What Is The Sifting Process In Pharmaceutical Industry?

What Is The Sifting Process In Pharmaceutical Industry?

Are you looking for ways to homogenize the size distribution of your product? Indeed, there is a way and it is known as the sifting process.

The sifting process in the pharmaceutical industry is one of the core processes but its application is not limited to the pharmaceutical industry. It is well-recognized in the food, chemical, cosmetic, construction, and many other industries.

It handles granules, pellets, active pharmaceutical ingredients, etc in the pharmaceutical industry. It boosts product integrity and quality while avoiding contamination risk. It has a role in fulfilling strict regulatory compliance in various industries.

In this blog post, we will discuss what constitutes the sifting process in the pharmaceutical industry, its benefits, and its types. If you are an expert or novice in this area, then stay tuned for the informative voyage.

1.What is the Sifting Process in the Pharmaceutical Industry?

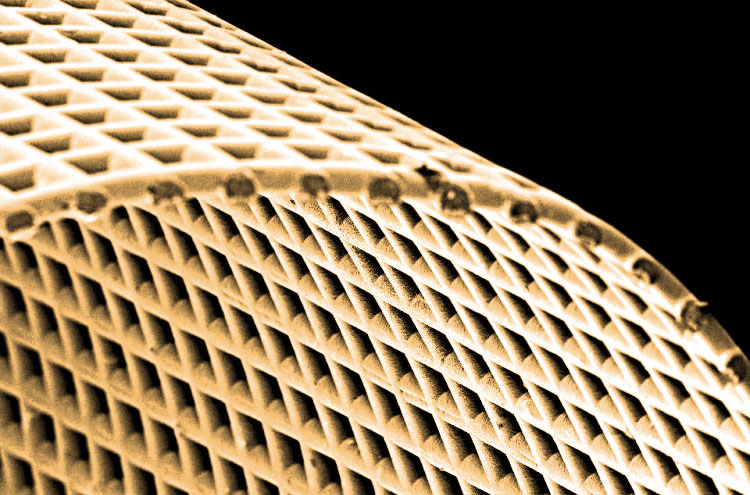

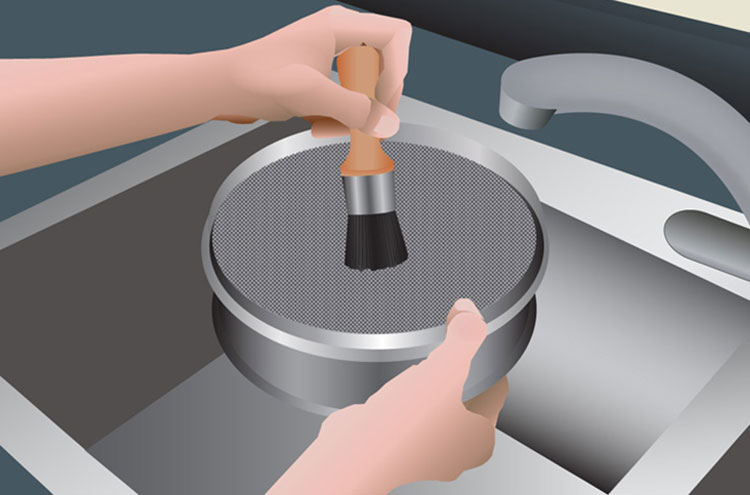

Sifting Process in the Pharmaceutical Industry- Picture Courtesy: Particles Technology Labs.

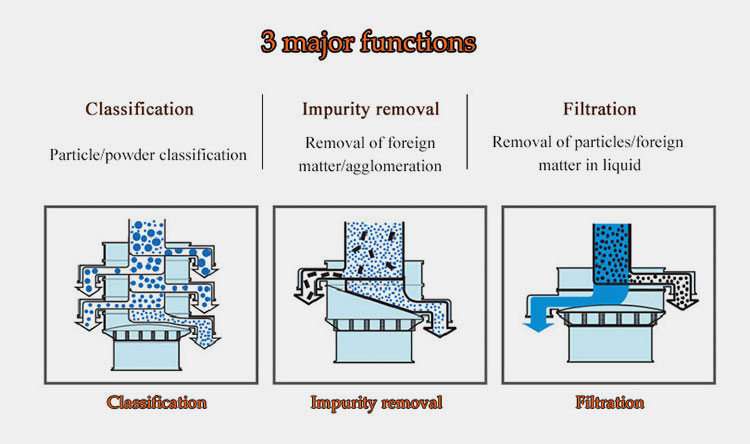

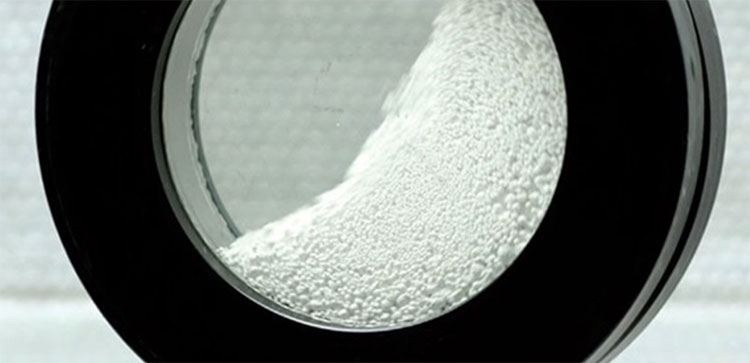

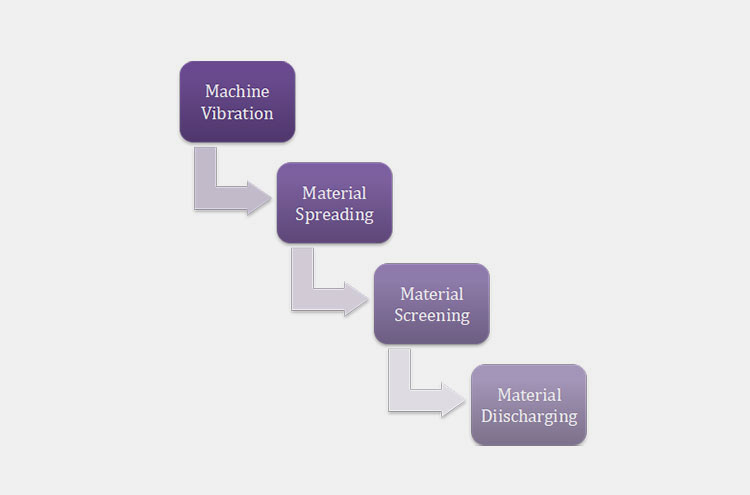

The sifting process in the pharmaceutical industry is a fundamental process that serves the purpose of screening the particles. It is synonymous with the sieving process. This operational step is executed by passing particles through a sieving screen or size mesh.

In this process, foreign materials are removed from the powders or other pharmaceutical preparations. It also excludes particles beyond a certain size limit. It separates diverse types of material particles depending on their size, density, or other characteristics.

The primary objective of the sifting process is to remove large particles and unwanted objects from smaller-sized particles. It also eliminates large agglomerates or lumps from the mixture, and results in uniform consistency of raw materials.

2.What is the Significance of Sifting Process in the Pharmaceutical Industry?

The sifting process in the pharmaceutical industry has an enormous impact because it allows to achieve uniformity, a major requirement during tablet and capsule manufacturing. It is a significant step in the preparation of liquid and semisolid dosage. Let’s discuss the useful benefits of the sifting process in the pharmaceutical industry.

Uniform Size Distribution

Uniform Size Distribution- Picture Courtesy: The Collagen Co.

The chief benefit of the sifting process in the pharmaceutical industry is uniform-sized distribution. It ascertains that the end product has even-sized particles, which is essential for the desired bioavailability, solubility, and drug profile. It helps in maintaining dose accuracy and effectiveness.

Homogenous Mixing

Homogenous Mixing- Picture Courtesy: Vitacost

Varying particle sizes lead to poor mixing of raw materials and often powder segregation. The sifting process is used in the pharmaceutical industry to prevent this issue. Fine mesh is utilized for sieving diverse-sized particles, resulting in even-sized raw materials, preventing the risk of segregation, and ensuring homogeneous mixing.

Ease in Compression

Ease in Compression- Picture Courtesy: Still Detox

Larger-sized granules unsettle the die filling, consequently leading to weight differences in tablets. Moreover, they also affect the disintegration duration and dissolution profile, causing longer disintegration time and poor dissolution. Whereas, very fine particles lead to poor fluidity of powders.

Thus, the sifting process has significance during granulation to obtain uniform-size granules, assisting in smooth and seamless compression.

Removal of Foreign Contaminants

Removal of Foreign Contaminants- Picture Courtesy: Walcoom

One of the main purposes of the sifting process in the pharmaceutical industry is the elimination of foreign objects like dust, debris, fibers, metal fragments, glass shards, and other contaminants. These contaminants may enter raw materials during handling.

Product Quality and Safety

Product Quality and Safety- Picture Courtesy: HealthLine

Impurities in the formulation negatively impact the product efficiency and safety. However, this problem is not of concern with the sifting process. It separates impurities from the final product and protects consumers from damaging contaminants. Furthermore, it allows manufacturers to adhere to stringent safety standards.

Boost Process Efficiency

Boosts Process Efficiency- Picture Courtesy: Pravek

The sifting process in the pharmaceutical industry enhances the process efficiency by protecting equipment from wear and tear due to oversized particles. Furthermore, with sifting, the productivity of downstream procedures, for example, dry and wet granulation is increased because of lower wastage and high yield of end product.

3.What are the Types of Sifting Processes in the Pharmaceutical Industry?

There are two major types of sifting processes in the pharmaceutical industry:

Safety Screening

Safety Screening- Picture Courtesy: Soln Pharma

It is also referred to as check sieving, control sieving, or security sieving. It is typically employed for eliminating foreign materials, contaminants, and larger-sized particles from the resultant product. Its main goal is to separate particles having desired or smaller sizes by sieving them from the screen. It preserves the purity and quality of materials.

Starting material is passed from the screen containing a specific size. Unwanted substances are retained on the screen, while required particles go through the screen. Usually, a single screen is used in the safety screening.

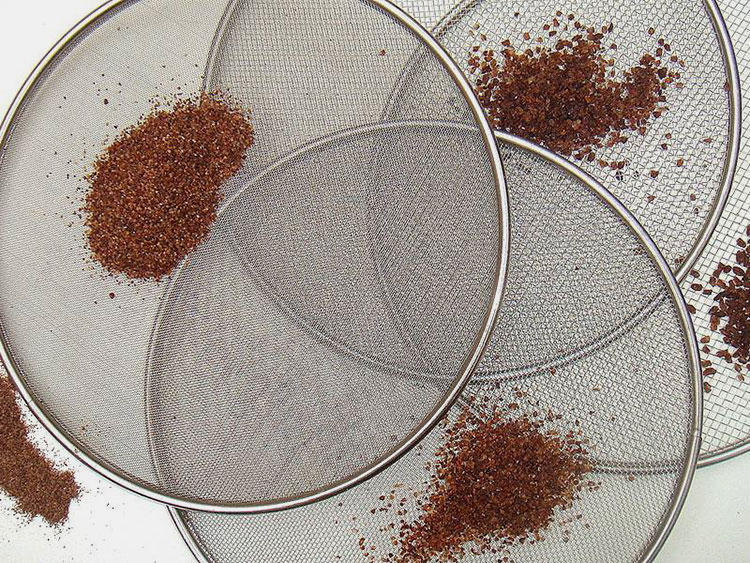

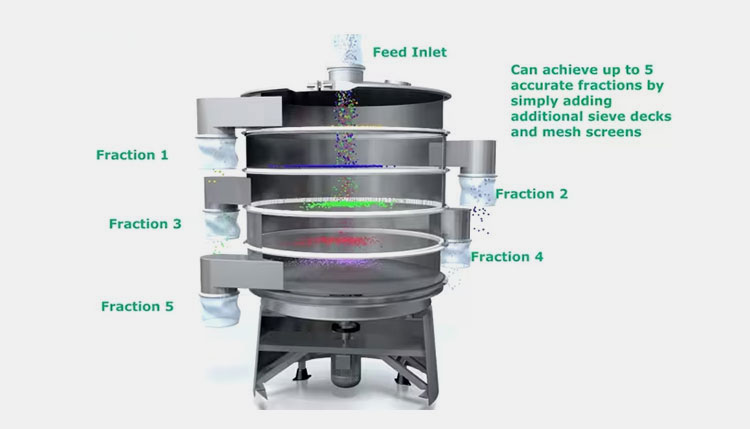

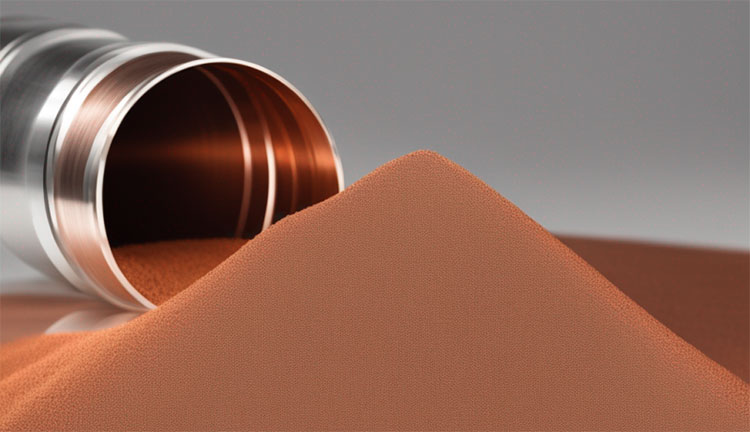

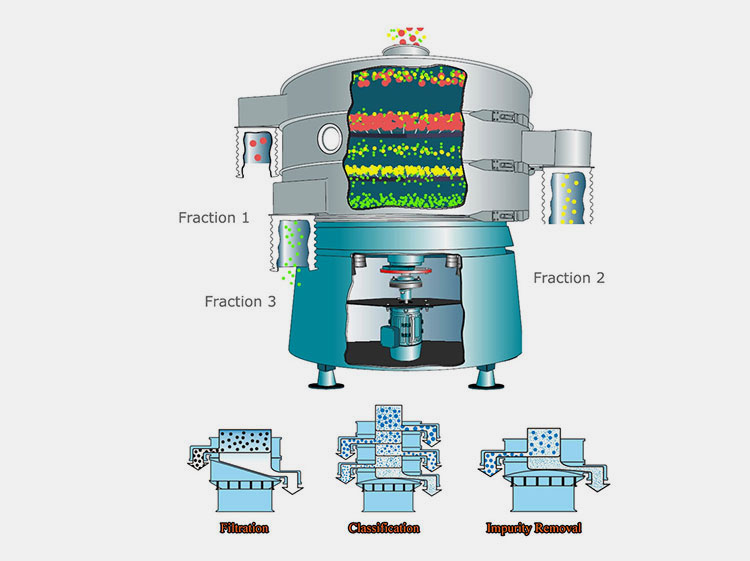

Grading

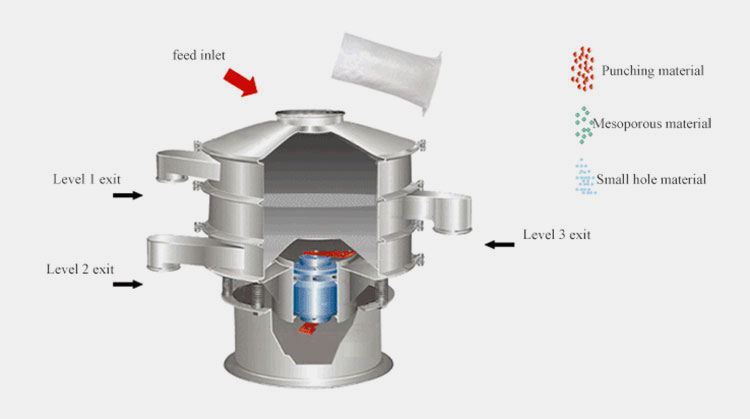

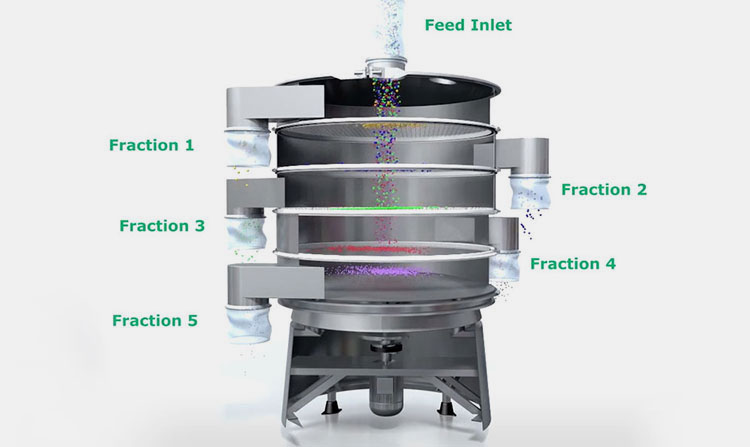

Grading- Picture Courtesy: DAHAN Vibration Machinery

It is also named classification sifting. In this process, particles are separated into diverse-sized fractions. It classifies the materials into different sized ranges. Its objective is to categorize powders or granules depending on their size, thus forming numerous grades of materials in the product batch.

In grading, the starting product is distributed through a series of screens with succeeding screens with smaller mesh sizes. Every screen filter particle of a defined range, whereas, fine residues go through the next sieve.

In the pharmaceutical industry, primary and intermediate substances are sieved to discharge oversized and undersized particles, which results in particles ready for granulation and tablet pressing.

4.What are the Different Types of Sifters in the Pharmaceutical Industry?

There are multiple sifters in the pharmaceutical industry to separate and sort the particles. Below mentioned are fundamental kinds of sifters, take a look:

Types of Sifters Based on Mode of Operation

Vibratory Sifter

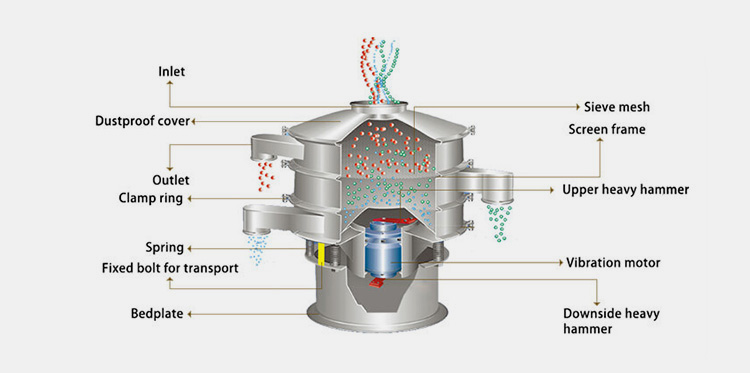

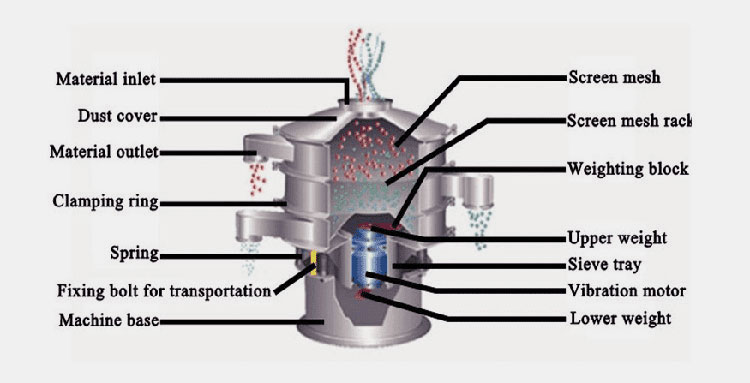

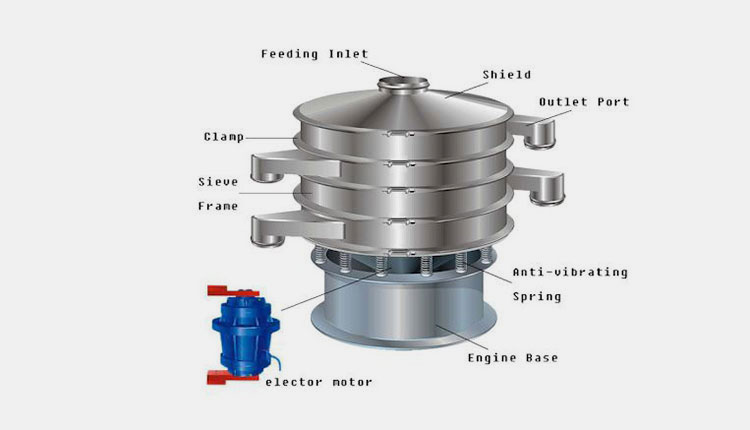

Allpack Vibratory Sifter

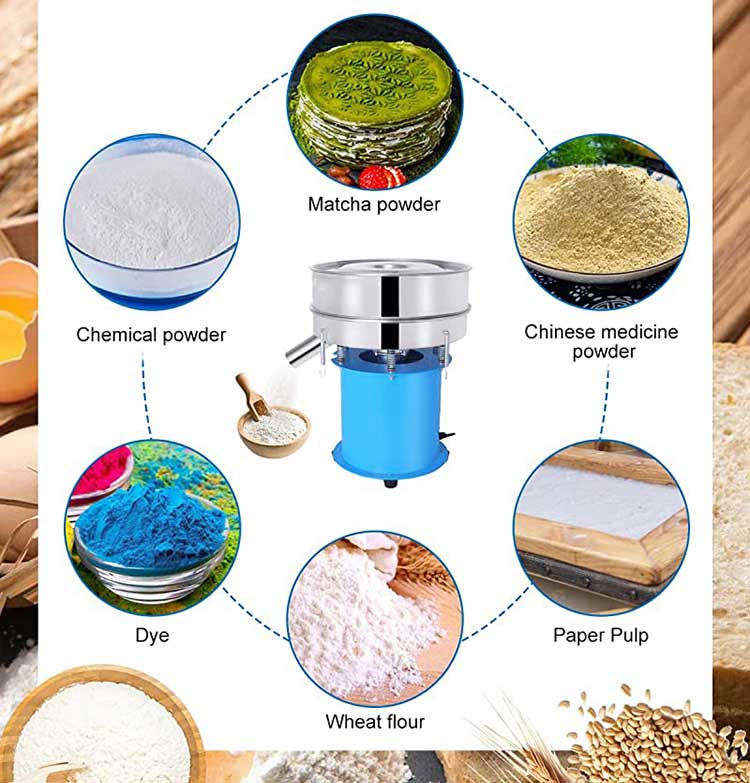

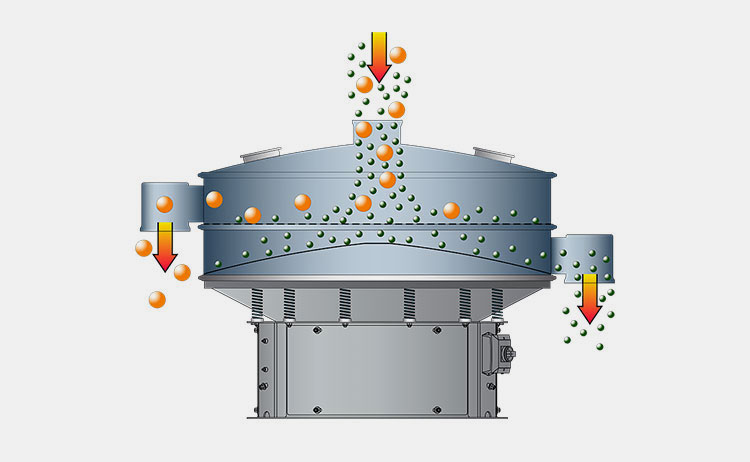

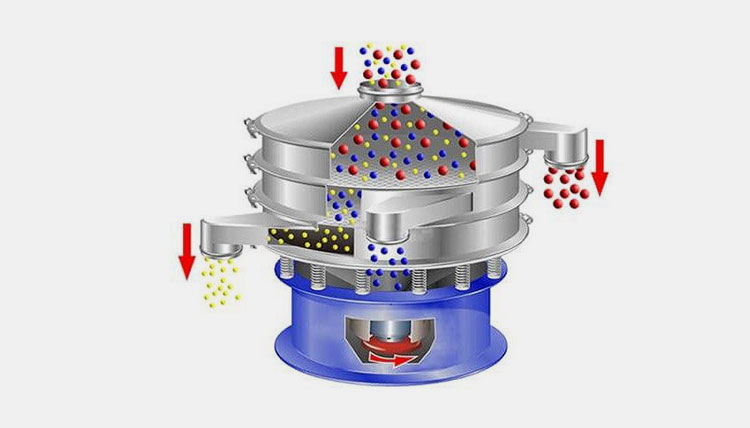

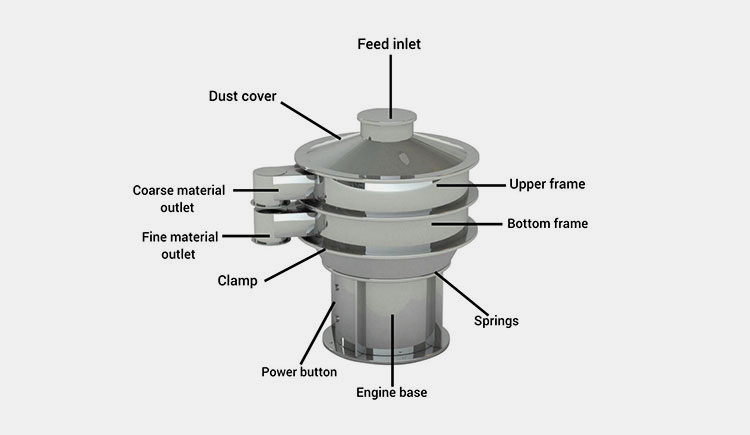

It is also called a vibratory screen machine. It is employed to separate particles that have a size smaller than 0.85 mm from larger particles. This machine has a vibrating sieve surface that screens the materials based on density and size. It uses vibration to attain separation, scalping, and, grading.

It consists of a circular mesh screen, an electric motor, and, eccentric weights present at the top and bottom part of the vibration-producing part. It is a cost-effective option for low-capacity sifting in the pharmaceutical industry.

The particles begin to vibrate very rigorously and travel through screens according to their size. The materials move quickly to trek across the screen with vibration. The tilting of the screen results in a vertical motion, which in turn leads to the passing of under-sized particles from the screen, while oversized particles move to the edges of the screen for discharging from the machine.

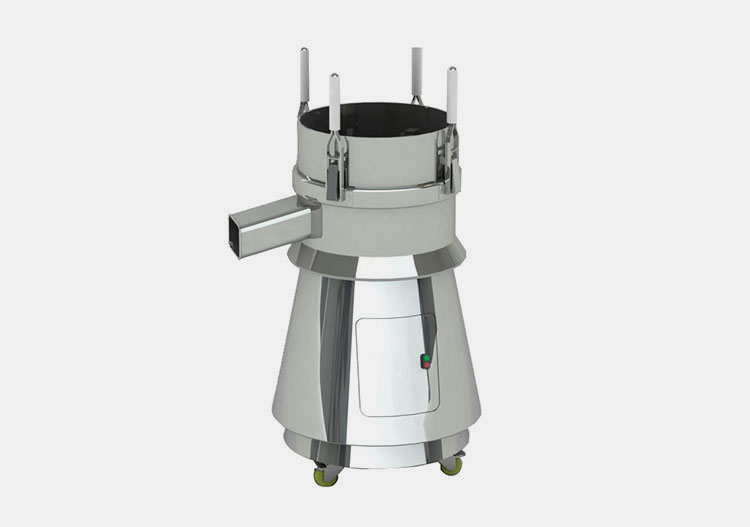

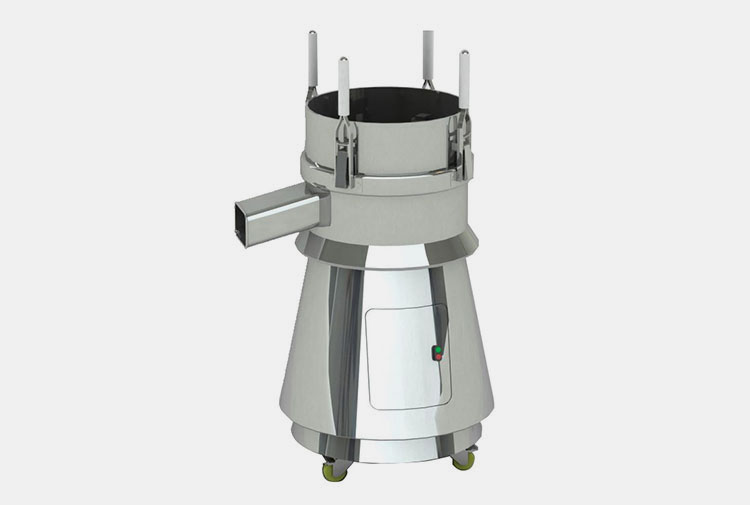

Centrifugal Sifter

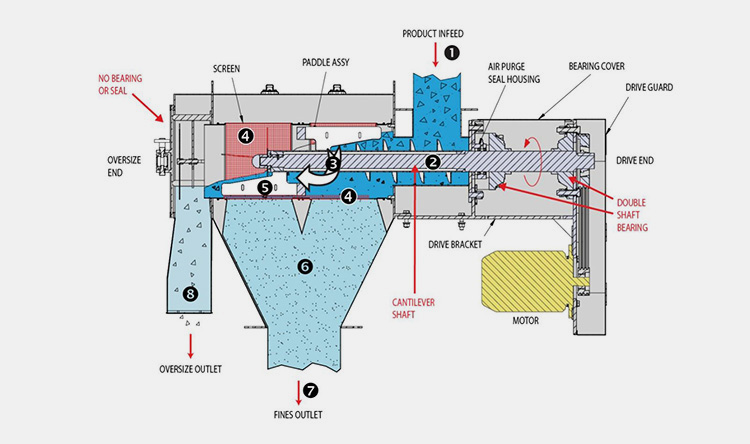

Allpack Centrifugal Sifter

It is an industrial screening machine that sieves the materials instantly. It handles a diverse range of materials like powders, agglomerates, and lumps. Centrifugal sifter is the best machine for removing larger particles and foreign substances without much noise and vibration.

It screens powdery and granular feed with the aid of centrifugal forces. A small auger forces the bulk substances into the sieving chamber. The feed tumbles inside the chamber because of swiftly rotating paddles. The particles smaller than the mesh hole go past the sieve and are transported into the collecting hopper, whereas, big particles travel across the length of the screen and discharge from the refuse outlet.

Gyratory Sifter

Gyratory Sifter- Picture Courtesy: Sweco

It is also called a circular vibratory sieve or square swing sifter. This type of sifting machine employs circular or elliptical motion to sort materials. Contrary to other types of sifters in the pharmaceutical industry, this equipment operates gently and is ideal for separating fragile products. It produces finer particles.

It is a deck of screens stacked on top of each other, with the coarsest sieve on the upper part and the finest one at the bottom. The feed is placed at the topmost screen and with the gyratory motion, minute particles penetrate the screen while big materials are retained on the screen. It operates continuously.

Air Jet Sifter

Air Jet Sifter- Picture Courtesy: W.S Tylor Blog

It is a sifter device that uses air jet technology for separating materials with greater efficiency and precision. Very fine particles often tend to clump on the mesh screen, which is why, air jet sifters typically classify fine and agglomerated materials. Utilizing a specialized vacuum device, it forms a strong airstream that de-lumps the larger agglomerates.

Slotted nozzles present in air jet sifter speed the incoming air from below. The samples are raised upward by the projected air, resulting in their slamming against the lid and deagglomeration. Nevertheless, almost immediately, fine particles are sucked through the mesh apertures with vacuum force while coarse materials stay on the screen and are re-weighted.

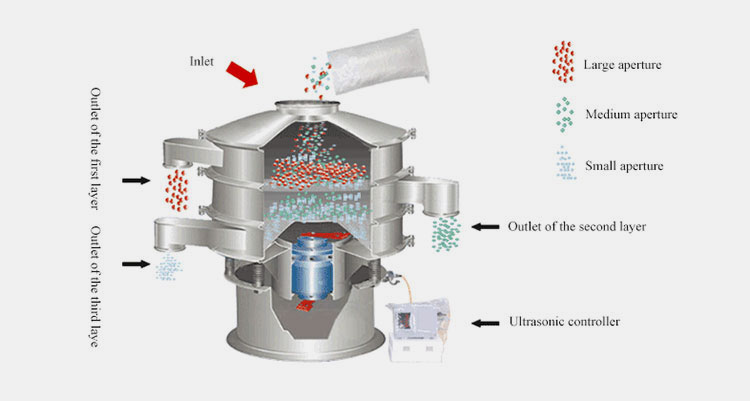

Ultrasonic Sifter

Ultrasonic Sifter- Picture Courtesy: sieving machine

It harnesses the power of ultrasonic waves for sieving and screening the particles. The screen mesh vibrates using ultrasonic waves and this vibration can go to a maximum level of 36,000 times per second, leading to the formation of a micro-suspension of fine particles on the sieve.

The objective of the ultrasonic sifter is to avert the clogging risk, boosting efficient particle separation. It can screen particles up to 4um efficiently. High-frequency ultrasonic waves are conveyed across the screen and affect the cohesive forces binding the particles, causing their de-agglomeration. These disbanded particles penetrate the mesh screen easily.

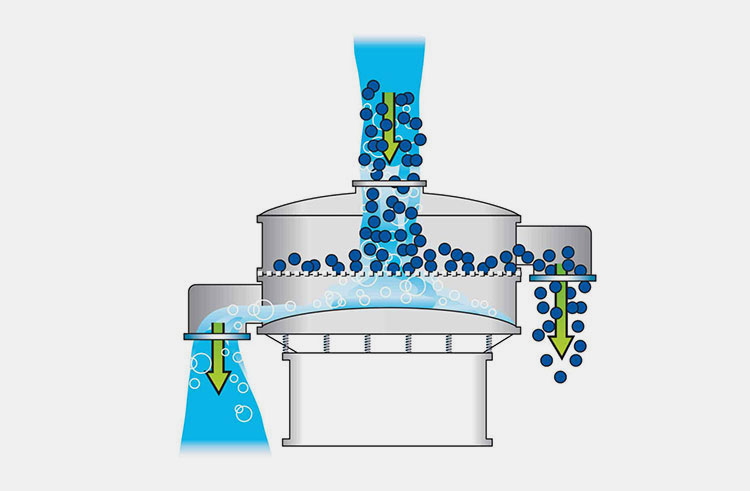

Wet Sifter

Wet Sifter- Picture Courtesy: Elcan Industries

In this type of sifter equipment in the pharmaceutical industry, feed is sorted with the use of water and other liquids. This sifting instrument is generally suited to raw materials with sticky and cohesive characteristics. It treats materials that have trouble in screening with dry sifting techniques.

The water or other appropriate liquids are normally mixed in the starting material before the sifting process. These liquids facilitate the dispersal of samples and minimize clogging. Afterward, wet feed moves through the mesh screen, causing undersized particles to enter through the aperture of the mesh.

This sifting equipment also acts as a washing instrument, eliminating the impurities from the sample.

Static Sifter

Static Sifter- Picture Courtesy: Kason

It is also named a static sieve separator. Static sifter is favored in smaller-scale industries, laboratories, and quality check processes. It has a simple design and is easy to use.

Unlike the other sifting instruments in the pharmaceutical industry, which rapidly shake or rotate particles for sorting, a static sifter uses simple gravitational force along with a static mesh screen to vet particles depending upon their size.

The screening mesh is stationary in the static sifter and only the force of gravity and natural particle flow lead to the penetration of particles through the holes of the mesh.

Types of Sifters Based on Mode of Design

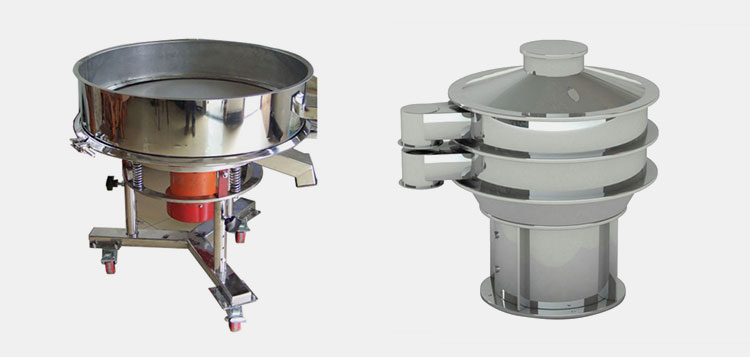

Circular Sifter

Allpack Circular Sifter

This equipment is also regarded as a circular screen separator. It is frequently employed in different industries for material separation. It has a specialized design with a circular screen mesh. The circular sifters utilize circular vibration, produced via motors or electromagnetic vibrators.

The materials are introduced into the center of the screen and because of the oscillation of the screen, they disperse along the entire area of the screen. The vibratory motion promotes effective separation, grading, and de-watering. With a circular design, it is convenient to access, maintain, and clean the equipment. Furthermore, circular sifter has smaller footprints than other types of sifters.

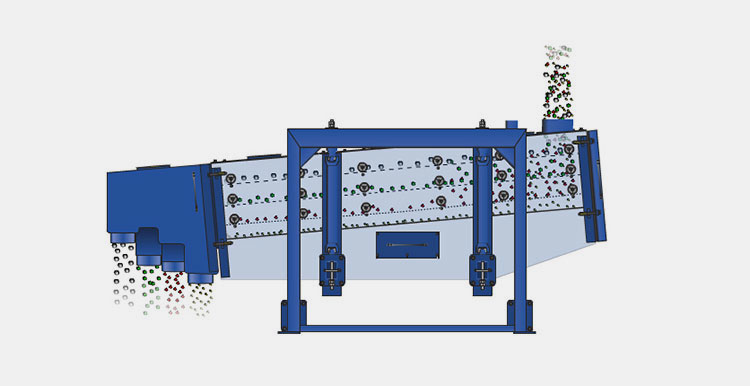

Rectangular Sifter

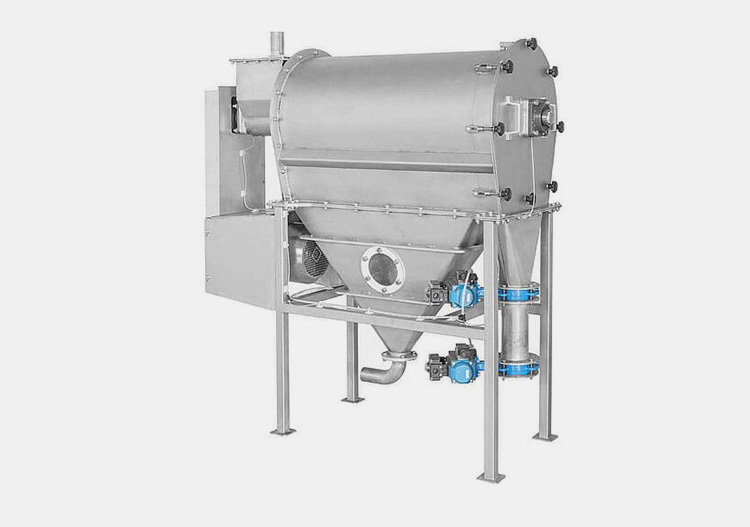

Allpack Rectangular Sifter

In contrast to circular sifters in the pharmaceutical industry, the distinguishing feature of a rectangular sifter is that it is designed with a rectangular or linear mesh screen. This sieve offers more surface area for high-capacity and high-volume operativity. It is also termed a rectangular screener or rectangular separator

These types of sifters usually employ a linear, circular, or gyratory vibratory motion for sorting and classification of various pharmaceutical compounds. Similar to circular sifters, a rectangular sifter is manufactured with numerous stacking screens or decks, which allows finer separation of particles. These screens have different mesh sizes, which leads to grading of different size fractions in the single go.

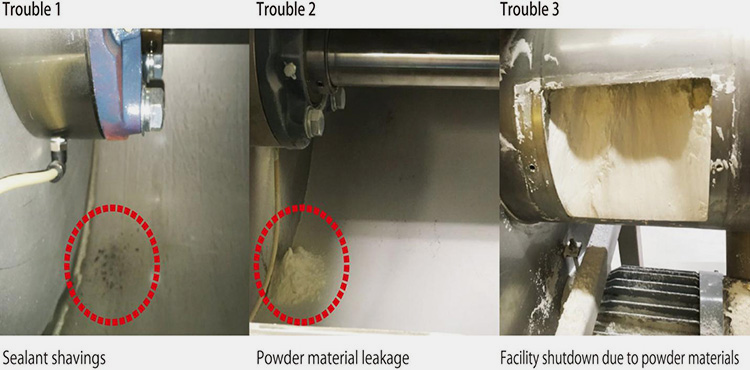

5.What are the Frequent Challenges Encountered During Sifting Process in the Pharmaceutical Industry?

The sifting process in the pharmaceutical industry, is the fundamental method, establishing and fulfilling size demands of pharmaceutical powders and granules. However, several challenges are associated with the sifting process, impacting the speed, excellence, and safety of the end product.

Some widespread challenges encountered during the sifting process in the pharmaceutical industry are stated below:

Binding and Clogging

Binding and Clogging- Picture Courtesy: Delite Industries

Sticky or ultra-refined particles present a challenge in the sifting process, as they result in screen binding. This occurs when particles form lumps causing clogging of mesh and preventing the passing of particles. This affects the process efficiency and leads to inconsistent separation of particles.

Solution

This problem is avoided by using an ultrasonic or air jet sifter that uses ultrasonic waves and compressed air, respectively to dislodge particles from each other. Moreover, regular cleaning can eliminate accumulated material. This issue is also prevented by using mesh screens impervious to clogging.

Cross-Contamination

Cross-Contamination of Product

When the sifting process is performed in the pharmaceutical industry, an issue of cross-contamination also arises, leading to poor efficacy and safety of the end product. Broken screen wires, airborne particles, dust, and other foreign objects may contaminate the feed.

Solution

Nevertheless, this issue can be easily resolved with regular cleaning of the sifting area. Implementing a closed sifting system with dust-tight enclosures prevents contamination chances. Routine inspection of the sifting equipment also aids in averting contamination.

Electro-static Charges Accumulation

Electro-static Charges Accumulation- Picture Courtesy: DAHAN Vibration Machinery

Often ultra-fine materials produce electrostatic charges during the process of sifting in the pharmaceutical industry, which tends to cause the stickiness of feed to the walls of the sifter and with each other. It is the reason for product loss and non-uniform flow.

Solution

By equipping the sifter with anti-static sieves or liners, the generation of static charges is prevented. The charges are dissipated with accurate grounding of equipment. Furthermore, creating controlled humidity surroundings also decreases static electricity.

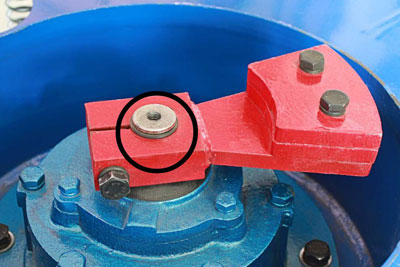

Screen Damage

Sieves or screens undergo regular processing, consequently leading to their wear and tear. This damage is more evident when handling abrasive materials. Screen wear and tear often initiate product quality errors.

Solution

Choose screens manufactured with durable materials, for instance, stainless steel or other alloy to improve the 9screen's operational life. Besides this, regular checking of the sifter instrument often detects early wear and tear, resulting in the replacement of screens before their extensive degradation.

Conclusion

When creating formulations or other solid and liquid preparations, the sifting process in the pharmaceutical industry has immense significance. It is the dream of every manufacturer to attain increased product yields with zero contamination and consistent particle sizes. So, the sifting process for particle separation has been in use since the old times. Currently, an automatic and efficient sifter is designed to boost the sifting process efficiency. Are you preparing to buy a sifter? Then contact the world's best manufacturer- Allpack. We are a one-stop platform, offering top-notch sifters and sieves. Discuss your requirements with us through our contact services.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide

What Is The Sifting Process In Pharmaceutical Industry? Read More »

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours