Manual Bottle Labeler: The Complete Buying Guide in 2025

A manual bottle labeler is a type of machine mainly used to apply labels on bottles manually. It is a cost-effective labeling solution for small businesses or individuals who need to label their products manually. The labelers come in different types and designs to meet various labeling needs.

If you're looking to buy a manual bottle labeler, it's important to consider several factors such as the type of labeler, bottle size, label size, label material, and ease of use, among others. In this buying guide, you'll delve deeper into these factors and it will provide you with valuable insights to help you make an informed decision when buying a manual bottle labeler.

1.What Is Manual Bottle Labeler?

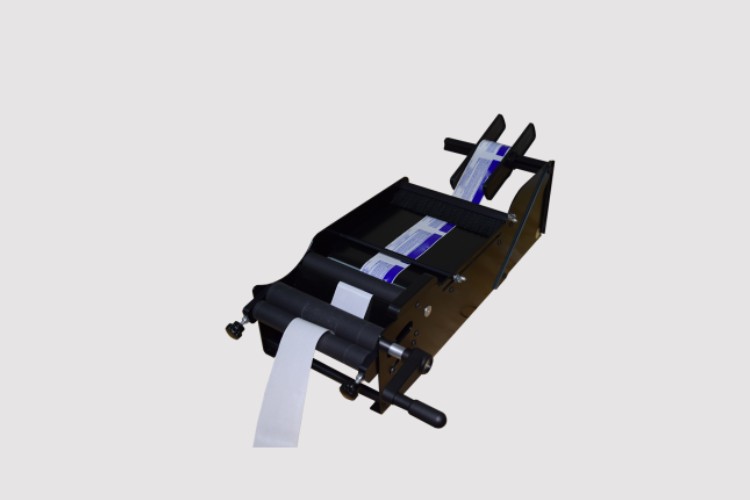

Manual Bottle Labeler-Photo Credit:Pack Solution

A manual bottler labeler is a machine used to apply labels to bottles manually. It is often used in small-scale operations where the production volume does not justify the cost of investing in an automatic labeling machine.

The manual bottler labeler machine typically consists of a base, which holds the bottle steady, and an arm or roller that applies the label to the bottle. The operator places the bottle in the base, positions the label on the arm or roller, and then applies the label to the bottle by pressing down on the arm or rolling the roller across the label.

2.What Are The Functions Of Manual Bottle Labeler?

Branding:

The manual bottle labeler can be used to apply custom labels with unique designs, logos, and branding information to bottles, helping to increase brand recognition and loyalty.

Decorating:

The manual bottle labeler allows for flexibility in label design, with the ability to use labels of various shapes, sizes, and colors to create a visually appealing look. The application of labels by using the manual bottle labeler can help enhance the shelf appeal of products, making them more attractive to potential customers.

Giving Necessary Information:

The manual bottle labeler is used to apply labels that contain important product information, such as ingredients, nutritional values, and expiry dates.

3.How Can Manual Bottle Labelers Benefit You?

Overall, manual bottle labelers provide practical, adaptable, and user-friendly labeling options for a range of sectors. There are many benefits that manual bottle labelers can bring to you, such as:

- Ease of Use:

Manual bottle labelers require minimal training, they don't require specialized technical knowledge or expertise, which means that anyone can learn to operate them. Additionally, they can be used anywhere, making them an ideal option for home-based small businesses.

- Versatility

Versatility is another benefit of manual bottle labelers. They have the ability to label a variety of bottles, including wine, beer, sauce, and more. A manual bottle labeler allows you to modify the labeling procedure to suit your unique requirements, making it a flexible and adaptable option for different sectors.

- Accuracy

The manual bottle labelers are designed to provide precise labeling, minimizing the risk of error. This accuracy helps to maintain the quality of your products and enhances your brand's image in the market.

- Cost-Effectiveness

The most significant advantage of a manual bottle labeler is its cost-effectiveness. Manual bottle labelers are much more affordable as compared to automated labeling solutions. It requires little maintenance and has a low initial investment cost, is an ideal choice for small businesses or those on a tight budget.

4.Are There Any Limitations Of Manual Bottle Labeler?

Yes, there are some limitation of manual bottle labeler, which are as follows:

Limited Production Capacity:

Since manual bottle labelers are operated by human, they are generally slower than automatic bottle labelers. This makes them a great solution for small production runs, but they may not be suitable for businesses with high labeling volumes.

Operator Dependence:

Unlike automatic bottle labelers, manual bottle labelers require a human operator to load and align the bottles, apply the labels, and adjust the machine settings. This means that the labeling process can be more prone to human error, particularly if the operator is not properly trained.

5.What Are The Common Applications Of Manual Bottle Labelers?

Manual bottle labelers are valuable equipment that can be used for a broad range of industries, providing an efficient and cost-effective method to label bottles correctly and accurately, some of its main applications are as follows:

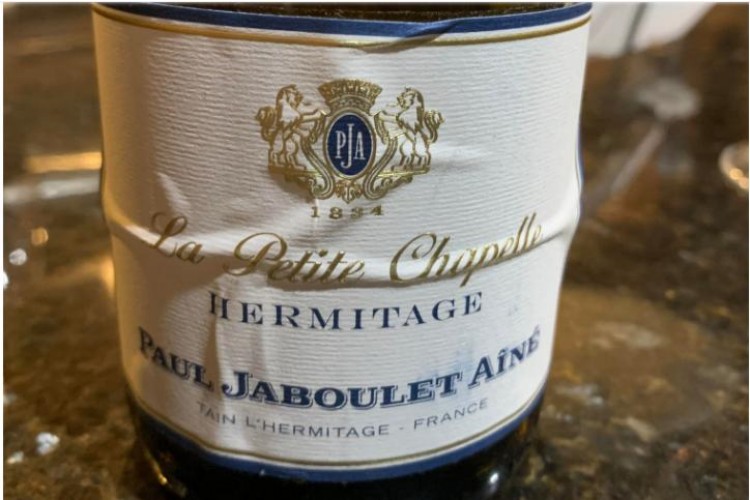

Food and Beverage Industry:

Manual bottle labelers have a wide range of applications in the food and beverage industry. They are commonly used by small-scale producers, such as craft breweries and artisanal wineries, to accurately label their products with branding, ingredient information, and batch or date codes.

- Pharmaceutical Industry:

The pharmaceutical sector relies heavily on manual bottle labelers because they make it easier to label drug bottles in a way that is accurate and compliant. These manual bottle labelers are used to apply labels with important data on them, including drug names, doses, strengths, lot numbers, expiration dates, and manufacturer information.

- Cosmetics Industry

Manual bottle labelers are essential in the cosmetics industry. By providing clear and comprehensive labeling, manual bottle labelers help consumers identify and select the right cosmetic products for their needs while ensuring they are aware of any potential risks or precautions.

- Chemical Industry

Manual bottle labelers play a key role in the chemical industry by facilitating the safe and accurate labeling of chemical products and containers. These machines allow for the application of labels that provide crucial information such as product names, hazard symbols, warning signs, precautionary statements, safety instructions, and regulatory compliance details

6.How Many Types Of Manual Bottle Labeler There Are?

There are several types of manual bottle labelers available in the market, some of the main types are as follows:

Handheld Manual Bottle Labelers:

Handheld manual bottle labelers are portable devices used to apply labels to bottles manually. It consists of a compact device with a handle, a label holder or dispenser, and a mechanism to apply the label onto the bottle's surface. The handheld manual bottle labeler may have adjustable features to accommodate different bottle sizes and label dimensions.

Benchtop Manual Bottle Labelers:

These manual bottle labelers are designed to sit on a tabletop or workbench. They usually have a crank or lever mechanism that allows you to manually apply the labels.

Benchtop manual bottle labelers are suitable for low-volume labeling tasks and are often used in small-scale production or labeling individual bottles.

7.What Are The Differences Between Manual Bottle Labeler And Automatic Bottle Labeler?

Some of the differences between manual bottle labeler and automatic bottle labeler are as follows:

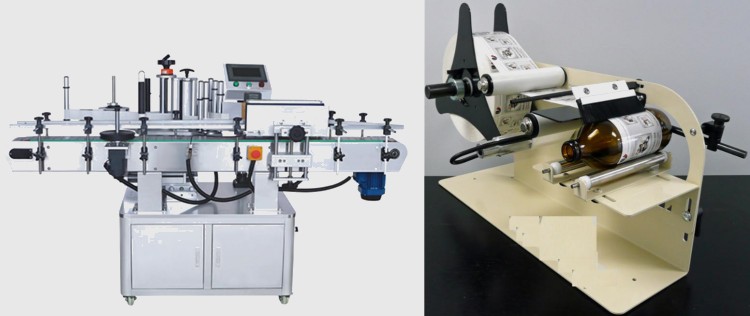

Difference between Manual and Automatic Bottle Labeler Photo Credit Rhino Pak & Label On labeler Machine

| Aspect | Manual Bottle Labeler | Automatic Bottle Labeler |

| Operation | Requires manual labor to operate | Fully automated, requires no manual intervention |

| Speed | Limited and slow speed | Much faster than manual bottle labeler |

| Capacity | Limited capacity, suitable for small batches | Higher capacity, suitable for larger batches |

| Accuracy | Relies on operator's manual dexterity and accuracy | More precise and consistent labeling, less reliant on operator skill |

| Flexibility | Limited flexibility in label sizes and bottle shapes | Can accommodate a wider range of label sizes and bottle shapes |

8.What is the Working Principle of Manual Bottle Labeler?

Working Principle Of Manual Bottle Labeler-Photo Credit:Desertcart Pakistan

A manual bottle labeler's working principle is very simple. The system is made up of a label dispenser that contains the roll of labels and a labeling head that attaches the label to the bottle.

You must first load the roll of labels onto the dispenser before you can use a manual bottle labeler. The guide rails should then be adjusted to fit your bottle's size. You can start labeling your bottles once the guide rails have been established.

Before applying a label, you must first remove the label's backing paper. In order to apply the label, insert the bottle into the labeling head and depress the lever. After the labeling head has finished its work, you can remove the labeled bottle from the machine and move on to the next bottle.

9.What Key Components Constitute Manual Bottle Labeler?

Components of Manual Bottle Labelers-Photo Credit :Wine Makers Depot

- Roll Control/Label Dispenser

The roll control or label dispenser component is designed to hold and control the roll of labels. It ensures that the labels are fed smoothly and consistently through the labeling head.

- Sticker Applicator/Labeling Head-

The sticker applicator, also known as the labeling head, is the principal element in charge of putting the label to the bottle. It typically consists of a pad or roller that contacts the label and transfers it to the surface of the bottle.

- Bottle Handler/Guide Rails-

The bottle handler, also known as the guide rails, is essential for placing the bottle accurately within the labeling head. The use of these movable rails, the bottle is guided through the labeling procedure, ensuring that the label is placed where it is meant to be on the container.

- Manual Handler/Level-

The manual handler or level is the part of the machine that activates the labeling head. Typically, it involves pressing down on a lever or handle to initiate the label application process.

- Frame/Base:

These are the components of the machine that offer stability and support. They make sure the equipment stays there while you label the bottles.

10.What Kinds of Containers Can Be Labeled By a Manual Bottle Labeler?

- Round Bottles:Manual bottle labelers can label round bottles of different sizes, from small vials to large containers.

- Flat Bottles:These include containers with a flat surface, such as square or rectangular bottles.

- Curved Bottles: Curved bottles, such as those used for sauces or condiments, can also be labeled using a manual bottle labeler.

- Cans/Jars:Cans and jars come in different shapes and sizes, from small to large, and manual bottle labelers can be adjusted to accommodate various sizes and shapes of containers.

11.What Kinds of Labels Can Be Applied By Manual Bottle Labeler?

A manual bottle labeler can typically be used to stick various types of labels, including:

- Paper Labels:These are the most common type of labels used in labeling bottles. They are made of paper material and can be printed with text, graphics, or images.

- Clear Labels: Clear labels are made of transparent materials and are ideal for labeling clear glass bottles or plastic bottles, as they do not obscure the product inside the bottle.

- Foil Labels:Foil labels are made of thin metallic materials and are often used for premium products, such as wines or spirits, to create a high-end look.

- Waterproof Labels:Waterproof labels are made of materials that can withstand exposure to water, making them ideal for labeling bottles that will be stored in coolers or refrigerators.

- Removable Labels:Removable labels are designed to be easily removed from the bottle without leaving any residue or damage. They are often used for temporary labeling, such as for promotions or seasonal products.

12.How To Troubleshoot Manual Bottle Labeler?

Uneven Labels:

If the labels are not being applied evenly, make sure the bottle is properly aligned with the manual bottle labeler and that the label roll is properly positioned. Adjust the tension and alignment as necessary.

Wrinkled Labels:

If the labels are wrinkling during application, make sure the label roll is properly positioned and that the manual bottle labeler is applying the right amount of tension. You may need to adjust the tension or the speed of the manual bottle labeler to achieve a smoother application.

Labels Not Sticking:

If the labels are not sticking to the bottle, check the adhesive and make sure it is properly formulated for the label material and the bottle surface. You may need to adjust the temperature or the pressure of the manual bottle labeler to ensure proper adhesion.

Label Jamming:

If the labels are getting stuck in the manual bottle labeler, make sure the label roll is properly positioned and that the machine is properly aligned with the bottle. You may need to adjust the tension or the speed of the machine to prevent jams.

Electric Supply:

If the manual bottle labeler is not working at all, check the power supply and make sure it is properly connected. Check the fuse and circuit breaker and make sure they are not tripped. If the problem persists, you may need to contact the manufacturer for technical support or repair services.

13.How Can You Improve the Performance of A Manual Bottle Labeler?

Improving the performance of a manual bottle labeler can enhance its efficiency and productivity. Here are some suggestions to optimize the performance of a manual bottle labeler:

Standardize Label Placement:

Develop a standardized positioning guide or template that clearly indicates where the label should be placed on each bottle. This ensures consistent label placement and reduces the need for adjustments or rework.

Optimize Label Adhesion:

Ensure that the bottles' surfaces are clean and dry before applying labels. Use appropriate labeling adhesives or techniques suitable for the bottle material and label type to ensure strong adhesion and prevent labels from peeling or detaching.

Regular Maintenance and Calibration:

Establish a regular maintenance schedule to keep the manual bottle labeler in optimal working condition. This includes cleaning, lubricating moving parts, and replacing worn components as needed. Also, calibrate the manual bottle labeler periodically to ensure accurate label placement.

14.Is Manual Bottle Labeler Customizable?

A manual bottle labeler can be customizable to some extent, depending on the specific design and manufacturer. Here are some parts of a manual bottle labeler that can often be customized:

Labeling Head or Applicator:

The labeling head or applicator is the component responsible for applying the labels onto the bottles. It may be possible to adjust the positioning, height, or angle of the labeling head to ensure proper label placement on different bottle sizes or shapes.

Some manual bottle labelers offer interchangeable applicator heads or different label feed options to handle various label sizes or types.

Label Dispenser or Holder:

The label dispenser or holder is the part of the manual bottle labeler that holds and feeds the labels for application. Depending on the design, it can also be customzied to adapt to different sized labels.

Additional Accessories:

Some manual bottle labelers offer optional accessories or attachments that can be customized to enhance functionality or address specific labeling needs. These may include label counters, batch or date coders, adjustable label sensors, or special mechanisms for applying specialty labels or promotional stickers.

15.How To Choose The Best Manual Bottle Labeler?

When it comes to choose a manual bottle labeler, there are a few things to consider to ensure you select the best one for your needs. Here are some important factors to consider:

Labeling Requirements: Determine the type of bottles youneed to label and the specific labeling requirements. Consider factors such as bottle size, shape, material, and the type of labels you'll be using (e.g., paper, plastic, waterproof).

ProductionSpeed and Efficiency: Assess the volume of bottles you'll be labeling per hour or day. Look for a manual bottle labeler that can handle your desired production speed while maintaining accuracy and consistency.

Durability and Build Quality:The manual bottle labeler should be built to withstand regular use and potential environmental factors. Look for a machine which has robust construction and reliable components to ensure long-lasting performance.

User Reviews and Reputation:Research customer reviews and feedback on different manual bottle labelers. Read about other users' experiences to get an idea of reliability, performance, and overall satisfaction.

Budget:Set a budget based on your requirements and the value you expect from the manual bottle Compare the features and benefits offered by different models within your price range to make an informed decision.

By carefully considering these factors, you'll be able to choose the best manual bottle labeler that suits your specific needs and helps streamline your labeling process.

Conclusion

Manual bottle labelers offer multiple advantages, they are easy to set up and can be adjusted to label different sizes and shapes of bottles or containers. Hence, it makes their use an attractive option for small businesses or individuals who need a labeling solution that can be easily managed in-house without the need for specialized technicians or engineers and can save much. For this purpose, you need to choose the most suitable option to match your affordability and business requirements.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide