packing machine. |

| Ease of Use | It is simple to learn and operate a semi-automatic chilli powder packing machine. | It is difficult to learn and operate this machine. This machine requires much training to operate |

| Application | It is best for productions with budget constraints. | It is generally found in larger productions. |

| Budget | It is a less costly manufacturing unit. | It is a more costly option for production. |

14.How Chilli Powder In A Pack Stays Longer?

Shelf-Life of Chilli Powders- Picture Courtesy: Behance.net

Chilli powder stays in the pack longer because chilli powder packing forms a good barrier that does not allow water content and air inside the packaging. Oxygen is the main agent that spoils the chilli powders.

Oxygen causes the oxidation reactions of the oils in the chilli powders that affect the aroma and flavour of the chilli powders. Furthermore, due to its barrier properties, chilli powder packing prevents the evaporation of volatile oils, which otherwise leads to the deterioration of the taste and fragrance of chilli powders.

15.How Does Chilli Powder Packing Offer Tampering Evidence?

Tamper-Evident Chilli Powder Packing- Picture Courtesy: Packaging of the World

Yes, chilli powder packing provides tampering evidence by including tamper-evident labels and tapes around the corners of chilli powder. These labels and tapes are damaged and ripped if the chilli powder packing is opened.

It also contains tamper-evident seals like induction seals, shrink bands, and stretch wraps, aluminium foil seals. These sealed materials surround the lids, caps, and sealed areas of chilli powder tins, bottles, and pouches. These seals lose their structural integrity if the seals are tampered with.

Some types of chilli powder packing incorporate colour-changing sensors that alter the colouring of packing materials and labels if the chilli powder packing is opened and exposed to air.

These tamper-evident features are visible on the chilli powder packing and are not easily copied. These features ensure the quality and safety of chilli powders.

16.How To Preserve Red Chilli Powder Packing?

Preservation of Red Chilli Powder Packing- Picture Courtesy: designerpeople

Red chilli powder packing is stored in a cool, dry, and dark place for its preservation. This packing is stored at a low temperature setting away from heat and light because these agents increase the chances of reactions in the chilli powder packing. These reactions negatively impact the taste and nutritional value of chilli powders.

Moreover, red chilli powders are preserved in airtight containers such as capped glass bottles or resealable pouches that increase the impermeability to air and water, thus extending the shelf life of chilli powders.

Conclusion

Chilli powders breathe a new life into various recipes. It is necessary to preserve the taste and aroma of chilli powders which is achieved by chilli powder packing. This chilli powder packing aids in protection, product communication, branding, containment, tracing, and tracking. Smart technology, sustainability, and minimalist designs are the upcoming trends that have transformed the chilli powder packing. Now it's time to conclude this informative guide about chilli powder packing, if you still have queries about chilli powder packing then contact our Allpack sales representatives.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide

Chilli Powder Packing: The Complete FAQ Guide In 2024 Read More »

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours