Vacuum Packed VS Nitrogen Flushed: Which Is Better?

For the past few decades, many industries have been manufacturing high volume products and shipping it all around the world. These products have to go through the manufacturing process, packaging process and finally transported to their final destination. These products need strong and durable protection to prevent their interaction with external factors such as oxygen, moisture, dust, sunlight and other harmful pollutants. For this reason, there are two popular methods used to seal these products which ensures their safe and secure transportation. These are vacuum packaging and nitrogen flushing.

What is the difference between vacuum packaging and nitrogen flushing? What are their unique features which makes them different from each other? Which is more economical? Does one of them have certain qualities which makes it better than the latter? To answer these questions, let us discuss in detail which type of packaging prevails over the other.

1.What is vacuum packaging?

Vacuum packaging is a method which is used to seal products such as food items, pharmaceutical drugs, chemical products in a hermetic seal to protect them. This process is extremely important since it provides protection against any harmful factors.

These factors include oxygen which can serve as breeding ground for fungi and bacteria to grow, thus spoiling the products. Moreover, dust, moisture and other pollutants can damage these products as well since their interaction with them can chemically degrade these products, making them unusable.

Vacuum packaging is a popular method to increase the shelf life of your products. It uses plastic bags, jars, containers and bottles to package these items in a vacuum like environment.

2.What is nitrogen flushing?

Nitrogen flushing, like vacuum packaging, is a method which is used to seal and package many industrial goods such as pharmaceutical medicines, chemical products, food items etc. this method uses nitrogen gas which replaces oxygen to increase the shelf life of the products and prevent them from decaying. Since nitrogen gas is heavier than oxygen, it can easily replace it and take its place.

Nitrogen flushing too is a popular method which provides a strong and safe packaging to the products. It forms a protective barrier between the product and the harmful factors such as oxygen, air, dust and moisture which can degrade it and make it unusable.

3.What arethe differences between vacuum packaging and nitrogen flushing when it comes to?

1)Working principle

In vacuum packaging, the container is filled with the desired product. After that, the air inside the container is sucked out, making the environment inside vacuum like. Immediately after this, the container is sealed to prevent the oxygen from rushing inside. As a result, no oxygen is left inside the container, making the environment inside completely non-reactive.

However in nitrogen flushing, when the container is filled with the desired product inside, the oxygen inside the container is replaced by nitrogen gas. Since the nitrogen gas is heavier than oxygen, it easily replaces it. Moreover, nitrogen is an inert gas, that is, it is non-reactive and would be unable to interact with the product inside.

Thus in vacuum packaging, all the gases inside the container are sucked out, leaving only vacuum like environment behind. However in nitrogen flushing, one gas is being replaced with another gas. Moreover, in vacuum packaging, there are no traces of oxygen left inside but in nitrogen flushing, you can find minute quantities of oxygen inside, thus making it possible to interact with the product.

2)Structure

a)The main structure of vacuum packaging machine is as follows:

- Stainless steel: this is the main body of the machine which contains all the parts and is resistant to corrosion.

- Vacuum chamber: this is the main compartment where the air is sucked out. A vacuum like environment is made where the package is then sealed.

- Connecting rod: it connects all the components of the machine.

- Silicone strips: these strips are replaceable and are important for the vacuum sealing process.

- Chamber lid: this is the part which closes the top part of the machine. It can either be operated manually or work on its own.

- Control panel:this is where all the parameters of the machine can be adjusted such as the speed, time, temperature etc.

- Handles:as the name suggests, it assists in opening or closing the chamber lid.

- Wheels with brakes and anchor bolts:these wheels help in moving the machine from one place to another.

- Emergency stop button:this button is used in emergency situation when the process needs to be stopped immediately.

b)The main structure of nitrogen flushing machine differs from vacuum packaging machine

- Electric motor:this is the main power supply of this machine. Without this, we will not be able to initiate the nitrogen flushing process.

- Silicon wheel:this wheel applies pressure on the bag to keep it intact after it has been sealed off using heat.

- Rubber roller:this roller applies pressure on the bag as well to form a hermetic seal.

- PVC chain roller:this is used to rotate the roller shafts.

- Conveyor belt:this belt is automated which is responsible for transporting the sealed bag from one part of the machine to the other.

- Gas flushing device: this device is responsible for replacing oxygen inside the chamber with nitrogen gas continuously until the oxygen is removed completely, making the environment inside non-reactive with the package material.

- Potentiometer:potentiometer determines the potential difference between two terminals, thus it is used to adjust the speed of the motor.

- Control panel:it contains all the parameters of the machine and is used to adjust them accordingly for the optimization of the sealing process.

- Thermo-couple wire:this wire senses the change in temperature.

3)Advantages

a)The advantages of using vacuum packaging are:

- Increased shelf life

By eliminating oxygen from the bag and creating a vacuum like environment inside, it prevents the degradation of the contents and thus increases the shelf life of the product.

- Less space requirement

Unlike nitrogen flushing, vacuum packaging creates more space by eliminating the space required for the gas inside the bag. Hence, more products can be stacked together in your pantry or cabinet.

- Enhances the flavor of food

Vacuum packaging is great for improving the flavor of food items like meat, chicken and seafood. This can be done by marinating them and placing them in vacuum packaging.

- Prevention of freezer burn

The food item inside the packaging is protected from freezer burn since the vacuum like environment inside the package prevents the interaction of the air with the contents inside. This ensures the freshness of the food and maintains the texture and flavor.

- Elimination of air completely

Unlike nitrogen flushing in which a small amount of air still remains inside the bag, the vacuum sealing process completely eliminates the oxygen inside, thus ensuring complete protection of the product.

b)The advantages of using nitrogen flushing are:

- Provides cushion to delicate items

One of the best advantages of nitrogen flushing is that it provides protection to delicate items like chips and snacks which can get damaged during the transportation and shipping process.

- Saves money

Instead of buying nitrogen cylinders from the market, installing nitrogen producing generators can save huge sums of money since it can constantly generate nitrogen gas to sealing.

4)Disadvantages

a)The disadvantages of vacuum packaging are:

- Extra tools are required for the packaging process

Extra tools are needed such as rollers, cutters, external hoses which increase the initial cost of investing in the vacuum packaging machine.

- Unable to protect delicate items

Vacuum packaging is suitable for sturdy items like agriculture, pharmaceutical and food items like meat, chicken and fish. However, it would be unable to protect items like snacks and candies which would get damaged during the shipping and transportation process.

b)The disadvantages of nitrogen flushing are:

- Inability to detect any leakage

Since nitrogen gas is colorless and odorless, any leakage of it from the bag would go undetected. As a result, oxygen from the air will rush inside the bag, spoiling the contents inside.

6)Applications

a)The applications of vacuum packaging are:

- Pharmaceutical industry

This industry is involved in the production of medicinal drugs and medicines. These medicines are highly vulnerable to any damage caused by oxygen, moisture and other harmful pollutants. Placing these items in vacuum sealed bags will ensure their efficacy and potency and protect them from losing their effectiveness.

- Food industry

Many food items like beef, mutton, fish and chicken require safe packaging to ensure that they do not react with moisture or oxygen in order to maintain their freshness. Vacuum packaging would be the perfect option to safely package these items.

- Agriculture industry

This industry is involved in a variety of products such as rice, wheat, grains, making of cereals etc. these products are packaged by the vacuum sealing process to ensure their maximum protection.

- Chemical industry

Many chemical products such as solvents, inks, dyes and paints are highly vulnerable and can chemically degrade if they come into contact with air, moisture, dust or other pollutants. Thus vacuum packaging keeps these harmful factors away from them, ensuring their safe and secure shipping.

b)The applications of nitrogen flushing are:

- Food industry

Nitrogen flushing is primarily used for food items unlike vacuum packaging which can used in a variety of industries. It is great for packaging delicate food items like chips, cakes and candies since it provides cushion to these products during their shipping.

- Beverage industry

Nitrogen flushing is growing quite popular among industries who are making coffee products, drinks and beers. This provides prevent these drinks from getting contaminated and gives them the opportunity to maintain their flavor and texture.

4.Which equipmentare used for vacuum packaging?

When it comes to vacuum packaging, there are some types available which provide different features for vacuum packaging process. They have their own unique qualities. Let us discuss each of this type below.

a)Single chamber vacuum packaging machine

This machine consists of a single chamber, as the name suggests which is used to seal bags or pouches. It is ideal for small sized packets since it only contains one chamber. Thus it is a perfect option for small scale businesses and factories which manufacture small volume products daily.

Its portability, low cost price and easy to use features make it convenient for anyone to install it in his production line. It can package various items like candies, chocolates, medicines etc.

b)Double chamber vacuum packaging machine

This machine, as the name suggests, contains two chambers which provide huge space for medium and large sized pouches or bag to get sealed by the vacuum sealing process.

This makes it an ideal option to use in large scale industries and factories where there is a huge demand for a high speed machine which has the ability to seal thousands of products in a single day.

c)Rotary belt vacuum packaging machine

Rotary belt vacuum packaging machine contains a belt which rotates. This machine works almost exactly like the double chamber vacuum machine. The only difference is that in rotary belt vacuum machine, when the bag or the pouch is placed on the machine to get sealed, the belt rotates automatically until the sealing process is completed.

After this process, the sealed bags or pouches are unloaded automatically without any human interference.Due to this, the whole process takes place very conveniently at a quicker rate than the other machines.

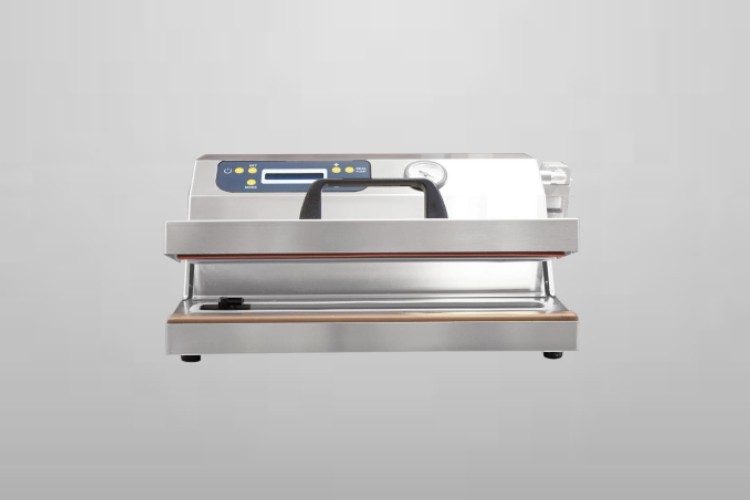

d)External vacuum sealing machine

In this machine, the bag or the pouch which needs to be sealed is attached outside the machine. The machine then sucks out all the air inside the bag, makes a vacuum like environment and seal it. Often times, the heating process is used for this purpose.

e)Thermoforming vacuum packaging machine

In this type of machine, the products are packaged with the help of rolls of packaging films. The products are placed on the thermoformed pockets and the upper part is sealed. This machine is excellent for high volume production since it has a great ability to package thousands of products in a single day.

Moreover, the thermoformed plastic is customizable and can be made in any shape, color and design according to the products specifications. This plastic can be used to package several products like meat, chicken, seafood, candies, chocolates etc. one of the most sought after thermoform plastic is PET which is known for its high tensile strength and tamper proof packaging.

f)Automatic belt vacuum chamber machine

In this machine, the product which has to be sealed is placed on the conveyor belt and sent to the seal bar. The product is then automatically oriented at its desired position. After this, the lid of the machine is closed and the air is taken out. The seal bar then seals the product, forming a hermetic seal. After the lid is opened, the air moves into the chamber. This incoming pressure removes the remaining air inside the bag.

This machine is ideal for high volume production due to its high speed and automated process. It can be used to package various products like food, chemical and pharmaceutical products.

5.Which equipmentare used for nitrogen flushing?

Nitrogen flushing machine has two different types. Each type carries out the process in its own way. Let us discuss each of these type below.

a)Vertical continuous nitrogen flushing machine

In this machine, the bags or pouches which need to be sealed are placed vertically on the machine. The conveyor belt then transports it to the heating blocks where the sealing process will take place. The heating blocks apply pressure on the bag to form an airtight seal around it.

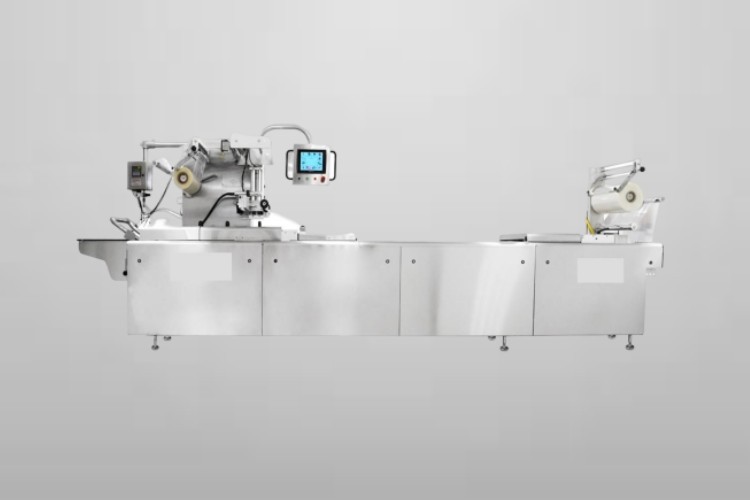

b)Horizontal continuous nitrogen flushing machine

In this type, the pouch or the bag is placed horizontally on the machine. The conveyor belt then transport it to the heating blocks. These blocks use the heating method to seal off the bag or pouch. The air inside the bag which contains oxygen is removed and is filled with nitrogen, an inert, non-reactive gas.

The contents of the bag would be unable to react with the filled nitrogen inside, thus ensuring the freshness of it.

6.Which is more economical? Vacuum packaging or nitrogen flushing?

Vacuum packaging is more economical than nitrogen flushing. This is because in nitrogen flushing process, you need to install nitrogen generators or buy nitrogen cylinders every time you want to fill the products with it. Moreover, the machines of nitrogen flushing are bulky and expensive.

Vacuum packaging machines are cheaper than the nitrogen flushing machine. Moreover, they do not require gas cylinders or generators which greatly reduces the cost of investing in it. Thus, it is ideal for small scale businesses to use vacuum packaging machines since it is a more cost effective option for packaging items. On the other hand, nitrogen flushing machines are more ideal for large scale industries which can bear the heavy cost of installing them.

Conclusion

After discussing all the points above, you can now understand the benefits and disadvantages of both the packaging. However, in order to decide which one is most suitable for your business, you need to check many other information. For more details, you can visit website www.allpackchina.com and find your answer.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide