Candy Packaging: The Complete FAQ Guide In 2024

Scrolling down to discover about candy packaging? What a coincidence? You have finally found it! Whether is it candy, its types, or candy packaging itself, it becomes difficult to get the right information about it. Therefore, this FAQ guide is going to be a comprehensive one to hold all the information associated with candy packaging.

It is a matter of fact, which you also confess by being here, that candy cannot be kept safe until it is well-packed. Similarly, mere wrapping it in a film does not ensure that safety and would ultimately be a reason for ruining its taste, quality, as well as structure. Then what is the right way for candy packaging? Which packages are best for candy packaging? And most importantly how Candy Packaging can be made more attractive? Just take a breath and be prepared to explore everything about candy packaging in this informative review!

1.What Is Meant By Candy Packaging?

Various candy boxes-Picture Courtesy: freepik.com

Candy packaging refers to the process of packing candies into various packages such as bags, wrappers, and boxes etc. These packaging options are used for promoting candy safety, retaining its quality, and providing information about it.

Multiple candies in a jar-Picture Courtesy: santemagazine.fr

Along with that, the major objectives of using beautiful packaging for candy is to attract consumer and help them distinguish your products into the sea of candy packages. Hence, different means are adopted to fulfill these aims encompassing the selection of packaging material, type of containers, and labeling etc. For employing these techniques, there are some candy packaging machines available in market and which we have mentioned in this guide for your convenience:

2.Explain The Essential Benefits Of Candy Packaging?

Candy packaging brings with it range of benefits which can help you in attaining your objectives regarding candy safety and business success. These are as follows:

Preserves Freshness

Various candy filled jars-Picture Courtesy: etsy.com

One of the prominent trait of packaging candy is that it keeps the candy fresh for over time by inhibiting harmful elements from getting into the pack. Similarly, the shelf life of a candy can be prolonged through its packaging.

Increase Charm

Consumers purchasing candy bags -Picture Courtesy: ohhappyday.com

Using beautiful packages with elegant design labeling can enhance the attraction of candy when placed on the shores of shelves. Resultantly, people get distracted towards your candy packs and are compelled to pick them.

Ease of Use

Chewy candy packs-Picture Courtesy: candylife.cz

Candy packaging allows consumers to easily handle small to large candy amount wherever they want. For instance, a single serving candy pack can be kept in a bag without any fear for wasting or a standup candy pouch may be resealed after taking few candies.

Ensures Safety

Candy filled cans-Picture Courtesy: gettyimages.fi

The primary purpose of candy packaging is to secure the products from damage especially during transit and transportation. In this way, the candy remains safe and sound from manufacturer to the end user.

Provide Information

Candy bag labeling presentation idea-Picture Courtesy: hi-chew.com

Another advantage of candy packaging is that it provides the manufacturer a way to communicate with their customers. In addition, packaging can be used for displaying information about product ingredients, date of expiration, brand name, product name, and allergens etc.

3.Write Down The Different Types Of Candy Delivered In Candy Packaging?

Candy is available in different forms due to its structure, internal, and external appearance. These forms may be well understand by looking into the table below:

| No | Name | Description | Picture |

| 1 | Hard Candy | As the name shows, hard candy is rigid in structure with having sugar as a principal ingredient. It is made from the mixture of sugar and starch syrup which are well cooked on high temperature to end the level of moisture present in it. Hard candies are often dark-colored, and they come in shape of fruits, flowers, and geometrical shapes. |

Various hard candy in bowl-Picture Courtesy: dhimanfoods.com |

| 2 | Soft Candy | Soft candy refers to a candy having higher degree of moisture present in it. It is due to the sucrose ester which creates a layer of crystal around sugar and stop it from getting hard. The common examples of soft candy include soft caramel, toffee, and jelly beans etc. |

Soft candies-Picture Courtesy: chronicguru.com |

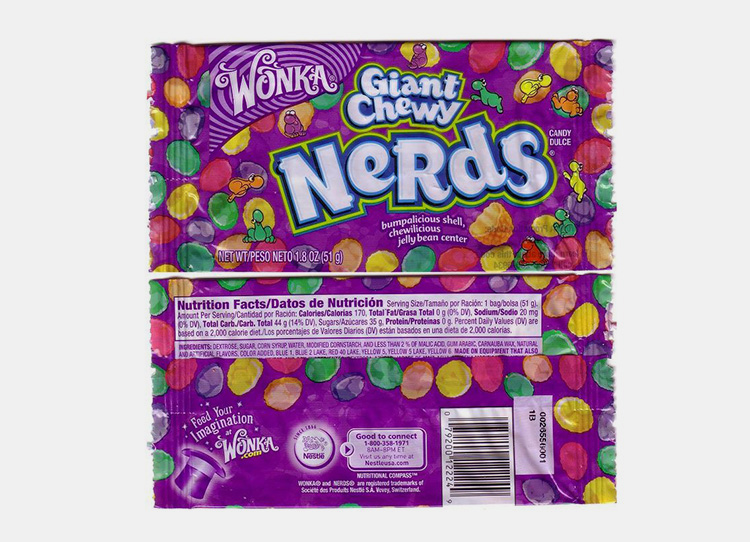

| 3 | Chewy Candy | Chewy candy is another type of candy having structure like hard candy, but, the gelatin present in it makes the candy chewy. Some of the popular chewy candy include sour patch kids and nerds chewy candy etc. |

Pink chewy candies-Picture Courtesy: maed.co |

| 4 | Cotton Candy | Cotton candy is a type of candy made from the fine processing of sugar with mixed flavors and colors. It highly resembles cotton due to which it is called cotton candy or a candy floss. Along with other candies, cotton candy is also popular among people. |

Cotton candy-Picture Courtesy: studiodiy.com |

| 5 | Candy Corn | Candy corn is yet another candy which you may know as a must-have candy for Halloween. It has a pyramid shape which is divided in three colors namely yellow, orange, and white. This candy is made in a similarity with corn. |

Candy corn serving idea-Picture Courtesy: littlehaloj.com |

| 6 | Center Filled Candy | There are candies filled with delicious liquids or sour powders. These candies are designed in such a way to suddenly release the new taste when cracked in center. |

Center filled candies-Picture Courtesy: Pinterest |

| 7 | Chocolate Coated Candy | Such type of candies are hard in nature, however, their outer appearance is turned to be look like a chocolate bar due to chocolate coating over them. |

Chocolate coated candy-Picture Courtesy: Pinterest |

| 8 | Lollipop Candy | Lollipop is a hard candy fixed at the end of a stick. The stick is added for convenient handling especially for kids. These lollipops can be found in range of colors, shapes, and flavors. |

Heart lollipops -Picture Courtesy: ae.com |

4.Which Type Of Bags, Boxes, And Containers Are PopularlyUsed For Candy Packaging?

When it comes to talk about the candy packaging options available in bags, boxes, and containers, you will be amazed to know the wide variations. So, let's discover these packages:

Bags Stick Bags

Candy bar stick bag-Picture Courtesy: candywarehouse.com

Stick bags are small size packs which are characterized by their long and narrow shape body. These stick bags can be used for packaging various candy such as lollipop, sour candy, and flat chewy candy etc.

Standup Bags

Standup candy bag-Picture Courtesy: marinarbull.com

Standup bags are flexible packaging options suitable for bulk candies. There is a piece of gusset attached to the bottom of standup bags which help in providing extra room for holding large number of candy and gives support to the pack for standing upright.

Flow Wrap Bags

Flow wrap candy bags-Picture Courtesy: freepik.com

Flow wrap bags are also known as pillow bags due to their resemblance with pillows. These bags are highly flexible in terms of packaging candy as a single serving or in bulk.

Gusseted Bags

Gusseted candy bag-Picture Courtesy: webneel.com

Gusseted bags are known for their extended sides and bottoms which are integrated to them for adding more space to hold large amount of candy. Such bags are only suitable for bulk candy packaging.

Boxes Corrugated Cardboard Boxes

Christmas candy corrugated cardboard box-Picture Courtesy: gathered.how

Boxes which are made from the fluted card boards with one or two liners are known as corrugated cardboard boxes. Most of these boxes are used for packaging bulk candy after their primary packaging gets done, so, that their structure and quality would remain safe due to the protected card boards.

Paper Boxes

Candy paper boxes-Picture Courtesy: behance.com

As the packaging styles are evolving day by day, manufacturers are more concerned about molding the conventional packaging forms into new one. Here, they opt for paper boxes which can be easily turned into innovative design boxes like that of toffee shape which is shown in the picture above.

Bottles

Candy bottles-Picture Courtesy: packagingoftheworld

Bottles are the most common packaging containers used for storing candies. Usually, they have narrow neck and a lid for tightly covering. These bottles may be found in plastic and glass form, however, their shapes and sizes may vary.

Jars

Candy filled jars-Picture Courtesy: kelleynan.com

Jars are glass containers used for storing confectionary and so candies. As glass has zero bacterial presence, they can retain the product freshness, aroma, and taste for a longer period of time.

Cans

Candy cans-Picture Courtesy: Forbes.com

Cans are sturdy packaging containers made from steel, tin, or aluminum. They are durable enough to protect the candy from damage especially during transit. This is the reason, why luxurious and traditional candy manufacturing firms like to deliver their candy confectionaries in pretty cans.

Cups

Cotton candy cup-Picture Courtesy: prepobsessed.com

Among other containers, the most cheap, easy to use, and modern candy package is indeed cup. Cups are made from recyclable plastic and often used as disposable containers in large candy markets for packing candies on customer demand.

5.What Variations Are Available In Candy Wrappers For Candy Packaging?

Candy is a small confectionary whose primary packaging is an obligatory thing which cannot be overlooked. Therefore, most of the industries use various types of wrappers for candy packaging. These wrappers are described in the tables below:

On the Basis of Appearance

| No | Name | Description | Picture |

| 1 | Single Twist Wrapping | Single twist wrapping refers to the packaging of a candy in a wrapper having a single twist opening. This single twist wrapper not only preserves the quality of a candy but also promotes convenient usability. |

Single twist candy wrappers-Picture Courtesy: Pinterest |

| 2 | Double Twist Wrapping | Similar to single twist wrapping, in double twist wrapping the wrapper is twisted on dual sides of a candy in opposite direction. |

Double twist candy wrapper-Picture Courtesy: laure peeters |

| 3 | Fold Wrapping | Fold wrapping is another type of candy wrapping style where edges of the wrapper is folded around the candy instead of twisting. Such type of wrapping has universal shape of square, rectangle and cylinder. |

Fold wrap candies-Picture Courtesy: maed.co |

| 4 | Roll Wrapping | Another form for wrapping is roll wrapping which is done for the binding of multiple candy in one single wrapper. Here, the candies are aligned in a row and rolled in a wrapper which appears to be cylinder in shape. |

Bulk candy in roll wrappers-Picture Courtesy: candywarehouse.com |

On the Basis of Material

| No | Name | Description | Picture |

| 1 | Cellophane Wrapper | Cellophane is a thin transparent sheet derived from the cellulose of plants. Due to its less permeability to environmental elements, cellophane wrappers are good for packaging hard to soft candy, and lollipop etc. |

Various candies wrapped in cellophane wrappers-Picture Courtesy: akailochiclife.com |

| 2 | Aluminum foil Wrapper | Aluminum foil is a thin layer made from aluminum. Despite being fragile in nature, the foil has excellent barrier properties which can perfectly resist light, heat, and air. Therefore, most of the candies which are prone to get affected by bacteria like chocolate coated candy and caramel candy, are often wrapped in aluminum foil. |

Aluminum foil wrapped candy-Picture Courtesy: etsy.com |

| 3 | Paper Wrapper | Paper is extremely environmental friendly due to its 100% biodegradability and easy recycling. Therefore, most of the industries prefer using paper wrappers for primary candy packaging. |

Paper wrapped candy bars-Picture Courtesy: etsy.com |

| 4 | Plastic Wrapper | Apart from other wrappers, plastic wrappers such as polyethylene and polypropylene are also commonly used for candy packaging due to their resistance against moisture. |

PET candy wrapper-Picture Courtesy: yellowimages.com |

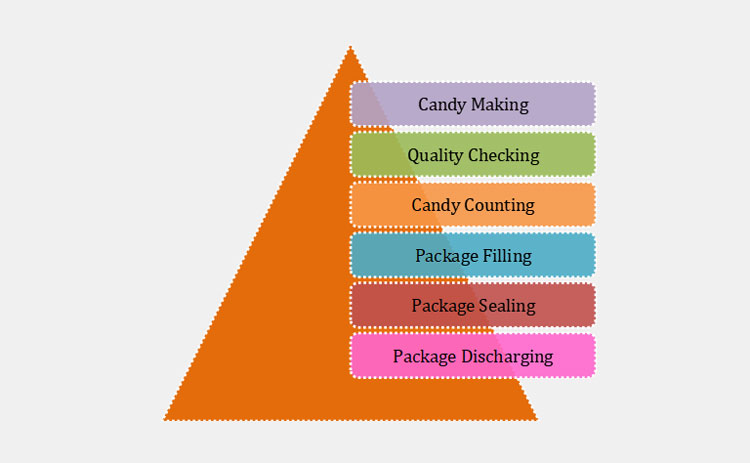

6.Elucidate The Major Steps Involved In Candy Packaging Process?

Generally, there are six major steps which are involved in candy packaging. These include:

Candy Making

Candy dough making process-Picture Courtesy: nytimes.com

The first step involves making candy for which gummy formula is prepared by mixing required ingredients such as sugar, colors, flavors, and thickening agent. These ingredients are well cooked in candy cooking machine on the temperature of 160 degree. Once, the candy is cooked for desired time, it is further processed to make finished candy.

Quality Checking

Candy undergoing detection-Picture Courtesy: oakpark.com

Now in second step, the manufacturers have to examine the quality of prepared candy as per the regulations set by confectionary sector. It will include the metal detection, weight checking, measurements, and over filling etc.

Candy Counting

Candy counting process-Picture Courtesy: issuue.com

Proceeding further, the well assessed candies would be collected together for counting purpose. Here, a candy counting machine with fitted detection and counting system is used to carry out this function.

Package Filling

Package filling-Picture Courtesy: Boevan Pack

At the same time, counted candies are filled in number of packages such as bags, wrappers, bottles, and cans etc.

Package Sealing

Package sealing-Picture Courtesy: Boevan Pack

After all the candy packages get filled with precise amount of candies, these bags and containers are tightly sealed through heat sealing and capping machine respectively.

Package Discharging

At last, all the finished candy packages are discharged in a sequential order.

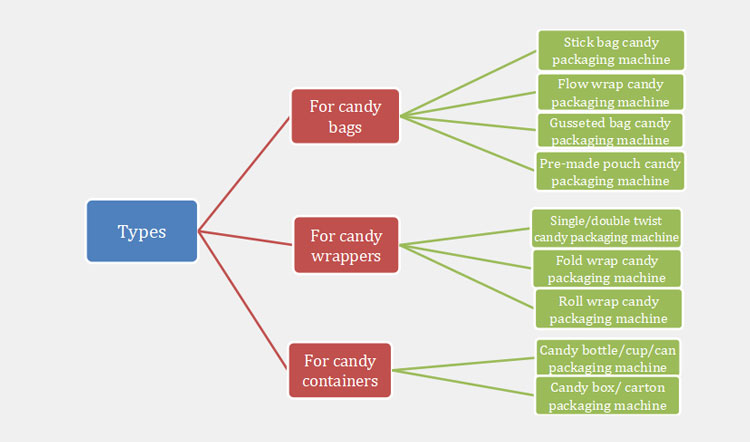

7.Describe The Various Packaging Machines Used For Candy Packaging?

There are different types of packaging machines used for candy packaging. These machines are described below in detail:

Stick Bag Candy Packaging Machine

Stick bag candy packaging machine-Aipak

Stick bag candy packaging machine is designed to fulfill the task of packing granulated candy like jelly beans into multiple stick bags simultaneously. It is made with advance features of product measuring, bag forming, filling, sealing, and control system. It works by pulling the plastic or laminated foil from roller and forming a bag from it through heat sealing. After that, the machine delivers the precise amount of candy into stick bag and seal it from the top. At the end, all packed stick candy bags are discharged by the machine.

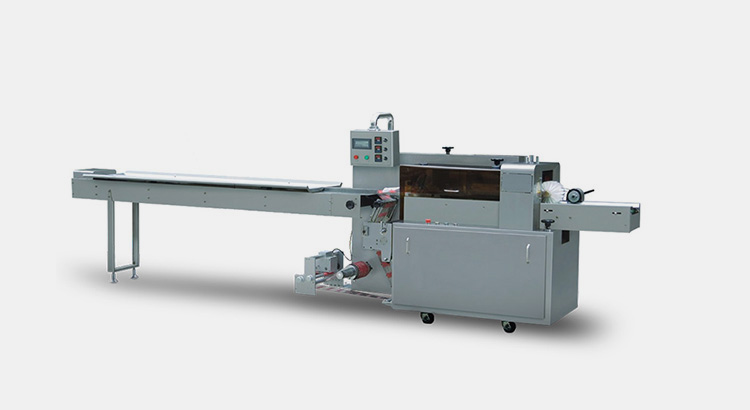

Flow Wrap Candy Packaging Machine

Flow Wrap Candy packaging machine-Aipak

Flow wrap candy packaging machine is another type of machine used for packing pillow bags or flow bags for candy. It consists of a stainless steel body, control system, sealing system, conveyor belt, cutting knife, and feed roller etc. The machine functions by taking the film from roller and molding it around the candy. Similarly, the pack is sealed by machine and discharged by conveyor belt after it is separated through knife.

Gusseted Bag Candy Packaging Machine

Gusseted bag candy packaging machine-Picture Courtesy: zon-pack.com

Gusseted bag candy packaging machine is suitable for weighing and filling of all types of candies. It has automatic system for accomplishing the task of packaging candy into gusseted bags. The process get started with machine taking candy from hopper and delivering it to the multi weighing head via z-shaped elevator. At the same time, the vertical form fill and seal station start forming a gusseted bag with the help of a bag forming device. When bag is formed, the machine release measured candy into bag and seal the bag from top.

Pre-made Standup Pouches Candy Packaging Machine

Pre-made standup pouches candy packaging machine-Aipak

As the name indicates, pre-made standup pouches candy packaging machine is particularly designed to carry out the function of filling already made doypack and standup pouches. It can be brought into use by loading the hopper of machine with bulk candies and bag holding station with required number of standup pouches. When all the parameters of machine are adjusted, it is ready to get started. From here, the machine will start taking pre-made standup pouches from station and will pass them through bag opening, candy filling, bag sealing, and ultimately discharging phase.

Single/Double Twist Candy Packaging Machine

Single/double twist candy packaging machine-Picture Courtesy: honorpack.com

This intelligent machine has been designed with dual features of packing single as well as double twist candy packages. It works by delivering the candy to a wrapping station where machine pull the film from roller, cut it through blades, wrap it around the candy, and finally twist the edge from single or double sides.

Fold Wrap Candy Packaging Machine

Fold wrap candy packaging machine-Picture Courtesy: loynds.com

Fold wrap candy packaging machine is particularly designed to pack soft candy, chewy candy, and caramel candy. The machine is composed of a durable main frame, control system, candy processing station, candy cutting unit, and packaging unit etc. With the help of these components, the machine can perform dual function of cutting the candy and then packing it into fold wrap.

Candy Roll Wrap Packaging Machine

Candy roll wrap packaging machine-Picture Courtesy: Alibaba

Candy roll wrap packaging machine is yet another machine in the list of candy packaging. This machine has been employed to facilitate the packaging of multiple candy in a single roll wrap. It consists of a candy counting unit, aligning station, foil wrapper, and rolling station etc. It functions by first counting the candies, and then aligning them on a foil. After that, a layer of paper or plastic film is wrapped around the aligned candies which gives final look of a candy roll.

Candy Bottle/ Cup/ Can Packaging Machine

Candy bottle/ cup/ can packaging machine-Aipak

This machine has brought into the field to pack small to large size candy bottles, cups, cans, and various other containers. The machine is made with a stainless steel body with having proper vibratory counting channel, automatic detection and control system. It starts operation by first counting the candies laying on a vibratory tray, then, these candies are loaded into bottles and cans through filling nozzles. At the same time, this machine is performing the responsible task of detecting filled bottles in order to ensure precision.

Candy Box/ Carton Packaging Machine

Candy box/ carton packaging machine-Aipak

Candy box and carton packaging machine is an automatic machine used for packing candy into cartons or boxes. The machine has integrated system of box forming, filling, sealing, coding, and discharging etc. When the operator turn on the machine, the machine starts taking unformed boxes from feeder and form it in a well set format. It is then moved forward where the machine infiltrate candy into box, seal it, and discharge the box after printing a code.

8.What Is The Role Of Labeling In Candy Packaging?

Labeling play a very essential role in candy packaging from several aspects. These aspects will be discussed in the underlying paragraphs.

Candy package label-Picture Courtesy: candywrappersarchive.com

Grab Attraction

After all, it is the labeling that appeals to the eyes of viewers. It implies, that without a labeling, your product may lose the charm for consumers.

Promote Brand

It is the labeling, through which you can promote your brand by displaying information about your logo, company name and contact etc. Therefore, labeling is crucial in your brand recognition among consumers.

Alarm People

Candies vary in shapes, sizes as well as ingredients. Similarly, most of the people have allergies from the ingredients used in candies. So, if your candy pack is holding information about allergens like gelatin, and artificial additives, it will help people to be cautious while taking these candies which may not be good for their health.

Informs Product Validity

Through labeling, date of expiration can be communicated to consumers which will too benefit the users to take the candy under validated time period.

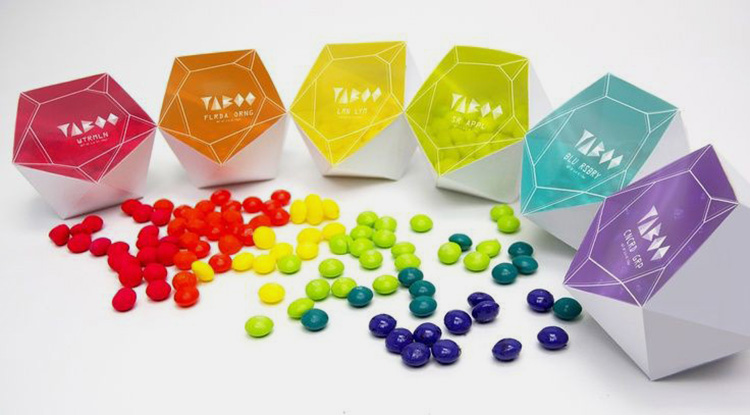

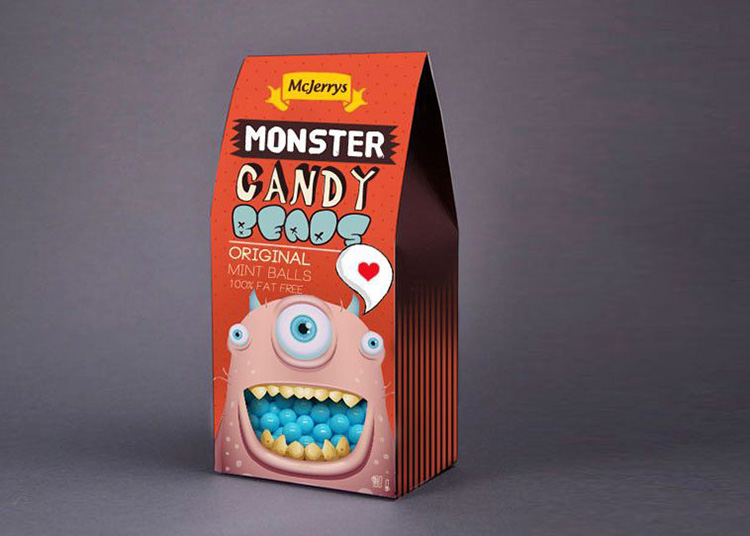

9.How Candy Packaging Can Be Made More Alluring?

If you want to make your candy packaging more eye catchy there are certain ways which can be adopted to get the desired aim. Some of these tips are mentioned below:

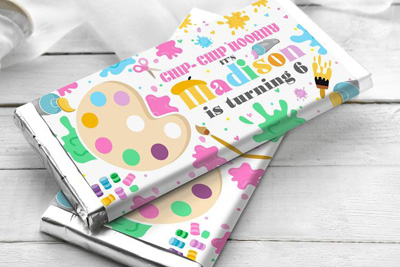

Beautifying Labeling

Candy pack labeling-Picture Courtesy: smartlabel-hersheys.com

The most prominent technique which you can adopt for making your candy packaging more attractive is to beautify your labeling. It can be done by using eye-catching colors, unique design fonts, and vibrant color combinations etc.

Packaging Type

Candy packaging boxes-bespoke-bride.com

You can also modify your packaging by turning your current packaging into new types of packaging. For instance, if you are using candy wrappers for packaging, you must replace it with other forms like stick bags, small boxes, and even cans etc.

Reusable Sealing

Reusable candy box-Picture Courtesy: boredpanda.com

Convenience is the core aspect of candy packaging which counts for your successful business. In essence, people like to buy candy packages which can be used for multiple times. Therefore, using reusable sealing can be beneficial in this regard.

Conclusion

After discussing in detail about candy packaging, it can be drawn into conclusion that candy packaging is the most important factor for determining candy safety, retaining quality and extending shelf life. Besides, candy packaging holds in it various benefits for your business success such as advertising your products along with your brand. So, if you are interested in availing all these opportunities, let us know by leaving a short message. We will reply you ASAP!

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide