Induction Cap Sealing Machine: The Complete Buying Guide in 2024

How do you ensure that your product packaging is tamper resistant and secure? An induction cap sealing machine is an absolute answer that offers a tremendous technology that has revolutionized the packaging industry in the competitive market across the globe. This machine is a super solution that rapidly provides you with the results that everyone look for in their dream production. Before purchasing we would suggest to please go through this article to know the best knowledge related to this machine. Let’s read!

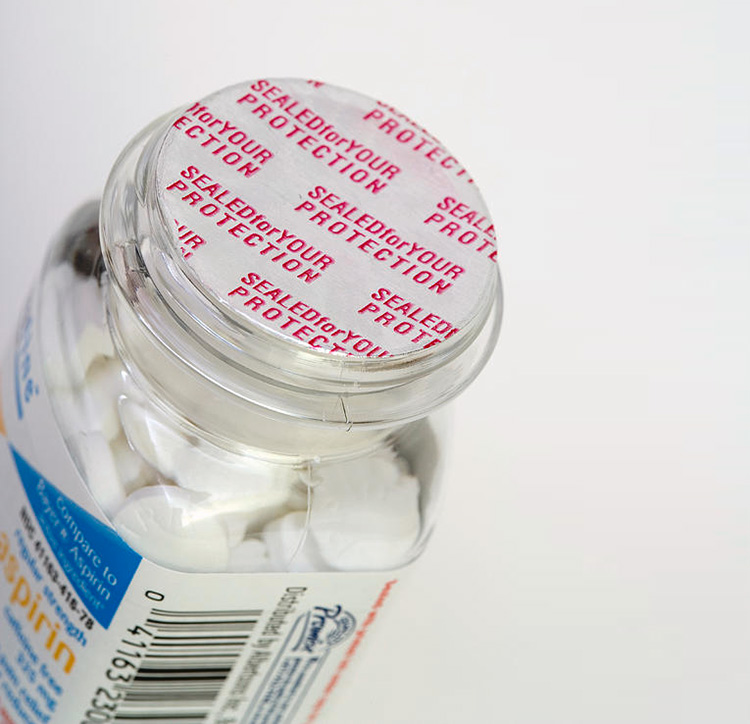

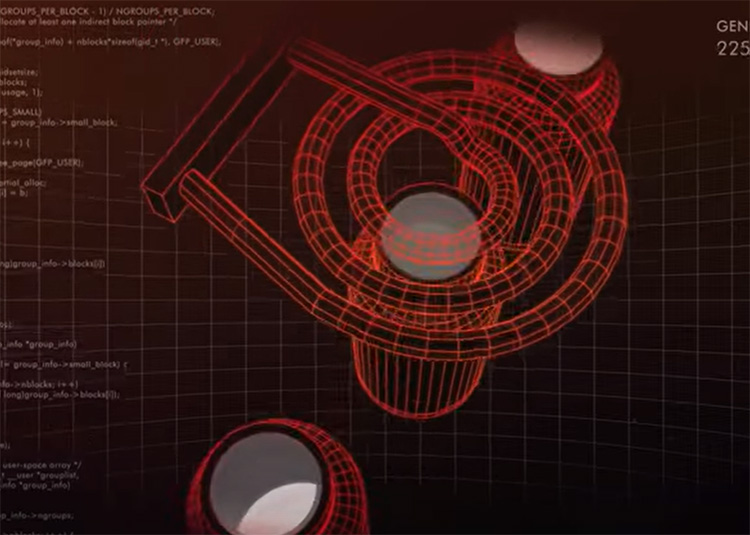

1.What Do You Know About Induction Cap Sealing Machine?

Picture Courtesy-Enercon Industries

An induction cap sealing machine is responsible for bonding a foil lamination around the bottle’s neck once they’re filled with packaging material. The induction cap sealing machine works by using electromagnetic power for generating heat waves that weld the liner to the container in order to seal hermetically.

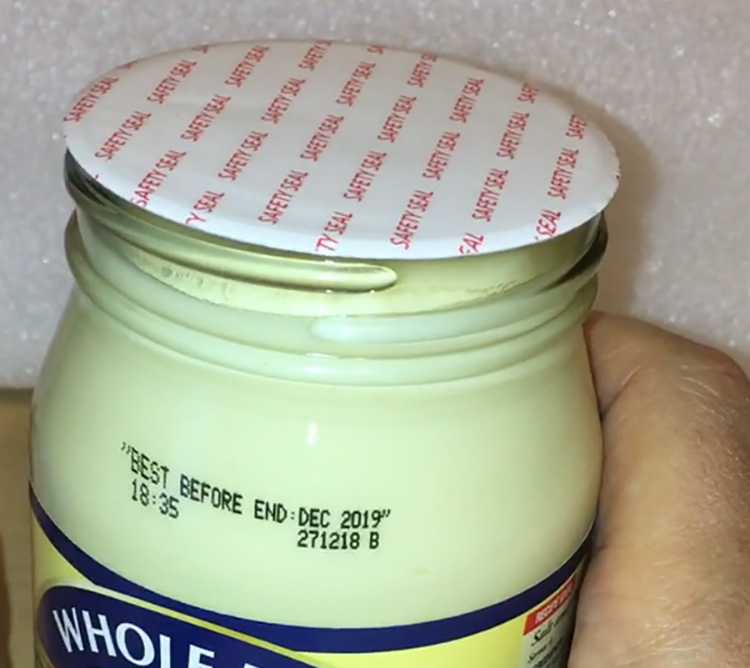

Plus, FDA has quoted this method as an effective way to achieve tamper evident products by providing firm and leak proof seal lining. Also, an induction cap sealing machine is suitable for a long term shelf life of your product by preserving them against unwanted environmental conditions that can interact with product and induce degradation.

The super technology is based on sealing various materials such as plastic, glass caps without contacting them or product. That s ‘why, an induction cap sealing machine is commonly used in healthcare, and food industries as it not only ensuring tamper proof but also integrity of product.

2.Where Is Induction Cap Sealing Machine Used?

An induction cap sealing is widely used in industrial sector due to the tremendous safety applications. Important industrial uses of this machine are described as:

Nutraceutical Industry

Worldwide top-notch nutraceutical industries packaging sectors rely on using an induction cap sealing machine to preserve quality of sensitive compounds such as vitamins, proteins, energy drinks, herbal supplement, enzymes, minerals, trace elements against interaction with oxygen and moisture that induce contamination of rancidity of product.

Food Industry

Manufacturers of food industrial sectors only trust on an induction cap sealing machine as it helps in creation of air-tight packaging of food products and keep them secure till end user. For example, ketchup, mayonnaise, yogurt, milk, sauces, condiments, spices, sweeteners, salts, etc., In fact this is a powerful protection way that satisfies customers with good quality as it guarantees against pilferage.

Pharmaceutical Industry

In pharmaceutical industry where quality, safety, and potency are considered as prime subject of product’s packaging; an induction cap sealing machine has been used for decades for this purpose. The inner foil sealing around the packaging material acts as a barrier against outer environment and locks the freshness and harming against moisture. This is used in production line of packing tablets, syrups, capsules, pills, ointments, medicinal jars, creams.

Chemical Industry

In chemical industry, an induction cap sealing machine is known for its best anti-counterfeit action for important chemicals products like alkali, salts, acids, bleaches, buffers, solvents like distil water, inorganic or organic, lab reagents, or neutral salts solution. Moreover, this machine ensure that sealed products are remain in active form, protected against spillage, and uncontaminated.

Cosmetic Industry

Cosmetic products are mostly sensitive to external environment and must be stored carefully for long term correct applications. For example lotions, serums, face foundations, eye creams, hand creams, pedicure, manicure sets, and other, which are always firmly sealed using an induction cap sealing machine to maintain products quality and offering tamper evident packaging.

Household Cleaning Products Industry

An induction cap sealing machine offering reliable packaging of products like detergents, floor cleaners, dishwashers, shiners and improving confidence in the product’s originality with air-tight and strong sealing.

Agro-Chemical Industry

The manufacturers of agro-chemical industry always seek for an induction cap sealing machine for packaging products like pesticides, herbicides, crops boosters, fertilizers, and other important products to ensure improved and safe handling during farming of crops.

Automobiles Industry

The packaging of automotive products cannot be done if an induction cap sealing machine is missing from its production line. Products like lubricants, engine oils, brake oil, and other fluid can be safely dispensed and stored with the sophisticated lining of aluminium sealings around the neck of bottles.

3.How Does Induction Cap Sealing Machine Work?

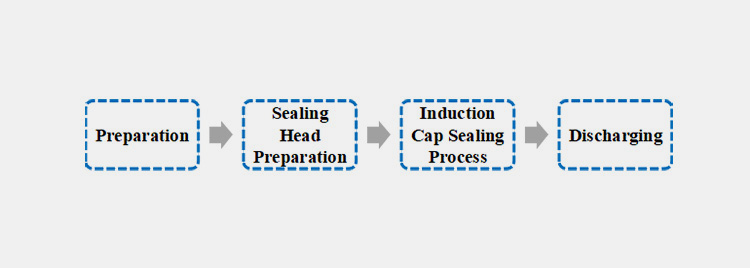

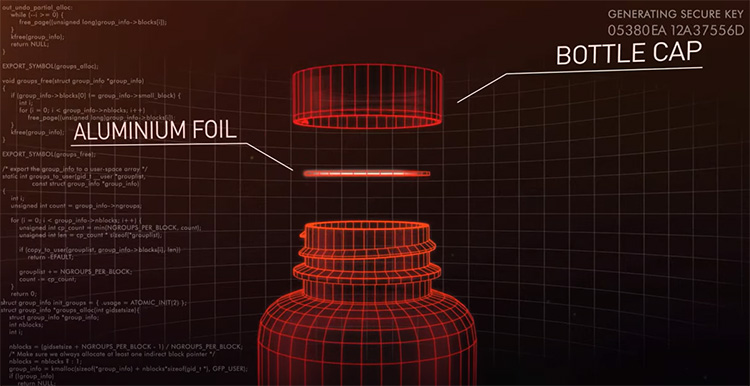

The working of induction cap sealing machine is quite simple. The working of the machine relies on heating coil which is induces by an electromagnetic field and its interaction with sealing material presented on the cap. Please look into basic four steps where the science of induction cap sealing takes place respectively.

STEP 1 Preparation

Indeed, this is a major step where bottles are first filled and secured with screwed cap or closure. This cap or closure is designed with an inserted liner which is composed of aluminum foil and thin film of laminated plastic or paper.

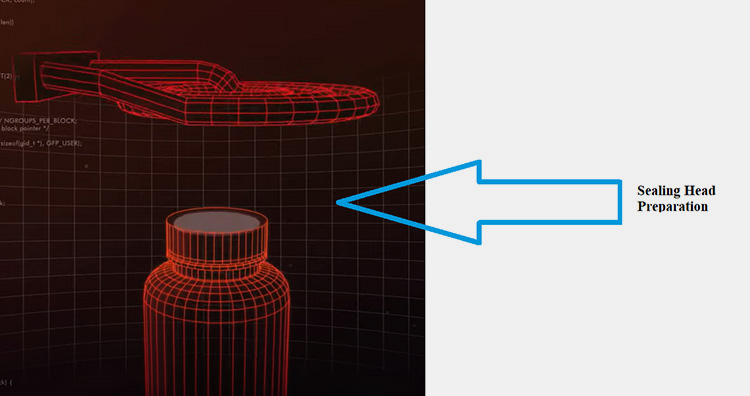

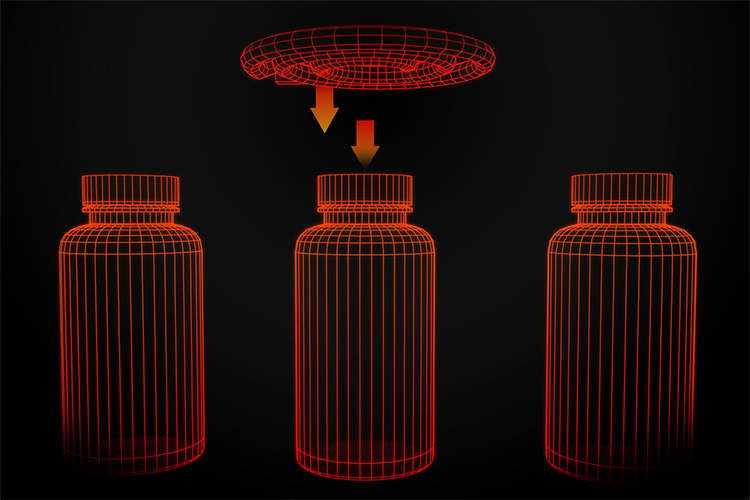

STEP 2 Sealing Head Preparation

A sealing head which is designed with an induction coil that helps in transferring of electromagnetic heat radiation and induce the field around the coil area. The surface or position of the head just above the container helps the stimulation of inner layer with heat energy. Before arriving, containers sealing head must be warm with recommended temperature.

STEP 3 Induction Cap Sealing Process

Picture Courtesy-Youtube

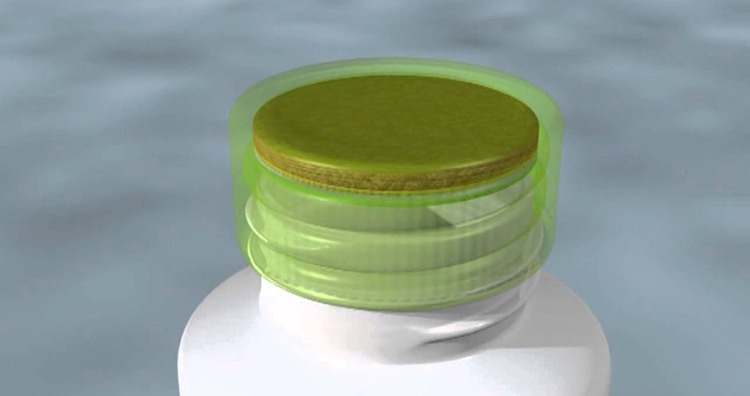

The process begins when step 1 and step 2 are ready and set of containers comes in the contact with electromagnetic waves that helps in emerging high-frequency waves which heats the liner. This liner melts and forms a loose bond around the neck of the container.

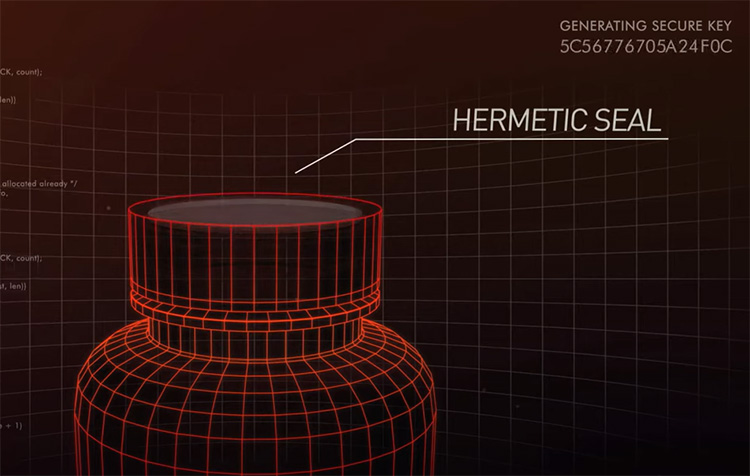

STEP 4 Discharging

After induction cap sealing process, set of containers leaves the sealing head zone and enters to the normal temperature where sealing cool and becomes to shrink and harden and forms a hermetic sealing layer around the lip of the containers on other words a tamper evident sealing layer is formed.

4.How Induction Cap Sealing Machine Benefits You?

An induction cap sealing machine offer various benefits to manufacturing and packaging companies. Those benefits are discussed below:

Preserve Freshness, Fragrance/Aroma, and Quality of Product

Nevertheless, an induction cap sealing machine is an excellent machine for offering an airtight hermetic sealing that will enclose the packaging against its external interaction of oxygen moisture, and light. This tightly enclosed container will be capable to fragrance or aroma of food products, maintain potency and efficacy of potential drug, or maintain integrity of the product for a longer time.

Tamper Evident Product

There’s no doubt every customer when pay money; they deserve the best one. An induction cap sealing machine offering promising packaging that convey message to potential clients that the purchase product is as original as dispensed by manufacturer.

User-Safe with Improved Product’s Safety

Picture Courtesy-Alibaba

Operating an induction cap sealing machine is super-easy. An operator has to in-feed the data such as heat exposure time, speed of conveyor, etc., and rest of function can be performed safely. You don’t need to worry about overheating the system as system is featured with cooling fan to overcome heat generation inside the system. Plus, a strong sealing of container safe your product against cross-contamination or leakage. So you can get Two in One task by a single machine.

Improving Brand Reputation

Picture Courtesy-Alibaba

By offering tamper evident product across the market regions will gain the attention of professionals due to its appearance and original material can ultimately lead to make a great reputation of your company.

Saving Your Budget

Now you don’t need glue or tape for packaging the lid over the container. An induction cap sealing machine is a reliable and robust solution that can save your money in the most sophisticated way just by-passing hundreds of containers under the zone of electromagnetic waves and that’s it- Your containers are perfectly sealed.

Quality Compliance

Picture Courtesy- Alibaba

This factor is always paramount to all manufacturers who belong to food, beverages, pharmaceuticals, nutraceuticals as they need to be very astringent to health regulatory needs. For this., an induction cap sealing machine is perfect solution as it will bind the liner to container’s neck without affecting integrity of the product and maintain product safety and quality throughout its shelf life.

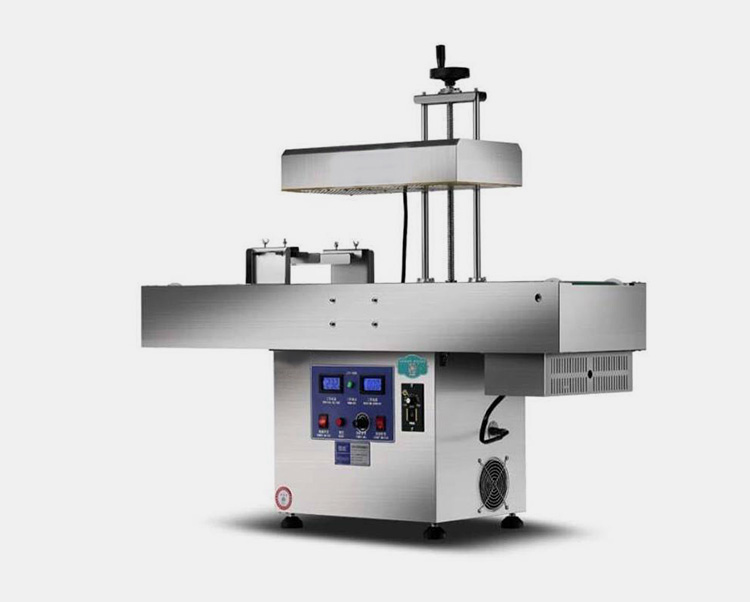

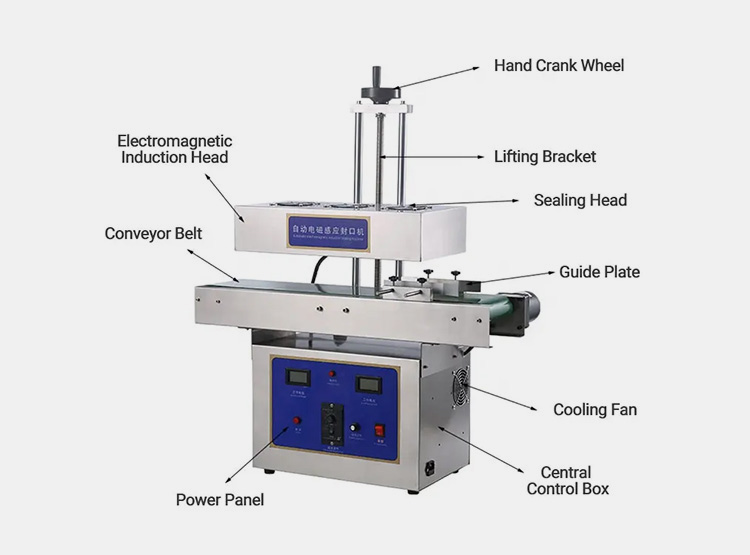

5.What Are Structural Parts of Induction Cap Sealing Machine?

An induction cap sealing machine is a simple machine that can easily perform complex functions in no time. Let’s go through some important parts of the machine also with their specified responsibilities.

| Electromagnetic Induction Head | This unit works as the heart of the machine which generates the electromagnetic high frequency zone around the moving bottle caps that strikes with high-frequency radiation when entering. A mentioned about cap is fitted with liners that become heated when pass by the field and absorb inside. This ultimately melts the firm bond and leads to stick around the rim of bottles and seals strongly upon cooling. |

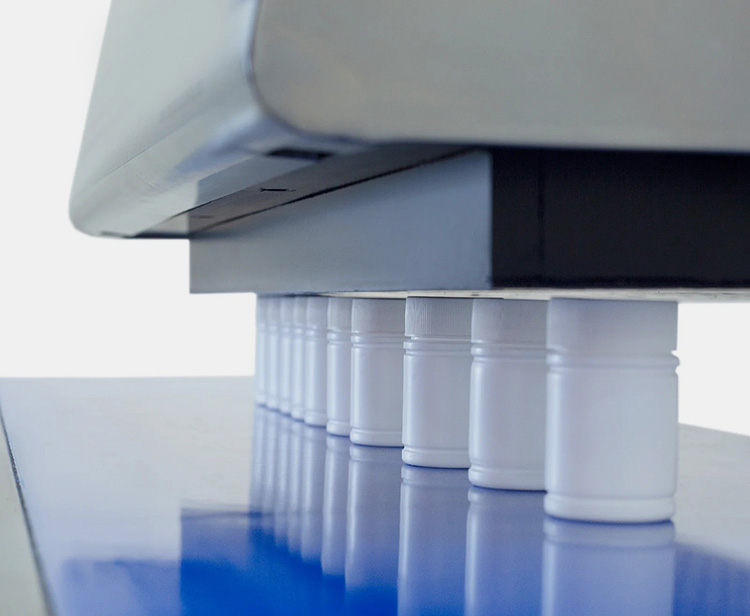

| Conveyor Belt | This unit works as a transporting medium that efficiently transports the containers for the induction cap sealing procedure. A set of bottles comes into the electromagnetic field via a conveyor and leaves after exposure. The speed of the conveyor and exposure time can be adjusted by using a PLC system. |

| Hand Crank Wheel | Some bottles are small while some are not, an induction cap sealing can ensure various height bottles treatment by adjusting the hand crank wheel to set the bottle height with a sealing head or conveyor. |

| Lifting Bracket | An induction cap sealing machine is supported by lifting bracket which lift the sealing head in an upright position and with vertical alignment. Moreover, it also helps you in maintaining the portion between the machine and the caps of the bottles in order to achieve effective sealing. |

| Sealing Head | This section ensures the applications of electromagnetic radiation in order to produce perfect sealing. This is located just above the cap liners hence easily gets exposure of bottle caps and provides fast heating. |

| Guide Plate | As its name shows, it helps containers to stay in an upright position along with the conveyor pathway and ensure bottles are properly positioned following accurate movement for excellent and even sealing. |

| Cooling Fan | This is well-known to you if a machine produces heat must be prone to over-heat. To balance this a cooling fan is featured within a machine that lowers the chances of overheating and offering 100% safety and security to the operator and the working environment during continuous operation. |

| Central Control Box | This is known as the brain of the machine that controls the major functions of the operation such as sealing time, exposure time, speed of container movement, etc. Moreover, the operator can visualize the process and get notifications and alerts from this unit. |

| Power Panel | This unit is comprised of important electrical components that merge and runs the system. |

6.What Is the Classification of Induction Cap Sealing Machine?

The classification of an induction cap sealing machine is described below:

BASED ON AUTOMATION

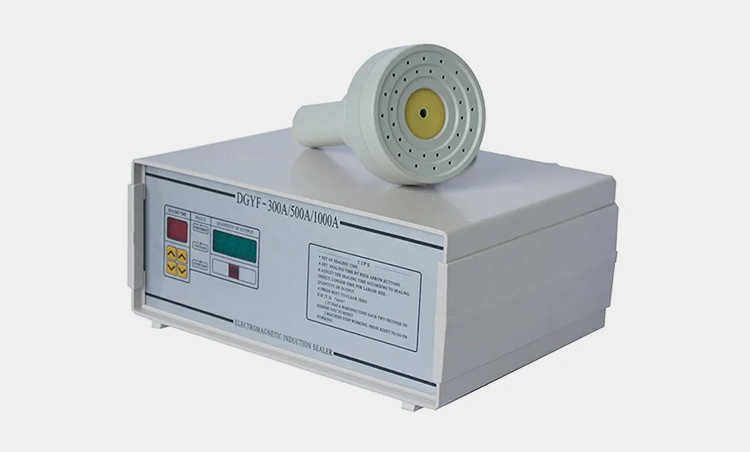

Manual Induction Cap Sealing Machine

Manual Induction Cap Sealing Machine -Picture Courtesy: Alibaba

This is an ideal machine for smaller production units or for laboratory applications that require manual handling by holding an induction cap sealing machine in hand and positioning it over the container to radiate an electromagnetic field. This machine offers a limited number of containers sealing each minute and per hour.

Semi- Automatic Induction Cap Sealing Machine

Semi-automatic Induction Cap Sealing Machine -Picture Courtesy Technopack

This machine offers to cater large production capacity per hour. Loading and discharging of containers required manual handling whereas remaining of the task can be performed by the machine itself. This type of machine is ideal for small to moderate production lines.

Automatic Induction Cap Sealing Machine

Automatic Induction Cap Sealing Machine- Picture Courtesy Alibaba

Running a large production line with high speed processing requirements prefer an automatic induction cap sealing machine as it can treat hundreds of jars/containers/bottles per minute and thousands of containers per hour. This machine is suitable for working day and night without the need for fixed supervision or manpower.

BASED ON WORKING

Capless Induction Sealing Machine

This machines is specifically design to seal the quality assurance of the product by applying an aluminium liner of helmetic seal without having caps over the bottle. The seal is temper evident and airtight applies on the mouth of the containers which helps to secure the product from tempering and contamination.

Continuous Induction Cap Sealing Machine

For high throughput production lines for packaging of products in batches, this machine is used for consistent quality sealing with lids. This machine has significance in industries with annual mass production.

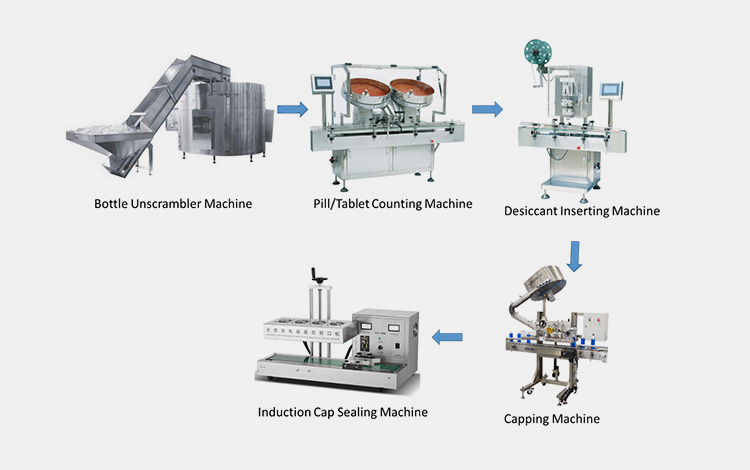

7.What Is The Production Line Of Induction Cap Sealing Machine?

Bottle Unscrambler Machine

This machine is very useful in several packaging industries like pharmaceutical industries, beverage factories, and cosmetics. At high throughput production levels, the bulk of jumbled bottles need to be arranged in the correct orientation which enables to align them in the production line of packaging. This machine work by rotating disk and belts for the proper alignment of bottles. It is used in high speed packaging industries with mass production.

Tablet/Pill Counting Machine

It is most commonly used in pharmaceuticals, health care related industries mainly required to fill batches of containers with an accurate number of pills or tablets. This machine automates to ensure product accuracy and efficiency for fast packaging.

Desiccant Inserting Machines

This machine is mainly responsible to enhance the quality of the product. It is specialized to insert humidity-repellent pouches, most commonly used in pharmaceutical, food, and electronic goods to avoid moisture-sensitive products from damage.

Capping Machines

To secure the product, this machine intends to apply caps on the bottles/containers like screw-on caps, snap-on lids, and press-on caps, etc for quality assurance. This step is the first sealing step, in the next step caps are properly sealed to save the product for transportation and shifting of the batches. Improper capping can lead to contamination or leakage.

Induction Cap Sealing Machine

The application of aluminum foil seal or liner on the edge of the container is generated by heat in induction cap sealing machines. This machine works on the principle of induction heating to seal the mouths of the bottle to secure the product efficacy.

8.How Does Induction Cap Sealing Machine Work with Different Caps Sizes?

An automatic induction cap sealing machine is capable of sealing caps hooked to various sizes, on various heights and materials instantly.

This can be adjusted using the automatic controller or manually modulating the height of the sealing head by moving them up or down to the size of the bottle/container to achieve exceptional use.

Due to this flexibility, an induction cap sealing machine is enough to integrate with another machine for a variety of purposes for diverse formulation packaging and ensuring the fastest changeovers.

Plus, if you’re thinking about what cap’s diameter it can handle then most of the machines offering induction cap sealing with cap diameter size varies from 20mm to 120 mm or 7.87 - 47.24 inches.

9.What Types of Containers And Caps Are Compatible With Induction Sealing Machines?

An induction cap sealing machine is suitable and compatible with mentioned containers and sealing materials, such as:

TYPES OF CONTAINERS

PET Containers

Polyethylene Terephthalate can create lightweight and transparent bottles that are commonly used in storing food, beverage, and personal care products and can be compatible with an induction cap sealing machine with one piece or two-piece liners.

HDPE Containers

High-Density Polyethylene which is a highly durable and rigid plastic used for various purposes can produce effective sealing with an induction cap sealing machine and prevent leakage of product offering high packaging security.

LDPE Containers

Low-Density Polyethylene containers are flexible and can store produce that are used by squeezing the tubes or containers, such as kinds of toothpaste, lotions, etc., An induction cap sealing machine produces effective sealing with LDPE containers.

PVC Containers

Polyvinyl Chloride containers are absolutely cost-effective for storing various products used in medical supplies industries or food packaging companies. An induction sealing machine is highly compatible with PVC containers with particular sealing liners.

PP Jar & Bottles

Polypropylene plastic containers and bottles are highly popular for their high melting points. These jars and bottles are used in various industrial applications. An induction cap sealing machine is best known for its compatibility with packaging material composed of PP materials.

Glass with Plastic Caps

Products like jams, jellies, pickles, sauces, and spices, are commonly stored in glass jars; but their packaging is done by screwing plastic caps to make them induction cap sealing machine friendly for airtight sealing.

TYPES OF CAPS

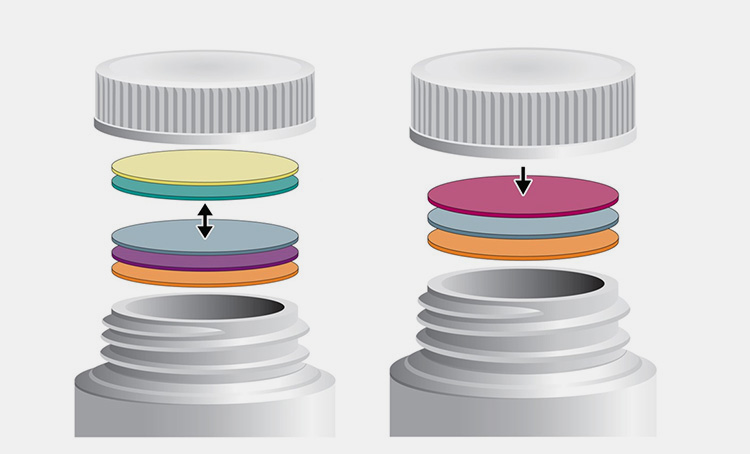

One Piece Liner

It is a single-piece liner that is fixed in the cap and typically made up of foam or pulp joined with a layer of foil. This is best known for its cost-effectiveness and firm sealing.

Two-Piece Liner

This is mainly composed of two layers. One is backing material and a film seal. The backing material is made up of foam and pulp while the other layer is made up of film seal. This cap is suitable for air-tight and tamper-evident sealing.

Higher Barrier Version

This is a highly specialized form of cap liner which is made up of multiple layers of resilient materials that forms an effective barrier against the external environment such as chemical, or physical factor forming more stronger integrity with the bottle/container.

10.What is the temperature of the induction Cap sealing Machine?

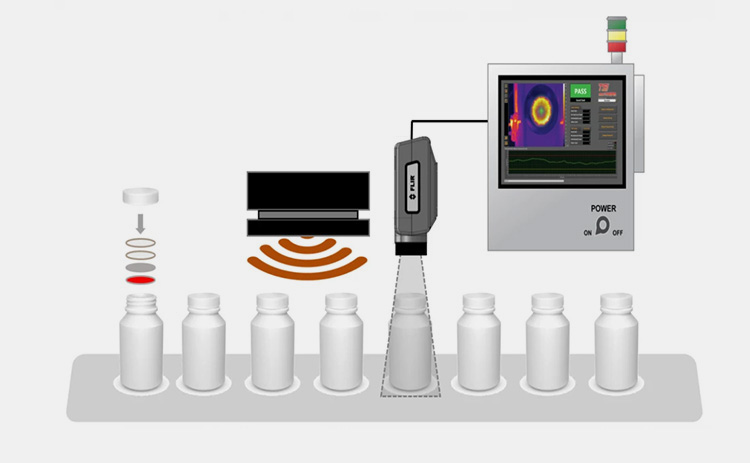

Picture Courtesy- enerconind

The sealing head of an induction cap sealing machine is designed in a way that can induce heat temperature varying up to the type of material.

The material cap sealing layer made up of aluminum foil commonly requires a temperature limit of 185-350F to conduct heat and activates the heat seal inner coating.

A sealing head has an affinity to transfer heat radiation in the foil layer uniformly and evenly to prevent the liner's weakness or damage sealing.

As an electromagnetic field absorbs underneath the layer of sealing foil it tightly bonds with the container. After leaving the induction, once the sealing cools down the film’s hermetically seal can be seen when you open the cap of the bottle.

When the cap material is PET, HDPE, LDPE, and PVC, the observed sealing temperature ranges from 150 to 250°C.

11.How To Clean & Maintain Induction Cap Sealing Machine?

For cleaning and maintenance, you must follow the manufacturer’s guide to maintain the efficiency of the machine and prolong the life span. Following are some of the most important instructions for cleaning and maintaining the induction cap sealing machine.

Cleaning

| Superficial residual removal | Always take a dry cloth for cleaning the exterior of the machine and be careful in cleaning the surrounding areas of the sealing head and control panel carefully |

| Safety Precautions | Before cleaning make sure all the electric connections are powered off |

| Sealing Head | There must be the use of soft and damp cloth, avoid the usage of abrasive clothes for cleaning the sensitive parts of the machine |

| Conveyer Belt | For proper cleaning, you have to remove the conveyor's belt according to the manufacturer’s instructions and clean it with warm soapy water and rinse it thoroughly and dry it first before reinstallation |

| Cooling System | From the prevention of overheating the cooling system has cooling vents and fans to make a proper airflow. It is important to remove the dust for their proper rotation |

| Electric connections | This is the most crucial part of cleaning where it is important to note any rust and wire damage from the connection of the machine to the main powerhouse board. |

Maintenance

| Regular Lubrication | It is highly recommended to make a chart of weekly checks on lubrication because it has a strong impact on the machine's functioning. All parts of the machine like the conveyor belt, moving trays and rotary pulleys, etc. must be greased at subsequent time intervals to maintain the efficiency of the machine |

| Replacement of Gaskets | Gaskets are the sealing liners between the containers and the caps. Keep on check for any damage, or crack on the gaskets and remove them once they are damaged. |

| Calibration | It is important to calibrate the machine periodically effectively to the sealing temperature and duration. Improper calibration can damage the packaging materials. |

| Maintain the Stock | According to the manufacturer’s guidelines, there is always an inventory list of the machine's spare parts to avoid any unexpected issues. |

| Professional Check | For the maintenance of the machine’s optimal performance, according to the manufacturer’s recommendations, there must be monthly visits arranged by the company for the professional technicians. |

12.Is Induction Cap Sealing Machine the Same as Heat Sealing Machine?

No, although Induction Cap Sealing and heat sealing offering the sealing but the working use is different for the creation of sealing.

An induction cap sealing machinefollows the principle of electromagnetic induction for thermal radiation to form a tamper evident sealing. On the other side, a heat-sealing machine creates sealing with the help of high temperature heat sealers.

An induction cap sealing machinebonds the laminated material over the tip of the bottle via the non-contact method. This sealing is ideal to preserve the freshness, fragrance, and quality of the product inside the container without harming its integrity via heat radiation. Whereas the heat sealing machine works by contacting the sealing material.

An induction cap sealing machineneeds a conductive pathway to run electromagnetic energy and transfer movement of electrons to induce heat, such as aluminum foil those seals around the edges of the container. Whereas a heat sealing machine can be used for sealing a variety of materials such as paper foiled laminated goods, plastic film, bags, etc.,

An induction cap sealing machineis an advanced way of sealing whereas a heat sealing machine is comparatively more simpler version that can be used anywhere even in the kitchen for sealing bags.

When a container comes across an induction cap sealing machine; it produces sealing. Besides this,a heat sealing machine required pressure to seal the material, if pressure is insufficient to seal may fail.

13.What Technical Problems You Face with Induction Cap Sealing Machine?

An induction cap sealing machine can sometimes encounter technical problems; one must know how to deal with them. Below table is describing common faults as well as their corresponding solutions.

| Problem & Cause | Solution | Picture |

| No Seal

This could be the result when the bottle passes through the sealing process but does not show sign of adhesion around it. Causes Insufficient Induction field. Improper exposure time. Insufficient or wrong induction liner. Improper sealer running |

Increase the Percent Output of the induction cap sealing machine.

Slow down the speed of the liner. Check the alignment of the sealing head. |

|

| Weak Seal

When the bottle shows sealing but fails the pressure seal test. Causes Low output pressure and poor settings. Inadequate exposure time. Improper Sealing Poor Toque

|

Increase Pressure Percentage OUTPUT of the induction cap sealing machine.

Determine the torque requirement of the bottle and closure. Monitor and verify the alignment of the sealing head. |

|

| Burned Sealing

This can be checked when the seal liner shows discoloration or a wrinkled surface. That can also be determined by burned smell or a change in the taste of product. Causes Excessive exposure of induction heat field. The improper head setting of the machine. Excessive temperature and time exposure.

|

Verify and reset the OUTPUT % on the sealer.

Correct the alignment of the sealing head. Reset exposure time and temperature. |

|

| Overheating or Underheating Problems

Machines mostly have a failure with sensors that results in these two problems. Causes Incorrect power setting. Improper detection/sensor problem. |

Re-calibrate the machine’s settings.

Reset the exposure time of the sealing zone. Reset the speed of the conveyor belt to assess bottle exposure time. |

|

14.What Things Should Be Considered When Purchasing an Induction Cap Sealing Machine?

Purchasing an induction cap sealing machine is a tricky experience, there are various things you must consider when looking for a purchase. Such as:

Determine your Need!

Consider your packaging needs and estimate your production capacity requirements per minute or per hour. Look at what type of packaging containers you use. Also, check what size caps you use and what type of material you deal with. Knowing your goals must be the first step to begin with your plan.

Pay Attention to the Machine’s Specification

Picture Courtesy- Wikipedia

Call your manufacturer or communicate with them via email to assess the manual and measure the machine’s specifications. Consider the workforce, your estimated budget, and the machine’s efficiency.

Your Area

Picture Industry- Kaps Industry

Estimate your lab size and the machine's width, height, and size when assembling with other units in order to achieve better installation and working conditions.

Competitive Vendor

Choose competitive vendors like Aipak Pharmaceuticals who always pay attention to consumer’s requirements and offer promising products and services.

Pre-Sale and Post-Sale Services

Good manufacturing companies always strive their best to offer excellent services whether pre-sale or post. You must know a good pre-sale service will allow you to get the right machine and post-sale services will ensure greater productivity.

Conclusion

For effective sealing, an induction cap sealing machine is the mainstay for major business firms ranging from food to health, household to agriculture. Thus, selecting the correct option can boost your investment. We hope this guideline has conveyed some very informative points about the induction cap sealing machine that you always look for. Allpack understands what a customer really needs to integrate into their packaging production line. We’re here to assist you! Please message us to open a gateway of discussion for future investment.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

Tell us your material or budget, we'll reply you ASAP within 24 hours