Oatmeal 3 Side Sealing Packing Machine: The Complete Buying Guide In 2024

Yummy oatmeal is a way to kick start the sleepy days. It delivers healthy benefits to people all around the world. But how these health benefits are packed in small packing of oatmeal? The answer is by oatmeal 3 side sealing packing machine.

This machine is a light in the dark in the food processing industry, as it hygienically packs oatmeal for their protection. Extra care and packaging efficiency is achieved by the oatmeal 3 side sealing packing machine. It diligently packs the oatmeal for its protection and preservation of taste and nutritional quality.

Are you switching to the latest oatmeal 3 side sealing packing machine and are you interested in understanding the types, working, benefits, and applications of this machine? Then here is a blog post, full of information exclusively for you.

1.How To Define an Oatmeal 3 Side Sealing Packing Machine?

Oatmeal 3 Side Sealing Packing Machine

The oatmeal 3 side sealing packing machine is excellent and high-quality equipment, creating a diverse kind of sachets from a packaging film roll, filling them precisely with the oatmeal and hermetically sealing them.

The 3 side sealing formed by this machine can hold more quantities of the products by folding on one side.

It is a versatile machine creating huge varieties of sachets and pouches. It is a chief component of the food industry used for packaging cereals and spices besides oatmeal. It can be customized for packing powders in different industries.

2.Enlist the Advantages of the Oatmeal 3 Side Sealing Packing Machine.

Investing in an oatmeal 3 side sealing packing machine can bring numerous fruitful results to businesses. If you want to increase your output capacity then the oatmeal 3 side sealing packing machine is a valuable choice. It has many captivating advantages like:

Boosts Output Rate

High production rate

The oatmeal 3 side sealing packing machine is an efficient unit, increasing output rate far above the manual packaging. The latter can be slow and tiresome, but not the oatmeal 3 side sealing packing machine. It has state-of-the-art parts that carry out packaging at advanced rates. It offers optimized results within no time.

Accuracy in Every Fill

Greater accuracy

Accuracy is critical in production as over and underfilling has some serious consequences like product recall. But with an oatmeal 3 side sealing packing machine, you have guaranteed accuracy in the filling. It has top-notch sensitive sensors and weighing systems that offer accuracy in every fill.

Hygienic Packaging

Maximum protection

Yes, with an oatmeal 3 side sealing packing machine you can achieve hygienic packaging. It has sterile processing systems and a clean working environment and therefore, prevents contamination in the filling and packaging process. Thus, you can ensure packaging quality.

Cost-Effective Machine

Cost-Effective

Money is the biggest issue when it comes to packaging. However, the oatmeal 3 side sealing packing machine runs without needing support from human labor, so it saves a lot of labor costs. Furthermore, it packs oatmeal with minimal materials, thus saving materials. These two points make this machine a cost-effective choice.

Versatility in Packaging

Versatile packing

The versatility of product packaging goes a long way in attracting customers. Striking and unique oatmeal sachets and pillow pouches captivate kids and adults alike. Hence, the oatmeal 3 side sealing packing machine is used for its versatility as it efficiently creates diverse shape packaging.

3.What is the Design Engineering of Oatmeal 3 Side Sealing Packing Machine?

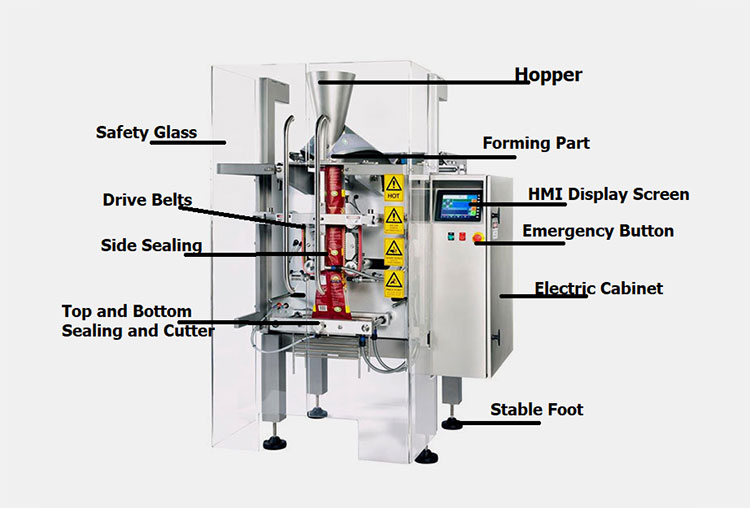

The oatmeal 3 side sealing packing machine consists of various technical, mechanical and electric components acting together for precise and fast working operation. Here we will discuss some important parts of the oatmeal 3 side sealing packing machine.

Oatmeal 3 Side Sealing Packing Machine

| Parts | Description |

| Hopper | It is an enclosed structure capable of housing huge quantities of powders and granules. It accurately moves oatmeal to a filling inlet. The shape and dimension of the hopper vary with the type of oatmeal 3 side sealing packing machine. |

| Forming Part | It is the primary part of the oatmeal 3 side sealing packing machine that guides and folds the packaging film to create sachets and pouches varying in shape and dimension. |

| Safety Glass | It is the barrier between the operator and machine, preventing the contamination of oatmeals while keeping the operator safe. It allows them to safely check the working performance of the machine. |

| Drive Belts | It is an integral part of the machine, capable of aiding the motion of packaging film, creation of packaging, oatmeal filling, and sealing. The drive belts are manufactured using rubber or polyurethane. |

| Side Sealing | These are the vertical sealing jaws that seal the sachets from one longitudinal edge. It creates a side folding sachet. |

| Top and Bottom Sealing | As the name suggests, these are the horizontal sealing bars that fuse the top layers and bottom layers of the formed sachet or pouch. |

| Cutter | It is a sharp knife that separates the formed and filled sachets from the rest of the packaging roll and guides them towards the product discharge chute. |

| HMI Display Screen | It is the main part of the machine where different program options are monitored and adjusted. It also helps in self-diagnosis and troubleshooting the machine. |

| Electric Cabinet | Different machine cables, switches, breakers, circuits, etc. are housed in the sturdy electric cabinet, thus it helps in powering the machine. |

| Stable Foot | It is essential in supporting and levelling the machine. |

4.How Does Oatmeal 3 Side Sealing Packing Machine Work?

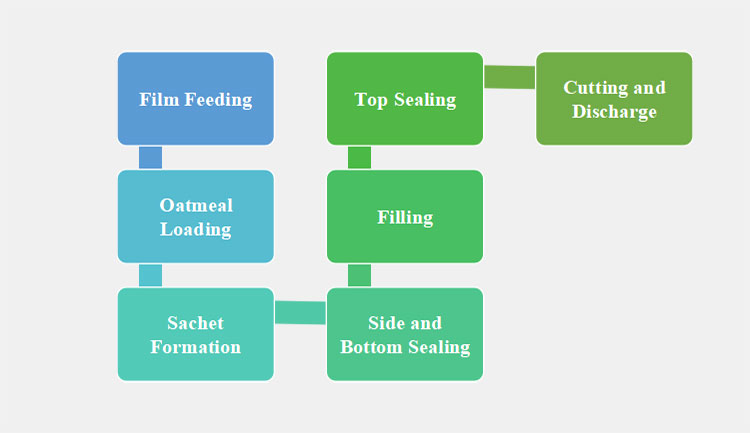

The working process of this machine is quite easy, it simply fills the formed packaging with sachets with simple collaboration between its parts. The working of this machine is described below:

Working flow chart of Oatmeal 3 Side Sealing Packing Machine

| Film Feeding | A continuous roll of film of required packaging material is fixed on the film holder. The operator unwinds the film and guides this film over tension rollers. These rollers are critical in keeping the film under consistent tension. |

| Oatmeal Loading | The oatmeal is deposited in the upper hopper. This process is either done manually or by an automatic feed tank. |

| Sachet Formation | A desired shape and dimension sachet is formed by the forming tube. It is a conical part that shapes the continuous film roll into the sachets. |

| Side and Bottom Sealing | The side and bottom sealing of the sachet is carried out by the vertical and horizontal sealing bars. These sealers fuse the layers of packaging film to create a hermetic seal. |

| Filling | The desired weight of the oatmeal is then fed into a shaped sachet by the combined action of filling nozzles and filling devices. |

| Top Sealing | After filling, the top side of the filled sachet is fused via horizontal sealing jaws to prevent leakage. |

| Cutting and Discharge | The sealed sachets are cut from each other using cutters. These sachets are directed to discharge in the discharge device or chute. These sachets are then collected and carried across further packaging steps. |

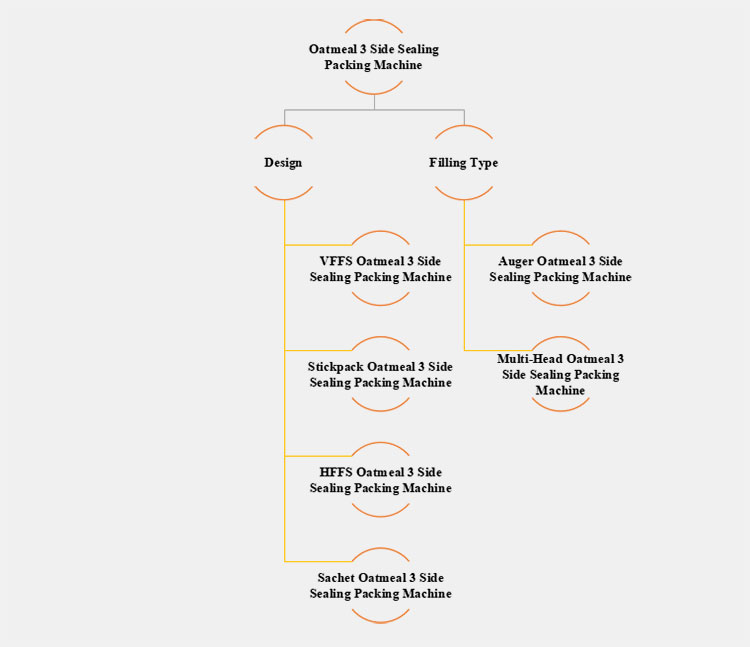

5.What are the Classes of Oatmeal 3 Side Sealing Packing Machine?

There are diverse ranges of oatmeal 3 side sealing packing machines depending upon design and filling devices. We are discussing each type briefly:

According to the Design

VFFS Oatmeal 3 Side Sealing Packing Machine

VFFS Oatmeal 3 Side Sealing Packing Machine

As the name suggests, it has a vertical mode of operation, meaning it packs oatmeal in an upside-down direction. It is routinely seen in the oatmeal industry because it has the highest output rate and increased efficiency. It is a versatile instrumentation, capable of producing packaging as per customized requirements.

Stick pack Oatmeal 3 Side Sealing Packing Machine

Stick pack Oatmeal 3 Side Sealing Packing Machine

It is a speedy machine with many lanes that produces many stick packs at increasingly high speeds. These lanes have their individual forming and cutting stations. The film is cut into small strips to form different stick packs. Each forming station plays a role in shaping stick packs, whereas these stick packs are sealed by sealers to avoid leakage and contamination.

HFFS Oatmeal 3 Side Sealing Packing Machine

HFFS Oatmeal 3 Side Sealing Packing Machine

This machine is a great addition to large-scale industries because it has a horizontal construction and thus, it has a much larger footprint. It is a robust and flexible instrumentation, forming, filling, and sealing in horizontal configuration. These processing stations in this machine are present close to each other for advanced packaging.

Sachet Oatmeal 3 Side Sealing Packing Machine

Sachet Oatmeal 3 Side Sealing Packing Machine

It is a simple and compact device that has one or more lanes for forming, filling, and sealing oatmeal sachets. It is the most common machine for packaging small sachets. It accurately introduces oatmeal in its packaging. The Sachet oatmeal 3 side sealing packing machine also has a vertical configuration.

According to the Filling Type

Auger Oatmeal 3 Side Sealing Packing Machine

Auger Oatmeal 3 Side Sealing Packing Machine

It has a specialized type of auger, often utilized for filling oatmeal powders. It has an auger-filling device that pushes a specific volume of powders into sachets. It consistently and evenly fills powders without any batch variations. Auger screws and auger plates help in smooth working operation.

Multi-Head Oatmeal 3 Side Sealing Packing Machine

Multi head Oatmeal 3 Side Sealing Packing Machine

This kind of oatmeal 3 side sealing packing machine uses multi-head channels for filling oatmeal granules in the packaging. Multi-head channels are increasingly utilized for packaging oatmeals because of their accuracy. Due to its multiple channels, this machine packs granules at higher speeds.

6.Where Is the Oatmeal 3 Side Sealing Packing Machine Used?

Oatmeal 3 side sealing packing machine is found in every major industry of the world because of its application in powder and granule filling. Some of the major uses of this machine are explored below:

Oatmeal Industry

Oatmeal industry

The utilization of an oatmeal 3 side sealing packing machine is inevitable in the oatmeal industry because it packs different types of oatmeal in the 3 side seal packing. It also packs oatmeal in individual serving sachets, which are easy to use. This machine has a significant role in keeping oatmeal fresh by sealing them in airtight sachets.

Confectionery Industry

Confectionery Industry

It is used also in the confectionery industry for packing different confectionery items like chocolates, gummies, jellies, gums, dessert toppings, festive treats, sugar-free confections, etc in sachet packaging. It is added to the confectionery industry because of its higher efficiency.

Snack Industry

Snack filling industry

Besides the confectionery industry, the oatmeal 3 side sealing packing machine is also utilized in the snack industry. It has precise dosing of snacks, hence; it packs different nuts, chips, biscuits, and popcorn in the sachet packing. It is widely popular for packing oatmeal-based snack products.

Condiment & Spice Industry

General food items

This machine is routinely added in the food industry because of its huge demand in this industry. It packs both powdery and granular items like cereals, grains, scented tea, spices, sugar crystals, salts, seeds, etc. Oatmeal 3 side sealing packing machine packs different food items in individual serving packs.

Health & Wellbeing Industry

health & wellbeing products

The significance of the oatmeal 3 side sealing packing machine is not overlooked in the medicinal industry. It is used for packing different herbal and nutritional mixtures in the portion-controlled sachet.

Hardware Industry

Hardware industry

Although, it seems strange oatmeal 3 side sealing packing machine is also applied in the hardware industry, where different types of nuts, bolts, screws, and many more are regularly packed in one-use serve sachet.

7.What are the Packaging Formats for Oatmeal 3 Side Sealing Packing Machine?

Since, the oatmeal 3 side sealing packaging machine is a diverse kind of packaging machine, it forms a great variety of 3 side sealing packing that are mostly sachets. These packaging formats are detailed below:

3 Side Seal Sachets

The three sides sealing is present in 3 sides seal sachets while on one side, it has folding. Due to these sealing placements, it can hold more quantities of oatmeal. It is space-efficient, as it has a compact design.

Pillow Pouch

The pillow pouch has sealing on three sides but instead of side sealing it has back sealing present along the complete backside of the pouch. It is the most economical retail packaging pouch. It has a simple design and flat appearance.

Tear-Notch Sachet

Although it is sealed on three sides, it has a tear notch below the upper seal for easy tearing of the sachet. There is no need for scissors to open a tear-notch sachet.

8.What is the Difference between an Oatmeal 3 Side Sealing Packing Machine and an Oatmeal Box Packaging Machine?

These two machines are routinely seen in the oatmeal industry for packaging oatmeal. However, they are vastly different from each other. Let’s discuss the difference between an oatmeal 3 side sealing packing machine and an oatmeal box packaging machine.

| Parameters | Oatmeal 3 Side Sealing Packing Machine | Oatmeal Box Packaging Machine |

| Picture |  |

|

| Packaging Type | Its packaging type is flexible sachets. | Its packaging type is rigid boxes or cartons. |

| Sealing Method | It utilizes heat or ultrasonic sealing to seal the sachets. | This machine utilizes gluing and folding approaches to close the boxes. |

| Packaging Size | It produces a single-serve sachet. | The oatmeal box packaging machine packs multiple servings of the oatmeal. |

| Applications | Oatmeal 3 side sealing packing machine produces sachets best for go-on consumption. | The oatmeal box packaging machine is applied for bulk and retail packaging. |

9.What Features Help in Creating an Air-Tight Environment in Oatmeal 3 Side Sealing Packing Machine?

Air tight packing

Protection from moisture, light, air, microbes, and vermin is very important in preserving the freshness, taste, aroma, and quality of the oatmeal. This protection makes oatmeal healthy for consumption. Without this protection, the health and safety of consumers are compromised.

For this protection is airtightly sealed by the oatmeal 3 side sealing packing machine. Different features help in creating an airtight environment in the oatmeal 3 side sealing packing machine like nitrogen gas feeding or degassing. Nitrogen feeding and degassing have the same purpose which is the removal of oxygen and moisture from inner oatmeal packaging.

These two are the main culprits in deteriorating the quality of oatmeal. Oxygen causes the oxidation of oatmeal, whereas moisture is linked with the sogginess of the oatmeal. Thus, nitrogen feeding and degassing extend the consumption period of the oatmeal.

10.What are Integrity Tests for Sachets Packed by Oatmeal 3 Side Sealing Packing Machine?

Quality testing

There are different seal integrity tests for sachets packed by oatmeal 3 side sealing packing machine like:

| Visual Test | It is the simplest form of seal integrity test in which at the end of the production, containers are manually inspected or by using technology like a vision camera and image processing. It can detect defects like improper sealing, leakage, breakage, and the presence of debris and dust. |

| Seal Integrity Test | Different seal integrity tests like dye penetration, vacuum decay, and air bubble tests are conducted to identify leakage or compromised sealing. |

| Burst Strength Test | A high pressure is subjected to the oatmeal sachet to ensure this packaging can resistant high pressure from inside without opening. The ability of the sachet to handle rough treatment and transportation journeys is accessed using this test. |

| Peel Strength Test | The force needed to peel apart the sealed edges of the oatmeal sachet is measured by this test. This test allows to set right parameters for sealing and it identifies the strength of the sealing. |

| Microbial Test | It is also called the sterility test and measures the growth of microbes in the content of sachet. This test ascertains there is no microbial contamination in the oatmeal sachets. |

| Tensile Test | The tensile strength of both packaging material and seal is checked through the tensile test. In this test, pulling force is applied to the oatmeal sachet until it tears apart. This test ascertains that packaging film and seal can withstand strain during packaging and transportation. |

11.Enumerate Technical Errors and Their Troubleshooting in the Oatmeal 3 Side Sealing Packing Machine.

Technical errors in the oatmeal 3 side sealing packing machine can disrupt the packaging stages and produce poorly filled, formed, and sealed sachets. However, there is no reason to worry and these errors are easily troubleshooted by following these guidelines:

Film Wrinkling

During the packaging steps, the film gets wrinkled or crumpled.

Causes

The reason for film wrinkling is poor film tension. This problem can be due to increased or non-uniform heating of the forming tube. Sometimes film slips or misaligns cause this problem.

Solutions

To resolve this issue, first, properly fix the tension parameters on the film feed mechanism. Inspect and recalibrate heating elements present in the forming collar to ascertain uniform heating. Properly align the film to avoid wrinkling and spillage.

Failure in Functioning of Sealing Jaws

Sealing jaws are not sealing the sachets properly

Causes

This problem can be due to several reasons like unclean sealing jaws. Insufficient sealing temperature and pressure. Short dwell time and worn-out sealing jaws.

Solutions

To solve this problem, clean the poorly cleaned sealing jaws. Also, increase temperature and pressure as per recommended guidelines of manufacturers. Increase sealing time. Repair and properly level the sealing jaws with the film to ensure smooth sealing.

Non-uniform Fill Weight

There are differences in the fill weight across every batch.

Causes

Differences in the oatmeal granule density and flow characteristics can be the reason for inconsistent fill weight. Damaged or worn-out sensors or filling devices. Poor calibration of the fill system is also the cause of this problem.

Solutions

To fix this issue, always control product fill settings like their density and flow characteristics. To prevent variation in fill weight repair and maintain the sensors and fill devices. Also, calibrate the fill system.

Variation in Sachet Shapes

The sachets produced are of varying shapes and sizes.

Causes

Forming parts are not aligned properly which could be the cause of this problem. It can also be due to high or non-uniform film tension. Mechanical problems in the forming part can be a reason for this issue.

Solutions

This problem is resolved by properly alignment or rightly adjusting the forming collar. Fix the tension in the film to avoid increased stretching or wrinkling. Check and repair the forming parts to see if they are worn out.

Software Unresponsiveness

The software sometimes freezes and does not respond to commands.

Causes

These software freezing or glitches can be due to software bugs and also because of programming errors. Corrupted files can also cause unresponsiveness of software.

Solutions

Restart the machine to reboot the machine HMI. It will reset the program processes. Install the latest update as provided by the manufacturer.

12.What are the Buying Factors When Procuring an Oatmeal 3 Side Sealing Packing Machine?

Investing in an oatmeal 3 side sealing packing machine can require substantial upfront investment, so care should be taken when procuring the oatmeal 3 side sealing packing machine. We are giving some buying factors that will aid you in your selection.

Automation and Speed

Speed of Oatmeal 3 Side Sealing Packing Machine

Speed is increased significantly when switching from a manual mode of operation to an automatic one. In the market, different kinds of oatmeal 3 side sealing packing machines have a diverse range of speeds. So, first, look into your required production rate and then choose the speed of the machine accordingly.

Packaging Style

Your packing styles

However, this machine usually produces 3 side sealing packaging. There are many tailor-made packaging styles with simple changes in sealing and cutting parameters. Thus, decide your required packaging style and then select a machine that makes your desired packaging style.

Budget

Your budget

Different models of oatmeal 3 side sealing packing machines require different ranges of investment. Price usually depends upon the technology and features of the machine. When you are overwhelmed, simply narrow down the options by selecting the machines that are in the defined range of your budget.

Compliance and Quality

International quality compliance

Adherence with different regulatory standards like ISO, GMP, CE, etc., is a measure of the quality of the oatmeal 3 side sealing packing machine. The equipment compliance with standards shows that machines are manufactured using strict quality guidelines. Thus compliance is a must for safe and hygienic processing.

Warranty

Warranty of machine

Warranty time offers a mental peace that is valuable for the manufacturer. Always look for a machine with the highest warranty period to ensure minimal downtime of the machine. The warranty period is related to production efficiency, as it gives protection from unpredicted repair costs.

Conclusion

Simply put, an oatmeal 3 side sealing packing machine is needed by every modern oatmeal brand and other manufacturers. It is because this machine is very useful in production, bringing a huge ton of benefits. It is not only used in the oatmeal industry but in other industries as well. Oatmeal 3 side sealing packing machine is efficient and precise and produces striking 3 side sealing sachets that spellbind a great many consumers. With so many benefits, everyone is in line to add this outclass machine in production. Want to know more about this handy machine or are keen on buying this machine, then without further delay contact our Allpack customer care. Because your convenience is our goal.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide