KFC Ketchup 4 Side Seal Packaging Machine: The Complete FAQ Guide In 2024

Are you craving KFC Ketchup and chips? Have you ever wondered how KFC Ketchup is packed? KFC ketchup 4 side seal packaging machine meticulously and beautifully packs KFC ketchup.

KFC ketchup 4 side seal packaging machine packs small quantities of KFC ketchup that comes with ketchup delivery. Whether camping, travelling, or hiking, KFC ketchup is a must with different meals. So, this machine is invented to meet the high production demands.

This machine provides superior quality results while reducing material wastage. If you want more details about the KFC ketchup 4 side seal packaging machine then grab a bowl of chips and KFC ketchup and read this FAQ guide.

1.What Is the KFC Ketchup 4 Side Seal Packaging Machine?

KFC Ketchup 4 Side Seal Packaging Machine

KFC ketchup 4 side seal packaging machine is a state-of-the-art piece of equipment that encloses KFC ketchup into small and large sachets. It contains and packs the ketchup that comes with different delivery meals.

It carries out processing like measuring KFC ketchup and then loading them in compact disposable sachets. It is a useful machine that boosts packaging speed and efficiency by automating every step of KFC ketchup packaging. It prevents KFC ketchup wastage and spillage by economically dispensing the latter in sachets.

2.What is the Significance of the KFC Ketchup 4 Side Seal Packaging Machine?

KFC ketchup 4 side seal packaging machine is rapidly gaining popularity because of the high demand for ready-made foods. KFC ketchup is a must with convenient foods and to fulfil the responsibility of packaging this ketchup, the KFC ketchup 4 side seal packaging machine is utilized in the industries.

All-in-One Machine

All-in-One Machine KFC Ketchup 4 Side Seal Packaging Machine

KFC ketchup is an all-rounder machine capable of processing multiple tasks all in one machine. It performs loading of KFC ketchup, forming of sachets, their sealing, printing, and cutting instantaneously. It frees the workforce from operating different machines for different tasks.

Versatility and Customization

Versatility with KFC Ketchup 4 Side Seal Packaging Machin- Picture Courtesy: syscoireland.com

Product visual appeal is a must for selling the product which is why KFC ketchup comes in all types of shapes to attract customers. By using this equipment, manufacturers can easily pack KFC ketchup in all shapes of sachet because of the versatile processing of this machine. Moreover, it also creates different types of seals like patterned, straight, tear-notch, and, many more.

High Accuracy

High Accuracy with KFC Ketchup 4 Side Seal Packaging Machine- Picture Courtesy: Outofeden

Manual filling always comes with under and overfilling that causes serious issues for the production. Hence, top-notch productions and small businesses employ the KFC ketchup 4 side seal packaging machine to accurately and precisely load KFC ketchup in the sachets. It features remarkable dosing, forming, and sealing systems that are utilized in the accurate loading of KFC ketchup and precise usage of material.

Tamper-Evident Seals

Tamper-Evident Seals with KFC Ketchup 4 Side Seal Packaging Machine

The threat of tampering and counterfeiting has been on the rise. However, with the KFC ketchup 4 side seal packaging machine, brands prevent this threat because this machine forms highly secure tamper-proof seals. Moreover, the seals created by this machine are leakproof which decreases the chances of leakage and product wastage.

High Efficiency

High Efficiency of KFC Ketchup 4 Side Seal Packaging Machine- Picture Courtesy: Corriere

Manual labour is slow and tiresome, leading to decreased packaging output. But the KFC ketchup 4 side seal packaging works in significantly less time. This is because it is equipped with sophisticated technology and advanced machine controls that automatically and independently carry out forming, filling, and, sealing jobs effectively and with speed.

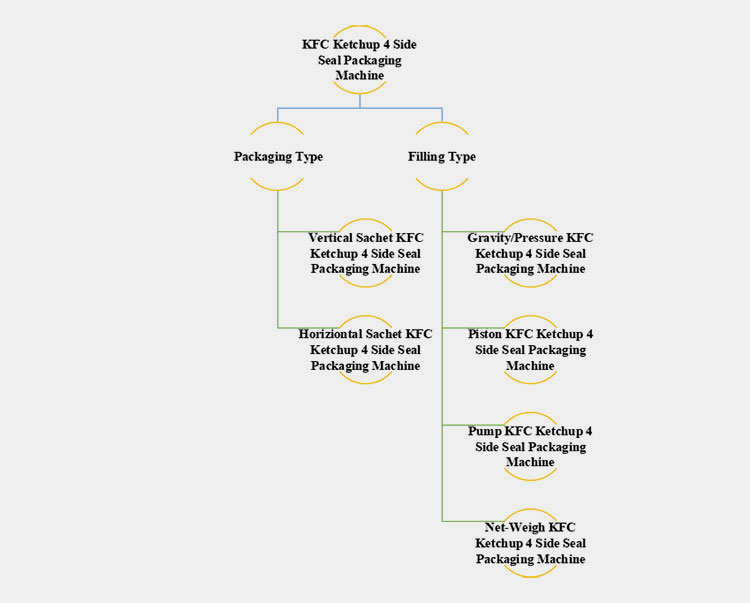

3.What are the Types of KFC Ketchup 4 Side Seal Packaging Machine?

There is quite a variety of types of KFC Ketchup 4 side seal packaging machines. We are detailing each type below:

According to Packaging Type

Vertical Sachet KFC Ketchup 4 Side Seal Packaging Machine

Vertical Sachet KFC Ketchup 4 Side Seal Packaging Machine

It is the most renowned type of KFC Ketchup 4 Side Seal Packaging Machine, where the equipment is defined by its small compact construction and vertical configuration. It is a completely automated manufacturing unit known for its simplicity and small footprint. Its packaging speed is generally dependent upon its number of lanes.

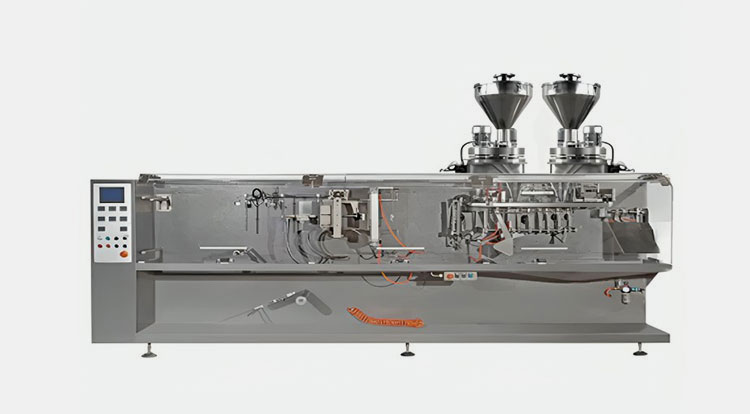

Horizontal Sachet KFC Ketchup 4 Side Seal Packaging Machine

Allpack Horizontal Sachet KFC Ketchup 4 Side Seal Packaging Machine

It is another frequently used machine type, best known for its packaging format. It typically outputs a straight rectangular-shaped sachet and has a horizontal body. It is developed with mechanical, electrical, and, computerized parts that automate every packaging stage. It is efficient and has a larger footprint. It gives good packaging results.

According to the Filling Type

Gravity/Pressure KFC Ketchup 4 Side Seal Packaging Machine

Gravity/Pressure KFC Ketchup 4 Side Seal Packaging Machine

It is a straightforward machine with a simple filling principle. It consists of a few parts. Gravity/pressure KFC ketchup 4 side seal packaging machine is usually used to process ketchup with thinner viscosities. The KFC ketchup is filled in the sachet under the influence of gravitational force or by the pressure difference. It is a cost-effective machine because it does not use much electricity.

Piston KFC Ketchup 4 Side Seal Packaging Machine

Piston KFC Ketchup 4 Side Seal Packaging Machine

It is routinely found in the food processing industries for the filling of different liquid products. it is composed of a cylindrical container and piston that move forward and backward for the filling. The vacuum created by the forward movement of the piston draws the KFC ketchup in the cylinder from the hopper while its backward motion forces the KFC ketchup in the filling nozzles from which this ketchup goes into the container.

Pump KFC Ketchup 4 Side Seal Packaging Machine

Pump KFC Ketchup 4 Side Seal Packaging Machine

This machine is used for the volumetric filling of KFC ketchup in the sachets. It comes with different pumps like gear, lobe, cavity, and rotor pumps which rotate to move KFC ketchup from the hopper into the filling nozzles. It is a safe machine used for dispensing KFC ketchup, as the latter does not come in contact with the filling devices. It is used for contamination-free loading of KFC ketchup.

Net-Weigh KFC Ketchup 4 Side Seal Packaging Machine

Net-Weigh KFC Ketchup 4 Side Seal Packaging Machine

Unlike other volumetric machines, the net-weigh KFC ketchup 4 side seal packaging machine fills the premium quality KFC ketchup by weight. It is a highly sensitive machine, dispensing exact quantities of KFC ketchup by measuring it with a weight scale. The communication between the machine PLC unit, load cell, and weighing scale load accurate amount of KFC ketchup in this machine.

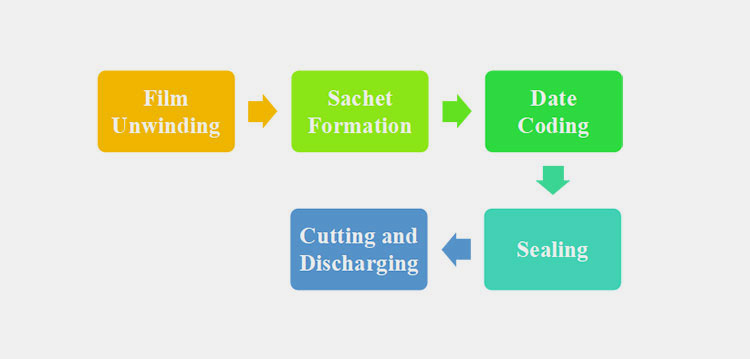

4.How Does KFC Ketchup 4 Side Seal Packaging Machine Work?

This machine executes a sequential order of steps to fabricate and pack sachets with KFC ketchup. Here is the detail of all these steps that are performed by the KFC ketchup 4 side seal packaging machine.

| Film Unwinding

First, the large film role is inserted on the unwinding disk. The film is unwound by the rotation of the roller and this film is passed over the dancer’s arm and rollers. These two components-rollers and the dancer’s arm keep the film on track and maintain the film tension. At the same time, the KFC ketchup is loaded in the product hopper. |

Film Unwinding |

| Sachet Formation

In the multi-lane KFC ketchup 4 side seal packaging machine, the film is cut into smaller strips which then go to individual forming stations while in the single-lane KFC ketchup 4 side seal packaging machine, the large film goes to the single forming tube. The packaging film is folded to align the two sides of the film with each other. The bottom and two vertical seams are sealed by the horizontal and vertical jaws, respectively. |

Sachet Formation |

| Date Coding

In the next step, after the fabrication of the KFC ketchup sachet, the manufacturing and expiry date, lot number, bat codes, etc. are printed upon the sachet. |

Date Coding |

| Filling and Sealing

It is a chief step of KFC ketchup packaging in which liquid KFC ketchup is dispensed into the formed sachet by the combined action of filling devices and filling nozzle. After filling, the horizontal sealing bars are again employed for airtightly sealing the top seam of the formed sachet. |

Filling and Sealing |

| Cutting and Discharging

Cutting knives are employed for breaking apart two joined sachets from each other. Afterwards, the finished sachets are dropped down into the product chute and they are collected for down-the-line packaging processes. |

Cutting and Discharging |

5.What are Other Products Packed by KFC Ketchup 4 Side Seal Packaging Machine?

Vast varieties of other products are packed by the KFC ketchup 4 side seal packaging machine such as:

| Condiments

Different types of condiments like mustard, mayonnaise, salad cream, Sriracha, honey, and wasabi are packed by the KFC ketchup 4 side seal packaging machine. |

Condiments |

| Sauce

Sauces like chili garlic sauce, hot sauce, soy sauce, tomato sauce and barbecue sauce are loaded into the sachet by this machine. |

Sauce- Picture Courtesy: Dipitt |

| Olive Oil and Other Edible Oils

Oils like sunflower oil, olive oil, and canola OIL for cooking purposes that boost the flavor of dishes are packed by the KFC ketchup 4 side seal packaging machine. This machine also feeds oils for cosmetic and aromatherapy purposes like lavender oil, peppermint oil, and tea tree oil that soothe skin and relax muscles |

Olive Oil |

| Jams and Jellies

Single-serve of jams and jellies for use in hotels and restaurants are also introduced inside the sachets. |

Jams- Picture Courtesy: heromea.com |

| Personal Care Products

For travelling and hotel use, personal care products like shampoos, hand wash, sanitizers, and conditioners are dispensed into the sachet by this machine. |

Personal Care Products- Picture Courtesy: Lash Doll Europe |

| Cosmetic Products

This machine also packs small samples of lotions, creams, and dyes in the compact sachet. |

Cosmetic Products- Picture Courtesy: Chagirmm |

6.What are the Materials Accommodated by KFC Ketchup 4 Side Seal Packaging Machine?

Material fabrication is important in the selling of KFC ketchup. So, there are various materials accommodated by the KFC ketchup 4 side seal packaging machine. These materials are discussed one by one below:

Laminated Films

Laminated Film Sachet- Picture Courtesy: dkngstudios.com

These films are formed by numerous materials deposited over others like food-grade plastics, aluminium foil, and nylon. It is one of the most common materials for KFC Ketchup sachets. These materials offer excellent printability, strength, and remarkable protection.

Metalized Films

Metalized Films Sachet- Picture Courtesy: Vending Superstore

These films are made of metal like aluminium. They are useful because they offer shiny metal luster that increases product appeal. Metal films provide high protection against elements.

Food-Grade Plastics

Food-grade Plastic Sachet- Picture Courtesy: Wolt

These materials are often used for making KFC ketchup by the KFC ketchup 4 side seal packaging machine. These include polyethylene, polypropylene, and nylon. These materials are cost-effective and flexible. Furthermore, food-grade plastics are tough and have lightweight characteristics.

Composite Films

Composite Film Sachet- Picture Courtesy: Dipti

These materials are formed by combining paper with plastics. They provide a wide range of properties like recycling, printability, and barrier properties and are superior to single-layered materials.

7.What are the Sealing Types & Shapes Processed by KFC Ketchup 4 Side Seal Packaging Machine?

Heat Sealing

KFC ketchup 4 side seal packaging machine uses different mechanisms to achieve different sealing types. Here is a list of sealing types processed by the KFC ketchup 4 side seal packaging machine.

| Heat Sealing | It is the most common sealing type used by the KFC ketchup 4 side seal packaging machine. In heat sealing, high-temperature sealing bars are pressed against the packaging film, causing the melting of the film. These melted films are joined together which forms a strong adhesivity between films. |

| Cold Sealing | It is unfrequently used by the KFC ketchup 4 side seal packaging machine. It does not involve heat instead uses pressure to join pre-glued packaging film. The application of pressure is important for creating a bond between the film layer. It is used for heat-liable materials that may degrade with high heat. |

| Ultrasonic Sealing | It is not routinely employed in KFC ketchup packaging. This sealing type is used with food-grade plastic. It involves the use of ultrasonic vibrations that are transformed into heat for bonding of film layers. However, there is a risk of leak with an ultrasonic seal. |

Shapes Processed by KFC Ketchup 4 Side Seal Packaging Machine

Rectangular Shape Packaging

Rectangular Shape Packaging- Picture Courtesy: Dieline

This sachet has four unequal sides and four distinct corners. It is the most popular type of oil packaging. The two sides of the rectangular-shaped packaging have a larger size than the other two sides.

Square Shape Packaging

Square Shape Packaging- Picture Courtesy: Packaging of the World

It is another most commonly used packaging type for the KFC ketchup. It also features four sides and four corners. However, unlike the rectangular shape oil packaging, all the sides of square 3 side seal packaging are of equal dimensions.

Bottle Shape Packaging

Bottle Shape Packaging- Picture Courtesy: go.com

It has a distinct bottle-shaped design, unlike the other 4 side seal oil packaging. It has a large base that tampers off towards the top. It is a tray-like sachet that is used for dipping as well as for squeezing ketchup out.

Oval Shaped Packaging

Oval Shaped Packaging

This packaging shape resembles an ellipse or egg-shaped and it is sealed at 4 sides-bottom, top, and two vertical sides. It saves space and thus has an advantage over rectangular and square shapes.

Trapezoid Shape Packaging

Trapezoid Shape Packaging- Picture Courtesy: Packaging of the World

This shape of KFC 4 side seal packaging has four sides and two opposite sides are equal and parallel to each other while the other two opposite sides are not equal to each other. It is also sealed on 4 sides.

8.How To Clean KFC Ketchup 4 Side Seal Packaging Machine?

Cleaning of KFC Ketchup 4 Side Seal Packaging Machine

Cleaning the KFC ketchup 4 side seal packaging machine is vital to remove leftover product residue and packaging materials. Properly cleaning different areas of this machine increases forming, filling, and, sealing efficiency. Detailed cleaning steps are discussed below:

| Power Off Machine | First, before cleaning, power off the machine and disconnect the machine cables from their switches to avoid accidents and electrical shocks. |

| Cleaning Exterior | Wipe down the machine using a clean cloth to remove leftover packaging film and dust from the machine frame. |

| Preparation of Cleaning Solution | Prepare mild detergent or other disinfectant solution according to the instructions mentioned in the machine manual. Do not harsh chemicals as they can damage machine parts. |

| Cleaning Interior | Use a cleaning solution, light brushes, and soft cloth to clean the interior of the machine, especially the sealing and filling area. It is important because KFC ketchup may accumulate in the sealing and filling area, leading to poor sealability and hinderance in product flow. |

| Rinsing | Rinse the machine with water after cleaning if specified in the manufacturer’s instructions. |

| Drying | Before starting the machine, allow it to completely dry by using a clean towel and compressed air. Afterwards, reassemble all the parts. |

9.KFC Ketchup 4 Side Seal Packaging Machine VS Powder 4 Side Seal Packaging Machine?

KFC Ketchup 4 Side Seal Packaging Machine and Powder 4 Side Seal Packaging Machine

Both these machines form sachet, but they are vastly different from each other because of their functionalities and filling systems. The details of differences between the KFC ketchup 4 side seal packaging machine and the powder 4 side seal packaging machine are discussed below:

| Features | KFC Ketchup 4 Side Seal Packaging Machine | Powder 4 Side Seal Packaging Machine |

| Applications | This machine is designed for the filling of diverse viscosity liquids like KFC ketchup. | This machine is typically employed for packaging, dry, free-flowing, and non-free-flowing powders. |

| Filling Devices | It usually uses piston or pump fillers for dispensing KFC ketchup inside the sachets. | This machine uses an auger and volumetric cup filler for loading powders into the sachets. |

| Sachet Materials | The laminated, metallized, and composite film materials are used by this machine. | It uses food-grade plastics and laminated films to form sachets. |

| Design | It typically forms rectangular, square or bottle-shaped sachets for packaging KFC ketchup. | It forms flat rectangular or narrow tubular sachets. |

| Sealing | Heat sealing is a common form of sealing utilized by the KFC ketchup 4 side seal packaging machine. | In addition to heat sealing, this machine also utilizes modified atmosphere packaging or inert gas flushing to eliminate the oxygen from the sachets or pouches. |

10.How to Resolve Sealing Issues Encountered by KFC Ketchup 4 Side Seal Packaging Machine?

Despite their automation and state-of-the-art parts, the KFC ketchup 4 side seal packaging machine faces some unanticipated issues that increase the production time and reduce the efficiency of the machine. Here are some tips that help solve these problems.

| Explanation | Solution | Image |

| Incomplete or Missed Seals | ||

| The seals of KFC ketchup 4 side seal packaging are not fully joined with each other due to which the product leaks from the sachet. This problem is due to incorrect temperature and pressure. It could also be due to unclean worn-out sealing elements | This problem is resolved by calibrating the temperature and pressure. Both these parameters must be within the specified range according to manufacturer guidelines. Cleaning, replacing or repairing sealing jaws also solves this problem. |

Incomplete or Missed Seals- Picture Courtesy: Average Socialite |

| Weak Seals | ||

| Although the seals are fully joined, there is no strong adhesivity between them which decreases seal integrity. This issue is due to a lack of correct temperature and pressure and also due to damaged sealing jaws. | Calibrate the heating elements and vacuum system so that temperature and pressure are within a specified range. Replace old and damaged sealing jaws. |

Weak Seals- Picture Courtesy: landpack.com |

| Wrinkled Seals | ||

| During the sealing step, the packaging material folds or creases. High pressure can be the reason for wrinkling. Overfilling of sachets may also lead to wrinkling. | Fixing pressure and lowering its range may solve this problem. Controlling the filling process also resolves this issue. |

Wrinkled Seals |

| Scorched Seals | ||

| Due to excessive temperature, the packaging materials get burnt, reducing the quality of the seal. It decreases the visual appeal of the product. | To resolve this problem, it is necessary to decrease the temperature by calibrating the temperature-measuring devices. |

Scorched Seals |

Conclusion

As you have learnt, this machine is important for food and cosmetic purposes. Its efficiency, flexibility, automation, speed, and accuracy provide a leg up to the productions and increase their profitability. This FAQ guide has covered every aspect of the KFC ketchup 4 side seal packaging machine. Now, you can make the best use of this machine by following the tricks and tips mentioned in this blog. By adding a KFC ketchup 4 side seal packaging machine, you can cost-effectively package your KFC ketchup. You can visit our Allpack website to procure the highest-quality machine at the best price.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide