Talcum Powder Filling Machine: The Complete Buying Guide in 2024

You will be surprised to know that the commercialized form of talcum powder originated in 1894 but now crude talcum powder domestic production in the US is estimated at 490,000 tons which is valued at 22 million dollars. Talcum is actually a mineral that has been applicable since very long more than 1800 years ago. This is taken from rock deposition of silicate minerals presented on the Earth’s crust.

The business strategy of talcum powder is significant, and today you can find the demand for talcum powder everywhere either for medicinal purposes, cosmetics, skincare, or fragrances.

The talcum powder filling machine is a giant piece of equipment that plays a hidden role in the production goals. If you’re a business-running person and looking to add a talcum powder machine and striking with various basic queries in your mind. Then don’t worry! Please read this blog to explore the basic knowledge about the talcum powder filling machine.

1.What is Talcum Powder Filling Machine?

Talcum Powder Filling Machine

A talcum powder filling machine is a robust equipment that is required to dispense a precise and accurate concentration of talcum powder into its respective packaging material such as sachet, jars containers, or bottles.

The filling content is subjected to packaging material via taking support of an auger. You can term a talcum powder filling machine as an auger filling machine as well which facilitates the packaging process of all dry talcum powder goods.

This is an extremely suitable machine for various tasks addressing the filling of fine powders, and granules powders, such as spices, food goods, and for other purposes. It basically employs combinations of working pathways including for of gravity, friction, centrifugal force, etc to make the filling process faster and efficient.

2.What are the various Industrial Usages of Talcum Powder Filling Machine?

The talcum powder filling machine is actually the filling solution preferred in the production industries for dispensing their formulations in a safe manner. That’s why the talcum powder filling machine is widely applicable in a broad range of industrial usage. Some of them are discussed below:

Cosmetic Industry

Cosmetic Industry- picture Courtesy: RWK Goodman

Frankly, the cosmetic industry manufacturing and packaging stages won’t be possible if you minus talcum powder filling machine from its working facility. From the very initial to the finished processes, the talcum powder filling machine utilization is paramount. The products such as blush, dusting powders, cheek glow powders, eye shadows, liners, foundations, face powders translucent fair powders, clay powders, pressed powders, and much more, need a talcum powder filling machine.

Personal Hygiene

Talcum Powder Filling Machine applications in cosmetic industries

This industry is another giant production field where a talcum powder filling machine is preferred during manufacturing, filling, and packaging of products like cleaners, face scrubs, talcum powders, masks, manicures, pedicure products, and much more.

Food Industry

Talcum Powder Filling in Food Industry

Obviously, a food industry's production lab is not completed without a talcum powder filling machine as there are a number of products that require a talcum powder filling machine for its aesthetic and quality packaging.

For example, spices, condiments, seasoning, and various flavoring agents, food products such as bakery items, wheat flour, rice flour, baking powders, sugars, corn flours, coffee, tea, etc., into respective containers, or sachet, or pouches.

Pharmaceutical Industry

Talcum Powder Filling Machine in Pharmaceutical Industry- Picture Courtesy: Cozzoli Machine Company

The talcum powder filling machine is the basic need in the preparation, formulation, and dispensing of pharmaceutical medicines and extemporaneous ingredients such as powders, granules, and pellets for making tablets, capsules, antibiotics, ointments, topical preparations etc.,

Nutraceutical Industry

Talcum Powder Filling Machine applications in nutraceutical industries

The demand for talcum powder filling machine in the nutraceutical industry is quite significant as you can observe various preparations such as probiotic, protein powders, energy boosters, enzymes, minerals, trace elements, supplements, milk powders, etc., products filling is perfectly packed by using talcum powder filling machine.

Chemical Industry

Talcum Powder Filling Machine applications in chemical industries

No doubt, talcum powder filling machine is very popular due to their important applications in the chemical industry such as filling chemicals including salts, buffers, alkali or acidic substances, fertilizers, pesticides, cleaning agents, and much more in their respective containers, bags, or pouches in a safe manner.

Construction Companies

Talcum Powder Filling Machine applications in construction industries

The talcum powder filling machine is used to fill products like plaster of Paris, cement, dry chips stones, sands, and other materials by using this machine.

Agriculture Industry

Talcum Powder Filling Machine applications in agricultural industries

The talcum powder filling machine is used in the agriculture industry for efficient packaging of materials like seeds, grains, cultivator boosters, rice, or other important products frequently used in the agricultural fields ensuring exact and correct proportions.

3.How Does Talcum Powder Filling Machine Works?

If you see the different classification of talcum powder filling machine; you will find difference in their working principles. But the major working of talcum powder filling machine is based on discussed following steps:

| STEP 1: Feeding of Talcum Powder | When you start the talcum powder filling machine; you need to load the talcum powder content onto the hopper or feeding tank. The process initiates when talcum powder is transported to hopper from the tank. This can be done by using vacuum suction unit and transferring system. |

| STEP 2: Feeding of Packaging Material | The filling material such as jars, bottle, or containers in an oriented position is conveyed to the machine with the help of conveyor belt. The empty containers are subjected to the machine, and it is fed toward the filling unit. In case of pouch or VFFS machine the plastic or thin film is loaded onto the roller. |

| STEP 3: Talcum Powder Filling Processes | Upon reaching the filling nozzles of the machine; the machine detects the presence of material and pour the talcum powder in an optimized concentration as fed into the system by using PLC touch screen. |

| STEP 4: Discharging Filled Container | Once the predetermined concentration of the talcum powder is filled inside the packaging materials. The set of finished products are transferred to other integrated machines to proceed the further steps of the production line such as capping, labeling, collection etc., |

4.What are the Basic Parts of Talcum Powder Filling Machine?

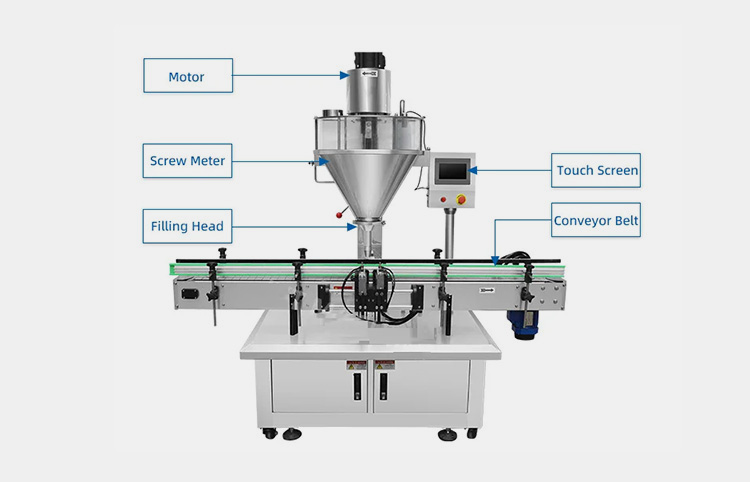

The Parts of Talcum Powder Filling Machine

The talcum powder filling machine is composed of simple parts and a compact structure. The given below is the exact description that will help you to understand the machine.

| Motor

|

The motor of the talcum powder filling machine offers you essential functioning and operation of the machine which includes the running of auger filler, vibratory unit, and conveyor belt, and ensuring you promising properties of the controlled filling procedure. |

| Screw Meter

|

This is also known as an auger. These are the major parts of the talcum filling machine which is basically responsible for providing a pathway for accurate measurement and dispensing of the talcum powder toward the fillers for a precise and confined filling process.

The screw meter is mostly available in various designs and sizes which is helpful in the estimating and filling of different textures of talcum powders. |

| Touch Screen

|

The talcum powder filling machine is controlled and operated by using a touch screen monitor equipped on the top of the machine. the user puts required keys using the touch screen such as the number of containers, amount of talcum powder to be filled, the speed of filling, speed of conveyor, etc., Plus, if the machine is struck with any problem or issue, the monitor will display the notification once it is detected by the machine. |

| Filling Head

|

This is the important part of the talcum powder filling machine which assists assisting the smooth flowability of the talcum powder toward the containers. The filling head is composed of a nozzle that addresses the powder received from the auger towards the filling materials. |

| Conveyor Belt

|

This is a transporting unit of the talcum filling machine which supports incoming and outgoing of the filling materials. Moreover, the conveyor belt is useful for connecting the talcum powder filling machine with other machines of the production line. |

5.How many different types of Talcum Powder Filling Machine?

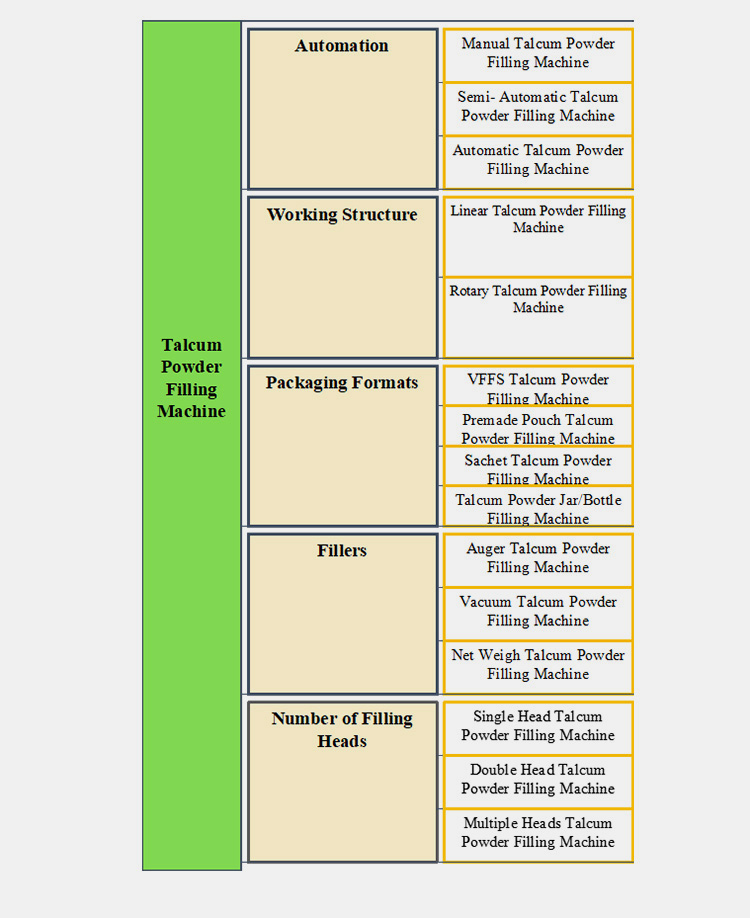

The talcum powder filling machine has not a specific description. Except some similar units such as an auger filler, metering device and HMI interface; the machine is presented with different various categories. Discussed below are various types of talcum powder filling machine which is successfully running its market worldwide.

An illustration chart composed of various types of talcum powder filling machine

Types of Talcum Powder Filling Machine- Based on Automation

Types of Talcum Powder Filling Machine- Based on Automation- Picture Courtesy: Weighpack

The talcum powder filling machine is available in the market with basic three automations.

| Manual Talcum Powder Filling Machine

Manual Talcum Powder Filling Machine- Picture Courtesy: VEVOR. Au |

The manual talcum powder filling machine is a small, compact, and handy equipment which is used in small production labs or facilities to bring talcum powder filling process efficiently.

The user loads the filling content in the hopper of the machine and place containers to be filled. By using a handle an optimum concentration of talcum powder directly drops down into the packaging material. Once it is filled, you to remove the container and place another one to run the operation. |

| Semi-Automatic Talcum Powder Filling Machine

Semi-Automatic Talcum Powder Filling Machine |

The semi automatic talcum powder filling machine is an advance device to run small to medium production labs or facilities.

This machine needs little bit of human intervention while some of operation can be run by the machine itself. The empty containers are placed by the operator manually on the conveyor of machine just behind the filling nozzles. Now, you need to press the foot pedal or machine’s key to run the process. Once the talcum powder is appropriately dispensed, manually remove the material from the machine. |

| Automatic Talcum Powder Filling Machine

Automatic Talcum Powder Filling Machine |

According to our experts, this is a giant machine in the territory of talcum powder filling field.

This is because from the scratch till packaging, the working procedure is carried out automatically without needing technicians or human monitoring. This machine is ideal to install for large scale production batches. The conveyor brings empty packaging materials toward the filling nozzle where fast micro-processor senses the presence of containers and orders the machine to allow precise amount of talcum powder as commanded by you on PLC touchscreen. Once they’re filled, the materials move towards the next machine for completion of packaging process. |

Types of Talcum Powder Filling Machine- Based on Working Structure

Types of Talcum Powder Filling Machine- Based on Working Structure

If you have large production facility, then you would love to enjoy every design, format, and types of machines with various advancement.

Similarly, when selecting a machine to run large batches with small facility is tricky to decide. The discuss below types are mentioned in order to solve problem for such manufacturers.

| Linear Talcum Powder Filling Machine

Linear Talcum Powder Filling Machine- Picture Courtesy: IVS Engineering |

The linear talcum powder filling machine is basically a traditional machine with conventional structure where entire working of talcum powder filling is taken place in a linear fashion.

For example, in feed of bottles or containers, filling, with subsequent discharging. This type of machine is simple and suitable for almost every production process which offers you flexible integration of machine with other units. |

| Rotary Talcum Powder Filling Machine

Rotary Talcum Powder Filling Machine- Picture Courtesy: Just Dial |

If you’re looking for comparatively fast filling solutions for talcum powder filling business with a compact area; we would suggest going for rotary talcum powder filling machine.

Here, the machine is capable of running a continuous filling process in seamless rotation of rotary table where containers or pouches are subjected to filling nozzles for accurate filling. The incoming and outgoing of packaging materials is taken place in a circular manner with high speed, thus this is suitable for large production fields. |

Types of Talcum Powder Filling Machine- Based on Packaging Formats

Types of Talcum Powder Filling Machine- Based on Packaging Formats

When it comes to various packaging formats, the talcum powder filling machines are presented with various different options such as:

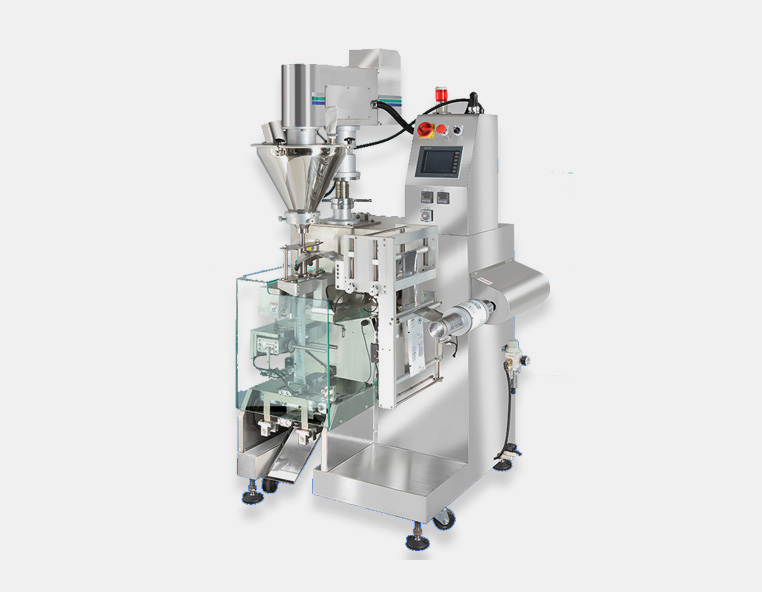

| VFFS Talcum Powder Filling Machine (Vertical Form Fill Seal)

VFFS Talcum Powder Filling Machine- Picture Courtesy: Grace Food Process |

In this type of talcum powder filling machine, a film roll is subjected to the machine.

You need to adjust the roll manually and put the required settings using PLC. The machine is capable of opening and pulling of the roll and creating a pouch or bag by using narrow forming tube for a correct shape and jaw sealers for joining and creating the pouch. Once it is formed, the talcum powder is poured down followed by sealing of remaining portion of the packaging material. This is a cost-effective and highly popular machine as it is easy to use and offering versatile operation with high throughput. |

| Premade Pouch Talcum Powder Filling Machine

Premade Pouch Talcum Powder Filling Machine |

This is another cost-effective option of talcum powder filling where you need to load the stack of pre-made pouches in the magazine of premade pouch machine.

The presence of gripers allows to pick the pouch and air-inflators helps in the opening for filling of the material. Once the pouches are subjected to the filling nozzles, an optimized concentration of the talcum powder directly poured into the pouches, and it goes for further sealing steps for final process. |

| Sachet Talcum Powder Filling Machine

Sachet Talcum Powder Filling Machine |

This machine is following similar working principle as VFFS where machine can form small packs of sachet using film formation of the sachet, sealing, filling, and cutting of the small pouches.

The prime difference you can find in the working is its size of the sachet. The making of sachet with filled ingredients are just an option for a single serving that is carried out a small portion of the talcum powder. |

| Talcum Powder Jar/Bottle Filling Machine

Talcum Powder Jar/Bottle Filling Machine |

When thinking of talcum powder filling, the jar/bottle/container filling machine comes in mind. The machine is quite simple with easy working parameters and working principles.

This machine offers ideal and flexible working when integrated with other units such as the unscrambler, and capping machine. The empty containers come toward auger filling nozzles of the bottle /jar/container filling machine where the detector senses its presence and allow specified proportion of the talcum powder into each container and allow it to leave for the next step. |

Types of Talcum Powder Filling Machine- Based on Fillers

Types of Talcum Powder Filling Machine- Based on Fillers

Depending upon types of talcum powder consistency and flowability ration. You always look for various filling options to carry out the filling task of the machine properly and accurately. The mentioned below are the different types of fillers featured on talcum powder filling machine offering you promising dispensing without generating dust or product’s wastage.

| Auger Talcum Powder Filling Machine

Auger Talcum Powder Filling Machine |

This machine is accompanied with an auger filler that works by using a rotary screw that allow fast and efficient dropping of the talcum powder onto the packaging material precisely and accurately which ultimately presents a quality throughput with rapid packaging solution. |

| Vacuum Talcum Powder Filling Machine

Vacuum Talcum Powder Filling Machine- Picture Courtesy: Fillermatic |

A vacuum talcum powder filling machine is designed with a vacuum filler that utilizes a vacuum to drop a concise proportion of talcum powder without worrying about dust formation directly onto the packaging material.

This machine is suitable for working with aseptic materials because it is complied with offering a controlled packaging environment. |

| Net Weigh Talcum Powder Filling Machine

Net Weigh Talcum Powder Filling Machine- Picture Courtesy: Weighpack |

The machine basically works by measuring the net weight of the talcum powder and pour the exact quantity into packaging material. The net weigh talcum powder filling machine is suitable for those production companies that are more conscious about critical measurements and volume of ingredients. |

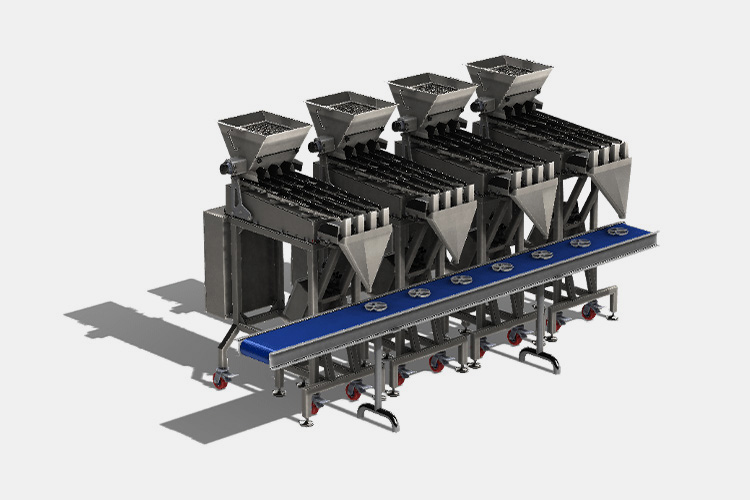

Types of Talcum Powder Filling Machine- Based on Number of Filling Heads

Types of Talcum Powder Filling Machine- Based on Number of Filling Heads- Picture Courtesy: Weighpack

If you’re worried about bring high production throughput with minimum or short installation space. Then, no need to stress about! You can simply check various types of talcum powder filling machine with different number of filling heads to bring this process more easy and more efficient.

| Single Head Talcum Powder Filling Machine

Single Head Talcum Powder Filling Machine |

This is conventional or traditional form of talcum powder filling machine which is designed with a single filling head. The machine is suitable for small or medium scale production fields. |

| Multi Head Talcum Powder Filling Machine

Multi Head Talcum Powder Filling Machine |

The more efficient and fast option for talcum powder filling process, where the machine is designed with more than one filling head capable of running multiple filling materials with promising accuracy. This machine is considered as an ideal option to run the large production capacities without worrying for error or manual labor cost. |

6.What are the Major Benefits of the Talcum Powder Filling Machine?

There are certain benefits of using talcum powder filling machine for every manufacturing and packaging companies. The following list of benefits is given below:

Talcum Powder Filling Machine- Picture Courtesy: Jawla Engineering

Talcum Powder Filling Machine with Enhance Processor

Talcum Powder Filling Machine with Enhance Processor- Picture Courtesy: Auger Process

Today, talcum powder filling machine is featured with amazing micro-processor abilities that not only enhance your working results, but it is able to give you fast and efficient output. The machine operational capabilities are entirely controlled by micro process with definite filling process.

No Chances of Ripping

The handling of the talcum powder filling machine is promising that ensure that talcum powder content is intact and not ripped by the machine during filling procedure so you can get a stable and perfect packaging.

Zero Chances of Slippage

The talcum powder filling machine is controlled by micro processor means the entire keys and process schedule is timely and visualized. The machine filling capabilities are much accurate so 100% controlled over spillage, so you can find a maintained and safe filling.

Eliminates Costly Labor Charges

Eliminates Costly Labor Charges- picture Courtesy: Auger Enterprises

The use of talcum powder filling machine is required for small, medium and large production sectors due to its fast working and ultimate lowering of labor charges as you can get triple maximum throughput with this robust equipment.

7.What is the Production Line of the Talcum Powder Filling Machine?

The talcum powder filling machine is basically following the mentioned below production line. In the case of pouches, bags, unscrambler, capping, induction sealing are not used. Let’s find the basic production line of talcum powder filling machine.

| Bottle Unscrambler

Bottle Unscrambler- Picture Courtesy: Aipak |

Bottles are received from a large hopper to an inclined conveyor which forwards them to a rotary bowl. Here the bottles are organized and sorted in such a way that the neck of bottle is leading position, so you receive bottles that are upright. Further on, they move to bottle filler, capping machine and for the rest of processing. |

| Capping Machine

Capping Machine- Picture Courtesy: Aipak Pharmaceutical |

It is responsible for capping bottles in various styles of caps and closures by assisting efficient and quick placement. Either pick off or pick and place method is applied. In the former one, a highly accurate chute delivers caps onto the bottles while in the latter method more automated feature carries out picking of the cap and presenting to cap chuck for it to be sealed. |

| Induction Sealing Machine

Induction Sealing Machine |

By the use of an electromagnetic field that is directed towards the foil liner inside the cap, it gets heated and melts. When this hot foil liner gets cooled, a hermetic seal is created which protects the product from contamination and gives an airtight seal. |

| Labeling Machine

Labeling Machine |

The bottles are carried by the conveyor belt to the labeling machine where the drive wheel pulls the label out of the reel and with the help of the labeling wheel the label is stuck onto the bottle. To prevent the misplacement or disorientation of the label, the sensor reads the mark on the label to ensure each of them is placed accurately. |

8.What are the Basic Problems and Troubleshooting of the Talcum Powder Filling Machine?

The talcum powder filling machine is an advanced and innovative device for accurate filling procedures. But this machine also encounters some basic problems, you must know how to deal with certain common issues. Please find discuss below points for easy operation.

Problem: Inconsistent Weigh

The Problem of Inconsistent Weigh

This problem has mostly occurred with talcum powder prohibiting a non-free flowing texture or any variation in its flow characteristics. In this situation, talcum powder needs to be pushed by the machine agitator toward the auger screw in order to complete its filling flight toward the packaging.

Troubleshoot

As you already know, the talcum powder filling machine is accompanied by an agitator blade present in the metering screw of the machine which is there to speed as well as push the flow of powder smoothly.

With the help of the HMI touchscreen system, you can regulate the speed of the auger agitator which will directly correct the flow of talcum powder and ultimately correct the uniform filling.

Problem: Jamming of the Talcum Powder in the Machine

Jamming of the Talcum Powder in the Machine

This problem is possibly occurring when the position or orientation of the hopper is not correctly installed. In this case, the flow of the talcum powder becomes gradually starts piling up, instead of flowing down.

Troubleshoot

It is recommended to keep the hopper surface in a slop or inclined direction to achieve a seamless flowability rate of the talcum powder filling machine. Another way to avoid this problem is to use an auger agitator that assists you in the avoidance of clogging. Thirdly, use a vibration mechanism to improve consistency in the flowability of talcum powder.

Problem: Spillage or Leakage of Talcum Powder from Packaging

Spillage or Leakage of Talcum Powder from Packaging

You may have noticed the product’s leakage or spillage when subjected to the talcum powder filling machine and every time it may make your product waste as well as your precious time. The problem basically occurred in those packaging materials which is formed by either pouch makers or bag makers such as VFFS, Sachet, and other. This is due to the wrong sealing site of the machine.

Troubleshoot

To solve this problem, adjust the heat sealer setting, so it can accurately seal at the required edges of the pack so spillage of talcum powder can be avoided. Also, use the dust controller which can reduce the formation of unwanted dust and its sticking at the sealing site so joining can be efficiently achieved.

9.What is the Future Prospect of Talcum Powder Filling Machine?

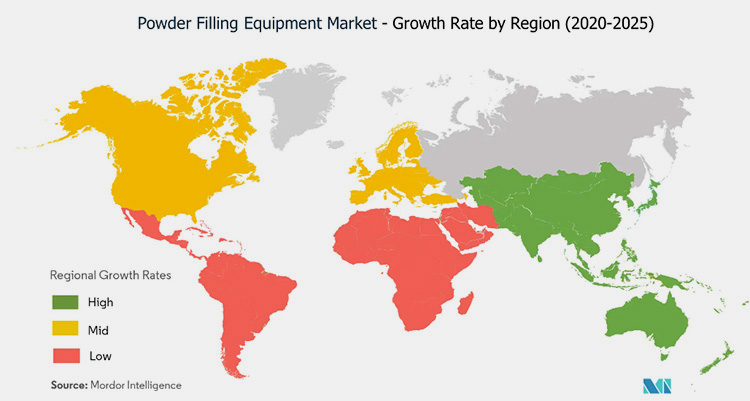

The Major Profitable Regions of Talcum Powder Filling Machine demand

The talcum powder filling machine's future prospect is expected to be registered as high as observed around 7% CAGR for the forecast period of 2021 to 2026. This is all because of day to day-to-day innovation and functionality of talcum powder filling machines and their convenience with end-users in broad industrial fields.

The high adaption is the leading reason behind the boosting of productivity and profitability. Also, its rising demand is due to its aseptic and automatic features that help in fast production.

The major hold of talcum powder filling machines is expected from the largest pharmaceutical sectors as these machines comply with quality standards such as FDA, CE, CDC, and others.

Conclusion

The talcum powder filling machine offers absolutely precise and leveled dosing of the talcum powder without any possibility of error. Hence for every entrepreneur, company, or branding firm gets a promising result when using this machine. If you looking to find the right talcum powder filling machine to run your business successfully; contact Allpack Team right now to avail free consultation about product and procurement.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide