Hand Washing Gel Sachet Packing Machine: The Complete FAQ Guide In 2024

When it comes to deliver small number of materials, sachets are considered the most desirable and convenient form of packaging on part of both the entrepreneur and consumer. Similarly, hand washing gel which is a must have thing when in a workplace, a hotel, during traveling or an outing. Therefore, Hand Washing Gel Sachet Packing Machine is introduced into the field.

This machine provides a remarkably efficient performance to the businesses in meeting their high production targets while reducing the packaging costs. You may be among one of them. If yes! Then let us take you on the journey to explore a Hand Washing Gel Sachet Packing Machine with all its benefits, classification, working, and many more. Stay tuned and keep reading this FAQ guide!

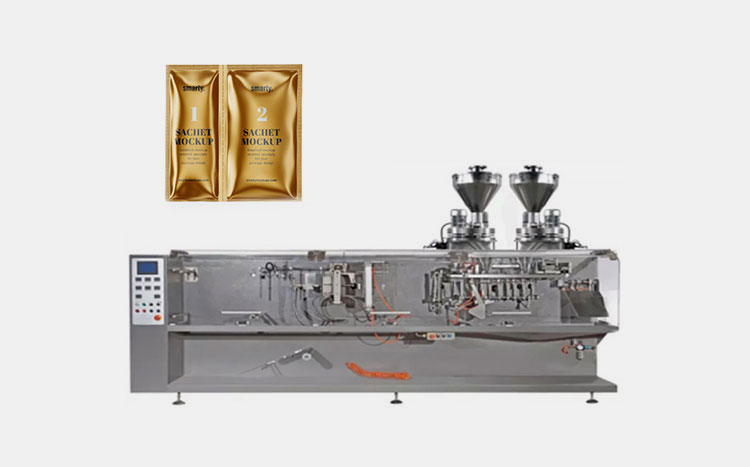

1.What Is Hand Washing Gel Sachet Packing Machine?

Allpack APK-110 Flat Pouch Horizontal Sachet Machine

Hand washing gel sachet packing machine is an ideal equipment designed to pack liquid hand washing gel into different types of small to large disposable sachets. The machine wonderfully deals with this packing process by first measuring the desired amount of sachet and then packing it into bags precisely.

In this way, it prevents hand washing gel spillage and greatly enhances the packaging efficiency through automatic forming of sachets and their filling and sealing etc. Moreover, the machine support quick and easy way of making standard to customizable sachets.

2.Explain The Importance And Various Benefits Of A Hand Washing Gel Sachet Packing Machine?

The importance of a hand washing gel sachet packing machine has seen a rapid growth due to the people's concern regarding their hand cleaning especially after COVID-19. They consider small sachet of hand washing gel a must have thing all the time. To meet this end, hand washing gel sachet packing machine is always utilized. Below are some of its top benefits:

High Accuracy

Display of sachet sealing- Picture Courtesy: yellowimages.com

A hand washing gel sachet packing machine give you high precision in accurately dosing the required material into sachets and adopt excellent system for forming and sealing of sachets. Therefore, both the packaging and material accuracy is realized.

Customization

Customized sachets- Picture Courtesy: thefeed.com

One thing which every manufacturer desire for a successful business is the visual appeal of packaging that is definitely associated with customization. By using this machine, you will be able to make different sizes, shapes, and designs of sachets along with eclectic sealing methods like tear notch and spouts etc.

Multi-Tasking

Another attribute of a hand washing gel sachet packing machine is its multi-tasking nature which allows it to perform sachet forming, filling, sealing, printing, and cutting simultaneously.

Boost Production

Bulk of ointment sachets

Hand washing gel sachet packing machine can boost your production efficiency by following automatic technology to deal with high output targets. It thus multiplies the returns to your investment.

Simple Operation & Maintenance

Hand washing gel sachet packing machine follows easy operation method and require low maintenance on daily and weekly basis. Therefore, you need only a single operator to administer its functioning.

3.What Materials Can Be Filled By A Hand Washing Gel Sachet Packing Machine?

Hand washing gel sachet packing machine is highly resilient with outstanding capability to process almost all kinds of free flowing and viscous liquids including pastes, gels, and juices. Some of these are mentioned below for your understanding:

Gels

Liquid hand sachets- Picture Courtesy: anar.biz

Gels are popular liquids that you can easily pack by using a hand washing gel sachet packing machine. The common gels used by this machine include hand washing gel, hair gel, and nail glue gel etc.

Pastes & Sauces

Different sachets of pastes & sauces- Picture Courtesy: thedieline.com

Due to the growing expansion of home delivery services, now, all kinds of pastes like tomato ketchup, mayonnaise, and special sauces are delivered in sachets. So, you can use this hand washing gel sachet packing machines for all these sauces.

Drugs

Medical oral liquid sachet- Picture Courtesy: asteronline.com

The technological advancements have made the lives of humans very easy. Now, you will find medicine not only in tablets or syrup form but also in other forms like pastes and oral strips. Therefore, a hand washing gel sachet packing machine is eligible to pack this liquid medication.

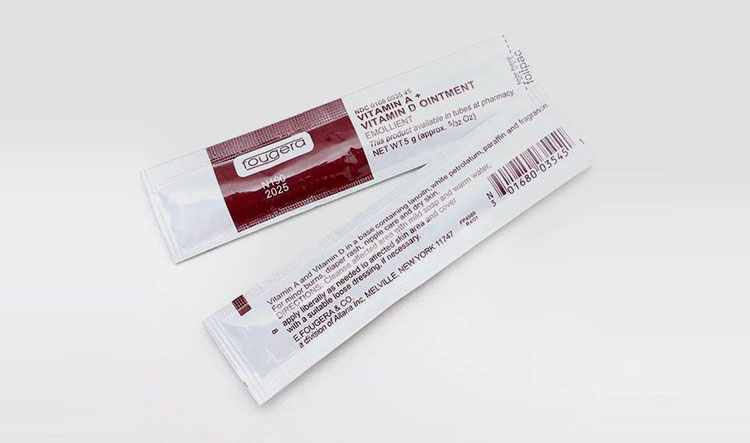

Ointment

Vitamin A+D ointment stick sachets presentation idea

Ointments are also packed in sachets especially for first aid purposes where an individual is not bothered to carry heavy tubes and other supplies. Therefore, a hand washing gel sachet packing machine is good suitable to pack ointments.

Chocolate

Liquid chocolate- Picture Courtesy: cadeg.com.br

Liquid chocolate can also be packed by a hand washing gel sachet packing machine in various types of standard and stick sachets often with spout sealing.

Drinks

Pineapple enzyme drink sachets

Various concentrated juices of fruits like apple, mango, and pineapple are often delivered in beautiful small sachets especially for kids. Hence juices can also be processed by this machine.

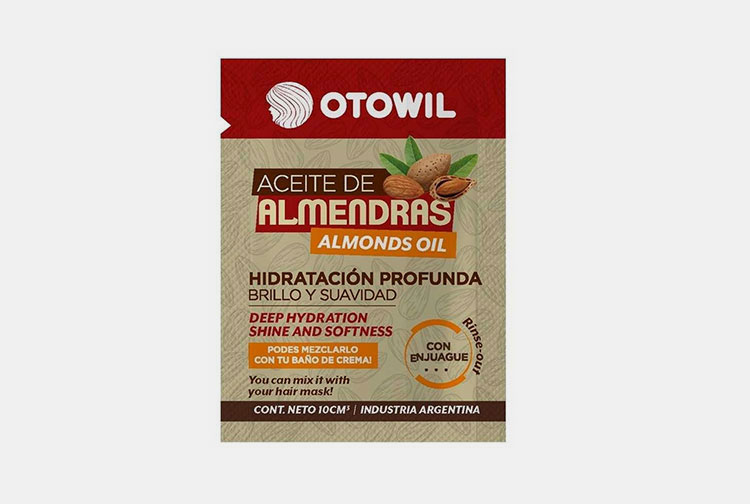

Oils

Almond hair oil sachet- Picture Courtesy: lac2b.com

Most of the oils used for beauty care like Omega-3 oil, almond oil, and other supplemented oils are mostly packed in small sachets. So, a hand washing gel sachet packing machine is applicable to carry out this task.

4.What Formats Does A Hand Washing Gel Sachet Packing Machine Support?

A hand washing gel sachet packing machine can form and pack different shapes and sizes of sachets along with varying sealing. They are as follows:

Standard Sachet

Square hand sanitizer gel sachet- Picture Courtesy:

Standard sachet is the most common format of sachets packaging made by a hand washing gel sachet packing machine. It has a square shape body which may slightly vary in some forms and look like rectangular shape. This form of sachet is widely adopted for packing gels, shampoo, and ketchup etc.

Stick Pack Sachet

Stick pack sachets- Picture Courtesy: psdrepo.com

Another popular form of sachet is a stick pack sachet characterized by its long narrow body. It is frequently used for ointments, liquid medication, and juices etc.

Contour Sachet

Various baby care liquids in contour sachets- Picture Courtesy: pipettebaby.com

Contour sachet refers to the type of sachet which do not follow the four sides square sealing rather it has a specific shape that tilted on the top and become narrower on upper side. Such type of sachet provide charm for customers. Hence, a hand washing gel sachet packing machine is capable to make it.

Twin Sachet

Double sachet mockup- Picture Courtesy: yellowimages.com

As the picture shows, twin sachet refers to double sachets paired together. Such type of sachet is broadly used for two separate products which are meant to be used together or in a sequence. In addition, shampoo and conditioner are the common liquids often delivered in twin sachet.

Irregular Shaped Sachets

Round sachet with spout- Picture Courtesy: Freepik

Apart from the above discussed particular types of sachets, there are multitude of sachets on the basis of their shapes. They play a huge role in promoting brand reputation and attracting consumers. So, a hand washing gel sachet packing machine make sure to create such sachets for your liquids.

On the Basis of material

When it comes to discuss the types of sachet material which a hand washing gel sachet packing machine can make, there are three basic materials which are highlighted below:

Plastic Sachet

Plastic sachets with spout- Picture Courtesy: mealite.co.kr

Plastic is a common material used for making sachet. It is because plastic has high resistance to moisture, air, and pollution and most importantly, it is cost-effective.

Aluminum Sachet

Aluminum foil sachet- Picture Courtesy: Freepik

Aluminum sachet is made up of a thin layer of aluminum foil. Although it has a comparatively higher packaging cost, however, aluminum sachet maintain high protection barrier against heat, light, and pollution.

Paper Sachet

Kraft paper sachet- Picture Courtesy: yellowimages.com

The use of paper is growing in making sachet as it is environmentally friendly. For liquids such as gels, pastes, and sauces, a thin layer of plastic film is attached to end spillage.

5.How Does A Hand Washing Gel Sachet Packing Machine Seal?

Unlike dry products like powders and grains, for which back sealing of sachet is recommended, a hand washing gel sachet packing machine uses side sealing for closing sachet. Below description will highlight the further variation in the side sealing of sachet along with the possible closure formats:

Three Side Sealing

Three-sided sealed sachet- Picture Courtesy: yellowimages.com

This type of sealing creates three-sided seal of sachet and leave one side. Three-sided seal sachets are made from single film layer and has a unique shape. This method is often utilized for products like ketchup, honey, and hair color etc.

Four Sides Sealing

Four-sided sealed sachet- Picture Courtesy: yellowimages.com

Four side sealing, on the other hand, seal the sachet from all its four sides to provide extra protection against spillage and leakage. Therefore, liquids requiring high protection are often packed in four-sided seal sachets such as drugs, ointments, and gels.

Spouted Sachet

Spouted hand sanitizer gel sachet- Picture Courtesy: thecremeshop.com

As far as the closure formats of sachet is concerned, spouts sachet is one of the popular forms where recloseable spouts are welded into the opening of sachet in order to control the liquid flow.

Tear Notch Sachet

Shampoo sachet with visible side tear notch

Tear notch is another common sealing format adopted for its convenience as well as cost-effectiveness. This type of sachet features a notch at the top corner of sachet which is meant to be used for opening sachet.

6.Write Down The Working Principles Of A Hand Washing Gel Sachet Packing Machine?

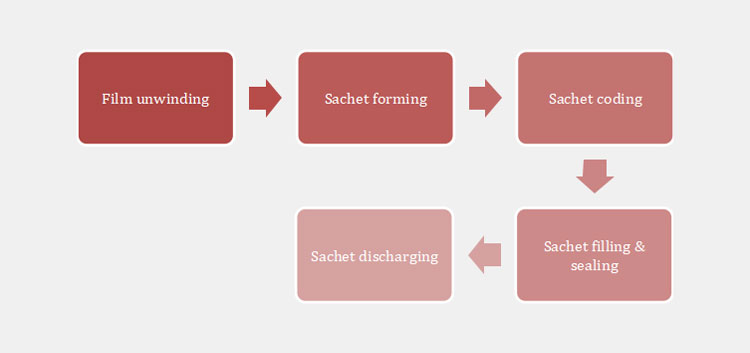

Hand washing gel sachet packing machine follow sequential order for creating and filling sachets simultaneously. Below you will know the working principles step by step:

Film Unwinding

The very first step of a hand washing gel sachet packing machine is the unwinding of film from roll. This film is pulled by support rollers and is further guided by the film guide to travel across different stations horizontally or vertically.

Sachet Forming

In the second step, the prototype film is folded in a way that both the front and back are parallel to each other. Afterwards, the film is sealed on the bottom and vertical sides to form a sachet while leaving the top side open for filling.

Sachet Coding

After formation of sachet takes place, the sachet is coded with date of expiration and batch no. At the same time, sachet separated from film and moved forward for material filling.

Sachet Filling & Sealing

This is the major step, when precisely weighed volume of hand washing gel or any other liquid substance is deposited into sachet. After the filling get completed, the top of sachet is sealed through heat.

Sachet Discharging

At lest, finished sachets are one by one discharged through chute from the machine towards collection container or conveyed to the integrated machine for further packaging.

7.Describe The Structure Of A Hand Washing Gel Sachet Packing Machine?

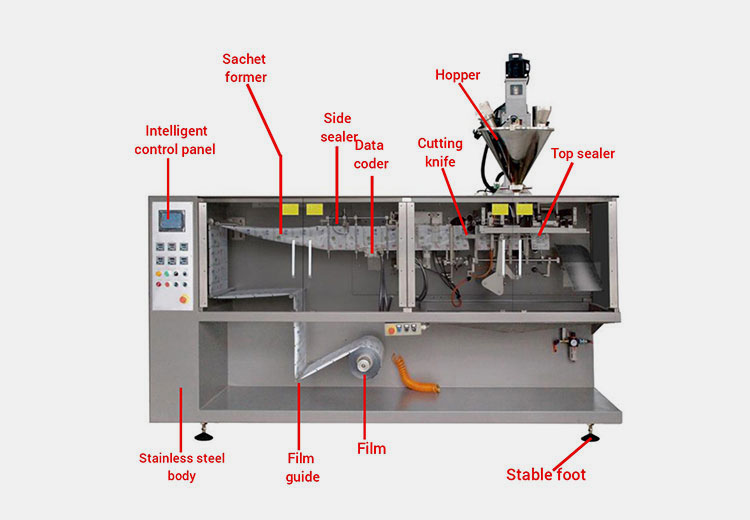

Hand washing gel sachet packing machine is composed of several components to accomplish the sachet packing. These parts are described below:

Components of Allpack APK-130 sachet machine

Hopper

Hopper is the feeder or material holder where bulk of hand washing gel or other liquid material is loaded before operating the machine. It is corrosion resistant and has antibacterial properties. From here, the material is filled into sachets through funnel.

Film

Film is a stock of rolled thin layer of plastic, aluminum or laminated paper film. It is one of the crucial components of a hand washing from which the sachets are formed.

Film Guide

Film guide or film unwinding units are multiple strong metallic rollers attached to the main machine. It enables the film to unwind and move forward towards sachet forming.

Intelligent Control Panel

Intelligent control panel is the most crucial part of a hand washing gel sachet packing machine from where user control the machine working by setting different parameters. For instance, the length of a sachet, sealing temperature, and coding etc., are fixed through this component.

Sachet Former

This unit has a photocell that detect and help in the formation of sachet from flat film layer.

Data Coder

Data coder is an electric device located in the hand washing gel sachet packing machine. It is used to print, manufacturing date, expiration date, and batch no.

Cutting Knife

Cutting knife is a stainless steel tool with sharp edges which is used to split the sachets from each other.

Stainless Steel Body

The overall body of a hand washing gel sachet packing machine is made from quality stainless steel. Therefore, it is both compact and hygienic for processing every type of liquid materials.

Heat Sealing Side

Heat sealing side mainly include the sealing jaws which are responsible to seal the vertical side or sides of sachets.

Top sealer

As sachets are also sealed from the top side when get filled with material, so, top heating sealer is used for accomplishing this task.

Stable Feet

There are four stable feet attached to the hand washing gel sachet packing machine which enable the machine to stand on surface. Hence, they are helpful in making sure the stable operation of machine.

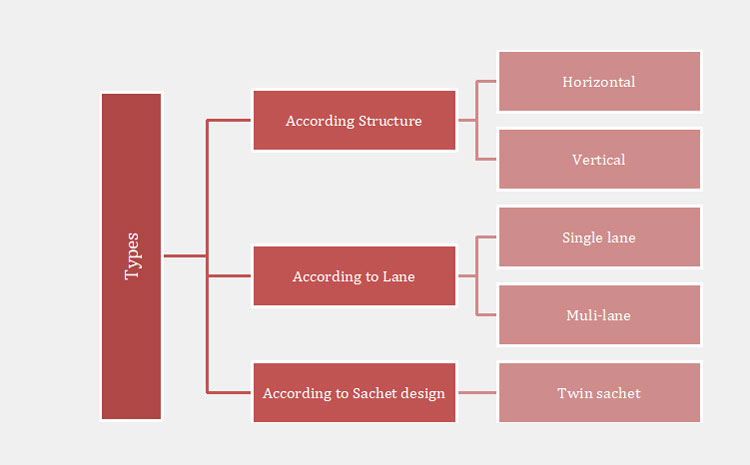

8.What Are The Different Types Of A Hand Washing Gel Sachet Packing Machine?

There are different types of a hand washing gel sachet packing machine. In below paragraphs, you will know these all types in detail:

According to Structure

Horizontal Sachet Machine

Allpack APK-240D Horizontal honey ketchup sachet machine

This type of hand washing gel sachet packing machine is the most popular type where the machine is characterized by its long horizontal body. This machine by Allpack support flat heat sealing, tear notch, zipper, and spout sealing for the convenience of sachet opening.

It is fully automatic in technology with optimal production rate of packing 200 sachets per minute. Moreover, it can also be integrated with other machines.

Structure

The structure of machine is large occupying more space. The important components which it constitutes include double hoppers, a film roll, control panel along with multiple knobs, film pulling mechanism, sachet former, coding unit, cutting knife, and discharge chute.

Working Principles

The machine start working by pulling film from roll and traveling it across the multiple horizontal units for simultaneous forming, coding, filling, sealing, cutting, and discharging phase.

Vertical Gel Packing Machine

Liquid Gel VFFS Form Fill Seal Packing Machine- Picture Courtesy: samfull.net

Vertical gel sachet packing machine is another type of sachet packing machine characterized by its vertical body. It is available in both fully automatic and semi-automatic form. Moreover, it follows an extremely straight forward way for sachet packing while giving good production speed of packing 25 sachets in a minute.

Structure

The machine has comparatively small structure composed of different units including a feeding station, transfer pump, vertical form fill and seal unit, and discharge conveyor etc.

Working Principles

The machine start working by forming sachet from film roll and filling in it the accurately weighed gel. Similarly, the opening of sachet is closed through sealing after which the sachet is discharged out of the machine through chute.

According to Lane

Single Lane Sachet Packing Machine

Single Lane Liquid Packing Machine for Sachet & Stick Pack- Picture Courtesy: samfull.net

Single lane sachet packing machine has one unit to form sachet. Therefore, its price is lower than other types of machines and give you good throughput ratio. You can use it in medium to large cosmetic industry, food industry, and beverage industry etc.

Structure

This hand washing gel sachet packing machine is an assembly of several components encompassing a film roll, product feeding and measuring unit, sachet forming unit, control system, and overall body.

Working Principles

It simply starts functioning when the basis parameters are fixed by operator and machine is powered on. In this way, the film is pulled by rollers and turned into a sachet after getting sealed from sides. This single sachet is then filled with pre-measured dosage of liquid and the sachet is closed from top and discharged from the machine.

Multi Lane Gel Sachet Packing Machine

Multi-lane energy pharma gel sachet & stick pack packing machine

Multi-lane gel sachet packing machine is yet another category of a hand washing gel sachet packing machine which comes with 4 to 12 lanes for packing sachet in single run. This type of hand washing gel sachet packing machine is perfectly suitable for large and extra large pharmaceutical, seasoning, and beauty care industries. Furthermore, you can also attach this machine directly with secondary packaging machines.

Structure

This machine has large size heavy-duty machinery due to multiple sachets forming stations and hopper for gel filling. Therefore, it is composed of a human machine interface with power switch and emergency stop, a stainless steel robust body, four stable feet, a hopper, transparent window, multiple filling nozzles, coding, and sealing tools etc.

Working Principles

Its working principles are similar to other types of hand washing gel sachet packing machine. However, its formation of multiple sachets from a single film layer is unique way. The machine turns the single film layer into range of sachets, fill them with predetermined volume of gel and finish it after closing and cutting of the top of sachet.

According to Sachet Design

Twin Bag Sachet Packing Machine

APK-180T Horizontal 3 4 side seal twin bag sachet machine

This type of a hand washing gel sachet packing machine is an amazing one that offers you to have a single sachet with double sections just joined together with perforated sealing. Hence, materials such as shampoo along with conditioner and hand washing gel with hand sanitizer etc., are best to be delivered through this type of sachet packing.

Structure

With long structure, this machine incorporates dual hoppers, film roll, control board, touch screen penal, sachet former, data coding unit, cylinder, measuring barometers, filling nozzles, sealing jaws, perforation device and cutting knives etc.

Working Principles

The working process of this hand washing gel sachet packing machine starts with film unwinding from roll towards sachet former. The sachet is sealed from bottom and vertical sides. Here one additional sealing is done in the middle of sachet that divide the sachet into two sections. Afterwards, twin sachet is filled with two separate liquids, sealed from top side, and discharged from the machine.

9.Differentiate Between A Hand Washing Gel Sachet Packing Machine And Powder Sachet Packing Machine?

Hand washing gel sachet packing machine and a powder sachet packing machine are two different machines according to the product which both fill. In the table below you will find many crucial differences that exist between these:

| No | Aspects | Hand Washing Gel Sachet Packing Machine | Powder Sachet Packing Machine |

| 1 | Definition | It is a type of liquid sachet packing machine which is only used to pack liquids into sachets. | On the other hand, powder sachet packing machine can pack dry powders and granules into sachets. |

| 2 | Filler | It uses piston filler or volumetric filler for filling material. | While as, powder sachet packing machine use an auger filler to perform material dosing. |

| 3 | Sealing | It uses heat sealing and spouts for forming and using sachets respectively. | In contrast, powder sachet machine uses heat sealing and zippers for sachets. |

| 4 | Design | Sachets used for packing liquids are both standard type like square sachets/ stick pack sachets and customized irregular shape sachets. | Contrary to that, the shape and design of sachets formed by powder sachet packing machine are flat square sachets and long narrow stick packs. |

| 5 | Application | This machine is suitable for all liquids such as gels, ketchup, chocolate, and cream etc. | It is good for dry powders and granules such as coffee powder, milk powder, protein powder, and coco powder etc. |

| Picture |

Gel Sachet Packing Machine- Picture Courtesy: samfull.net |

Powder sachet packing machine- Picture Courtesy: coretamp.com |

10.Where Can A Hand Washing Gel Sachet Packing Machine Be Used?

Below discussed areas are showing the broad application of a hand washing gel sachet packing machine:

Beauty Care Industry

Women with face mask- Picture Courtesy: beautywithhollie.com

Most of the beauty care products such as shampoo, lotion, hair gel and hair color are the common things we are familiar with. These liquid materials are often packed in small sized regular to customized sachets to aid consumer in their usage. Hence, a hand washing gel sachet packing machine is utilized in beauty care industry.

Seasoning Industry

Consumer spreading gram duck sauce on roll- Picture Courtesy: WebstaurantStore

Another notable industry with inevitable demand for a hand washing gel sachet packing machine is the seasoning industry. Here different seasonings including tomato ketchup, mayonnaise, and chilli sauces are mostly packed in sachets through this machine.

Medical Industry

Medical industry icon- Picture Courtesy: trivitron.com

You may wonder how a hand washing gel sachet packing machine can be applied in medical industry. However, packing little volume of ointments, medicated creams, and fluidized drugs is now the common thing practiced by medical industry

Confectionery Industry

Honey presentation idea- Picture Courtesy: worldbranddesign.com

This machine is also used in confectionery industry where liquid chocolate, honey, jellies, and processed creams are produced.

Beverage Industry

Orange juice sachet- Picture Courtesy: runnersworld.com

All kinds of beverages including juices, milk shakes, smoothie, and even mineral water can be easily packed by a hand washing gel sachet packing machine. Therefore, this machine is applicable in beverage industry.

11.What Is The Cleaning And Maintenance Requirements Of A Hand Washing Gel Sachet Packing Machine?

Regular cleaning and maintenance are very crucial part of using a hand washing gel sachet packing machine as it keeps the machine smooth running and function for longer. In this way, the underlying explained steps are helpful:

Operator setting machine- Picture Courtesy: parsable.com

Cleaning

Cleaning is the inevitable step that should be carried out after your hand washing gel sachet packing machine gets done with daily working. It will simply include the disassembling of various parts such as the hopper and filling nozzles.

Wash these parts with clean water and make them dry using a dry cloth or if necessary, you can use air blower to reach all the ends of machine. Afterwards, cutting knife, and sealing jaws must be wiped out to remove out all the first and debris left while packing.

Before Operation Maintenance

Before operation maintenance simply include the adjustment of structural tools such the sachet former, rightly placing of film roll over spindle, and setting the parameters of machine etc.

After Operation Maintenance

In after maintenance, you need to check the vaiouyparts of a hand washing gel sachet packing machine for possible damage and wearing. In case of damage, replace the parts timely and also lubricate the movable parts of machine to reduce friction ND stagnancy.

12.How To Solve The Sudden Problems Encountered When Using A Hand Washing Gel Sachet Packing Machine?

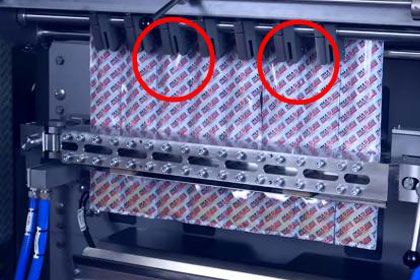

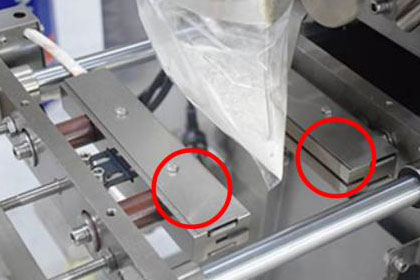

When operating a hand washing gel sachet packing machine you may encounter few malfunctions of the machine. There is no need to worry about them, you just need to identify the problem and take relevant action. For this consider the table below

| No | Problems | Causes | Solutions | Pictures |

| 1 | Film is unwinding in wrong track | It happens when film carriage does not move freely, and film is loose on one side while tight on the other side. | So, it can be troubleshot by making sure that film carriage is moving freely, by adjusting the film unwinding wheels through screws, and locating the film on center of spindle. |

Encircled film unwinding- Picture Courtesy: coretamp.com |

| 2 | Sachets fail to open | This occurs when the sachet sag downward or the timing for opening sachet is incorrect. | This issue can be easily resolved by correcting the time duration for opening each sachet and adjusting the sachet feeding tools in a way to hold sachet from top vertical sides to avoid sagging. |

Highlighted sachets opening and filling phase- Picture Courtesy: IMA Dairy & Food |

| 3 | Improper sealing of sachets | Improper placement of film, insufficient temperature, or the pressure of sealing bars is incorrect which leads to wrinkled and weak sealing. | You need to place the film in center, increase temperature to suitable level, and adjust the pressure of sealing bars. |

Encircled end sealing of sachet- Picture Courtesy: coretamp.com |

| 4 | Printer doesn't function properly | Either the printer is damaged, or the printer cable is disconnected. | Make sure to check the printer ribbon and other parts for damage and replace accordingly. Also check the printer ribbon connection with power through its switch. |

Highlighted data coder- Picture Courtesy: Aipak Pharmaceutical Equipment |

| 5 | Sealing jaw jamming | Reason for this problem is the material in end seal and the improper timing of material filling and bag sealing. | This can be corrected by adjusting the time between material filling and sachet sealing. |

Encircled sealing jaws- Picture Courtesy: coretamp.com |

13.Tips To Look For When Choosing A Hand Washing Gel Sachet Packing Machine

Buying the best hand washing gel sachet packing machine is the dream of every manufacturer. However, this dream can only become true when you undergo some vigilant considerations including:

Production Range

Multiple liquid sachets- Picture Courtesy: myspringenergy.com

What is your current production level? And how much do you want to expand it? These questions are significant because the level of production will mark whether you need to buy a semi-automatic hand washing gel sachet packing machine or fully automatic one. Similarly, machines come in various sizes, capacities as well as speed.

Type of Packing Style

Apple shape juice sachet pouch- Picture Courtesy: gaoaog.com

Which between standard sachet packing and stick sachet packing do you prefer the most? It is a question that will enable you to opt for either a square sachet packing machine for liquid or have a stick sachet packing machine.

Budget

Budget is an important factor that must not be overlooked rather should be given priority. You can opt for the machine which is pocket friendly. One thing is clear that the labor cost of semi-automatic hand washing gel sachet packing machine is higher than that fully automatic machine.

Quality Certification

ISO quality standard icon- Picture Courtesy: iStock

Checking the quality certifications of a hand washing gel sachet packing machine is eminent to ensure its quality standard. For this, few notable quality standards include ISI, GMP, and FDA whose approved machines and products are if high quality.

Conclusion

The above FAQ guide about a hand washing gel sachet packing machine has covered every facet of the machine which are necessary for the manufacturers of cosmetic, medical, food, and beverage industries. By taking help from these tips and factors you can increase your production efficiency as well as preserving your valuable liquids in a cost-effective way. So, don't make any delay and contact Allpack for presenting you an amazing line of hand washing gel sachet packing machine. For further information please contact us!

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide