V Blender Dry Powder Mixer: The Complete Buying Guide in 2024

Do you know that homogenous mixing is crucial in compounding formulation? A perfect blend of dry powders is achieved using a V-blender dry powder mixer. Blending is a pivotal step in product manufacture in any industry whether pharmaceutical, cosmetic, chemical or food, so v blender dry powder mixer is integral equipment that cannot be omitted in any production line.

Planning to invest in this handy device and look for resources to improve your knowledge before purchase then this blog is just the place for you. In this guide, advantages, parts, classification, working, problems, and many more will be discussed about v blender dry powder mixer.

Let’s get started.

1.What is Meant by V Blender Dry Powder Mixer?

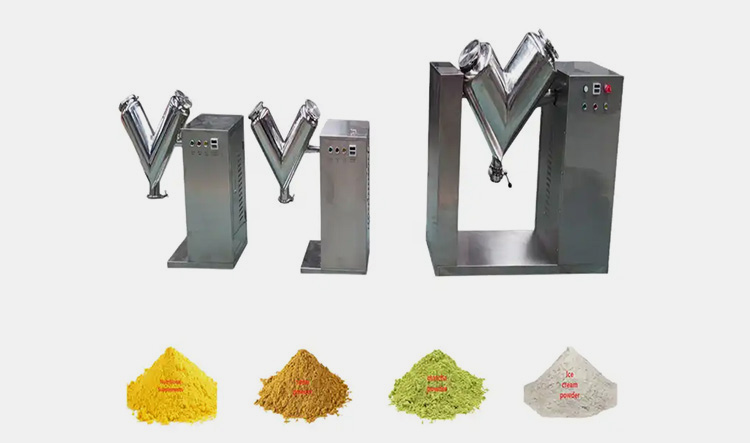

V Blender Dry Powder Mixer

Its name is derived from its V-shape construction. It is also called Twin Shell Blender because of its two hollow enclosures. It comes from the family of tumbling blenders and other blenders in this family are double cone and slant cone blender.

V blender dry powder mixer is one of the most efficient and popular machines for smooth and precise mixing of dry powders and even liquids. This blender offers a uniform blend of solid particles both in granular and ground states as well as pellets.

However, because of the low shearing forces developed in it, the V blender dry powder mixer is not employed for blending soft granules.

2.What are the Significant Benefits of V Blender Dry Powder Mixer?

The significance of blenders cannot be ignored in industries particularly, those involved blending of components. V blender dry powder mixer is a perfect example of a blender that provides gentle mixing and in turn, generates heavy revenue for the businesses.

Some significant benefits of V blender dry powder mixer are:

Accurate and Precise Blending

Accurate and Precise Blending- Picture Courtesy: SPX Flow

V blender dry powder mixer is perfect for consistent and gentle blending tasks with a high percentage of precision. There are minute batch variations of less than 2% providing, reliable and accurate blending fractions every time. It is tiny quantities of trace constituents using this machine.

Size Reduction

Size Reduction- Picture Courtesy: BulkInside

Various blenders and mixers have agitators that are employed to reduce the size of powders and granules. But V blender dry powder mixer is perfect for applications that do not need size reduction.

It is because the substance flows in the hollow space where there is no chopper fitted, thus, this machine is best for blending brittle substances.

Versatility

Versatility of V blender dry powder mixer- Picture Courtesy: amixon GmBH

V blender dry powder mixer is not only great for blending granular and dry powders but it is also adopted in industries for blending fragile substances without changing their structural integrity. It is possible because of its low-impact shearing forces.

In addition to solid materials, it can also blend viscous liquid with ease due to its simple construction.

Simple Maintenance and Cleaning

Simple Maintenance and Cleaning- Picture Courtesy: International Products Corporation

Because of its minimal design, the V blender dry powder mixer does not demand strenuous and laborious maintenance and cleaning. Furthermore, it does not have long downtimes more often. With simple routine maintenance, it can last long and serve a blending purpose.

Moreover, there is little or low dust generation in this blender which also makes cleaning job easier.

Convenience in Operation

Convenience in Operation- Picture Courtesy: ProChem GmBH

V blender dry powder mixer has an inverter motor, brake, and VFD that offer speed controls and prevent overloading of equipment. It is operated by a PLC control panel equipped with various power buttons for regulating the working of every component.

Optional data recipes are also stored in a machine processor to allow extreme batch-to-batch uniformity and swift processing.

3.Where is the V Blender Dry Powder Mixer Used in Industries?

A blending of solid and liquid ingredients is a step performed in every industry and this step is executed in various businesses owing to the presence of a V blender dry powder mixer. Some of the industrial uses of V blender dry powder mixer are:

Pharmaceutical Industry

Use of V Blender Dry Powder Mixer In Pharmaceutical Industry

Uniform blending of active pharmaceutical ingredients is important in the pharmaceutical industry to ensure the constituency of drugs in every medication.

Therefore, the V blender dry powder mixer is an essential part of the pharmaceutical industry as it accomplishes even blending and reduces segregation of the powders. It is utilized before the granulation step in pill manufacturing.

Food Industry

Use of V Blender Dry Powder Mixer In Food Industry

V blender dry powder mixer is valuable in the food industry for the gentle mixing of dry flavours and baby food. Moreover, it is also employed in the homogenous blending of spices, milk powders, and coffee blends. It is also used in formulating cereals, herb blends to bring out the essence of various culinary dishes.

Cosmetic Industry

Use of V Blender Dry Powder Mixer In Cosmetic Industry

In the cosmetic industry, various delicate powders are processed, consequently, V blender dry powder mixer is popular for handling fragile cosmetic powder. This machine formulates even distribution of various cosmetic powders by blending melted wax, oils, and pigments, for instance, face blushes, eye shadows, shimmers, lipsticks, hair dyes, etc.

Paint Industry

Use of V Blender Dry Powder Mixer In Paint Industry

This industry is one of the biggest users of the V blender dry powder mixer. In this machine, multi-coloured pigments are blended with solvents to form an emulsion. It is favoured by the paint industry because of its low shear mixing that allows it to achieve flawless cohesivity of paints.

Agriculture Industry

Use of V Blender Dry Powder Mixer In Agriculture Industry

Yes, the V blender dry powder mixer is also adopted by the agriculture industry to create a seamless blend of powders and granules,which is an important step in manufacturing animal feed, fertilizers, herbicides, and pesticides.

Construction Industry

Use of V Blender Dry Powder Mixer In Construction Industry- Picture Courtesy: Kennametal

In the construction industry, V blender dry powder mixer has different applications. It is employed for consistently blending pigments, fibres, and, powders to prepare additives, modifiers, protective coatings, grouts, cement mixture, and concrete.

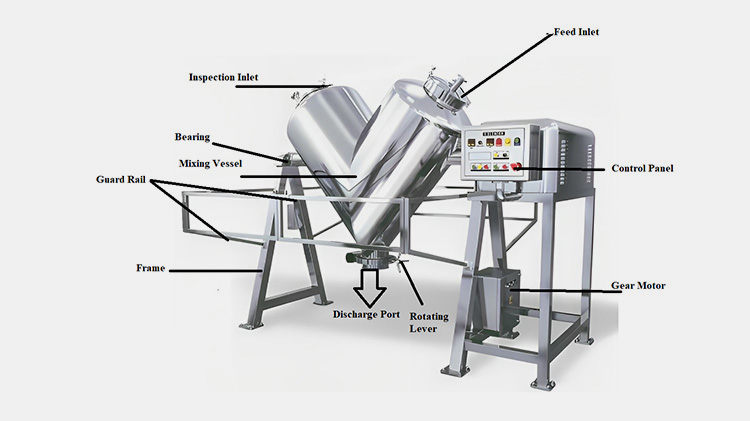

4.What are the Primary Parts of the V Blender Dry Powder Mixer?

This machine is composed of two hollow chambers that are fused with an angle of 80° to create a V shape. Some of its primary parts are:

Parts of V Blender Dry Powder Mixer

| Inspection Inlet | It is an inlet that allows operators to access, inspect, maintain, and, clean the main mixing vessel. It is closed by a cover. |

| Feed Inlet | The starting materials for blending are introduced through this port inside the V blender dry powder mixer. The materials are either loaded manually by the operators or through pipes connected to the feed inlet. |

| Bearing | The bearing has a vital role in supporting the shaft of the machine. They are fixed on the sides of the frame and aid in the uniform rotation of the V blender dry powder mixer. |

| Mixing Vessel | It is the central part of the machine where the actual blending process takes place. With the rotation of the mixing vessel, tumbling and falling of feed occur, which results in blending. |

| Control Panel | It is the core programming centre of the V blender dry powder mixer and it is essential in the right working of the system. It has different buttons and sensors that control the blending operation. |

| Guard Rail | The system is designed with a guard rail that is integral in providing electrical safety to the operator and it reduces the operator's access to the main machine while it is running. |

| Frame | It is the main foundation of the V blender dry powder mixer that provides support and reinforcement to the main mixing vessel during rotation. |

| Rotating Lever | It is present at the side of the discharge port and is rotated for opening and closing the butterfly valve in the discharge port. |

| Discharge Port | It is located at the lower end of the V-shaped mixing vessel where two cylinders are fused. It is a butterfly valve that is either opened using a rotating lever or by using an automatic pneumatic system. This is the main outlet from where blended substances are removed from the machine. The butterfly valve in the discharge port lowers the wastage of the final product. |

| Gear Motor | It is usually present in lateral support. Gear motors are powered by electricity which in turn mechanize the mixing vessels and baffles. |

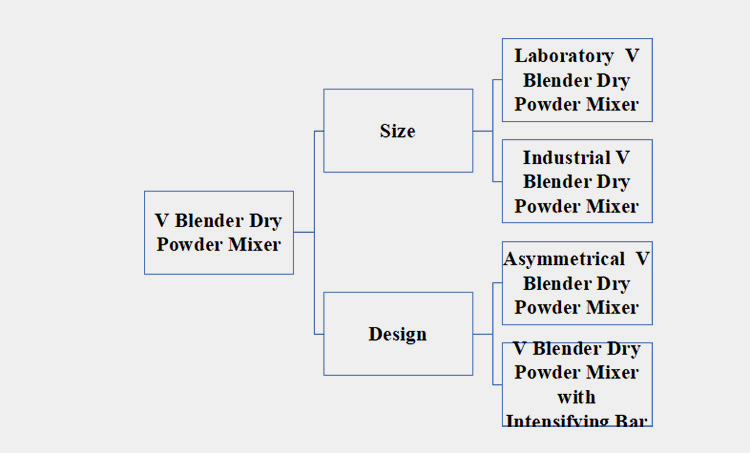

5.Do you Know About the Classification of V Blender Dry Powder Mixer?

V blender dry powder mixer is categorized into basic types depending upon their size and design. This classification is discussed below:

According to Size

There are two kinds of V blender dry powder mixers according to size.

Laboratory V Blender Dry Powder Mixer

Laboratory V Blender Dry Powder Mixer

It is a small-sized V blender dry powder mixer, mostly employed in small industrial settings and research laboratories for product preparation. It is fabricated in various sizes that are in the range of from 5 litres to 1 cubic foot.

Laboratory V blender dry powder mixer is created using stainless steel therefore, it has a durable and hygienic design. It processes small batches and its working volume is low. But this machine has ease of maintenance and cleaning.

Industrial V Blender Dry Powder Mixer

Industrial V Blender Dry Powder Mixer- Picture Courtesy: Proton Engineers

As the name suggests, it is a part of routine operation in large-scale industries because it has a higher working volume and is suitable for blending materials with bulk densities of about 150 lbs/cu.ft, whereas, some heavy-duty industrial V blender dry powder mixers can blend highly dense powders with a density of 900 lbs/cu.ft. or more.

It has the same design construction as its smaller counterpart but has higher productivity.

According to Design

Asymmetrical V Blender Dry Powder Mixer

Asymmetrical V Blender Dry Powder Mixer- Picture Courtesy: Lanka.Tax

This type of V blender dry powder mixer has an asymmetrical design because there is a difference in the length of the two shell containers. This construction allows fluidity of the powders which aids in reducing segregation, consequently decreasing mixing time.

Baffles in the main mixing vessels help to achieve design asymmetry but this configuration does not have ease of accessing a machine

V Blender Dry Powder Mixer with Intensifying Bar

V Blender Dry Powder Mixer with Intensifying Bar- Picture Courtesy: PreMix

Often the V blender dry powder mixer is modified by adding an intensifying bar or agitator to accomplish a high shearing rate. When this intensifying bar rotates at higher velocities, it creates a high shear force that in turn increases the blending feat. It is especially important when processing cohesive powders.

Moreover, this high shearing force breaks the agglomerated particles and this type of V blender dry powder mixer is used during wet mixing.

6.How Does a V Blender Dry Powder Mixer Work?

To maintain and troubleshoot the V blender dry powder mixer, it is imperative to understand how it works. Here are some basic working steps of this equipment.

Loading

Material Loading- Picture Courtesy: Hayward Gordon

At first, by the operators or by feed pumps, starting materials are fed into a V blender dry powder mixer through the feeding apertures or ports, located at the top of the equipment. It is recommended to load the machine about 50-60% of its total working volume to attain blending in a short time.

Blending

Blending of Dry Powders- Picture Courtesy: BulkInside

Upon filling the materials, the V blender dry powder mixer starts operating. This machine rotates at 360° to blend the ingredients by breaking and amalgamating them. With each rotation, the ingredients flow to the central point and then shift away from the centre.

This random motion and high friction between particles and walls of equipment create a consistent yet gentle blend.

Unloading

Product Discharge- Picture Courtesy: SPX Flow

After blending, the blended mixture is unloaded from the port having a butterfly valve. This valve is sealed but it is opened manually using a hand lever or automatically through a pneumatic system when product removal is required.

7.How are V Blender Dry Powder Mixer and Octagonal Mixer Different from Each other?

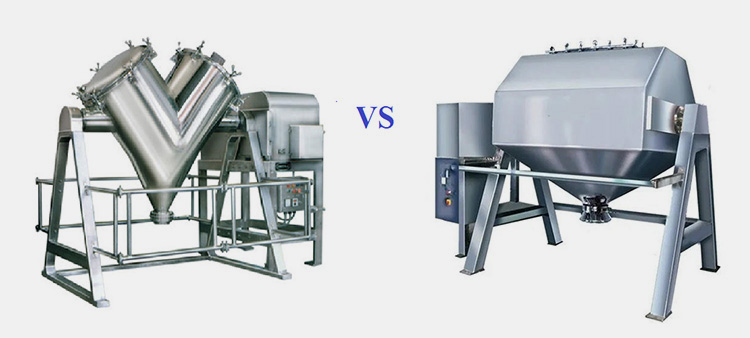

Difference Between V Blender Dry Powder Mixer and Octagonal Mixer

Both these machines are utilized for blending dry powders, but there are some notable differences in their design configuration and operations. These differences are discussed in detail below:

| Feature | V Blender Dry Powder Mixer | Octagonal Mixer |

| Design Construction | The main vessel has a V-shaped design where two shells are joined at 70-120°. | The main vessel is an octagonal-shaped container supported at two ends. |

| Blending | It is rotated at a significantly higher speed than an octagonal blender, therefore, creating tumbling and cascading of ingredients, consequently decreasing the blending time. | It is rotated at the slower velocities and thus has a gentle blending action. The mixing time is lengthy as compared to a V blender dry powder mixer. |

| Shearing Force | High shearing forces are developed in this type of V blender dry powder mixer, consequently, it separates agglomerates. | Gentle mixing creates low shearing forces thus, it is ideal for sensitive powders and can maintain integrity. |

| Loading and Discharging of Materials | V blender dry powder mixer is loaded and discharged from two separate ends. | An octagonal mixer is tilted for loading and unloading materials from the machine. |

| Footprint | It has a larger footprint. | It has a smaller footprint. |

| Ease of Cleaning | Some models of V blender dry powder mixers are equipped with baffles and, therefore are difficult to clean. | It has a straightforward configuration and, hence, is cleaned more easily. |

| Energy Consumption | It is operated at higher velocities; therefore, it uses more power. | As the speed of rotation is low in the octagonal mixer, so, it consumes less power. |

8.What is the Difference between V Blender Dry Powder Mixer and Ribbon Blender?

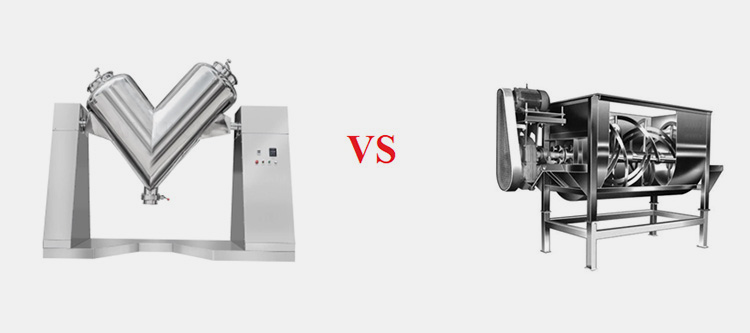

Difference Between V Blender Dry Powder Mixer and Ribbon Blender

Both these machines are commonly employed in the industries for blending and mixing diverse granular and powdery products. However, these machines vastly differ from each other based on configuration and operation.

Here are some important differences between the V blender dry powder mixer and ribbon blender.

| Feature | V Blender Dry Powder Mixer | Ribbon Blender |

| Design Structure | It is shaped like the letter V because of its two shells that join angularly with each other. | This blender has a U-shaped vessel in which a shaft is fixed at the centre for mixing. |

| Blending Operation | The blending typically occurs due to the rotation of a mixing vessel. | The blending action is mainly performed by the helical ribbons that lift and drop the powders. |

| Charging and Discharging of Materials | The materials and products are charged and discharged from the top and bottom ends, respectively. | Ribbon blenders typically have a top-loading construction for loading materials, there is a bottom discharge port in some types of ribbon blenders. |

| Powder Contact | Powders are not in direct contact with the walls of the vessel, which decreases the rate of product sticking on the walls. | The starting feed is in direct contact with the ribbon helical structure which could lead to material fatigue. |

| Space Requirement | It needs more space due to its larger footprint. | It has a compact construction and thus requires smaller room for installation. |

| Ease of Cleaning | Due to their straightforward construction, this machine can be easily cleaned. | It has complicated ribbon construction, thus is difficult to clean the ribbon blender. |

9.What is the Speed of a V Blender Dry Powder Mixer?

Powder Blending- Picture Courtesy: amixon GmBH

The V blender dry powder mixer with a working capacity of 500-2000 litres has a blending speed of about 10 to 25 RPM (revolutions per minute). This speed is in the medium range and thus, V blender dry powder mixer is best for products that are required to be processed at low temperatures.

The blending speed impacts the quality of blending in the V blender dry powder mixer. There is a critical speed for this machine at which it has a lower mixing rate. The normal mixing cycle is completed in about 15 minutes.

10.What are the Quality Certifications of the V Blender Dry Powder Mixer?

V blender dry powder mixer should abide by different quality certifications to ensure the quality of products, the safety of operators and the environment. These are some important quality certifications of V blender dry powder mixer:

cGMP

cGMP- Picture Courtesy: GMP Labs

It stands for current good manufacturing practices and is a must in the food and pharmaceutical industries. This certification ascertains that the V blender dry powder mixer is manufactured with clean practices and has a hygienic design to avoid cross-contamination of products. cGMP ensures that blended product is safe for human consumption and the environment.

FDA

FDA- Picture Courtesy: BioWorld

This certification is standardized all across the globe, especially in the United States. It tells that the V blender dry powder mixer fully complies with regulations and safety guidelines imposed by the Food and Drug Authority. This means that products do not pose risk to humans.

ISO

ISO

It is an international manufacturing quality standard like ISO 9001. This states that manufacturers of V blender dry powder mixers are committed to improving their quality standards and following quality management protocols set by the International Organization for Standardization.

ATEX

ATEX- Picture Courtesy: Atexindustries

It is necessary to have ATmosphères EXplosibles certification when a V blender dry powder mixer is intended for blending explosive substances. This certification ascertains that the machine has design features and safety systems to prevent the explosion and ignition of volatile materials.

HACCP

HACCP- Picture Courtesy: FESSMANN

This certification is mostly used for food industries. It ensures food safety by preventing access to biological, chemical, or physical agents in the V blender dry powder mixer that could risk the safety of food products. V blender dry powder mixer with Hazard Analysis and Critical Control Points certification ascertains hazard-free manufacturing and distribution of end-products.

11.How to Maintain a V Blender Dry Powder Mixer?

Maintaining V Blender Dry Powder Mixer

Regular maintenance ensures high productivity, lower machine wear and tear, decreased downtimes and the safety of operators. Some tips for maintaining a V blender dry powder mixer are discussed below:

| Daily Maintenance | Regularly clean the machine after every shift to avoid product buildup and to reduce cross-contamination.

Wipe regularly the external frame and support system of the V blender dry powder mixer with a clean and wet cloth. Tighten any loose screws and nuts. |

| Weekly Maintenance | Oil and lubricate the bearings and other moving parts.

Check and correct the alignment of drive systems like drive belts and motors. |

| Monthly Maintenance | Calibrate the sensors and alarms of the machine.

Check for defects in the interior of the machine and its shafts. Inspect the operability of safety features like gaskets, seals, and interlocks. Examine the electric components like cables, breakers, and safety switches for wear and tear. |

| Yearly Maintenance | Replace the bearing of the machine.

Change the old agitators and shafts of the equipment as per instructions of the manufacturers. Conduct a detailed examination of the V blender dry powder mixer to ensure the perfect working order of every component and to ascertain the stability of the system. |

12.What are Common Problems and their Remedies for V Blender Dry Powder Mixer?

With time, certain issues may arise in the V blender dry powder mixer that lead to prolonged machine failure and high profit loss. But with proper maintenance and troubleshooting, these problems are easily remedied.

Here is a list of some common problems and their remedies for V blender dry powder mixer:

| Cause | Remedy | Image |

| Material Degradation | ||

| Incorrect mixing parameters

High rotational speed of mixing vessel Incompatibility between machine design and properties of starting material Application of intensifying bar at extreme rotational speed |

Change the mixing process settings

Decrease the rotational speed Consider altering the design of the machine Reduce rotational velocity or do not employ an intensifying bar if not needed |

Material Degradation- Picture Courtesy: Manufacturing Chemist |

| Abnormal Vibrations in the Machine | ||

| Misalignment of components

Old and defective bearings High material load in the mixing vessel Defective drive system or motor |

Properly align the skewed components

Change the old bearings Reduce the material amount in the mixing vessel Address mechanical problems in the drive system and motor and if required replace them |

Abnormal Vibrations in the Machine- Picture Courtesy: AVEKA |

| Stickiness of Blended Powders on Walls | ||

| Inadequate movement of materials can cause sticking

Poor cleaning schedule Unsatisfactory design of mixing vessel |

Optimize the fluidity of powders

Implement a proper cleaning schedule Consider altering the construction of the mixing vessel |

Stickiness of Blended Powders on Walls- Picture Courtesy: HAL |

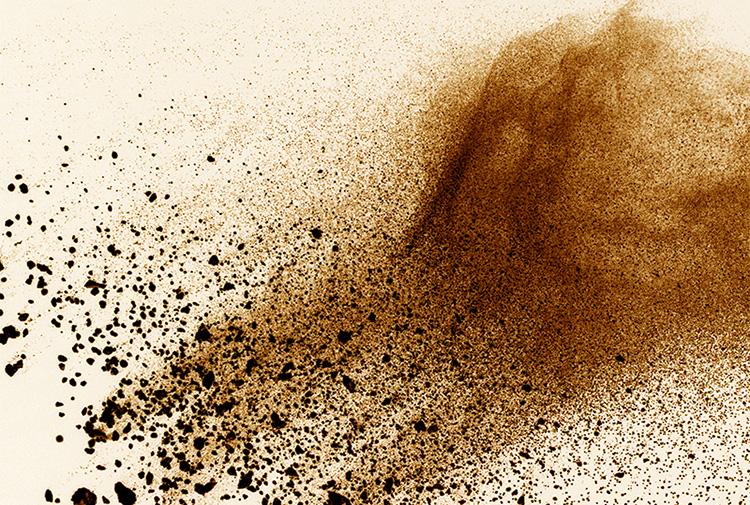

| Powders Segregation During Blending | ||

| Variations in powder particle sizes and their densities

Incorrect filling sequence Insufficient blending duration |

Use powders with uniform particle sizes and densities

Employ the correct loading sequence Change the blending time duration |

Powders Segregation During Blending- Picture Courtesy: Stellar Manufacturing |

| Inadequate Mixing of Materials | ||

| Inaccurate rotational speed of mixing vessel

Poor loading sequence Inadequate blending duration |

Adjust the rotational speed of the mixing vessel to ensure adequate blending

Change the loading order of materials Adjust the blend time |

Inadequate Mixing of Materials- Picture Courtesy: Alpha Chemical Services |

Conclusion

Today, the market for a V blender dry powder mixer is expanding at a much faster rate. This high growth is due to the high demand for uniform and hygienic mixing results of the V blender dry powder mixer. It is routinely seen in diverse industries because it generates seamless blends at lower costs, consequently making high revenue for businesses. Now are you looking to add this outclass equipment to your manufacturing unit then message us with all your machine details and we will find a perfect V blender dry powder mixer for you.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide