IBC Bin Blender: The Complete Buying Guide In 2024

A conventional way of blending is always proved as slow & more expensive. What’s the solution? Of course, its solution is a very simple and advanced machine known as an ‘IBC Bin Blender’ which is preferred by manufacturing industries worldwide.

IBC Bin Blender – Picture Courtesy: MedicalNewsToday

Today, this machine is known as an effective solution for simple mixing without any risk of cross-contamination and time waste. Planning to purchase? You are at the right place. This blog will have all the necessary points that you are looking for. After reading, you’ll be able to select the best machine for your manufacturing facility. Read on!

1.What is IBC Bin Blender?

IBC Bin Blender

An IBC bin blender is a highly popular type of blender used for mixing powders. IBC stands for ‘Intermediate Bulk Container’ which simply means it is used for processing bulk materials for manufacturing various products. This is a specialized machine that provides you with surety for hygiene and safety. A highly modern and innovative equipment that has eased the job of mixing and blending without risk of cross-contamination.

2.What Leading Industries Require IBC Bin Blender?

In worldwide leading manufacturing industries utilize IBC bin blender for powder processing for a broad range of applications. Let’s view the major industrial uses of IBC bin blender.

Bakery Manufacturing Sector

Bakry- Picture Courtesy: Sydney Morning Herald

Baking is all about the game of blending and mixing.

IBC bin blender has significant utilization in the manufacturing of bakery items that are mostly involved in powdery material handling, such as wheat, flour, sugar, baking soda, starch, and so on. All you must do is mix them uniformly which is nevertheless a challenging task. By following, the process steps of IBC bin blender, it enables their customers to achieve homogenous blend which makes bakery item absolutely perfect.

Nutrition Products Manufacturing Companies

Nutritional Products- Picture Courtesy: Jefferson Centre

Acquiring nutrition is essential for well-being. An IBC bin blender primarily impacts on nutritional products manufacturing. For example, dry powders, milk powders, protein powders, whey, casein, pea, probiotics, allergen-free, lactose intolerant products, vegan. Whether it is sticky powdery particles or free flowing, an IBC bin blender is ideal in the overall production procedure.

Remember, nutritional products are very sensitive to moisture and contamination, therefore right equipment such as IBC bin blender can offer high safety to keep and maintain your nutritional formulation stable.

Beverage Makers

Beverage Makers- Picture Industry: Kemin

Beverages and mixes are the appealing and trendiest items that is shown with superior market values. The beverage makers have no other ideal option than IBC bin blender to bring the tremendous processing. That’s why industrialist prefer IBC bin blender for their products.

Flavoring

Flavoring Agents

Your food recipes contain flavoring, fragrances, spices, seasoning, and so much more. IBC bin blender is a straightforward machine that facilitates easy processing including mixing, dosages, discharging and offering effective method to their customers to build high trust.

Pharmaceutical Industry

Pharmaceutical Industry- Picture Courtesy: Conversation

The IBC bin blender plays an essential role in the blending, dispensing, combinations, and manufacturing of solid dosage form, i.e., tablets, capsules, granules, and making of semi-solid dosage form, such as ointments, creams, lotions, and preparation of liquid preparations such as syrups, inhalers, eye-drops, nasal drops, etc. This machine prevents the segregation of blended materials during and after process.

Chemical Industry

Chemical Industry- Picture Courtesy: Carolina Knowledge

No matter what your end product is, the chemical preparation always requires safety and containment to keep products, your health, and environment safe.

IBC bin blender is proven equipment for excellent blending and high control over ingredients of different flow rate. That’s why it is commonly used in the preparation of products with plastic, metallic, organic, and inorganic in nature.

Cosmetic Preparation

Cosmetic Preparation- Picture Courtesy: Cosmetic Technology

An IBC bin blender provides fast and easy blending of cosmetic powder directly in their containers that are available in various ranges to form a uniform or homogeneous product with high user acceptance. Whether it is liquid foundations, primers, compact powders, eyeshadows, or blush, their formulation is not possible without an IBC bin blender. That’s why there is a high demand in the cosmetic sector to meet production demand.

3.What are the advantages of IBC Bin Blender?

For your business, an IBC bin blender is a promising piece of equipment. There are some very important benefits that it offers to its consumers. For example,

An Enclosed System

IBC Bin Blender- Picture Courtesy: AVEKA

The machine is designed with a high level of protection and hygiene. The body material is of food-grade stainless steel. It assures no chances of accumulating debris and piling products around the corners. Because a machine has no hollow sections or crevices that may cause contamination.

Dust Tight Unit

IBC Bin Blender- Picture Courtesy: METO System

Rigorous standard equipment with dust dust-tight unit that has no chance to blow out the powder dust or interact with external physical environment. Therefore, it is beneficial for general as well as sensitive materials blending.

Fast & Easy Blending

Fast and Easy Blending- Picture Courtesy: iHerb

This machine is typically made for the manufacturing of pharmaceuticals, foods, and related industries where high production procedures take place under high-quality demand. By installing an IBC bin blender, you will get fast and high mixing performance for broad spectrum ingredients.

No Powder Spillage

Neat and Clean Production- Picture Courtesy: Freund Vector

A unqiue designed IBC bin blender offers speedy mixing without the risk of spillage your product. This means you’re not only saving your time but also money.

High Rotation

High Rotation- Picture Courtesy: Pharmaceutical Tech

This is a tremendous equipment that supports your products and perfect blending by rotating its body around 360°. Therefore, you won’t find any compromise blending when it comes to IBC bin blender.

Easy Operating Mode

Easy Operating Mode- Picture Courtesy: Oxford College

The machine has easy operating modes, with equipped detectors, strong locking units, and easy installation procedure. So, you don’t need extra training time, or requiring experts to run the device.

4.How IBC Bin Blender Works?

An IBC bin blender is a kind of diffusive mixer. The blending and mixing of the particles are not enforceable by any tool such as an agitator.

IBC Bin Blender- Picture Courtesy: SPM

The working principle of IBC bin blender is discussed below:

| Step 1: Loading of Material. | Process begins with introducing materials to be blended inside the container by an opener. Locked the container and hooked it mechanically into the arm lifter. |

| Step 2: Blending | In the blending procedure, the machine creates a mixing of ingredients due to its rotation which creates an effect of movement of particles that is almost similar to avalanche. The blending is entirely dependent on free movement of the powdery molecules. For non-free flowing particles, the machine will need to exert extra force to keep powder segregated. The overall rotation of the IBC bin blender is created by movement of the arm of lifter. |

| Step 3: Discharging | Once the material is homogeneously mixed by revolving clockwise and anti-clockwise, it is then discharged from the IBC bin blender by fixing container at the bottom of the machine. Upon fixation, you can release the blended material by using setting keys available in PLC system. This will allow the opening of discharge valve and the emptying the container respectively. Now the bin blender is ready to proceed another mixing batch. |

5.What Are the Available Types of IBC Bin Blender?

There is a broad classification of IBC bin blender. Lets see below to know more about the classification.

Large Capacity IBC Bin Blender

Large Capacity IBC Bin Blender

This is an automatic series of IBC bin blenders which is ideal for pharmaceutical manufacturing as it has ability to accommodate a large capacity of ingredients for blending task. This machine offers you subtle blending speed, with maximum bin volume and loading volume. Therefore, it is widely accepted in pharmaceutical, chemical, food industries.

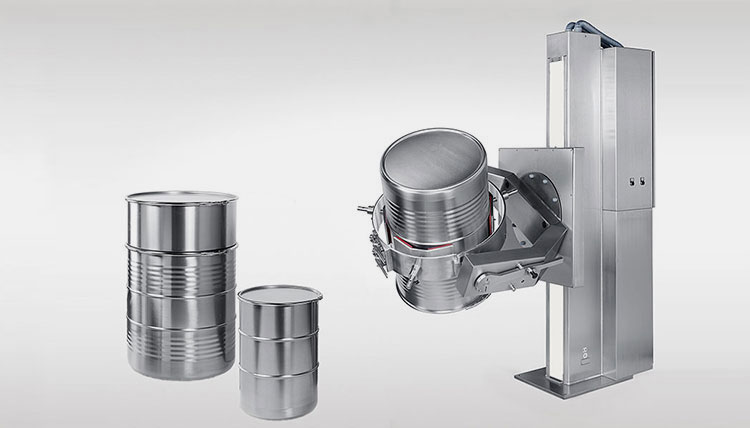

Lab/ Low-Capacity IBC Bin Blender

Lab/ Low-Capacity IBC Bin Blender

If you’re working in research labs or running a small production line. The IBC bin blender is also available for lab purposes. It has a small design which is basically capable of accommodating a small number of powders, granules, or combinations. It has modern designs and features. It is easy to use and portable solution which is widely used in pharmacies, research labs, and related manufacturing fields.

V- IBC Bin Blender

V- IBC Bin Blender

This is a popular type of IBC bin blender that has a particular design which looks like ‘V’. Its design is very simple that’s why it is considered as an ideal IBC bin blender for blending and mixing of ingredients with easy applications and maintenance.

As its structure has no complication, it has reduced chances of cross-contamination, so there won’t be any chances for product piling up or leftover after the procedure. There are various weight and capacities offered by V- IBC bin blender which is mostly depending on customer’s request and capacities.

Octagonal IBC Bin Blender

Octagonal IBC Bin Blender

This is a quite different type of IBC bin blender that you have observed before. This machine has been designed with crafted corners that make an octagon-shaped bin with uppermost design demonstrated with a polygon.

So, you might be thinking about why there’s a need to introduce this shape; its answer is technical but simple; the need for this design is to provide more collision to powdery particles and offer high rigorous blending during process. This is commonly used for mixing of granules, fine particles, grains, etc.,

Cage IBC Bin Blender

Cage IBC Bin Blender

This is another type of IBC bin blender with features with a cage as a supporting structure. The cage is responsible for firm connections of various points of the machine with the frame to allow easy movement of the blender. This type of bin blender is commonly used in large-capacity production industries to produce uniform blending mixtures.

Tumble IBC Bin Blender

Tumble IBC Bin Blender-Picture courtesy: Bulkinside

This is the type of IBC bin blender where the nature of working is basically based on the tumbling. This is a widely used machine which offers several benefits when it comes to uniformity and time saving.

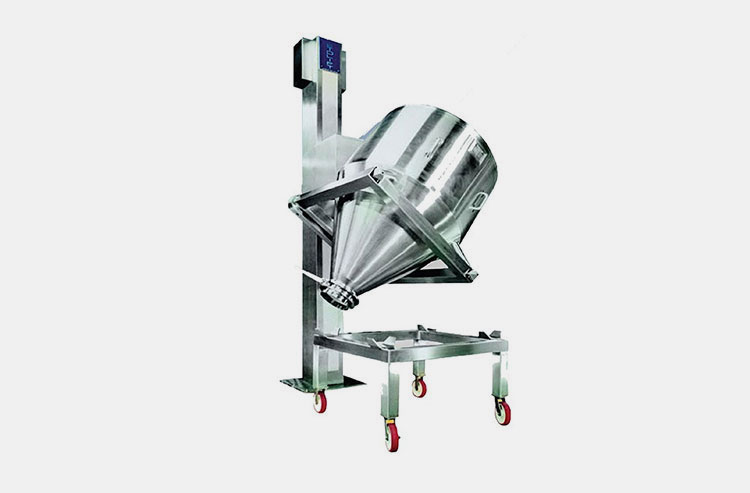

Double Cone IBC Bin Blender

Double Cone IBC Bin Blender-Picture Courtesy: ServoLift

This type of IBC bin blender is distinguished by double cones to bring an effective blending procedure for several varieties of raw ingredients. It has offered a broad spectrum applications to its customers which include powders, grains, abrasive and sensitive materials. Due to double cones design, this machine is suitable to bring production procedures that are involved with large capacities.

Hydraulic Clamping IBC Bin Blender

Hydraulic Clamping IBC Bin Blender- Picture Courtesy: Servolift

This type of IBC bin blender features with high-power hydraulic system which is used to operate the bin blender with efficient movement. This system is mostly applied to carry large bins and supporting heavy blending materials without risk for hydraulic leakage.

Twin Column Bin Blender

Twin Column IBC Bin Blender

This machine is featured with two supporting arms to fix the IBC bin blender for perfect rotation and with more stable performance. The bin blender is mostly performing its operation in the middle of supporting columns ensuring an ideal uniformity and subtle performance. However, you can adjust the height of the IBC bin blender by regulating the supporting arms.

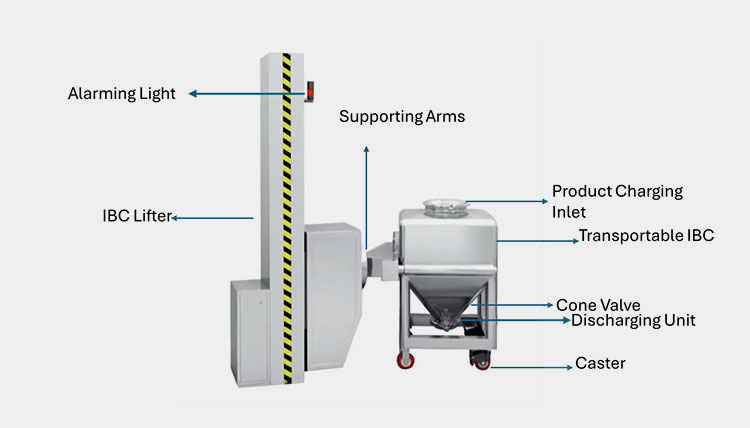

6.What Are the Major Parts Of IBC Bin Blender?

Parts of IBC Bin Blender

| Alarming Light

|

This is the most prominent part of the machine which notifies the user about certain situations, such as the completion blending procedure, running of the machine, or situations that need emergency support. |

| Supporting Arm | The movement and rotation of IBC are basically facilitated by a supporting arm that ensure easy and flexible movement around the fix axis. |

| IBC Lifter | IBC lifter is an integrated option of the machine which is useful in lifting of IBC and makes possible revolution and facilitates loading and unloading without chances of destabilizing the unit. This unit has affinity to hold and lift an empty and loaded container easily which ensuring maximum blending proportionality via proper mixing method. |

| Product Charging Inlet | You load the materials to be filled inside an IBC bin blender by a charging inlet. This is mostly located at the top position of the blender and offering you a convenient way to introduce your product easily without any chances of spillage or tiresome. This part of the machine is mostly designed with valves and handles to close the unit firmly. |

| Transportable IBC | This is a large tank for storage, movement, and blending of the material in bulk. An IBC bin blender tank is mostly made up of stainless steel ensuring smooth processing and no corners which leads to piling materials. This unit is mainly available in various sizes and is able to carry various different weights. |

| Cone Valve | This is typically equipped at the lower position of the machine which is mainly required for flowing of controlled rate of the material and is mainly used to prevent material against clumping or aggregation. |

| Discharging Unit | This is an opening which allows material’s discharge after blending treatment. The unit is also linked to cone valve which helps in the regulation of material flow. |

| Caster | It is also known as a wheel or roller that is meant for supporting the IBC bin blender allowing easy mobility and installation in order to maintain an optimized workflow. |

7.What Is the General Blending Time of The IBC Bin Blender?

IBC Bin Blender- Picture Courtesy: PAT Group

There are various manufacturing companies and vendors who claim that the IBC bin blender is capable of offering correct blending by taking only four minutes of blending time.

This is simply untrue. The thing you must consider is to weigh up the end-to-end process steps which include from filling till emptying.

You must know that IBC bin blender may take more time to load and un-loading and few minutes to blend which is often observed in 10 to 15 minutes. Also, you can reduce more blending time if you work on your particle size, considering the state of flow properties, etc.,

8.What are the Basic Problems and Solutions Related to IBC Bin Blender?

Nevertheless, an IBC bin blender is an easy-to-use machine, although you must know the basic challenges and solutions. This knowledge would help to save your time and ease in processing.

Poor Product Flow

Poor Flow- Picture Courtesy: Meritics

There are two types of powders- free-flowing and non-free flowing. Sometimes, powders with cohesive molecules or stickiness can be very difficult to blend in an IBC bin blender. Therefore, some users can exert manual intervention to achieve correct blending.

Solution

To solve this problem, you can modulate the blending time which promotes flow and avoids bridging. Also, there are various kinds of IBC bin blender designs available with optimized working principles ensuring no manual intervention is required.

Recipe Segregation

Powder Segregation- Picture Courtesy MATCON

This is not an uncommon problem, there are different ingredients with various states of flow ratio are blended in an IBC bin blender during the process. However, once the machine is stopped, it can cause recipe segregation which is not desirable results for every user.

Solution

We are going to tell you the universal solution to improve recipe segregation by improving the material properties. This can be done by optimizing size distribution spread, avoidance from irregular or random particle size, applying correct blending time, and regulating free fall height of the IBC bin blender. Therefore, you can get a uniform particle blending.

Cross- Contamination

Cross-Contamination- Picture Courtesy: Very Well Health

This is another common problem. Cross-contamination may result in batch failure as well as potential health problems if the batch is released by mistake. This can be caused by inadequate bin cleaning or maintenance.

Solution

An unsuccessful cleaning module may result in potential contamination problems. Therefore, IBC bin blender is particularly designed with the Spray Ball method which is used to attain an effective cleaning. The Spray ball unit allows CIP or clean in place procedure to wash entire inside unit of the machine and reduces the cross-contamination problems.

9.What You Should Consider When Purchasing an IBC Bin Blender?

An IBC bin blender is a significant machine that is used to blend raw materials required for the production of various formulations. Although, it is very important to know some important points when you’re purchasing the machine. This would help you to select the best one without wasting your time and money.

Type of Material

Flow of Material- Picture Courtesy: Refresh

You must know the nature of the materials when planning to purchase the machine. this is because some materials require an agitator to maintain homogenous mixing while some don’t. Therefore, you should properly understand the state of ingredients you’re dealing in the production line.

Production Capacity

Production Capacity- Picture Courtesy: Jiya Ayurveda

As discussed above, there are various types of IBC bin blender. Some are suitable for small, moderate, and large production, therefore, knowing your production capacity would be helpful in selecting the right type machine.

Your Budget

Budget Planner- Picture Courtesy: Punch Newspaper

This is very important to consider to budget when purchasing an IBC bin blender. If you ‘have an astringent budget, we would recommend choosing a simple version and small size machine. However, if you have more production then you should spend investment as a time option because the machine will definitely revenue higher.

Your Installation Space

Consideration Production Space- Picture Courtesy: Nisshineng.jp

You should know your installation dimensions; it would help the manufacturer to assess and guide you to the right option that can best fit in your place.

Trustworthy Supplier

Trustworthy Supplier

Contacting and purchasing machines from trustworthy suppliers like Allpack would be a lifetime best decision. You must scrutinize good suppliers from online sources, viewing their reviews, and by direct communication to assess their deals, guidance, and expertise.

Conclusion

An IBC bin blender is a worthwhile piece of equipment that gives a refined and promising profit to its customers. Due to its several benefits, this machine is the first choice of everyone who belongs to manufacturing companies. This is not only reliable, fast, and economical, but it offers their customers 100% blending uniformity. With a heritage of over 10 years, the Allpack team has a renowned profile in offering excellent types of machinery. We have an amazing track record of supporting our customers globally. If you’re looking for refined solutions for your production line, then Contact us for more information & Machine Purchase.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide