Juice 4 Side Seal Packaging Machine: The Complete Buying Guide In 2024

Delicious and refreshing juices are the go-to drinks on sunny days. And for protection, these drinks are packed by juice 4 side seal packaging machine.

This machine carefully packages juice and plays a significant role in the longevity of juices. Juice 4 side seal packaging machine has a flare of efficiency, speediness, and, accuracy. This machine is one of the pillars of the juice packaging line. This machine brings businesses to far limits.

Are you trying to replace your old juice 4 side seal packaging machine or are you planning to invest in this machine then carefully read this guide because, by the end, you will know this machine.

1.What is Meant by Juice 4 Side Seal Packaging Machine?

Juice 4 Side Seal Packaging Machine

It is the type of machine that prepares juice powders or liquids for retailing, handling, and, delivery. It encloses juices inside the packing container that is sealed on all four seams- two sides, one upper, and one lower seam.

Juice 4 side seal packaging machine fully wraps juice powders and preserved juices inside the hermetically seal pouches or sachet.

2.What are the Industrial Uses of the Juice 4 Side Seal Packaging Machine?

The industrial uses of the juice 4 side seal packaging machine go beyond the food industry. Its applications encompass several industries because of its swiftness and error-free dispensing. Here is a list of industrial uses of juice 4 side seal packaging machine:

Beverage Industry

Application of Juice 4 Side Seal Packaging Machine in Beverage Industry

First and foremost, the juice 4 side seal packaging machine is an integral component of the beverage industry. It as the name suggests, plays a significant role in packaging juice powders, fresh fruit juices, and preserved juice inside 4 side seal packs. Besides this, it is also employed in packaging tea, coffee, sodas, and energy drinks inside all side seal packs.

Food Industry

Application of Juice 4 Side Seal Packaging Machine in Food Industry

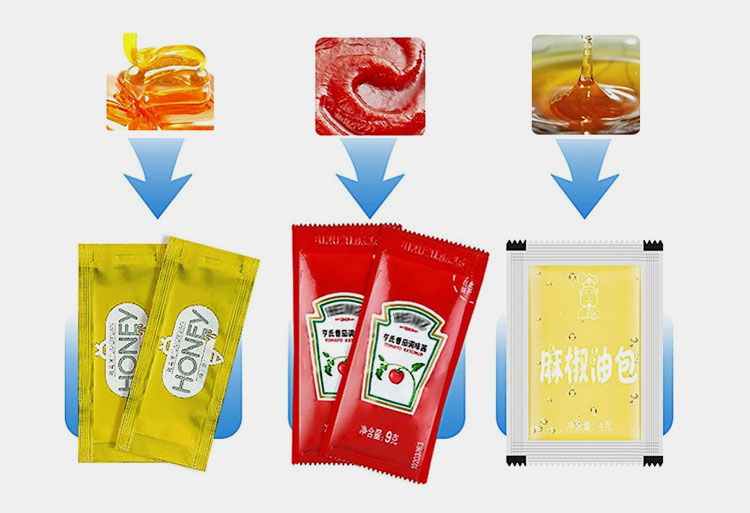

In addition to the beverage industry, it is used in the food industry, this is because 4 side-seal packing containers are one of the popular packaging styles for food applications. It packs spices, sugar, salt, herbs, curry powders, condiments, sauces, pastes, ketchup, etc in small compact pouches and sachets.

Confectionery Industry

Application of Juice 4 Side Seal Packaging Machine in ConfectioneryIndustry

Colored kinds of sweet food products taken as a snack like chocolates, colored beans, cookies, candies, toffee and many more are loaded inside compact pouches or sachets that are sealed at all sides. This machine packs confectionery products in eye-catching wrappers.

Cosmetic Industry

Application of Juice 4 Side Seal Packaging Machine in Cosmetic Industry

Look and presentation are two important aspects of cosmetic packaging and both are fulfilled by the juice 4 side seal packaging machine. It creates premium quality cosmetic packaging containers that attract customers from all walks. This machine packs lotions, creams, scrubs, moisturizers, dyes, and many more in 4 side seal packaging.

Personal Care Industry

Application of Juice 4 Side Seal Packaging Machine in Personal Care Industry

Good quality and hygienically packaged personal care products inspire the customers. This personal care packaging is prepared and fabricated by an all-rounder packaging machine called the juice 4 side seal packaging machine. This machine loads shampoo, soaps, face wash, conditioners and other hygienic products in sturdy packaging.

Chemical Industry

Application of Juice 4 Side Seal Packaging Machine in Chemical Industry

Use of juice 4 side seal packaging machine also includes chemical industry. In the chemical industry, this machine dispenses different kinds of paint samples, grease, glue, adhesives, varnishes, polishes, and detergent in 4 side seal packaging. It does not waste precious chemicals due to its high accuracy rate.

3.What is the Significance of the Juice 4 Side Seal Packaging Machine?

Juice 4 side seal packaging machine is well-favored and has special importance in different world industries because this machine has proven itself as a worthy instrument. It is a significant machine because of its wide range of benefits like:

Works Without Break

Juice 4 Side Seal Packaging Machine Works Without Break

This machine unlike human labor works without stopping. It does not take breaks and works without tiring. Human labour is prone to become tired after repetitive packaging tasks. But the juice 4 side seal packaging machine carries out monotonous packaging tasks 24/7.

Speed For High Output Rate

Juice 4 Side Seal Packaging Machine Speed

Juice 4 side seal packaging machine works quickly and packs juice products with more speed. Its packaging speed is far more than human packaging. Due to its extra high speed, it packs more juice 4 side seal packaging in less time. More speed means more juice packaging in the market, hence, bringing more profits for brands.

Secure Sealing For No Leakage

Juice 4 Side Seal Packaging Machine Secure Sealing

Packaging done by human laborers usually has weak sealing and poor film bonding, which leads to leakage of juice from the packaging. But by using juice 4 side seal packaging, brands do not worry about weak sealing because this machine creates strong and secure sealing. This tough sealing saves juices from getting spoiled and losing their freshness.

Saves Wastage Save Earth

Juice 4 Side Seal Packaging Machine Lower Wastage

This machine also promotes sustainability efforts by reducing the film and product wastage rate. It conserves the film packaging and does not spill and waste juice powders and liquids while packaging. Therefore, it serves to sustain the Earth's environment by saving the planet's resources.

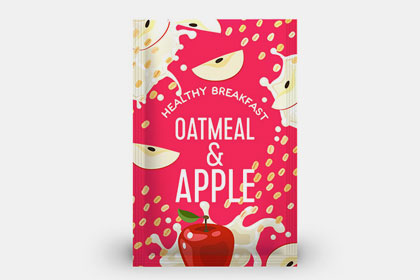

Marketability for Attracting Customers

Juice 4 Side Seal Packaging Machine Marketability

Juice 4 side seal packaging machine assembles creative and stylish juice pouches for captivating and engaging customers. This 4 side seal packaging is tailored to meet the customer expectation and their aesthetic presence on retail shelves boosts impulse buying.

Works Smartly and Accurately

Juice 4 Side Seal Packaging Machine Accuracy

This machine is equipped with the latest and up-to-date technology and gadgets like measuring sensors and load cells. These sensitive gadgets measure minute differences in the filling and accurately and precisely load juice materials inside the packaging.

4.What are the Primary Parts of the Juice 4 Side Seal Packaging Machine?

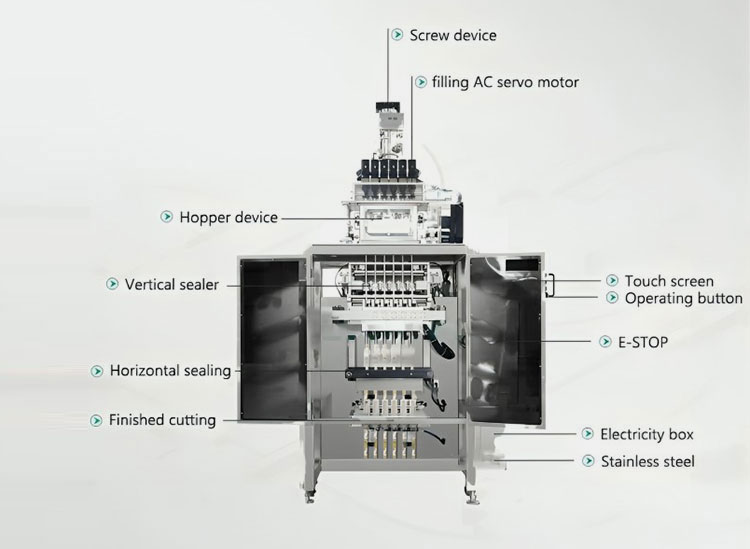

A juice 4 side seal packaging machine consists of different mechanical and technological parts that are capable of working efficiently to fill and seal juice 4 side seal packs. Here is the list of primary parts of the juice 4 side seal packaging machine:

Parts of Juice 4 Side Seal Packaging Machine

| Screw Device | This device has an essential role in the dosing of juice powders. It rotates to dose the powders into the packaging containers. It rotates in the cylindrical device and moves the product along its rotational path. It plays a significant role in delicate and precise filling. |

| AC Servo Motor | This motor is powered by electricity and rotates the screw. It regulates the speed and direction of screw movement. |

| Hopper Device | It is a rectangular device found at the top of the machine. Large quantities of juice products are housed in the hopper device for speedy operation. |

| Vertical Sealing | This part of the juice 4 side seal packaging machine is essential in forming 4 side seal packs. These vertical sealers seal the side seams of packaging film. |

| Horizontal Sealing | For sealing the top and bottom sides of the 4 side seal pack, the horizontal sealing bars are employed. These sealing bars use heat, pressure, and ultrasonic waves to seal the packaging containers. |

| Finished Cutter | In the last, sharp cutters are deployed for cutting and trimming the edges of finished packaging containers. |

| Touch Screen | It is an intelligent touch screen that behaves like the brain of the juice 4 side seal packaging machine. With this touch screen, operators can adjust filling parameters and bag length. Quick adjustment of machine operation is possible with a touch screen by saving data recipes. |

| Operating Button | This button powers the machine. It is pressed for turning on the juice 4 side seal packaging machine. |

| Electric Box | Different circuit breakers, switches, relays etc. are present in the electricity box to power different parts of the machine. |

| Stainless Steel Frame | This frame supports and balances the machine. |

5.How to Classify Juice 4 Side Seal Packaging Machine?

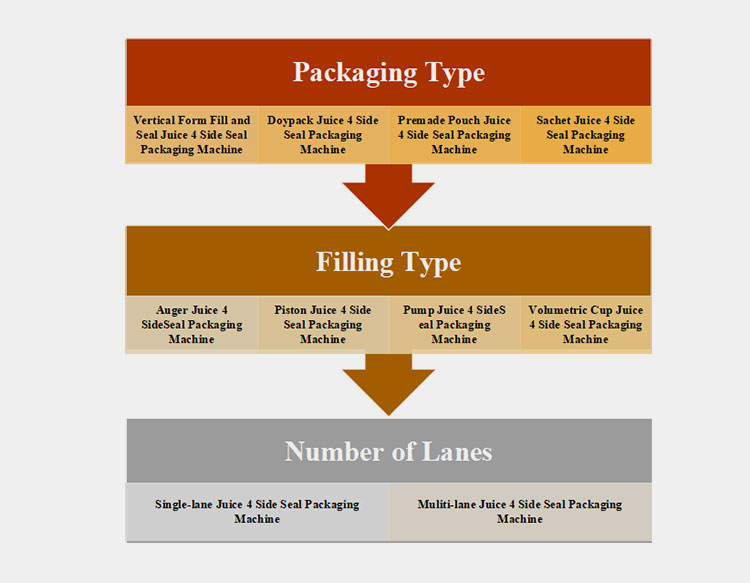

There are different classes of the juice 4 side seal packaging machines that are categorized into different makes and models based on packaging type, number of lanes, and filling type:

According to the Packaging Type

Vertical Form Fill and Seal Juice 4 Side Seal Packaging Machine

Vertical Form Fill and Seal Juice 4 Side Seal Packaging Machine

This machine is one of the most frequently utilized machines in the juice packaging line. It has a vertical configuration; therefore, it has a smaller footprint. The packaging operation also occurs in the upside-down direction. Versatility and speed are its key features.

Doypack Juice 4 Side Seal Packaging Machine

Doypack Juice 4 Side Seal Packaging Machine

This machine packs liquid juice and juice powders with its integrated auger and piston systems. It mainly performs the functions of conveying, weighing, dosing, and sealing functions. Doypack juice 4 side seal packaging machine consists of automated parts that are fully capable of working independently.

Premade Pouch Juice 4 Side Seal Packaging Machine

Premade Pouch Juice 4 Side Seal Packaging Machine

This type of juice 4 side seal packaging machine loads and seals premade pouches, hence the name premade pouch juice 4 side seal packaging machine. It swiftly doses pouches, consequently, it has far more output rate than its VFFS counterpart. It is an adaptable unit that processes diverse pouch styles.

Sachet Juice 4 Side Seal Packaging Machine

Sachet Juice 4 Side Seal Packaging Machine

It is a compact smaller-sized machine that has straight-forward working. It has one or more lanes with which it generates 4 side seal sachets. It is employed in the industry for quick and efficient single-time servings packaging of juice powders and liquids.

According to the Filling Type

Auger Juice 4 Side Seal Packaging Machine

Auger Juice 4 Side Seal Packaging Machine

This type of juice 4 side seal packaging machine fills dry juice powders inside the sachets or pouches. Auger juice 4 side seal packaging machine relies on the closed auger device for instant and contamination-free filling. Auger screws in auger fillers rotate to smoothly load the juice powders.

Piston Juice 4 Side Seal Packaging Machine

Piston Juice 4 Side Seal Packaging Machine

The filling in this type of juice 4 side seal packaging machine is accomplished with the movement of the piston. The forward motion of the piston draws the juices from the hopper into a cylinder while the backward motion of a piston cylinder forces the liquid out of the cylinder into the filling nozzle.

Pump Juice 4 Side Seal Packaging Machine

Pump Juice 4 Side Seal Packaging Machine

This machine is equipped with pumps that rotate to move the juice liquids from the hopper to the filling nozzles. It easily handles juices of both thinner and thicker viscosities. Filling in juice 4 side seal machine is time-based or pulse-based. Time-based filling means the pump is set to rotate for a fixed duration while pulse-based filling means the pump is programmed to rotate for fixed revolutions.

Volumetric Cup Juice 4 Side Seal Packaging Machine

Volumetric Cup Juice 4 Side Seal Packaging Machine

This type of juice 4 side seal packaging machine is comprised of cups. First, quantities of powders to be loaded inside each cup are measured, and then these pre-measured quantities of juice powders are dispensed from the hopper. This machine ensures that each 4-side seal containers receive a precise amount of juice powders.

According to the Number of Lanes

Single-lane Juice 4 Side Seal Packaging Machine

Single-lane Juice 4 Side Seal Packaging Machine

As the name suggests, it has only one lane that allows this machine to form one pack during one cycle. Therefore, a single-lane juice 4 side seal packaging machine has a lower productivity rate. It is best for smaller industries. It costs less than a multi-lane juice 4 side seal packaging machine.

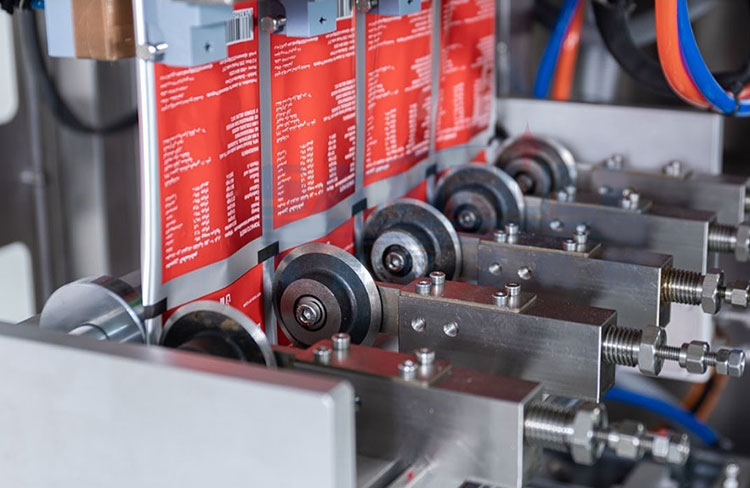

Multi-lane Juice 4 Side Seal Packaging Machine

Multi-lane Juice 4 Side Seal Packaging Machine

It has more lanes sometimes up to twenty which means it can produce up to twenty 4 side seal sachets in one go. The number of sachets formed typically depends upon the number of lanes. Due to its complicated design and higher output rate, this machine is more expensive.

6.Can You Tell Me About the Working of Juice 4 Side Seal Packaging Machine?

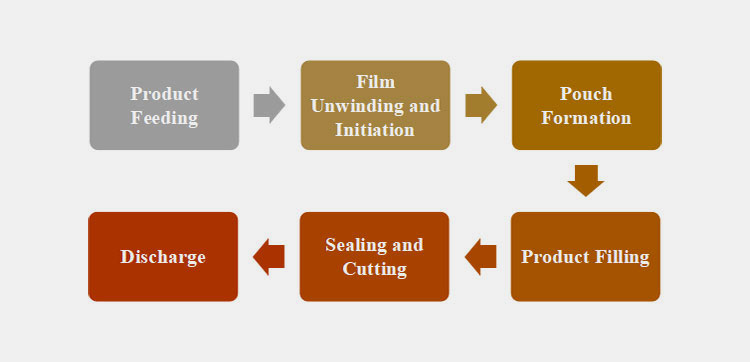

Working of Juice 4 Side Seal Packaging Machine

Every part in the juice 4 side seal packaging machine works efficiently and in synchronicity for seamless and streamlined operation. For your simplicity, we are penning detailed working of the juice 4 side seal packaging machine.

| Product Feeding

Product Feeding |

In this machine, a large hopper is present in which the operator or infeed pump feeds the juice products. The materials may be liquid or instant juice powders. |

| Film Unwinding and Initiation

Film Unwinding and Initiation |

A large film roll is placed on the film holder and is passed over the rollers and the dancer’s arm. Upon the PLC signalling, the film begins to unwind or open. |

| Pouch Formation

Pouch Formation |

On reaching the forming tube, this film is fashioned into a pouch or sachet with the harmonious action of forming collar and vertical sealers. The forming tube is a cone-shaped component on which film is doubled and wrapped to form a juice pack. Vertical sealers are used for sealing two sides of the pouch. |

| Product Filling

Product Filling |

After formation, the next step is juice filling. The piston, auger, pump, or other fillers dispense precise volume of the juice in the 4-side seal pack. |

| Sealing and cutting

Sealing and Cutting |

Upon completion of filling, the juice pouch is sealed at the top by horizontal sealers. Simultaneously these horizontal sealers seal the bottom part of the next juice pack. A cutting knife is responsible for cutting and separating two consecutive juice packs. |

| Discharge

Discharge- Picture Courtesy: Moon Juice |

The packed product leaves the machine through the outfeed chute. The unwanted film waste is collected in the recycling bin. From the outfeed chute or product conveyor, you can collect the finished and prepared juice 4 side seal pouches. |

7.What Type Of Sealing Mechanism Does Juice 4 Side Seal Packaging Machine Use For The 4-Side Seal?

Juice 4 side seal packaging machine seals juice bags and other packaging containers through different sealing mechanisms like:

Heat Sealing

Heat Sealing by Juice 4 Side Seal Packaging Machine

It is one of the most frequently employed methods for sealing 4 sides of a packing container. In this method, heated sealing bars or jaws carry out sealing by melting and fusing ends of seams using high temperatures. This method creates a strong seal.

Cold Sealing

Cold Sealing by Juice 4 Side Seal Packaging Machine

This method is an uncommon sealing method. Instead of using high temperature, high pressure is exerted on the packaging film to generate a strong bond between seams. This method is mainly used for sealing heat-liable materials.

Ultrasonic Sealing

Ultrasonic Sealing by Juice 4 Side Seal Packaging Machine

This is another common method for sealing in which high-energy ultrasonic waves generate heat for melting and joining the two edges of the packaging film. This sealing mechanism forms an airtight seal.

Impulse Sealing

Impulse Sealing by Juice 4 Side Seal Packaging Machine

This sealing mechanism is utilized for materials that degrade at high temperatures. A rapid and short impulse of heat radiation is utilized to create a swift bond around the seams of packaging containers.

8.What is the Difference between Juice 4 Side Seal Packaging Machine and 3 Side Seal Packaging Machine?

3 Side Seal Pouch

Juice 4 side seal packaging machine and 3 side seal packaging machines are two important machines in the packaging machine but there are some big differences between these two which we will discuss now:

| Features | Juice 4 Side Seal Packaging Machine | 3 Side Seal Packaging Machine |

| Sealings | This machine seals the pouches or sachets at all four sides; top bottom, and sides. | This machine seals the pouches or sachets at 3 sides; one top and two sides. It also creates a sealing combination of one side, one top and one bottom. |

| Applications | This machine is best for filling heavier-weight liquids like pastes, honey, etc. | It is used for packaging lightweight powders and liquids, like snacks, nuts, and other granular products. |

| Security | It creates a more secure closure. It forms a leakproof closure best for increasing the shelf-life of products. | 3 side seal packaging machine creates less secure packaging. It is fairly leakproof but its sealing is not strong when compared with the sealing of juice 4 side seal packaging machine. |

| Design | It has a more complicated design | It has a simple design construction. |

| Productivity | The juice 4 side seal packaging machine is slower than the 3-side seal packaging machine because it forms one additional seal. | It is quicker than its counterpart. |

| Cost | This machine cost more. | It is a more budget-friendly option for small businesses. |

9.What Packaging Type is Processed by the Juice 4 Side Seal Packaging Machine?

There are different packaging types processed by the juice 4 side seal packaging machine like:

| Standup Pouch

This pouch type is sealed at four sides-one top, one bottom, and two longitudinal. Due to flat gusseted folding at the base, it stands upright in the display cases. Due to these features, brands prefer to use standup pouches for marketability. |

Standup Pouch- Picture Courtesy: FoodBev Media |

| Flat-lay Pouch

This pouch also has 4 seals- one top, one bottom, and two vertical seals. Unlike the standup pouch, it does not have a bottom gusset or flat base, thus it lays on its back. However, with support, it can stand on the retail shelves. |

Flat-lay Pouch- Picture Courtesy: Virtual Packaging |

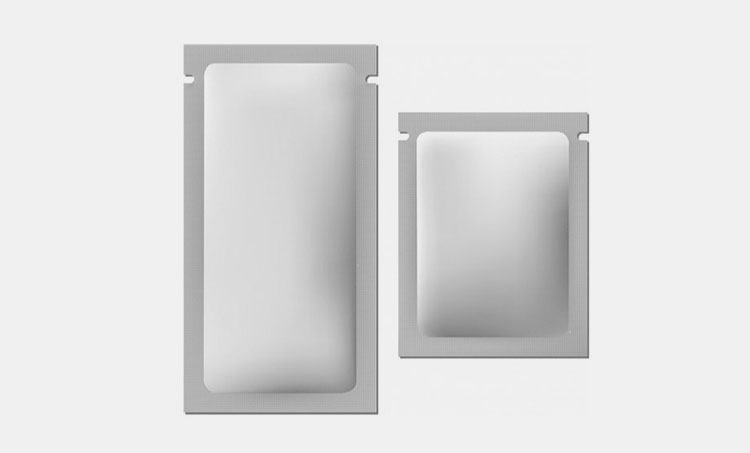

| Sachets

These sachets are also sealed on 4 sides. Sachets house single-serve of the juice powders and liquids. They are available in rectangular or square shapes. |

Sachets- Picture Courtesy: Evohealths |

10.Can You Explain Problems, Their Causes, and Their Solutions in the Juice 4 Side Seal Packaging Machine?

Yes, the juice 4 side seal packaging machine is a sophisticated unit that sometimes faces unanticipated problems that cause significant production interruptions and expensive repairs. However, we are giving some tips and tricks to solve these problems.

Wrinkling and Creasing of Film

Wrinkling and Creasing of Film

| Cause | Solution |

| The film feed mechanism experiences high tension.

Incompatibility of film with the machine. |

Fix the tension problems by adjusting the film on the rollers.

Ensure that the film is compatible with the machine. |

Unevenness in the Juice Filling

Unevenness in the Juice Filling

| Cause | Solution |

| Filling systems out of calibration.

Filling nozzles are clogged. Air bubbles in the juice Old filling systems |

Recalibrate the filling system

Clean the filling nozzles. Remove air bubbles Replace old filling systems |

Juice Leakage out of Seal

Juice Leakage out of Seal

| Cause | Solution |

| Inaccurate sealing due to insufficient temperature and pressure

Incompatibility of film material with the equipment Old sealing jaws Dusty or unclean film material |

Fix the issues of sealing temperature and pressure

Use packaging material that is compatible with the equipment Replace old sealing jaws Clean the film material |

Jamming of Film Material

Jamming of Film Material

| Cause | Solution |

| Incorrect alignment of film rollers and dancer’s arm

Poor positioning of the film roll of the roller Hindrances in the path of the film |

Properly align the roller and dancer’s arm and then correctly pass film over rollers.

Position the film roll rightly over the holder. Clear the obstructions in the path of the film and ensure the smooth film-feeding |

Uneven Packaging Shape and Size

Uneven Packaging Shape and Size

| Cause | Solution |

| Misaligned cutting knives

Out-of-calibration forming system Incorrect alignment of the forming system Film material differences |

Properly align the cutting blade in the centre of the sealing jaws.

Adjust the calibration of the forming system. Fix the alignment issues of forming system Make ensure that there is consistency in the packaging film |

Conclusion

Juice 4 side seal packaging machine is an advanced equipment that is the gateway for quick accurate packaging. This machine is added to businesses to achieve striking and captivating packaging in drastically less time than simple hand packaging. It is indeed the best way to take your business to new horizons. If you want to procure this dynamic unit for your business, then instantly message us. We, the Allpack Team will be more than happy to discuss your options with you.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide