Powder Packaging Equipment: A Complete Buying Guide in 2024

How to pack powders? A top piece of equipment called powder packaging equipment has prime importance in every industry because almost every industrial sector of the world processes and packages powder one way or another.

Integration of the powder packaging equipment slowly but steadily has been on the rise. The need for automated technology to promote productivity has fueled the growth of powder packaging equipment. Also, increased demand for on-the-go packaging styles has led to increased adoption of powder packaging equipment in the industrial sector.

If are you looking for a solution that safely and hygienically packs your powder products then we recommend installing powder packaging equipment in your production. But before that, first, carefully read this guide to discover more about this useful machine.

1.What is a Powder Packaging Equipment?

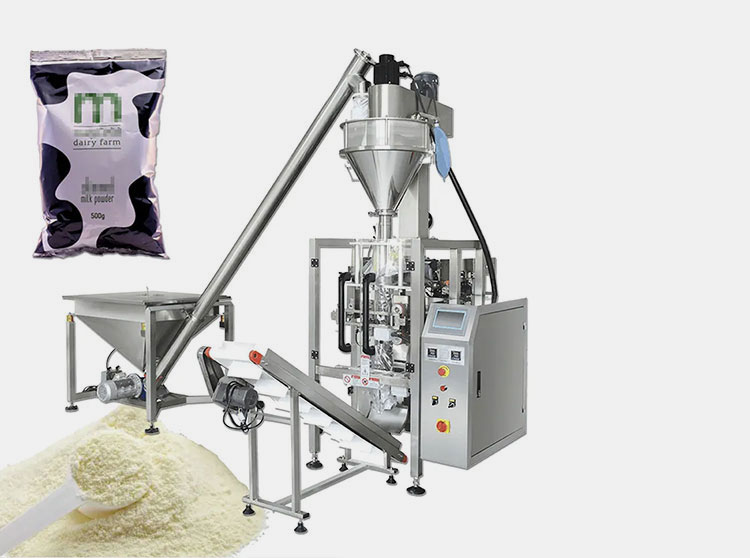

Powder Packaging Equipment

Powder packaging equipment is a versatile and handy manufacturing and filling unit that efficiently packages different types of powders in a wide range of packaging containers. It loads and contains powders in sturdy and airtight packaging containers for mess-free and leakage-proof shipment, retailing, handling, and delivery.

This machine typically forms, fills, and seals different types of packaging containers like pouches, sachets, stick packs, bottles, jars, vials, etc. Due to its diverse benefits, it is used in a broad range of industries like food, pharmaceutical, beverage, cosmetics, and many more.

2.Why Use a Powder Packaging Equipment?

Powder packaging equipment is an automated unit, flexible and robust capable of handling different packaging containers. Adopting this manufacturing unit is beneficial for industries. We are discussing some important benefits of this machine for your ease.

Improve Accuracy and Lower Wastage

Improves Accuracy by Powder Packaging Equipment- Picture Courtesy: All-Fill

Humans are more prone to mistakes which leads to lower accuracy. This in turn causes increased profit loss by overfilling or product rejection by underfilling. But by adding powder packaging equipment in the production, you are assured of accuracy. This machine has sensitive measuring devices that increase accuracy and reduce product wastage.

Better Product Quality

Better Product Quality by Powder Packaging Equipment- Picture Courtesy: Packaging of the World

By performing repetitive tasks, humans get tired, consequently making more packaging errors like wrongly packaging products, overfilling, or underfilling. With automated powder packaging equipment, product quality is ensured. It safely and consistently packs products with no chance of error.

Lower Labour Costs

Lower Labour Cost by Powder Packaging Equipment- Picture Courtesy: All-Fill

Labor comes with high costs, especially when you calculate different types of pay and training expenses. Although, the powder packaging equipment is a hefty investment in the longer run it earns more than its initial investment by requiring less labour force. This translates to lower labour costs and high benefits.

Versatility

Versatility by Powder Packaging Equipment

The powder packaging equipment is a handy and flexible investment, capable of processing a broad range of powders. It is useful for industries that pack multiple products every shift. Moreover, it can handle varying ranges of pouches, jars, sachets, and many more differing in their designs and sizes.

Fulfills Packaging Demands Easily

Fulfills Demands by Powder Packaging Equipment- Picture Courtesy: CVC Technologies

More orders mean more profit. But with handfilling, it is difficult to meet such rising requirements. However, with powder packaging equipment, you can easily fulfil high demands and satisfy more customers. This machine quickly packages more products and produces more orders in a short time.

3.What is the Design of a Powder Packaging Equipment?

The design construction of the powder packaging equipment is detailed below for your understanding.

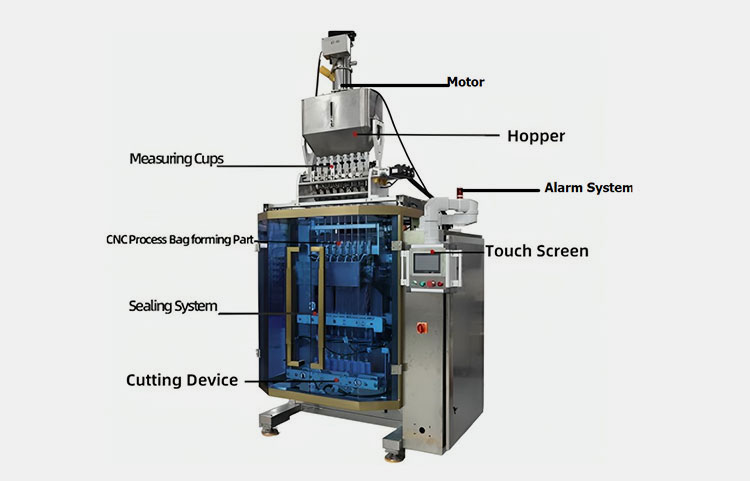

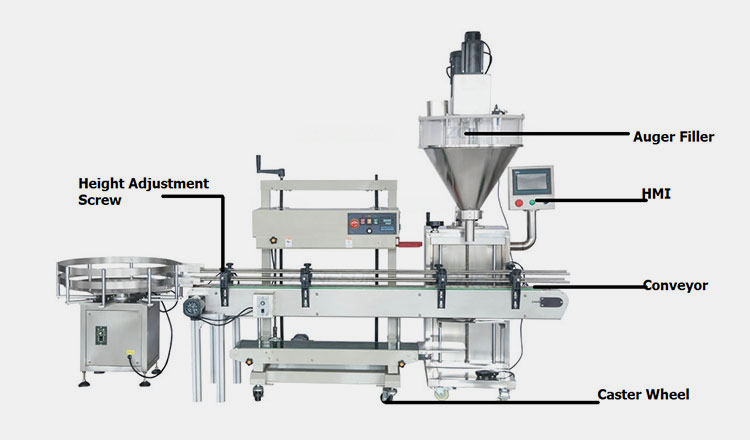

Both Pictures Represent Parts of the Powder Packaging Equipment

| Motor | It is an electric component that offers powering energy to different machine components for continuous machine operation. It converts electric energy into mechanical energy and moves filling devices, conveyors, sealing systems, etc. |

| Hopper | It is the hollow square or cylindrical chamber of powder packaging equipment that houses bulk quantities of powders. |

| Measuring Cup | The function of the measuring cup is to measure and dispense the correct quantity of powders inside the packaging container. |

| Alarm System | It is a safety feature that notifies operators of faults in the machine by lighting up and sounding an alarm. |

| Touch Screen HMI | The programming of the machine operation is done by touch screen. It is the interactive feature present in modern powder packaging equipment that assists in monitoring its performance. |

| CNC Process Bag Forming Part | It is a technologically advanced part that accurately and precisely forms the packaging bags using packaging film. It ensures that the formed bags are of the right dimensions and perfect quality. |

| Sealing System | It consists of horizontal and vertical sealing jaws and it fuses different edges of packaging film to create airtight seals that result in leak-proof bags. |

| Cutting Device | It consists of sharp cutting knives that cut the edges of the two bags for their exact separation. |

| Auger Filler | The function of this component is to dispense an accurate quantity of powders in the packaging container. It is a closed device ideal for the contamination-free filling of powders. |

| Conveyor | This part consists of drive belts and chains and is featured in a powder packaging equipment for the transportation of containers between different packaging stations. |

| Caster Wheel | The caster wheel provides mobility to the machine. They rotate to move the powder packaging equipment from one place to another. |

| Height Adjustment Screw | This part is a screw-like device with which conveyors are moved up and down to accommodate different-sized containers. |

4.What is the Useful Application of Powder Packaging Equipment?

Numerous products come in powdered form, so powder packaging equipment is needed by several important industries. Some of the useful industrial applications of the powder packaging equipment are:

Pharmaceutical Industry

Use of Powder Packaging Equipment in Pharmaceutical Industry- Picture Courtesy: Dieline

The powder packaging equipment is employed in the pharmaceutical industry for the packaging of different kinds of antiemetic powders, antiseptic powders, pain relieving powders, etc. It also packs different cannabis powders in both flexible and rigid packaging containers. It hygienically packs aseptic pharmaceutical powders in vials and bottles.

Nutraceutical Industry

Use of Powder Packaging Equipment in Nutraceutical Industry- Picture Courtesy: Packaging of the World

This machine is high in demand in the nutraceutical industry to uphold production efficiency. It fills accurate dosages of nutraceutical powders like supplement powder, protein powders, minerals, probiotics, prebiotics, dietary fibre powders, etc in strong packaging safely and precisely.

Food Industry

Use of Powder Packaging Equipment in Food Industry- Picture Courtesy: Dieline

It is the most demanding industry, where the powder packaging industry is utilized because different kinds of food products are available in powdered form. It loads food powders like flour, spices, coffee, sugar, salt, baking soda, baby formula, herbs, seasoning, curry powders, milk powders, etc.

Beverage Industry

Use of Powder Packaging Equipment in Beverage Industry- Picture Courtesy: Dieline

Yes, powder packaging equipment is utilized in the beverage industry for packaging different kinds of beverage powders like instant juices, coffee, iced tea, powdered juices, and other kinds of beverage powders. Single-pack sachets are an important factor that improves the utilization of this machine in the beverage industry.

Chemical Industry

Use of Powder Packaging Equipment in Chemical Industry- Picture Courtesy: Dieline

The powder packaging equipment is used in the household chemical industry for safely and securely packaging different types of sensitive chemical powders like laundry powders, bleaches, paint pigments, washing soda, alkali salts, detergent, dishwashing powders, and cleaning powders. It also fills agrochemical powders like fertilizers, pesticides, and herbicides, etc.

Cosmetic Industry

Use of Powder Packaging Equipment in Cosmetic Industry- Picture Courtesy: Dieline

This machine holds the promise of accurately and elegantly packaging cosmetic powders like face powders, dyes, dusting powders, eye shadows, and blushes, to name a few. It gently loads specialized cosmetic products in classy pouches and premium jars for captivating high-end customers.

Coating Industry

Use of Powder Packaging Equipment in Coating Industry

This industry deals with the creation of paints, resins, polishes, varnishes, furniture polishes, whitewash, finishes, and primers. The powder packaging equipment is used in this industry to airtightly package these coating powders to prevent their deterioration by environmental elements.

Construction Industry

Use of Powder Packaging Equipment in Construction Industry- Picture Courtesy: Packaging Connections

In the construction industry, different kinds of construction powders are processed and packaged by the powder packaging equipment. It loads sealant, additives, cement, silica, grouts, etc. in bulk quantity pouches. A seamless packaging with a speedy workflow is carried out by the powder packaging equipment in the construction industry.

5.Explain the Working Steps of the Powder Packaging Equipment.

| Product Loading

|

First, the infeed tanks are employed for storing the powders inside rectangular or conical hoppers, typically present on the top. The powders from the hopper flow into measuring cups. The latter are equipped with weighing devices that dispense exact quantities to the filling nozzles. |

| Filling

|

A powder filling machine is featured with a rotating auger which is helpful in flowing powder without interruption as it pushes powder forward toward filling nozzle.

Upon presence of filling containers or any packaging type, machine senses it and allows an optimized concentration of powder to fill inside. |

| Discharging

|

In the next step, the final discharging of filled container takes place toward the next integrated unit. |

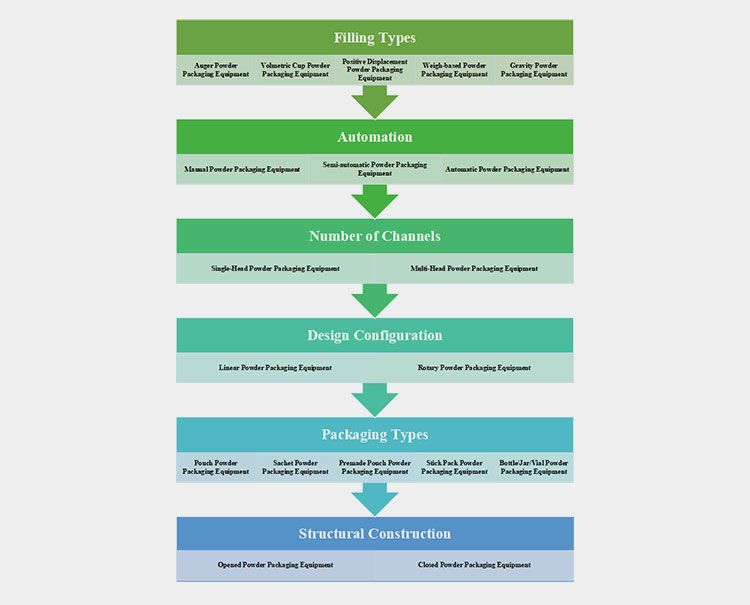

6.What are the Types of the Powder Packaging Equipment?

Different types of powder packaging equipment are seen in the industries, each customized for specific packaging operations. These types vary in their filling devices, automation, number of channels, design configuration, and structural construction. Below is the detail of the classification of the powder packaging equipment:

According to Filling Types

Auger Powder Packaging Equipment

Auger Powder Packaging Equipment

It is routinely used in the powder-filling industries because of its simple and quick filling of powders. It is a closed structure that hygienically fills the powder with no chance of contamination. Auger screw assists in the fluidity of powders by rotation. Powder passes auger devices smoothly and precisely.

Volumetric Cup Powder Packaging Equipment

Volumetric Cup Powder Packaging Equipment

This machine consists of several cups in the tray. A precalculated amount of powders is loaded inside the cup by the hopper and then these cups dispense a precise amount of powders in the container. This machine is well-suited for consistent particle size and free-flowing powders.

Positive Displacement Powder Packaging Equipment

Positive Displacement Powder Packaging Equipment

It uses pistons and pumps for the loading of powders inside the container. Rotation of pumps and to and fro motion of the piston displace powders from the hopper and dispense them in containers. This machine processes a wide range of products such as free-flowing powders.

Weigh-based Powder Packaging Equipment

Weigh-based Powder Packaging Equipment

This machine is popular in mass-scale productions because it can easily process large batches of powders. Unlike other powder packaging equipment, this machine dispenses quantities of powders by measuring their weight. A weigh-based powder packaging equipment uses load cells or other balancing parts to calculate the weight of the products.

Gravity Powder Packaging Equipment

Gravity Powder Packaging Equipment

This machine has simple design construction with straightforward working. Using gravitational force, the powders trickle down into the container. It is a valve for controlling the filling rate. It is best for free-flowing powders.

According to Automation

Manual Powder Packaging Equipment

Manual Powder Packaging Equipment

It is a simple and convenient machine, affordable for small industries, research centres, and pharmacies. It has a smaller footprint and is often placed on the desktops. It has rotating levers and handles for filling. It is labour-intensive because operators have to perform loading and unloading by hand.

Semi-automatic Powder Packaging Equipment

Semi-automatic Powder Packaging Equipment

It is a compact-sized machine that is best for medium-sized industries. It occupies a smaller space in the production. Loading and unloading of containers is manual in this machine while filling is automatically performed under the control of the machine’s PLC unit. It is recommended to use this machine if you do not require a higher processing speed.

Automatic Powder Packaging Equipment

Automatic Powder Packaging Equipment

It is an outclass machine with its up-to-date controls and modern gadgets. It is needed when higher volume production is required because of its exceedingly higher output. This machine requires a minimal number of operators for programming the HMI of the machine. Other functions like forming containers, filling powders, and unloading containers are executed independently.

According to Number of Channels

Single-Head Powder Packaging Equipment

Single-Head Powder Packaging Equipment

This machine as the name suggests, has only one filling head or nozzle. The powders flow into this nozzle so it packs one container in one cycle. This means it has a lower production capacity, so it is usually found in smaller productions. However, it has a simple design configuration, so it is quite budget-friendly.

Multi-Head Powder Packaging Equipment

Multi-Head Powder Packaging Equipment

It is a complicated design machine with many filling heads, thus it can pack multiple containers in one go. Large industries with heavier processing install this kind of powder packaging equipment because of its higher output rate. It comes with a higher price tag and needs more room for its installation.

According to the Design Configuration

Linear Powder Packaging Equipment

Linear Powder Packaging Equipment- Picture Courtesy: WeighPack

It is constructed in a straight line and has a U, Z, or L-shaped configuration. Filling heads are arranged one after another for filling multiple containers. The containers travel using a conveyor. However, it operates at slower speeds as the movement of the conveyor pauses for filling. But it has the benefit of compact construction and simple maintenance.

Rotary Powder Packaging Equipment

Rotary Powder Packaging Equipment- Picture Courtesy: CVC Technologies

It is constructed with a rotary carousel with multiple stations arranged around its circumference. It is fast because it does not stop during the filling steps. It has higher productivity but it is difficult to clean and maintain this machine because of its complicated design.

According to Packaging Types

Pouch Powder Packaging Equipment

Pouch Powder Packaging Equipment

It is a popular machine because pouches processed by this machine are favourite among buyers and sellers. This machine fabricates pouches on its own; hence, it is customized to produce different styles of pouches. It is fast, versatile, and is dominating the packaging world.

Sachet Powder Packaging Equipment

Sachet Powder Packaging Equipment

This kind of powder packaging equipment is adopted in the industries because it forms small single-serve sachets that are popular among on-the-go customers. It has a compact and simple design usually containing one lane; therefore, it has limited processivity.

Premade Pouch Powder Packaging Equipment

Premade Pouch Powder Packaging Equipment

This machine is perfect in such a way that it processes already-made pouches that can be customized according to brand image. This machine has a rotary turntable with different processing stations, consequently, it carries out pouch filling and sealing at much higher rates. Due to the rotary turntable, it has a complicated design construction and a much higher purchase price.

Stick Pack Powder Packaging Equipment

Stick Pack Powder Packaging Equipment

This machine forms, fills, and seals small single-serve stick packs. It features four, eight, twelve, sixteen, or twenty lanes which is why it can perfectly and swiftly pack large stick packs during one cycle. It has a larger footprint than a sachet powder packaging equipment.

Bottle/Jar/Vial Powder Packaging Equipment

Bottle/Jar/Vial Powder Packaging Equipment

It has a different design construction, unlike above mentioned machines because it consists of single long conveyors and an arrangement of multiple filling heads. The containers for filling are loaded on the conveyor.

According to Structural Construction

Opened Powder Packaging Equipment

Opened Powder Packaging Equipment

This machine is an open system, where filling heads freely pack powders without using any specialized device. This machine is commonly seen in industries and is used for packing different kinds of powders that do not require any special loading conditions.

Closed Powder Packaging Equipment

Closed Powder Packaging Equipment- Picture Courtesy: HUDIA Packing Machine

For loading sensitive and hygroscopic ingredient powders, closed powder packaging equipment is employed in the industries. This machine has an enclosed chamber in which vacuum systems are used for drawing and fluidity of powders. Unlike other powder packaging equipment, that agitate powders, this equipment gently processes powders.

7.Does the Powder Packaging Equipment Include Anti-Dust Emission Devices?

Yes, the powder packaging equipment includes anti-dust emission devices to stop the production of dust. These are the safety features because if they are not present with the powder packaging equipment, the dust emitted may spark, causing severe accidents in the workplace. These devices include:

Dust Collection Hoods

It is an anti-dust emission device that is equipped with closed hoods. These hoods catch the powder dust at the filling stations.

De-aerators

De-aerator- Picture Courtesy: DirectIndustry

These are the devices that draw the air from the powders to prevent dust generation. The air pockets are eliminated by using de-aerators which play a significant role in dust production.

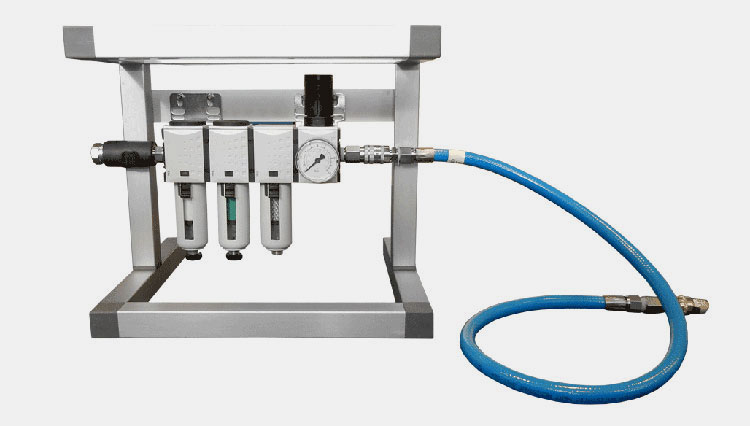

Vacuum Suction System

Vacuum Suction System- Picture Courtesy: FRITZ EMDE

By using vacuum systems, the powder packaging equipment draws the dust from the filling points. In addition to dust suction, it increases the cleanliness of the powder packaging equipment and prevents powder contamination.

Air Filtration Systems

Air Filtration System- Picture Courtesy: Matcon

These instruments can be installed in the powder packaging equipment that filters the dust from the air and recirculate filtered air. This improves the ventilation of the production floor.

Anti-Static Devices

Anti-Static Devices

These devices produce an electric field around the filling systems and transform static charges that may cause sparks by charging the powder dust.

8.Does the Powder Packaging Equipment Process Granules?

Powder Packaging Equipment

Yes, powder packaging equipment can be configured to handle granules. Some types of powder packaging equipment have dedicated systems that are only used for powders. However, these types of machines are customized to process granules by changing filling devices and program settings.

Nevertheless, numerous types of powder packaging equipment can process both powders and granules. These instruments have interchangeable parts that assist this equipment in transiting between both types of products.

9.What is the Difference between a Powder Packaging Equipment and a Liquid Packaging Machine?

Liquid Packaging Machine

Both of these machines have a similar objective- packaging products- however, both these machines have varying designs, packaging operations, and industrial applications. The powder packaging equipment and liquid packaging machine differ in the physical nature of the product. Some key differences in these machines are:

| Features | Powder Packaging Equipment | Liquid Packaging Machine |

| Nature of Product | This machine, as the name suggests packs solid particles- powders. | This machine processes liquid products. It processes both free-flowing and viscous products. |

| Filling Devices | The powder packaging equipment employs an auger, volumetric cups, and also a weigh filler to correctly load the powders. | It typically uses a pump, piston, overflow, and gravity fillers. |

| Packaging Container | It typically stores products in pouches, bags, stick packs or sachets. | It fills products in jars, bottles, and pouches. |

| Design | It has a complicated design due to the presence of anti-dust devices, vibrators, deaerators, and agitators. | It has a simpler design construction. |

| Applications | It loads spices, herbs, curry powders, tea, pigments, dyes, etc. | It packs water, juice, honey, condiments, pastes, sauces, fuel oils, and many more. |

10.What are the Frequent Issues and Their Troubleshooting in the Powder Packaging Equipment?

Sometimes, unanticipated issues occur in the powder packaging equipment, leading to troublesome production delays. If these issues are not handled correctly then expensive repairs bring about serious monetary issues. However, we are detailing some tips and tricks to resolve such frequent problems in the powder packaging equipment.

Inconsistent Packaging Weight

Inconsistent Packaging Weight

| Cause | Remedy |

| Poor powder flowability.

Out-of-order weighing scale. Powders are of varying sizes. |

Increase the product flow by using different kinds of agitators.

Fix and recalibrate the weighing scale. To decrease variations in powder particle sizes, first premix different powders. |

Clogged Filling Nozzles

Product Buildup and Clogged Filling Nozzles

| Cause | Remedy |

| There is a build-up of sticky powders inside the nozzles.

Powders are tightly packed inside hoppers or other filling devices. Presence of foreign products in the powders. |

Adhere to a proper cleaning schedule and thoroughly clean parts that come in regular contact with powders.

Inspect the moisture ratio in the powders and store the powders under low humidity settings. First, filter the powders before loading them in the hopper. |

Bursting of Powder Pouches

Bursting of Powder Pouches

| Cause | Remedy |

| Inconsistent pouch seals.

The packaging materials are of substandard quality. Overloading of powders inside the pouch. |

Alter the sealing parameters and ensure sealing jaws are working correctly.

Re-purchase high-quality packaging materials that fulfil packaging specifications. Adjust the filling parameters on the touch screen and ensure fill accuracy.

|

Powder Spillage and Dust Generation

Powder Spillage and Dust Generation- Picture Courtesy: JBT Corporation

| Cause | Remedy |

| High filling speed.

Incorrect alignment of filling nozzles with packaging containers. Poor dust control approaches. |

Reduce the fill speed.

Ensure that packaging containers are correctly placed under the filling nozzles. Install dust control devices. |

Incomplete or Poor Sealing

| Cause | Remedy |

| Inadequate temperature and pressure while sealing.

Contaminated surface of sealing jaws. Defective sealing jaws. Wrinkled packaging film. Insufficient sealing time. |

Ensure accurate temperature and pressure while sealing.

Clean the exterior of the sealing jaws. Replace damaged sealing jaws. Use packaging film of high quality. Provide adequate time for sealing. |

Conclusion

Powder packaging equipment has prominence in different industries because it processes a broad range of powders swiftly and accurately. This machine is adaptable, cost-effective and all-rounder in its performance. The powder packaging equipment is the most desired globally because of its efficient and timely powder packaging. To answer your queries regarding the powder packaging equipment, we at Allpack are always available. For further assistance and selection guidance, please contact our ever-ready customer care.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide