Vibro Sifter: The Complete Buying Guide In 2024

Does your business involve screening of particles and powders? Does your production setup involve processes done by Vibro sifter? Are you interested in buying a vibro sifter to improve your productivity? Do you want to know more regarding the operation and types of vibro sifter? This is the place where you can get all the related information that will support you in selecting the right type of vibro sifter for your production setup. Read the complete guide to resolve your queries.

1.What Is Meant By A Vibro Sifter?

Vibro Sifter

A vibro sifter or a vibro sieve is a unique type of equipment used for screening and separating of particles that are bigger in size or unwanted for any process. It contains both rotary and screening mechanism in its structure that makes it highly valuable for many industries. This equipment is widely used in pharmaceutical, chemical, cosmetics, food and other industries for sorting out granular substances with the help of vibratory motion.

2.Where Is A Vibro Sifter Used?

A vibro sifter due its highly versatile and efficient working is preferred by wide range of industries that use granular, powdered, particle or other relevant materials in its processes. Some of the industries that use vibro sifter to make their products with high quality are

Pharmaceutical Industry

Vibro Sifter For Pharmaceutical Industry

The largest consumer of a vibro sifter is pharmaceutical industry as it used fine powders for the preparation of all types of medicines. These fine powders are used for efficient preparation of tablets and capsules with ensuring uniform in its chemical formulation.

Food Industry

Fine Wheat Powder

After pharmaceutical industry, food industry is the second most important sector that uses vibro sifter for its processes. Ingredients like sugar, spices, grains that are smaller in size use vibro sifter for removal of impurities and other solid particles. It not only maintains the quality of product but also helps in their preservation for longer period.

Chemical Industry

Chemical Powder

Like other industries, chemical industry use vibro sifter for screening of chemical raw materials to get rid of large, unwanted particles. The solid particles not only can cause material wastage but also can add extra weight to chemical substances.

Cosmetics Industry

Loose Face Powder - Picture Courtesy: Gosupps

Variety of cosmetics products are found in powdered form these days. These are properly screened and refined using a vibro sifter. The screening improves the quality of products like talc, face powders, mask powders and etc.

3.What Are The Advantages Of A Vibro Sifter?

Some of the advantages of a vibro sifter are

Fine Sieving

Fine Aggregate Sieves

Different types of vibro sifters are available globally. These not only can remove particles from any fine material but also can give efficient filtration upto 5 microns. This shows that how fine sieving is performed by vibro sifter.

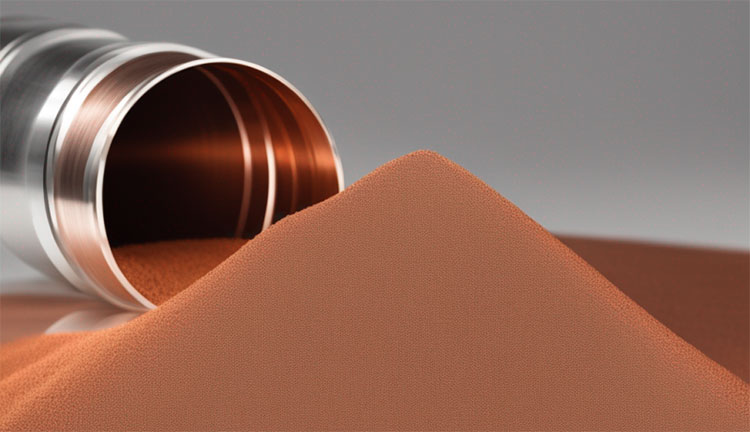

Quality Product

Fine Powdered Copper

Each of the material that is processed in a vibro sifter undergoes uniform vibrating operation that results in high quality product with consistency. The material quality remains always important as it has to further convert in finished products and vibro sifter is bound to work accordingly.

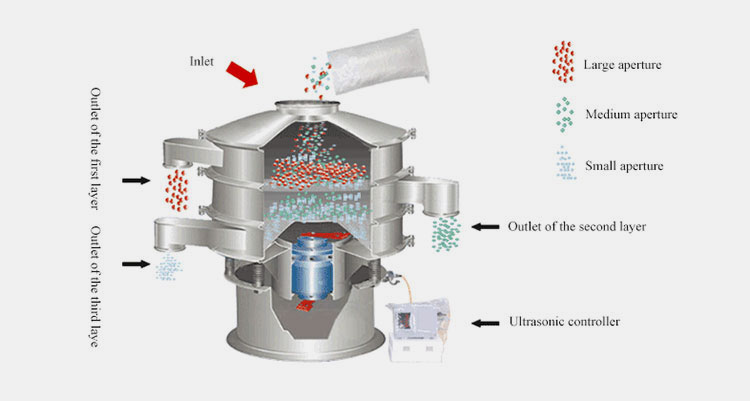

Multi Layer Sorting

Multi-Layer Sorting In Vibro Sifter

In some of the vibro sifter, more than one layer of sieve plates are available that makes the process of sorting more accurate. Each layer with different type of mesh ensures that no single unwanted particle is left behind in the material.

Versatility

Vibro Sifter For Solid Liquid Separation

This is also an important advantage of a vibro sifter that it can use for variety of products and materials. Whether it is a powdered, granular, liquid or oversized particle; a vibro sifter can easily remove the impurity from it and gives the desire output according to the requirements.

4.What Different Materials Can Be Processed In A Vibro Sifter?

Most of the vibro sifter can easily be accommodate with many fine particle materials. But some of the materials that can easily be processed in a vibro sifter are

Powders

Fine Powder Sizing And Separation - Picture Courtesy: HK Technologies

Most abundantly powdered material used in pharmaceutical, food and other industries are processed in a vibro sifter. These powders often contain many unwanted substance that are to be removed before their processing step. Vibro sifter supports in extraction of these particles and keeps the powdered material in fine form.

Granules

Granules For Pharmaceutical industry - Picture Courtesy: Anish Pharma

Other than powder materials granular materials like sugar, beans, nuts, resins, pellets and grains also use vibro sifter for their purification and extraction of heavy particles.

Solid-Liquids

Vibro Sifter For Liquid Materials Picture Courtesy: Pharmaceutical Process & Packaging Machine

Some of the suspensions or slurries that are solid-liquid in nature are also compatible with vibro sifter for removal of abrasive particles. These products like milk, sauces, chemical solutions, paint coatings and pharmaceutical suspensions use vibro sifter for their filtration and purification.

Fiber Material

Fine Meshed Bamboo Fiber

Fibers materials that are large in size are also required to be eliminated in number of products. This ensures the quality of products and makes it easy to consume.

Plastic Resins

Plastic Resins- Picture Courtesy: EuroPlus

Plastic resins that are used for the preparation of plastic coating, paint makes, plastic making, and polymer formation are also in irregular shapes. They also contain heavy particles that can spoil the consistency of any material. This is why vibro sifter is used for such products so that consistent and accurate materials can be formed.

5.How Does A Vibro Sifter Work?

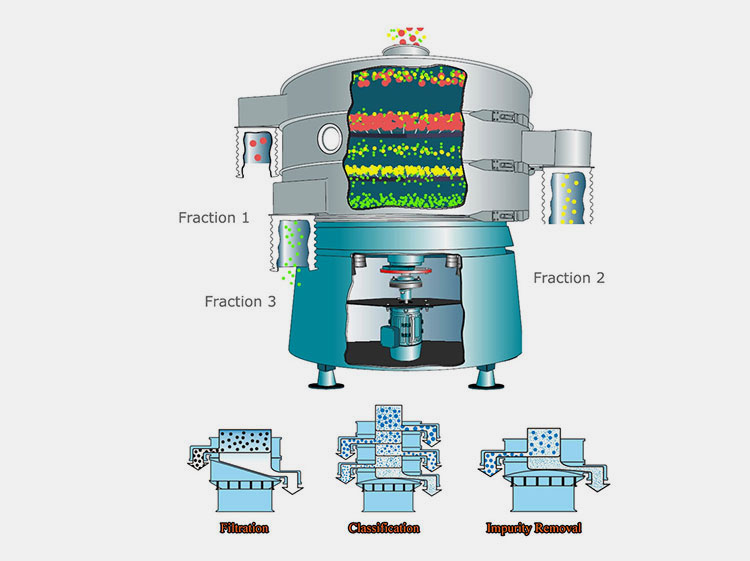

Working Of A Vibro Sifter - Picture Courtesy: iPharmachine

A vibro sifter is highly efficient equipment for separation of heavy particles and to make the product free from impurities. It operates in following working steps

Material Feeding

Firstly, the material is fed into the vibro sifter via feeding port onto the screening surface. This surface is made up of wired mesh that is used for the process if refining.

Vibration Mechanism

Once the material is fed into the sieving system, the vibratory motor allows the start of process which causes vibration in mesh. This vibration supports in circular motion of mesh and starts screening of material in a continuous manner.

Sieving

The fine particles are allowed to pass these small holes of mesh and remaining heavy particle remain on the surface of mesh.Each of the mesh performs its task in an efficient manner at every layer and the desired material flows down to the material collection duct.

Material Discharge

From here the material is discharged through discharging port and then utilized for preparation of final product.

6.What Are The Different Types Of Vibro Sifters Available Globally?

Some of the types of vibro sifter available globally are

Circular Vibro Sifter

Circular Vibro Sifter

The most common type of a vibro sifter available globally is a circular vibro sifter. It is usually available with a rotary functioned screen that connected with the shaft of motor. Heavy or solid particles are easily separated by the circular motion of a circular vibro sifter depending upon their sizes and shapes.

Ultrasonic Vibro Sifter

Ultrasonic Vibro Sifter

The other type of a vibro sifter is an ultrasonic vibro sifter. The machine has an internally generated ultrasonic wave that is used for the vibration of mesh at high frequency. The vibration is responsible for taking heavy particles along with the surface of screen in an accurate manner.

Centrifugal Vibro Sifter

Centrifugal Vibro Sifter

Centrifugal force is used in this type of vibro sifter for creating motion on the surface of mesh. To and fro and also up and down movement of heavy particles is caused due to this centrifugal force. Ideal material is received at the discharging port that is used for further processes.

Gyratory Vibro Sifter

Gyratory Vibro Sifter

A gyratory vibro sifter uses gyratory motion which allows the mesh moves in circular motion around the axis of the center shaft. This has an effective screening property that is used to screen materials that are even difficult to see from a naked eye.

Rectangular Screening Vibro Sifter

Rectangular Screening Inline Vibro Sifter

A rectangular screening vibro sifter is a unique type of vibro sifter that directly removes the heavy or unwanted particle from the system once it is collected. Due to this property it is also called as centrally discharging screen to ensure the proper refining of material. The vibro sifter also has variety of functions in it like removing dust, inspection and etc.

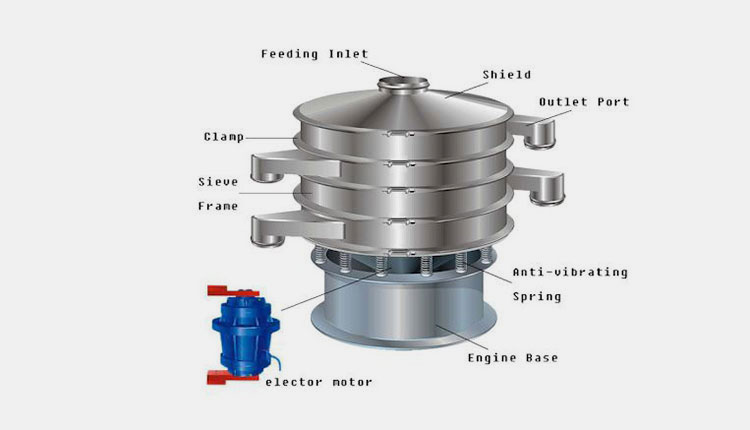

7.What Are The Main Components Of A Vibro Sifter?

Parts Of A Vibro Sifter - Picture Courtesy: Pharmaceutical Machinery

The main components of a vibro sifter are

Feeding Inlet

A feeding inlet is the basic component of a vibro sifter from where the material in inserted. It is mostly present at the top of a vibro sifter from where the material falls on mesh or frame. The inlet is mostly made up same material like the structure of a vibro sifter.

Shield

Shield is the top most covering of a vibro sifter that creates an internally closed environment. This shield also prevents material from getting out from the vibro sifter during vibrational effect.

Clamp

Clamps are present in each layer of a vibro sifter that are used for tightly closing each layer with the other. It prevents opening or exposure of any layer during the operational process.

Sieve Frame

A sieve frame is the main part of a vibro sifter that contains screen mesh, impellers and blades in it. It is the place where the purification or sieving process is performed.Different sizes and shapes of screen mesh made up of nylon, stainless steel and polyurethane are present in the sieve frame of a vibro sifter.

Anti-Vibrating Spring

This kind of springs are present at the base of a vibro sifter and are responsible to restrict the vibration of frame cause by the internal process. These spring makes the vibro sifter to stay still throughout the process by reducing vibration and tension.

Engine Base

It is the base of a vibro sifter made up of stainless steel that holds the whole equipment on it. It is mostly hard in nature that can bear both the electric and vibrational effect with high efficiency.

Outlet Port

Contrary to the feeding inlet, an outlet port is responsible to gather the final screened and purified material. Most of the vibro sifter have outlet ports are present just at the bottom whereas few have their outlet ports at the top.

Elector Motor

In a vibro sifter, elector motor is used for the rotation of internal shaft. This elector motor is responsible for creating vibration on screen mesh that further displaces lighter particles for heavy particles.

8.How Is Vibro Sifter More Beneficial Than Other Types Of Screening Machines?

Some of the advantages of a vibro sifter than other type of screening machines are

Design Structure

Series Vibrating Screen

A vibro sifter alone can be used for various types of material like solids, granules, liquids, powders and etc. Its design is done in a way that it can be customized according to the requirement of manufacturer which makes it beneficial that other type of screening machine.

Compact Footprints

Compact Footprints And Versatility Of Vibro Sifter

This is one of the unique advantages a vibro sifter has that its structure can be installed as per the need of process. The equipment can be moved from one place to another easily where other screening machines are much difficult to even move a single centimeter.

Energy Efficient

Power Filtering Rotary Vibro Sifter - Picture Courtesy: Xinxiang Hengyu Machinery Equipment

A vibro sifter is much efficient when it comes to energy consumption. The equipment consumes a very low amount of energy that makes the process efficient and economical.

9.How Does The Size Of Mesh Affect The Performance Of A Vibro Sifter?

Wired Mesh For Better Performance Of Vibro Sifter

The size of a mesh plays an important role in the performance of any type of vibro sifter. It not only separates particles by their sizes but also allows passing of desired particles. Due to its perforation task it is essential to select the appropriate mesh according to the material and process.

The screening efficiency of a vibro sifter is also important for improving its performance because it determines what size of particle will remain on the mesh and which has to pass through it. Greater screening efficiency can give greater quality results.

10.How A Single Deck Vibro Sifter Different From A Double Deck Vibro Sifter?

Single And Double Deck Vibro Sifter

Both the single and double deck vibro sifter primarily are distinguished on the basis of their structure. Some of the other important differential factors between single and double deck vibro sifter are

Structural Design

A single deck vibro sifter has a single screening mesh in its structure associated with a vibratory motor. The particle separation is completely processed done on this single mesh.

Whereas in a double deck vibro sifter, more than one screening mesh is present and stacked vertically on one above another. Each deck performs its own particle separation using their own perforated mesh surface.

Separation Features

A single deck vibro sifter are suitable for separating only a single size of particle as it contains only one mesh surface.

In contrast, the double deck vibro sifter has separate layer screen for more than one particle sizes. It makes it more reliable and efficient for variety of products.

Product Requirements

Where it comes to separation of single particle size, vibro sifter are very economical and with less structural footprints.

Materials with particles of different sizes can easily be screened using a double deck vibro sifter. The throughput of a double deck vibro sifter is much more than a single deck vibro sifter

Conclusion

Vibro sifters are highly efficient and precise when it comes to extraction of unwanted large particles from any material. This equipment not only separates the particles but also allows to remove them from the process whether they are of any shape or size. Before buying a vibro sifter it is always important to gather all necessary information regarding its use, application, working and other benefits. Allpack is always here to guide you in selecting the best type of vibro sifter according to your process requirements. If you have any query feel free to contact our customer representatives that are available 24/7 for your guidance.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586