Nuts Rice Snack Granule Bottling Line: The Complete Buying Guide In 2024

Nuts Rice Snack Granule Bottling Line: The Complete Buying Guide In 2024

Nuts rice snack granules are tasty and loved by everyone in every age group. Whether you’re on a keto diet or vegan, indeed nut rice snack granule bottles must be in your food plan. This is not just nutritionally perfect but helps in managing your hunger, especially in offices, exams, traveling, or other.

Due to impressive benefits, this snack mostly shows a high demand for nuts rice snack granule bottling line.

This is an absolute solution that carries production tasks from scratch. In this post, we have described all equipment included in this production line. Have a look to explore significant information that we help you in establishing the right production line.

1.What is the nut rice snack granule bottling line?

Nut Rice Snack Granule Bottling Line

A rising popularity for snacks, like nut rice and granules is represented with more demand for advanced production lines. However, this is an absolute solution offering an accurate counting and filling of products in bottles or jars. No matter what size or shape of bottles you are subjecting to, the performance of the unit is tremendous covering hygiene, no risk for cross-contamination, and accurate counting. Yet, this is a challenging process, but the nut rice snack granule bottling line can streamline processes such as unscrambling, filling, capping, and further tasks in a consistent manner.

2.Why nut rice snack granule bottling line have market demand?

Nut Rice Snack Granule Bottling Line

A nut rice snack granule bottling line has greater market demand as it is connected to fulfilling various operational demands and preferring your industrial requirements. The reason behind its popularity is discussed below:

| An Accessible Machine | Today margin of modern consumers is specifically higher due to their busy schedules and seeking an easy eatable option. A nut rice snack granule bottling line is the best option for perfect filling and packing bottles without requiring the tiring integration of various units, you can eventually enjoy the convenient way of fast-paced counting processing. |  |

| Inch-Perfect Filling | Health-conscious customers are now everywhere, they believe and scrutinize what is mentioned on the label of each bottle. whether it is nutritional value or quantity, your product must fulfill an effective serving size. This is the significant reason why you love adding nut rice granule bottling line as it manufacturing is up to your demand and can offer the finished product what you promise on its label. |  |

| Preserving the Freshness of Product | A nut rice granule bottling line is designed in a critical manner that carries you and your manufacturer's demands in balance.

What a manufacturer wants is fast, safe, and accurate packing; however, a consumer wants a nutritionally supportive product with freshness inside. A nut rice granule bottling line provides all these properties ensuring overall brand satisfaction. |

Picture courtesy: Yummiano |

| Branding and Market Boost Up! | The major element that influences manufacturers and the business sector about the nut rice snack granule bottling line is its well-executed designs and capability to produce bottles with improved aesthetics that attract consumers towards it, eventually enhancing your market value and quality among competitive brands. |  |

| Fast Production | A nut rice snack granule bottling line is a smarter step toward the modern way of production than the traditional filling mode; it saves your time, your product’s quality, and many unwanted steps, and bringing professional packing in a shorter time encompasses broader demography such as profitability, shelf life, taste, etc. |  |

3.Where do you use the nut rice snack granule bottling line?

There is a broad range of applications interconnected to a nut rice snack granule bottling line. We have discussed below:

Pharmaceutical Industry

Use of nut rice granule bottling line- picture courtesy: Vitacost

What matters the most when manufacturing pharmaceuticals? It is accuracy! A nut rice snack granule bottling line is providing you with more than you expect. A single set of equipment can provide correct bottles, right counting, and promising protection. In the pharmaceutical industry, this line helps in dispensing capsules, tablets, pills, cotton balls, lancets, glucometers, and so much more.

Food and Beverage Industry

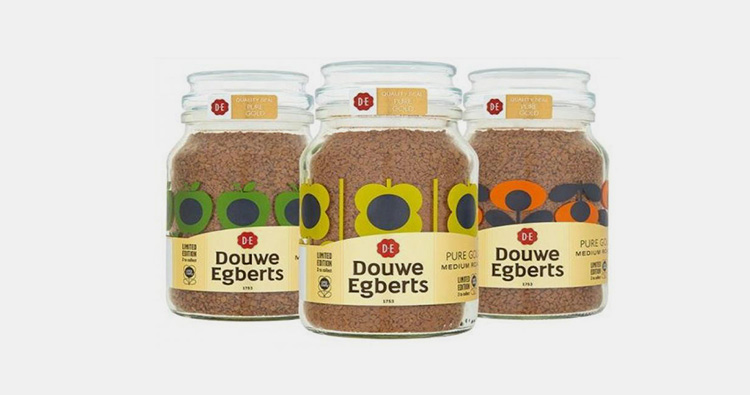

Nut rice snack granule bottling line- picture courtesy:Mycaffein

One of the busiest sectors where manufacturing and packaging never halt. A nut rice snack granule bottling line is used for dispensing and distributing products such as candies, coffee beans, dried nuts, candies, sweets like gummies, and related items into individual jars or bottles.

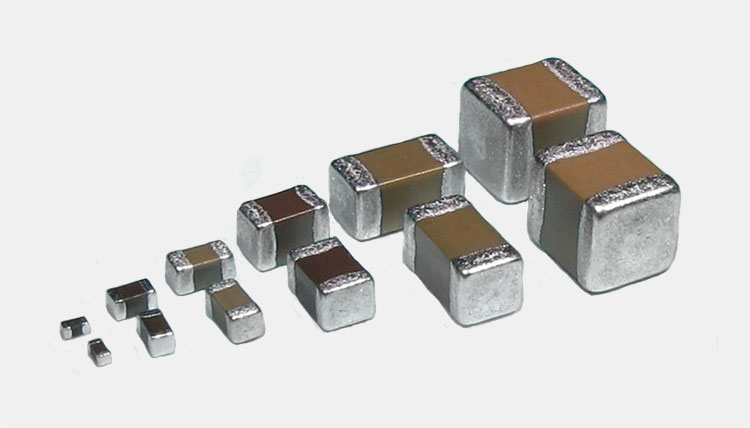

Electronic Industry

Electronic components

In the electronic industry, the manufacturing, polishing, and final packaging of items take place before their retail distribution. A nut rice snack granule bottling line shows significant demand in this field for packing items such as nuts, bolts, connectors, electric capacitors, various sizes of microchips, and more on bottle accurately.

Automotive Industry

Use of nut rice snack granule bottling line- Picture Courtesy: 3ERP

In the automotive industry, items such as screws, nuts, bolts, locking screws, washers, and many other small-size as well as large-size items are dealt with for making either compact kits or just individual products. A nut rice snack granule bottling line is used to fill the accurate quantity of product in each packaging material for final distribution.

Cosmetic Industry

Application of nut rice snack granule bottling line in cosmetics

Whether it is skin cleaning or the application of makeup products, you need applicators, small tools like exfoliator, and cleaning strips, that are mainly packed in small bottles. Similarly, for spa and body cleaning, products like bathing bubbles, waxing items in bead form, and related products are available in bottle packaging. A nut rice snack granule bottling line is worth buying setup to improve your cosmetic industry in terms of profitability.

Agriculture Industry

Pest Control Tablets

In the agriculture industry, a nut rice snack granule bottling line has been shown a greater impact on the packaging of products like seeds, various boosters in granular form as well as tablet formulations, pesticides, insecticides, crop supplements, etc. For packing a precise and correct form of product this entire bottling line shows tremendous results.

Toy Industry

Nut rice snack granule bottling line in toy factories

You would be surprised to know that a nut rice snack granule bottling line has a significantly important role in the toy packing industry like other industries. There are various toys such as puzzles, LEGO parts, small toys, etc can be accurately counted in positioned in each bottle using the bottling line.

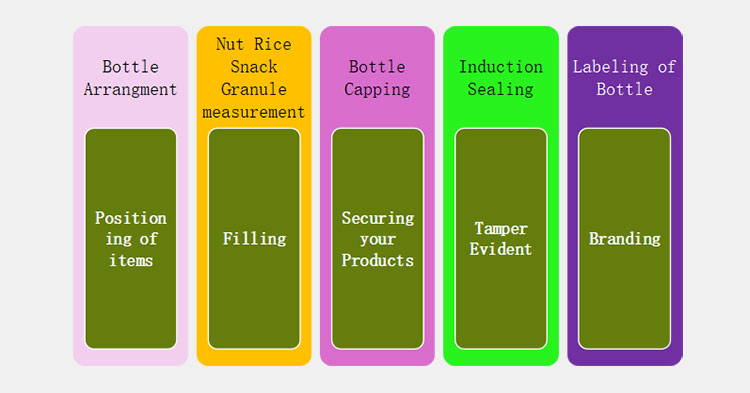

4.How does a nut rice snack granule bottling line work?

The working principle of the nut rice snack granule bottling line

In order to operate a nut rice snack granule bottling line, you must know its basic mechanism. But don’t worry because it is quite easy to understand. So, let’s see how this machine works below.

Bottle Arrangement

| First of all, the bottles you have bought from the market are all placed haphazardly in the hopper. So, to align them, they are made to go through bottle unscrambler where these randomly arranged bottles are oriented in a straight line and are then transported in a conveyor belt. |

Bottle arrangement |

Nut Rice Snack Granule Measurement

| Next, the perfectly aligned bottles are sent to the filling station where you can fill them with the desired product using a filling nozzle. These fillers will pour the accurate amount of product into the bottles so that each batch has the exact amount of product inside it. Here, a PLC notifies the amount of ingredient is measured and added into each bottle. |

Measurement of nut rice snack granules |

Bottle Capping

| Now you will seal the filled bottles by sending them to the capping station. Here, the bottles are sealed with an air-tight cap using high-pressure horizontal and vertical sealers to deliver perfectly packaged bottles that would not spill their contents during transportation. |

Capping |

Induction Sealing of Bottles

| This is the second last machine where electromagnetic radiation influence melts the sealing of the caps and upon cooling it forms a firm bonding around the bottle neck ultimately forming a tamper-evident packing. |

Induction Sealing |

Labeling

| Finally, the sealed bottles are moved to the labelling station where a sticker is applied to them. This sticker will contain your company’s information, product information, its manufacture and expiry date, and any other additional information you want to put. The labeled bottles are discharged from the machine and sent for final packaging for its shipping. |

Labeling |

5.What are the units of nut rice snack granule bottling line?

The nut rice snack granule bottling line is composed of the following set of machines integrated to form a complete production line.

Bottle Unscrambler

Allpack nut rice granule bottle unscrambler machine

This machine is mainly used in the production line where bottles, jars, or containers are used. The working of the machine is based on intense blowers, rotation of the circular disc, and movement of the conveyor which ensure consistent movement of the bottles. The following machine is available in high automation and helps you improve your production line by offering fast supplies of packaging matter.

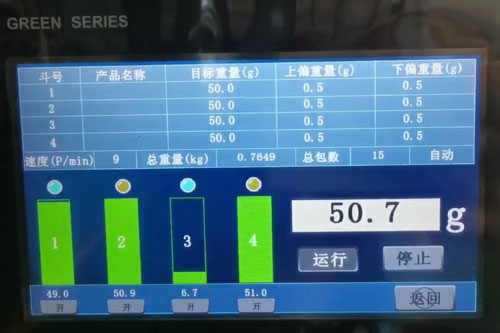

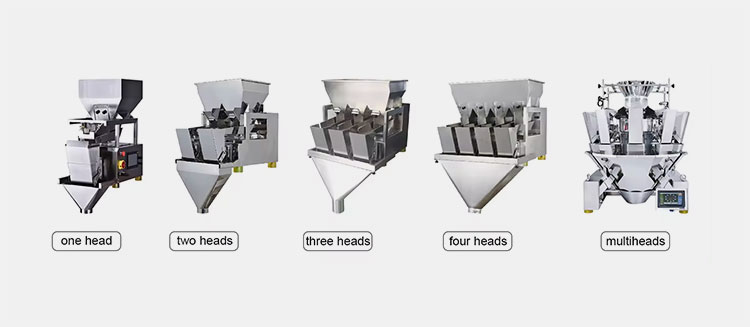

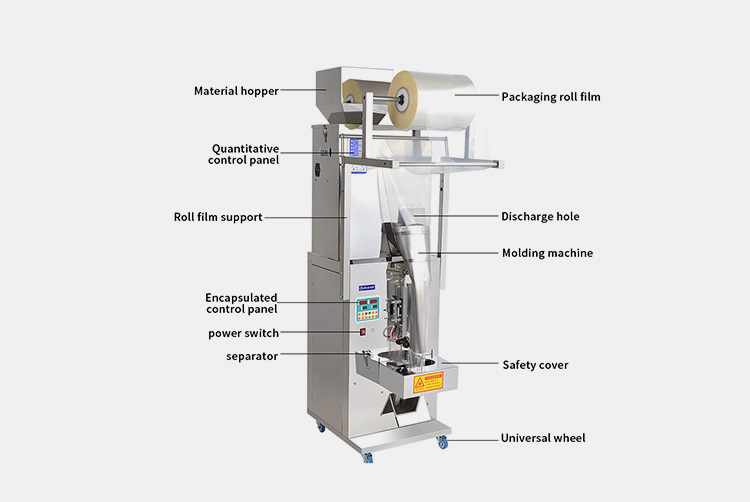

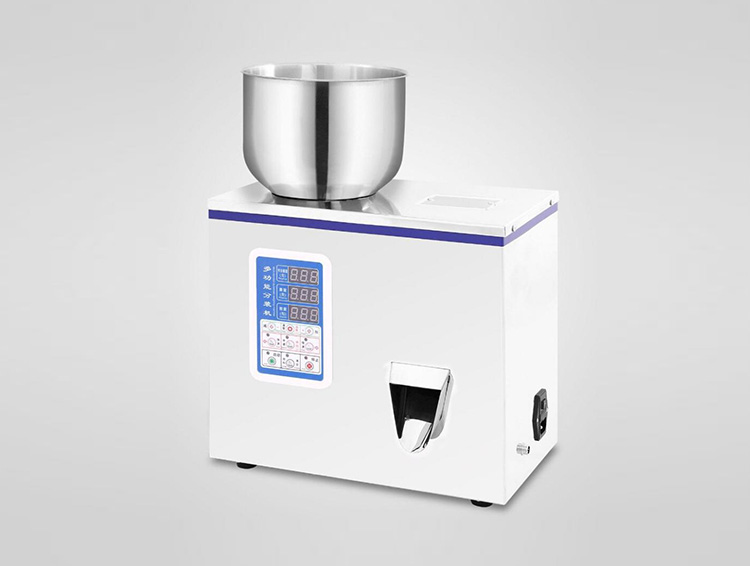

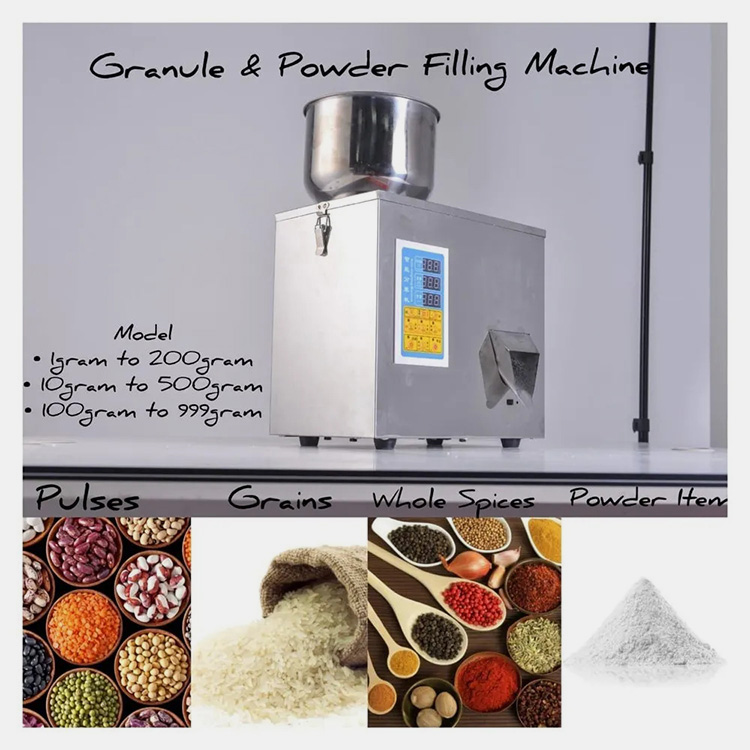

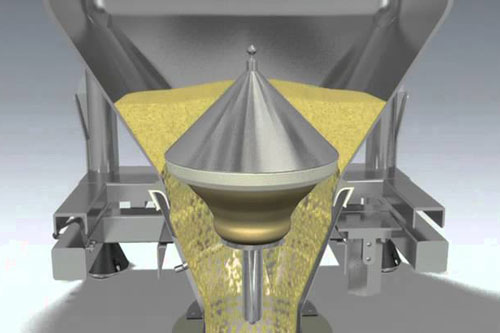

Nut Rice Snack Granule Filling Machine

Various heads nut rice snack granule filling machine

The filling machine is the prime unit of the nut rice snack granule bottling line which is mainly designed to fill bottles by measuring the exact weight of the ingredients.

The working of this machine is mainly based on a vibratory feeder allowing a smooth and gentle flow of materials and high-alert sensors ensure the presence of materials measure the pre-determined quantity and promote accurate portion of materials into each bottle. The filling machines are designed with single-head, dual, three, four, and multi-heads allowing an ideal production capacity depending on your requirements.

Capping Machine

Allpack nut rice granule capping machine

The capping machine is an important tool for nut rice snack granule bottling line that helps you in the proper securing of bottles from external or foreign particles. A sorted number of caps are entered into the machine and gripers pick and tightly screw them around the bottles. The capping machine is of various types and automation; you can select and integrate the machine depending upon your choice and kind of production capacity.

Induction Sealing Machine

Allpack nut rice snack granule induction sealing machine

A significant and popular machine to induce a hermetic sealing when bottles are passed through it. This machine is available in various automation and sizes ensuring you produce a leakproof foiling around the bottleneck till you open it.

Labeling Machine

Allpack nut rice snack granule labeling machine

The application of labels takes place by using a labeling machine that is responsible for positioning, gluing, and final pressing of labeling over the bottles. Like other machines, this is also represented by various automation and types such as round, square, or oval bottles, single-sided, or double-sided, vertical, or horizontal, glue-based, and other.

6.What products can be used in the nut rice snack granule bottling line?

Nut rice snack granule bottling line is a versatile line packaging hugely different types of products. It counts and fills a great variety of products such as:

Nuts

| Various kinds of nuts like walnuts, peanuts, almonds, cashews, pistachios, etc are packed by nut rice snack granule bottling line. This line automates the packaging of nuts, resulting in higher efficiency. |  |

Snacks

| Nut rice snack granule bottling line also packages different kinds of snacks like rice crackers, puffed rice, and rice chips. These products are flavorful and have high nutritional value. Therefore, the nut rice snack granule bottling line beautifully and securely counts and fills these products to preserve their flavor and nutritional quality. |

Snack Bottle Packaging- Picture Courtesy: Lazada

|

Cereals

| Different kinds of cereals like oats, wheat, corn, quinoa, rye, and many more are dispensed into the bottles by the nut rice snack granule bottling line. This line ensures precise counting of cereals in bottles every time. There is no miscalculation with the nut rice snack granule bottling line. |

Cereal Bottle Packaging- Picture Courtesy: Organic Orion |

Seeds

| China seeds, sesame seeds, sunflower seeds, pumpkin seeds, and many more are also loaded in bottles by the nut rice snack granule bottling line. This line is equipped with various sensors that precisely measure the number of seeds for packaging in bottles. |

Seed Bottle Packaging- Picture Courtesy: Behance |

Dried Fruits

| These include raisins, cranberries, apricots, figs, prunes, and plums. Dried fruits are accurately counted and rightly loaded into the packaging containers like bottles by the nut rice snack granule bottling line. It easily processes these different shapes and sizes of dried fruits. |

Dried Fruits Bottle Packaging- Picture Courtesy: Package Inspiration |

Chocolate and Candies

| Chocolate balls like dark chocolate, milk chocolate, mint chocolate, and other candies like bounties, gummies, and toffees, to name a few are loaded with the nut rice snack granule bottling line. This line packs these items efficiently and without any pause consequently, translating into more products in the grocery aisles. |

Chocolate Balls and Candies Bottle Packaging |

7.What is your product shelf life once packed in the nut rice snack granule bottling line?

Shelf Life of Nut Rice Snack Granules- Picture Courtesy: Chus.vn

Nut rice snack granule bottling line is a proficient piece of machinery that tightly and securely packs the nut rice snack granules into the bottles to maintain the freshness and quality of these items. Bottles made of glass and plastics are highly impermeable materials, thus they can protect packed items against different environmental culprits like moisture, oxygen, heat, and light. High-barrier packaging materials extend the shelf-life of the products.

Moreover, vacuum sealing and nitrogen flushing are the two techniques that remove oxygen before sealing, which gives a leg up in shelf-life.

However, the best-sealed products by the nut rice snack granule bottling line can last around 5-10 months.

8.What are common problems and solutions of nut rice snack granule bottling line?

Nut rice snack granule bottling line occasionally faces some problems that lower the efficiency of the packaging process, resulting in significant loss of money. However, these problems are easily resolved by knowing beforehand some following tips.

| Causes | Solutions | Images |

| Nuts Rice Snack Granules are Not Counted Accurately | ||

| Presence of dust and debris on counting scale.

High counting speed. |

Properly wipe out and clean the exterior and interior sides of the counting scale.

Lower the counting speed. |

Picture Courtesy: Ruidapacking GZ |

| Clogging and Jamming | ||

| Presence of dust and other small particles in machines.

Poor cleaning practices. |

Use a dust extraction device to remove dust and other small particles.

Properly implement cleaning practices. |

Picture Courtesy: LinkedIn |

| Inconsistent Filling | ||

| Poorly calibrated filling devices.

Clogging of filling devices. |

Recalibrate the filling devices.

Clean the filling devices to get rid of clogging. |

Picture Courtesy: Supplybunny |

| Product Bridging | ||

| Nut rice snack granules clump together, creating an arch over the hopper, resulting in a disruption in smooth product flow. | Use an agitator and hopper vibrator to remove product bridging. |

Picture Courtesy: Matcon |

| Product Contamination | ||

| Inadequate cleaning practices.

There are no contamination detection systems present. |

Clean the surface and interior of the machine after every batch.

Install contamination detection systems to check contamination. |

Picture Courtesy: Designepeople |

| Contaminated Seals | ||

| Presence of product residues in the sealing area.

Cleaning procedures are not followed properly. |

Use proper feeding protocols to avoid product spillage in the sealing area.

Properly follow cleaning guidelines. |

Picture Courtesy: Refill & co |

| Weak Seals | ||

| Sealing machines are out of calibration.

Sealing temperature and pressure are not sufficient. Short sealing time. |

Calibrate the sealing machine.

Reset the settings of sealing temperature and pressure. Increase the sealing time. |

Picture Courtesy: THEGEMMARKET |

| Loose Caps | ||

| Insufficient torque during the capping step.

Damaged or worn-out capping head. Difference between dimensions or caps and bottles. |

Adjust torque value during the capping process.

Replace or repair the capping head. Prevent variability between caps and bottles. |

Picture Courtesy: GUFoods |

9.What are the future prospects of the nut rice snack granule bottling line?

Future Prospects of Nut Rice Snack Granule Bottling Line

The market of the nut rice snack granule bottling line is expanding day by day because of increased demand for healthy nut rice snacks. Due to health awareness, people are going for nut rice snacks which increases the necessity of packing these products. Here is where the nut rice snack bottling line plays an important role.

Innovation is the key to the growth of the nut rice snack granule bottling line, so, more and more manufacturers are investing in research and development to innovate the bottling line. This advanced bottling line has state-of-the-art machines and the communication in these machines is established by Ethernet. Modern nut rice snack granule bottling lines are developed by using industry 4 technology like the ‘Internet of Things’ and ‘artificial intelligence’. This technology offers versatility, resilience, and enhanced productivity to the system.

Conclusion

Let’s wrap up this blog post by stating that the nut rice snack granule bottling line is an amazing solution to all the problems associated with manual counting and filling nut rice snack granules and other products. This extraordinary bottling line goes hand in hand with various benefits like high speed, superb efficiency, and consistent counting. It exceeds the expectations of manufacturers by its state-of-the-art packaging. Now if you are planning to add nut rice snack granule packaging line to your productions then consider top-notch machines expert Allpack. We manufacture high-tech bottling lines that offer you top-quality results.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide

Nuts Rice Snack Granule Bottling Line: The Complete Buying Guide In 2024 Read More »