Face Cream 4 Side Seal Packaging Machine: The Complete FAQ Guide In 2024

How Exactly Do You Achieve the Right Type Face Cream Packaging for Your Products?

Over recent years, evolution in the growth of the beauty industry has shown a sharp spike due to an increased demand for products. This trend has quickly risen fast by demonstrating annual market growth of 4.75% worldwide.

Much of this success is related to Face Creams and relevant products that are favored by many users with high global trading rates. Along with success, there’s the toughest competition that your packaging business faces. Yes, this is about packaging machines.

Face Cream 4 Side Seal Packaging Machine: The Complete FAQ Guide In 2024; here you’ll be enlightened with Face Cream 4 Side Sealing Packaging Machine and all relevant information that you will need to know in order to maintain new, innovative and satisfactory ways to implement packaging of your products to appeal your customers.

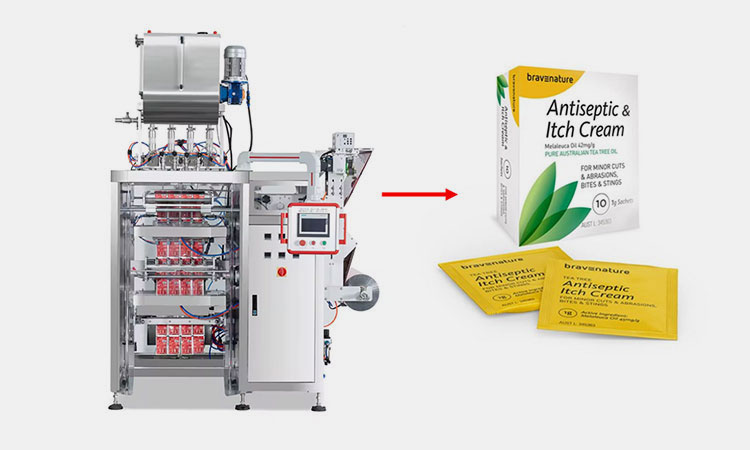

1.What Is Face Cream 4 Side Seal Packaging Machine?

Face Cream 4 Side Seal Packaging Machine

This is a multifunctional machine that is used for packaging face cream as well as a variety of other products. The machine is capable of sealing a flat piece of film around 4 sides to ensure firm and secure packaging.

There are a variety of different classes of equipment available in the market known for face cream 4 side seal packaging that can create and seal a film and pour cream simultaneously and ensure that your formulation is in a safe state till the end user.

In previous years, this task was considered tedious and faced challenges of inaccuracies, cross-contamination, and time-consuming which has been replaced with more advanced solutions in the form of face cream 4 side seal packaging machine in an affordable way.

2.Importance of Face Cream 4 side seal packaging machine: How It Influences your business success?

A face cream 4 side seal packaging machine is a versatile addition to the world of manufacturing industries. For your business, there are a number of valid reasons that show how this robust equipment intensely impacts your manufacturing line and how significant it is for you.

Multifunctional Options

Multifunctional Machine

This is a high-speed machine that is applicable to dose your product and seal it around its edges with unique and clean separation. The machine itself pulls, creates, seals, pours and separates the sachet. This means a single machine is capable of running so many tasks all alone in a perfect way.

High Standard Configuration

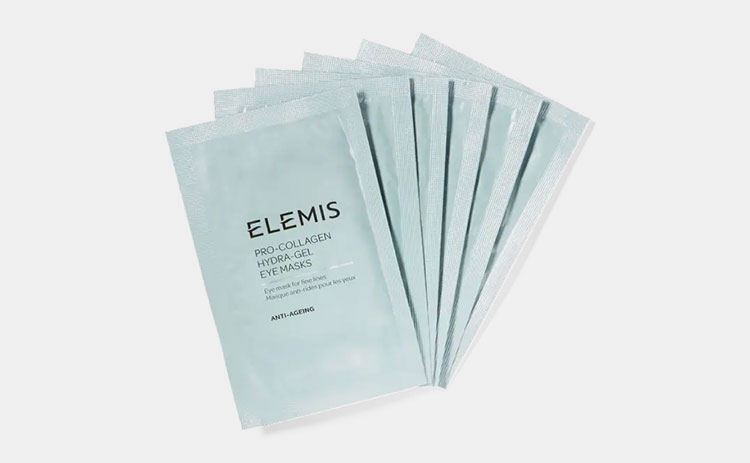

High Configuration- Picture Courtesy: plunket

A face cream 4 side seal packaging machine has adopted high standard configuration which complies with all essential requirements of international quality compliance. Its easy operating keys with high sensor system that controls temperature and notifies you in emergency situations. The body of machine adopted food grade levels of stainless steel which is safe for you but all other products including sensitive materials to your skin.

Accurate Product Insides

Accurate product filling- Picture Courtesy: premax

Machine production is based on digital measurements that help in filling face cream accurately as given concentration in the machine’s system.

There won’t be any chances of inaccuracies when using this efficient tool.

Compatible

A compatible Option

The machine is fully compatible with other units of the production line; so, if you’re running a large production facility. This is a great thing to add without stressing out about connecting and find installation procedures. Just connect and enjoy its running without long setup times.

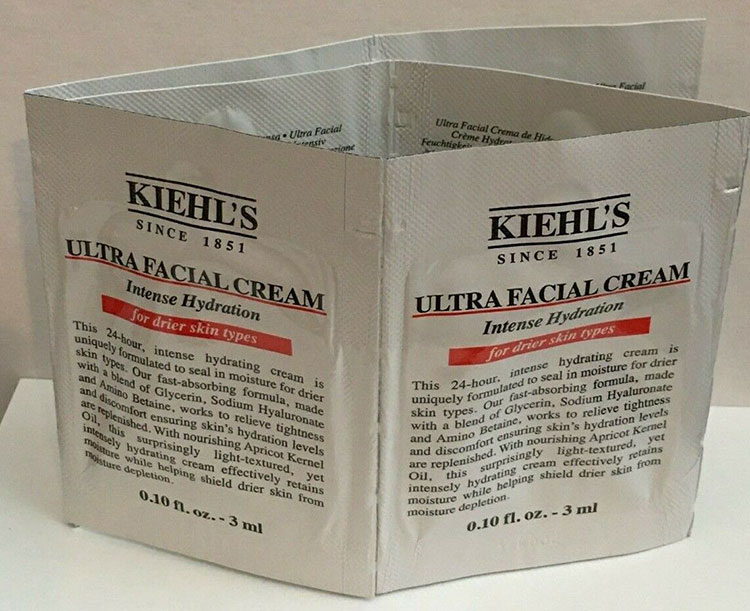

One Track Production

Flexible And One Track Production- Picture Courtesy: Dr. Barbara Strum

The machine is ideal for running a variable number of producing packaging bags with adjustable sizes and shapes by means of automatic control units.

Excellent Branding

High Market Value

The machine provides excellent packaging with eye catching presentations with pre-defined levels of product eventually helping you boost your brand in the competitive market.

High Production Capacity

Great Production Capacity- Picture Courtesy: Something Splended

The automatic face cream 4 side seal packaging machine can work rapidly for a longer period of time without requiring your constant monitoring or standing. So it is a greater tool to get fast and high productivity in cost-economical way.

Greater Product Shelf life

High Product Shelf Life

Your product is safe against external physical factors when packed by using a face cream 4 side seal packaging machine. therefore, it may give you a high shelf life for your formulation as it is potent and protective inside since day first.

3.Where A Face Cream 4 Side Seal Packaging Machine Can Be Used?

By its name, you can understand its major role which is none other than in the cosmetics sectors. But along with cosmetics, this machine can be used in other industries for packaging other important products also. For example,

Face Cream 4 Side Seal Packaging

| Medicines | In the medicinal sector, a face cream 4 side sealing packaging machine is worthwhile for dispensing products like granules, pastes, ointments, instant drinks, or other single serving dosages. |

| Adhesives | This machine is promising to pack adhesives for various uses that you can carry everywhere. |

| Foods | Single serving food products are mainly packed by using face cream 4 side seal machine that includes: seasonal spices, taste enhancers, sugars, salts, sauces, tea., etc. |

| Personal Care | One of the growing manufacturing sectors where you can pack various products like hair dyes, shampoos, shaving gel, conditioners, lotions, shower gels, cleaners, etc., in 4 side seal packaging. |

| Health & Wellness | Products like protein powders, prebiotics, probiotics, and other health-related creams, powders, and tonics can be packed in face cream 4 side seal packaging. |

| Pet Eatables & Pet Care | Pet care products like shampoo, medications, medicines, and supplements are commonly packed in 4 side seal packaging for convenient mobility along with your lovable pet. |

| Catering & Hotels | You have many products during your travel packed in 4 side seal packaging such as oral cleaners, lotions, and cutlery items., similarly in birthday parties, hospitals and related areas require this machine to pack items in a sachet for easy usage and single serving utilization. |

| Automotives | Products like lubricants, grease, sealing creams, shiners, and related products are commonly packed in 4 side seal packaging. |

4.Face Cream 4 Side Seal Packaging machine: How does it look?

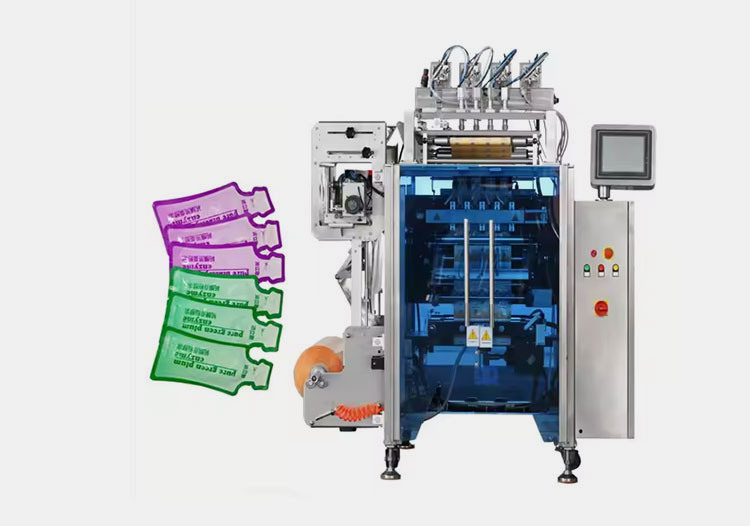

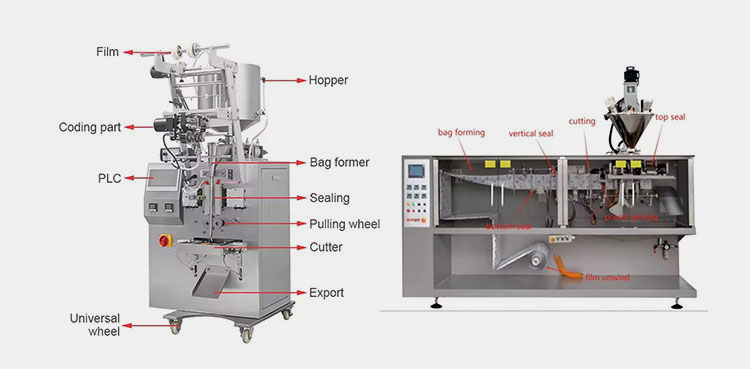

Picture Displaying Various Face Cream 4 Side Seal Packaging Machine

The above picture depicts the main machines that can help in the making of face cream 4 side seal packaging where each machine has basic and similar parts that assist in making of 4 side seal sachets. Let’s see them.

Parts of Machine

Major components of all machines that are used for forming face cream 4 side seal packaging are the same following the same tasks. But the alteration comes in designs that we have discussed in classifications. What is the function of each part is discussed in the below table.

| Film | This section is used to feed the film roll. |

| Hopper | This is a storage tank used to retain face cream for dispensing. |

| Coding Part | The machine is facilitated with coding section to print basics about products like batch no. expiry, manufacturing date, Etc. |

| Bag Former | A tube shape narrow structure is used to fold and form a bag. |

| Vertical Seal | This section is used to seal the bag, sachet by pressing sealer vertically. |

| Top Seal | The remaining edges of the bag or sachet are sealed by applied sealers topically (up and down). |

| Cutting | Sharp cutters are used to punch the formed bags to separate them. |

| Exit Port | A finished product is passed out to the machine by exit port or export. |

| Universal Wheel | These wheels allow easy mobility of the equipment inside or outside the facility and aid installation or fixation. |

5.What are the different classes of Face Cream 4 Side Seal Packaging machine?

There are various classes of face cream 4 side seal packaging, here we have illustrated them for you.

Semi Automatic Face Cream 4 side seal packaging Machine

Semi Automatic Face Cream 4 Side Seal Packaging Machine

This is the fast and accurate face cream dispensing machine that helps in 4 side seal packaging following some manual interventions. Here, you will need human involvement for feeding and receiving of packaging, whereas, the filling and sealing job is done by the machine automatically. This machine is ideal if you have an astringent budget or running a moderate production line.

Automatic Face Cream 4 side seal packaging Machine

Automatic Face Cream 4 Side Seal Packaging Machine

This machine is included with modern and advanced functional parameters to run the filling process of face cream. You will just need to pour the product into the machine and adjust the film roll. The remaining job is done by the machine itself without your constant monitoring or involvment.

This is an ideal solution to run non-stop large batch size production because it can produce large amounts of production capacity without exhausting the machine or environment.

Vertical Face Cream 4 Side Seal Packaging Machine

Vertical Face cream 4 Side Seal Packaging Machine- Picture Courtesy: Propac & Proright

A very common, simple, and compact machine for face cream 4 side seal packaging where the entire functionality takes place in a vertical manner. This includes: formation of a bag, filling, sealing, and discharging.

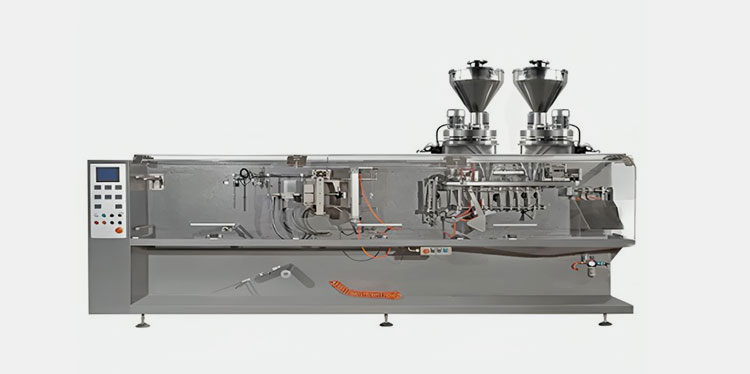

Horizontal Face Cream 4 Side Seal Packaging Machine

Allpack Face Cream 4 Side Seal Packaging Machine

A straightforward and excellent solution for face cream packaging where machine working design is based on horizontal functionality. Mean unwinding of a film, formation of a bag, filling of face cream and sealing, all processes take place in a horizontal fashion.

Compared to VFFS machines they are bigger in structure and occupy high footprint. This is ideal for running large production lines as the machine is able to produce large production capacities.

Gravity Face Cream 4 Side Seal Packaging Machine

Face Cream 4 Side Seal Packaging Machine

This machine is mostly required for dispensing easy-to-flow liquids. Face cream with moderate viscosity is preferably filled by using a gravity machine. As it name depicts,. The flow of material is mainly based on the force of gravity, thereby, this machine is mainly causing you less expenditure as less energy is utilized for filling.

Piston 4 Side Seal Packaging Machine

Piston Side Seal Packaging Machine

This machine is mostly used for filling products showing a high range viscosity and greater thickness. A piston is responsible for the accurate filling of cream by the generation of a vacuum inside the filling system that helps in forcing viscous cream easily and assuring proper leveling and quality filling.

Net-Weigh Face Cream 4 Side Seal Packaging Machine

Net-Weigh Face Cream 4 Side Seal Packaging Machine

The machine is very sensitive to the weight of face cream and helps in the dispensing of the exact concentration of the face cream as you feed it into the machine system. This machine is mainly preferred to run large production batches as it helps in measuring proper weight and takes less time.

6.How Does a Face Cream 4 Side Seal Packaging Machine Work?

Allpack Multi-lane Face Cream 4 Side Seal Packaging Machine

To pack face cream is indeed not an easy task, using a face cream 4 side seal packaging machine has made it extremely easy where you can achieve quality packaging without constant labor or spending hours. The basic working steps of the machine are given as follows:

Process Steps of Face Cream 4 side Seal Packaging Machine

| Face Cream Loading

Face cream is loaded into a storage tank or hopper which is designed as the topmost position of the machine to allow continuous and flexible flow of product. The material must be sufficient enough to run the process without interruption. This is basically estimated prior to running the production. |

Picture Courtesy: Harpar Bazaar |

| Film Loading

You have to manually adjust the film roll using given hooks or rollers to fix the film roll. Plus, add the protocol in the machine using the HMI touchscreen. This includes type of sealing, temperature, volume to be load inside the packet, speed of packaging per hour, etc., |

|

| Film Forming & Sealing

Now the game starts when the unwinding of the film takes place and wrapping around the former to make packaging of the sachet/stick pack with simultaneous heating around the edges. This required vertical sealing and a bottom seal. |

|

| Dispensing of Face Cream

A pre-determined volume of face cream is dispensed into the pack and final sealing at the top is done using heated sealing jaws. |

|

| Cutting & Discharging

The finished product is separated using a set of cutters by the machine. The final packaging is exported out for the next phase of packaging. |

|

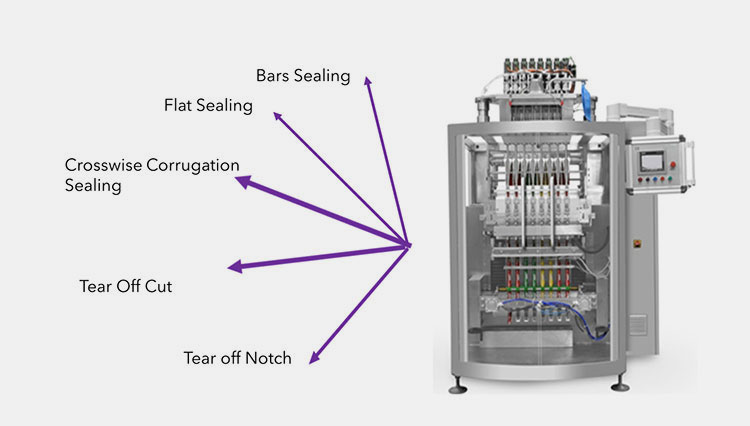

7.Face Cream 4 side seal packaging Machine: What Sealing Type it offers?

Sealing Type of Face Cream 4 Side Seal Packaging Machine

The machine itself offers various styles of sealing to your packaging products. See below to learn about each type and what it looks like.

Bars Sealing

| This type of sealing looks like horizontal long bars all around the four edges of the packaging which is mostly done by either heat sealing or other unit of sealing to make face cream effectively secure and sealed.

This type of sealing is commonly used for packaging in stick types offering you ultimate protection. |

Bar Seal |

Flat Sealing

| This is almost similar to bar sealing of face cream packaging but the different is a flat bar appearance around the edges of the sachet packing. This means you can see 4 side sealing with a flat bar done by either heat, ultrasonic, or pressure sealers making an aesthetic, secure and beautiful packaging. |

Flat Seal |

Crosswise Corrugation

| This is a unique way to apply on packaging by face cream 4 side seal packaging machine where a crosswise corrugation is punched by sealers. You can observe small corrugation that improves rigidity around the 4 sides of the packaging making packets more tolerant to pressure. |

Crosswise Corrugate Seal- Picture Courtesy: Centaur Packaging |

Tear-off Cut

| This packaging is very convenient to use as already pre-cut is punched on over the top of the face cream 4 side seal bag by the machine using a sealer with a pre-defined margin to form a tear off cut. This is indeed a recent advancement and is commonly used by good brands to boost market value. |

Tear off cut seal- Picture Courtesy: Topas Advanced |

Tear-off Notch

| This kind of sachet packaging is very similar to tear-off packets where a tear-off notch is punched by adding a tiny perforation allowing you an easy tearing of sachet or pack to draw a face cream easily and fast. |

Tear off Notch- Picture Courtesy: Carepac |

8.What Different packaging materials are compliant with the Face cream 4 side seal packaging machine?

To answer this question, please check below the description of the packaging material list:

Granules

Granules Packed By Face Cream 4 Side Seal Packaging Machine- Picture Courtesy: St. Luke

The face cream 4 side seal packaging machine is helpful equipment in the filling and sealing of granular materials and also allows its firm securing by keeping the product untouched and unharmed. This is commonly used to seal products like salts, sugars, spices, seasoning items, etc.,

Powders

Powders In 4 Side Seal Packaging- Picture Courtesy: Bartelt

The machine demonstrates an excellent profile in the filling and sealing of products that are powdery in texture. A dust free packaging can flexibly be attained by using a face cream 4 side seal packaging machine.

Liquid

Liquids- Picture Courtesy: Packing Machine

There are various products that are dispensed in liquid forms such as juices, beverages, syrups, shampoos, and others by using a face cream 4 side seal packaging machine.

Beans

Beans- Picture Courtesy: pouch.eco

Products that are in pellets or in beans can be packed in 4 side seal packs by using a face cream 4 side seal packaging machine. such as coffee, candies, or other confectionery items.

Gels

Gels- Picture Courtesy: Aiglone

This is a kind of thick substance that has semi solid consistency and is commonly used in food industries, Medicinals, herbal, and cosmetics products including handwashes, body wash gel, aloe vera gel, etc.,

Pastes

Pastes

As compared to gel, it has high thickness and can be dispensed by using face cream 4 side seal packaging machine in foods and other manufacturing sectors to pack products like mayo, ketchups, dental products, etc.,

9.Are the Face Cream 4 Side Seal Packaging Machine And 3 Side Sealing Packaging Machine the Same?

Allpack Face Cream 4 Side Seal Packaging Machine

Yes, the face cream 4 side seal packaging machine and 3 side seal packaging machine are the same. The only difference in sealing can be achieved when you configure the settings of the system using an HMI and tooling.

The machine setting can help to transmit the message to create sealing around the edges for example 4 sides or 3 sides. Similarly, you will need to adjust the tooling for either 4 side or 3 side sealing. This includes setting and adjustment of sealing jaws.

So, if you’re thinking of giving either sealing type, the face cream sealing machine is helpful in giving the acquired shape by simple settings.

10.Face Cream 4 side Sealing Packaging Machine: Does it Offer Irregular Shape Sachet Packaging?

Face Cream 4 side Sealing Packaging Machine

The answer to this question is hypothetical; and ‘ yes’!

The machine is capable of creating irregular-shaped face cream packaging. As you know this machine is mainly designed to offer simple and 4 side seals as standard packaging.

However, adding minor modifications in software settings and tooling can offer an excellent broad range of sealing options.

This machine is quite flexible and may offer easy functionality to create even non-standard sealing including non-rounded, curved, star-shaped, circular, etc packaging.

The game is all about the fixation of sealing jaws and cutting die that helps in the giving exact shape you acquire for your face cream. So, according to our expertise, if you want to attain irregular shape sealing; you can add alteration using the same machine.

11.How to Increase the Efficiency of Face Cream 4 Side Seal Packaging Machine?

Allpack Multi Row Face Cream 4 Side Seal Packaging Machine

To increase the efficiency of the machine, some cleaning patterns must not be ignored when using the machine routinely.

As the machine encounters highly viscous substances; their cleaning is almost more complex than other products. This is because the product might stick around the wall of the circulation system inside, and if ignored may result in cross-contamination.

For that reason, the Cleaning in Place or CIP system is followed to attain 100% cleaning.

On the other side, maintenance is crucial which involves the replacement of damaged parts, lubrication of movable parts (weekly or monthly), cleaning of cutters, and maintenance of temperature sealing bars by wiping their surface (in normal state) to removing any sticky particle over the surface.

12.How CIP Works for Your Face Cream 4 Side Seal Packaging Machine?

CIP Or Clean In Place- Picture Courtesy: Tetra Pak

CIP or clean in place is a modern procedure offering you high cleaning and sanitizing of face cream packaging machine to reduce chances of cross-contamination and progression of unwanted microbes.

This process is followed by some major cleaning steps:

Cleaning and washing of inner lining of pipes and system that involved product dispensing with hot water. This helps in the melting of sticky particles and vanishes them by a high burst of water flow.

The second phase is accompanied by a flow of hot water (80C) combined with fast and reactive substances such as 1.5% caustic soda to clean the inner system, moreover, high steam pressure is given with a high temperature of approximately 120 degrees centigrade.

The final rinsing is done by using steam and running water solution combined with the peracetic solution of 1.5% concentration followed by running plain water.

This method assures you high level sanitization and scrubbing which is indeed not only reliable but has reduced labor intensive cleaning with less exposure to cleaning chemicals.

13.Face Cream 4 side Seal Packaging Machine: What are common errors you face?

To dispense a face cream is a very technical job. However, there might be a possibility of encountering errors even when using an automatic machine. So, it is very essential to have proper knowledge about the machine and viscosities of the material to be dispensed.

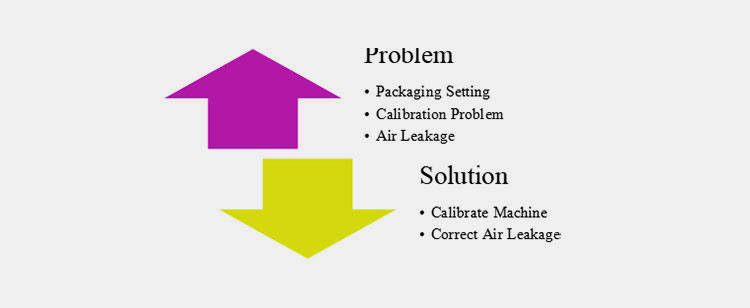

What Should You Do If Dispensing Is Not Correct?

Inaccuracies Of Product

This is a common problem mostly occurring due to improper sealing of the face cream packaging for example length, and width, Also, there is improper dispensing settings, or the machine is not calibrated. The third and foremost reason is an air- leakage that hurdles the proper filling of face cream.

To solve the problem, check the dispensing and sealing settings, calibrate the machine for accurate and sharp functionality, and correct the air-pressure to sort air leakage issues.

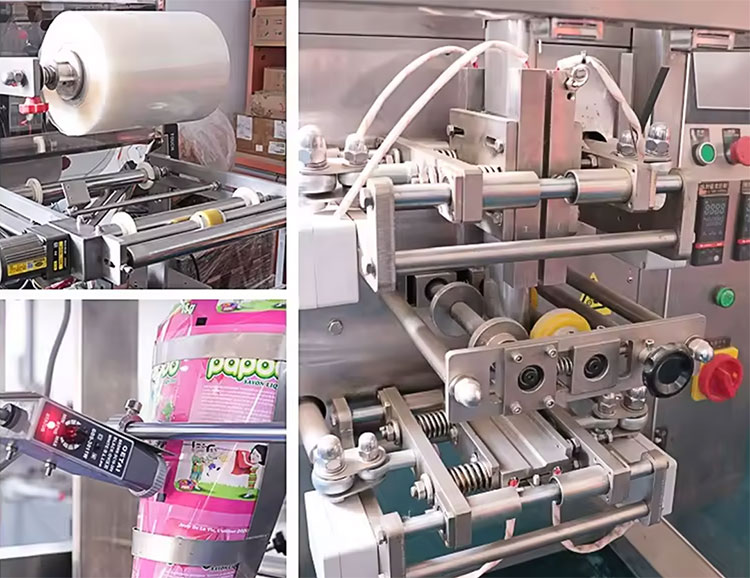

Face Cream Packaging Machine Does Not Discharge?

No Cream Dispensing

This is another issue that may interfere with the packaging process when the machine is unable to discharge cream fully.

This problem may be due to the greater thickness of the material that you load into the machine, Secondly, the filling line may be clogged or jammed which may block the dispensing. Thirdly, the sealing ring may be damaged and that may affect the filling process.

To solve this problem, it is recommended to have proper knowledge about viscosities ranges and utilization of filling system based on viscosity of the ingredients. For example, use piston or pressure filler in case of high thickness ingredients. Secondly, it is highly recommended to clean the system after each use to avoid clogging. Thirdly, use a sealing ring in the inner piston if it is damaged.

Why 4 Side Seal Packaging Are Burnt?

Seal Burning

This is an important problem that occurs when an excessive temperature is provided to the sealers which ultimately reduces the quality of packaging with wrinkled and burnt sealing.

To solve this problem, it is recommended to correct the temperature regulator, calibrate the machine, and run the test process.

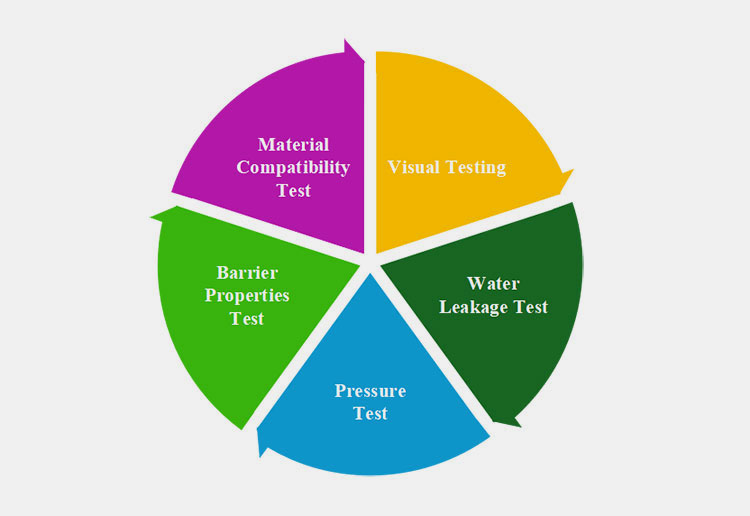

14.What Tests Assure Quality Packaging by Face Cream 4 Side Seal Packaging Machine?

Picture Courtesy: Oxileak Detection

After packaging face cream, there are certain quality tests that must be done to check the procedure is successfully showing desirable results. This task must be done in the quality control department before marketing the product. There mentioned below ensure quality packaging:

The Leakage Assessment Tests

Visual Testing: This is a visual inspection to assess the correct and finished sealing and packaging of the product.

Water Leakage Test: A packaging material is placed inside the chamber filled with water and compressed air is exerted to check the generation of water bubbles to assess the presence of leakage.

Pressure Test: This is the fastest way to find out the presence of leakage where you can exert air inside the packet and measure the pressure release. if the pressure level differs it verifies some leakage.

Barrier Properties Test: this is done to assess if the packaging material has intact properties and prevent external factors and parameters (oxygen, moisture, temperature) from penetrating and reacting with face cream. This includes the MVTR test, Oxygen Transmission Test, or OTT.

Material Compatibility Test: This attributes the interaction of face cream with packaging material type. There should not be any reaction within your product and material.

Conclusion

After reading the blog on Face Cream 4 Side Seal Packaging Machine: The Complete FAQ Guide In 2024, we hope you have found answers to basic questions in mind. It is not only a versatile addition to ease the complexities hooked to face cream dispensing but also a great solution to bring quality and accurate filling of low to high-viscous substances. If you’re planning to purchase the equipment; Tell Us. Allpack is one one-stop solution where you can enjoy a series of machinery involved in packaging products. For more information & Guidance, Click on Message Now.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide