Pedal Sealing Machine: The Complete FAQ Guide In 2024

Pedal Sealing Machine: The Complete FAQ Guide In 2024

The development of the pedal sealing machine has revolutionized our modern world. After the invention and launch of this highly efficient, easy-to-use device, a lot of companies have found that their packaging solutions have been improved significantly when it comes to time consumed, cost savings, and quality assurance.

Not only is it ideal for commercial applications, but its affordability makes it suitable even for smaller operations or personal use as well.

This amazing machine operates by thermoforming plastic bags around your product in no time at all – with seal strength up to 8 times better than manual operations! If you are looking for an effective method for efficiently packing items ranging from candy bars to premium products like cosmetics or perfumes, then this is definitely worth investing in.

In this blog post we will discuss why pedal sealing machines are essential for various reasons and how you can benefit from owning one today!

1.What Is A Pedal Sealing Machine?

A pedal sealing machine is a device used to seal bags or containers quickly and easily. It offers an air-tight, watertight seal that helps keep items fresh and free from contamination.

The equipment works by pressing down on the top of a bag or container with a lever or foot pedal. This action causes heat to be applied to the bag or container’s edges, creating a tight seal. These machines also provide excellent control over the width and temperature of the seal.

This makes them ideal for use in food processing, medical laboratories, and other applications where a secure closure of products is important. These machines are not only efficient but also cost-effective, making them an attractive option for businesses looking to save money and reduce waste.

Pedal sealing machines are a valuable tool for businesses in a wide range of industries and can help ensure that products stay fresh and secure during transport.

2.Where Can The Pedal Sealing Machine Be Used?

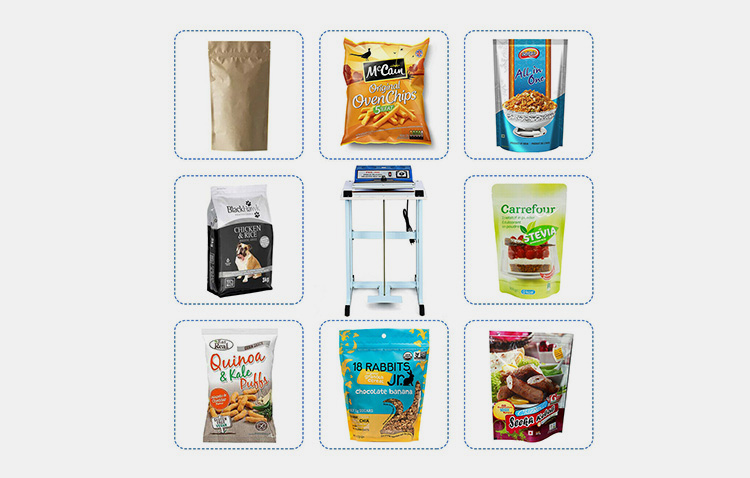

A pedal sealing machine is a highly versatile device with many different applications. These machines are typically used in packing and sealing operations to make sure products remain safe and secure during transport. Some common applications of pedal sealing machines include:

Food Packaging

Pedal sealing machines can be used for the packaging of food products such as snacks, candy, bread, confectionery items, and more. It is efficient in sealing flexible materials like plastic packaging film due to its adjustable temperature settings.

Industrial Packaging

Pedal sealing machines can be used for various industrial applications including the packaging of spares, components and tools. It is suitable for sealing materials like paper and cardboard.

Medical Packaging

Pedal sealing machines are used in the medical industry to package products like bandages, tablets, and diagnostic kits. The adjustable temperature settings make it suitable for sealing material such as plastic film which is often used for medical packaging applications.

Personal Care Packaging

Pedal sealing machines are also useful for packing and sealing personal care products like shampoo, lotion, soap, etc. It is suitable for sealing materials like plastic film or aluminum foil which is often used in the packaging of these products.

The machines also provide an efficient and reliable way to package and seal products in a variety of industries. Its adjustable temperature settings make it suitable for sealing many types of material, making it a great choice for those who require durable and secure packaging solutions.

3.What Are The Benefits Of Using A Pedal Sealing Machine?

Pedal sealing machines provide a number of benefits that make them an ideal choice for businesses looking to maximize efficiency and reduce costs. By using these machines, businesses can streamline their production process and create a more consistent product quality.

The first benefit is that pedal sealing machines are able to seal multiple bags at once with one pedal operation. This eliminates any downtime associated with having to manually open and close each individual bag. They also provide consistent, controlled sealing pressure for a superior seal that is more reliable than manual methods.

In addition to being faster and easier to use, pedal sealing machines are also much safer than traditional methods of sealing packages. With pedal operation, there is no risk of getting hands or fingers caught in the machine, which can be a serious hazard.

Finally, pedal sealing machines are much more economical than traditional methods. They can quickly pay for themselves in no time due to the speed and efficiency they provide. This makes them an ideal solution for businesses that need to seal countless bags each day.

Overall, pedal sealing machines offer many benefits over traditional methods and are a great investment for any business looking to streamline their packaging process. They provide faster, easier and more efficient sealing with no risk of injury, while also providing significant cost savings in the long run. Investing in pedal sealing machines is a wise decision that can help any business save time and money.

Pedal sealers are also ergonomically designed, making them comfortable to operate and reducing the strain on operators over time and finally, pedal sealers help to minimize scrap and save costs in the long run. This makes a pedal sealing machine an essential tool for any business in need of reliable and efficient seal packaging solutions.

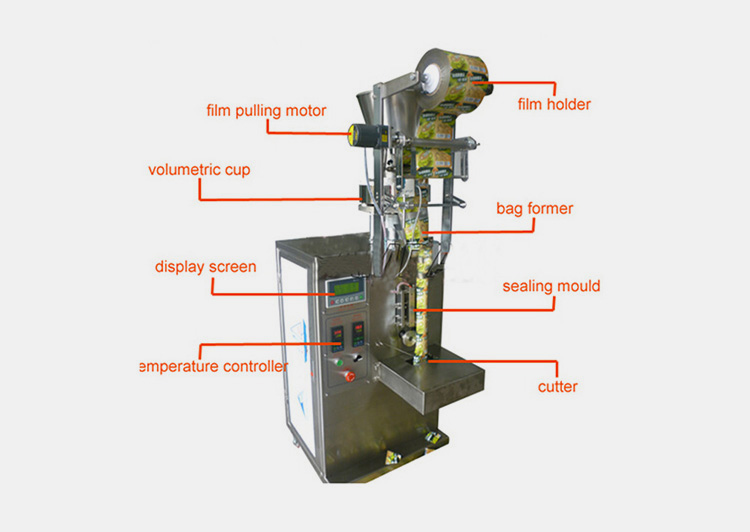

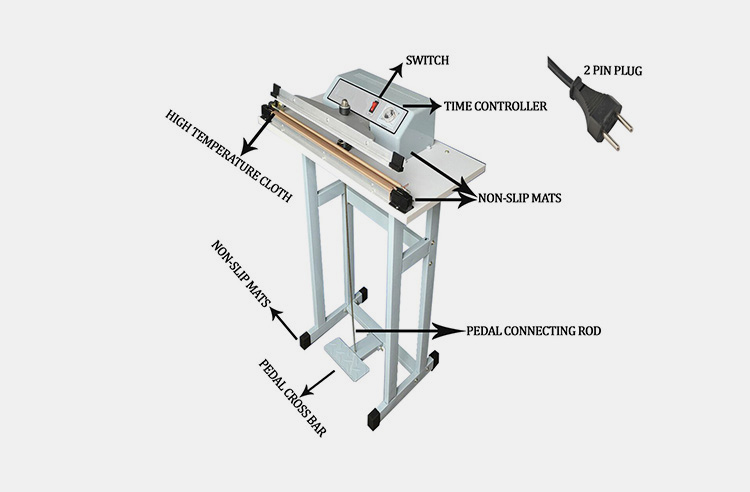

4.What Are The Components Of A Pedal Sealing Machine?

1.Switch: The switch is the main component which controls the pedal sealing machine. It is activated when a pedal is pressed, and this triggers the heating element to seal the plastic bag.

2.High Temperature Cloth: This cloth is usually made of silicone or fiberglass, and it has a high tolerance to heat. It is needed to ensure that the pedal sealing machine can work at the correct temperature for an effective seal.

3.Bracket: The bracket is used to hold the pedal and switch together, allowing them to work in tandem.

4.Non-Slip Foot Pad: This foot pad is used to ensure the pedal stays in place and does not slip when pressed.

5.Foot Pedal: The pedal is the main component that triggers the switch. When it is pressed, it activates the heating element which seals the plastic bag.

6.Power Cord: This cord is used to supply power to the pedal sealing machine.

7.Pedal Connecting Rod: This rod connects the pedal and switch together, allowing them to work in tandem.

8.Time Temperature Controller: This controller is used to regulate the temperature of the pedal sealing machine. It maintains a consistent temperature for an effective seal.

5.How Does A Pedal Sealing Machine Work?

A pedal sealing machine, also known as a heat sealer, is an innovative piece of equipment that uses pressure and heat to create a tight seal for various types of materials.

It works by sandwiching two pieces of material together between two heated jaws which apply pressure to the material and seals it shut. The pedal activates the heating element and starts the sealing process.

The pedal can be programmed to regulate the temperature, speed and pressure of the seal depending on the material being sealed or the desired result.

6.What Types Of Pedal Sealing Machines Do We Have?

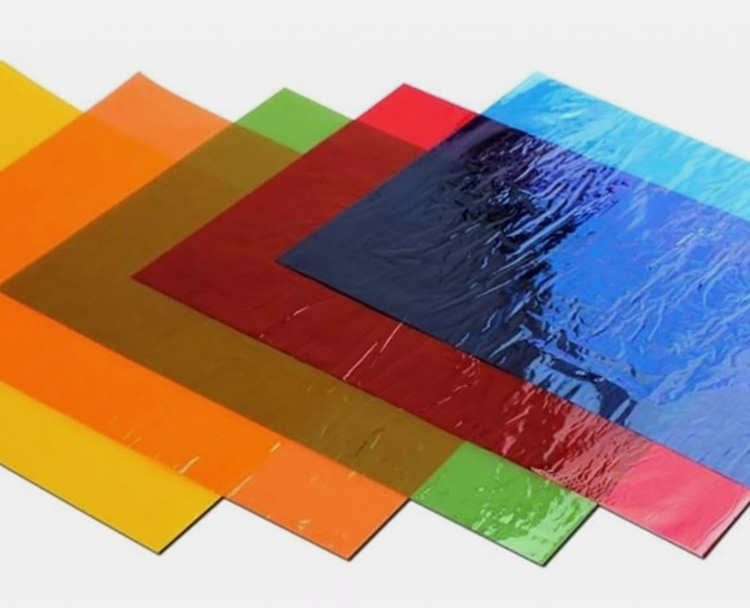

Pedal sealing machines are devices used to seal a variety of materials, including plastics, aluminum foil, paper, and other similar materials. The machines come in various types depending on the material being sealed and the application at hand. The most common types of pedal sealing machines include:

Manual Pedal Sealers

Manual pedal sealers are the most basic type of pedal sealer and are best for low-volume, occasional sealing applications. They are manually operated with a foot pedal that activates the sealer when the material to be sealed is placed between the sealing jaws. Manual pedal sealers are ideal for applications where each product being sealed needs to be adjusted, as they provide manual control over the thickness and pressure of the seal.

Automatic Pedal Sealers

Automatic pedal sealing machines are an upgraded version of manual pedal sealers, offering automated operation and increased sealing speed. They are typically used for heavier duty applications where a steady, consistent seal is needed. The foot pedal is used to activate the sealer, but is not needed for each product being sealed as the sealing process is automated.

7.What Types Of Materials Can Be Sealed With A Pedal Sealing Machine?

Pedal sealing machines are versatile tools that can seal a variety of materials. The types of material that can be sealed with this machine includes plastics, aluminum foil, paper, fabric, and cardboard.

Plastic material

Plastic material is the most common to be sealed using pedal sealing machines because it is easy to form a tight seal on plastic materials. The machines can also be used to seal aluminum foil, which is commonly used for food packaging and storage.

Paper materials

Paper materials such as paper bags, boxes, and labels can also be sealed with pedal sealing machines.

Fabric

Fabric items such as clothing or flags are often sealed using pedal sealing machines in order to keep them from fraying or losing their original shape.

Cardboard

This equipment can even be used to seal cardboard in order to keep it from becoming damaged or contaminated. These machines are a great tool for sealing any type of material, making them a more valuable tool for many businesses and individuals.

8.How Is Pedal Sealing Machine Different From A Hand Sealing Machine?

Pedal sealing machines have a pedal that is placed on the floor and operated by foot. This pedal is used to activate a heating element which then seals the plastic packaging around its contents. On the other hand, a hand sealing machine relies on one’s hands for activating the heat source.

Pedal sealing machines are more suitable for industrial applications as they are faster and more precise than hand sealing machines. Hand sealing machines tend to be better suited for small-scale operations due to their portability and ease of use in cramped spaces. Pedal sealing machines also generate less heat, meaning that the contents of the package are less likely to be damaged during the process.

Furthermore, pedal sealing machines can handle thicker packaging materials, making them a better option for heavier items. Both pedal and hand sealing machines have their strengths and weaknesses, so it is important to consider your particular needs before deciding which one to choose.

9.Does The Pedal Sealing Machine Have Adjustable Settings?

Yes, most pedal sealing machines have adjustable settings for both the temperature of the seal and time needed to create a tight bond. The temperature range can usually be adjusted from low to high depending on the type of material being sealed.

The sealing time can also be adjusted to ensure that the bag is properly sealed without any loss of contents. Adjustable settings are especially important for these machines used in retail or food service applications, as the temperature and sealing time must be precise to ensure safe storage of products.

It’s always a good idea to read the instructions provided with your pedal sealing machine before attempting to adjust any settings. Doing so will help ensure that you get the best seal and longest lasting products possible.

10.What Safety Features Does The Pedal Sealing Machine Have?

The pedal sealing machine is designed with a variety of safety features to ensure the safety and wellbeing of users. These include an emergency stop feature, which allows users to quickly terminate operations in case of an unexpected hazard or fault; a temperature monitoring system that ensures stable working temperatures at all times; and a shock-resistant shell that protects the machine from any unexpected impacts or falls.

Additionally, the pedal sealing machine includes an operability protector that prevents users from unintentionally activating the machine in hazardous conditions. All these safety features offer effective protection for users and ensure their safety while working with the Pedal sealing machine.

This device is also equipped with a safety guard system that prevents any accidental contact between the user and the hot sealing surface. The pedal sealing machine is also designed with an overload protection feature, which ensures that the machine does not overheat or experience any other form of malfunction due to heavy usage.

Furthermore, the pedal sealing machine offers a fireproof casing and insulation material to protect users from any potential fire hazards. All these safety features make the pedal sealing machine an ideal choice for anyone looking to safely get the job done.

Finally, this machine is designed with a number of safety features that ensure user protection and efficiency while working with this machine. These features include an emergency stop feature, temperature monitoring system, shock-resistant shell and operability protector, as well as a safety guard system and overload protection feature. All these features make the Pedal sealing machine an ideal choice for anyone looking to safely get their work done.

11.What Types Of Sealing Techniques Does The Pedal Sealing Machine Offer?

The pedal sealing machine offers three main sealing techniques: Heat Seal, Impulse Seal, and Band Seal.

Heat seal.

Heat seal is a process of bonding two heat-sensitive materials together with the application of heat, pressure, and time. It involves pressing two pieces of plastic film or laminates together with a heating element to create a uniform, airtight seal.

Impulse seal.

Impulse seal is another type of sealing technique that utilizes an electrical current to create a heat-seal bond between two pieces of plastic film or laminates. This process involves heating up a wire element for a short pulse of time and then quickly cooling it down to form an airtight seal.

Band Seal.

Lastly, this machine offers a band seal method. This technique involves heating an element and then pressing it into a continuous band of plastic film or laminate to create a secure seal. This process is ideal for creating airtight seals on large batches of products.

Each of these sealing techniques are used in different applications to create secure, airtight seals. The pedal sealing machine can be used to make a variety of different seal types depending on the materials being sealed and the desired end result. With its adjustable speed control and multiple sealing techniques, it can be used for an array of sealing applications.

These equipment are capable of providing quality seals on a variety of materials. With the pedal sealing machine, users can create secure seals and improve product integrity. The equipment is an essential tool for any processing or packaging environment in need of reliable sealing solutions. It provides efficient and cost-effective sealing capabilities for a wide range of materials and applications.

Conclusion

Allpack is your number one source for high-quality pedal sealing machines. We offer a wide variety of machines to suit your needs and budget, so you’re sure to find the perfect one for you. Contact us today to learn more about our products and services, or browse our website to find the perfect machine for your needs. Thanks for reading!

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide

Pedal Sealing Machine: The Complete FAQ Guide In 2024 Read More »