Dry Powder Blending Machine: The Complete Buying Guide in 2024

Do you want your dry powders to be well mixed without leaving any particle left? Probably yes! So, let us introduce you with the Allpack's latest dry powder blending machine which is going to revolutionize your existing manufacturing. Dry Powder Blending Machine is innovative tool brought into the field to carry out powder mixing. Designed with cutting edge technology, you can employ it for your vary needs in diverse sectors.

Not only that, but you can have the type of dry powder blending machine which suits you the most. But, how will you know that? The maintenance which it requires to stay longer? And most importantly, how to troubleshoot the possible problems caused during operation? These all followed by much other aspects associated with dry powder blending machine will be discussed in detail in this buying guide. So, let's embark on the journey of exploring it!

1.What Is Dry Powder Blending Machine?

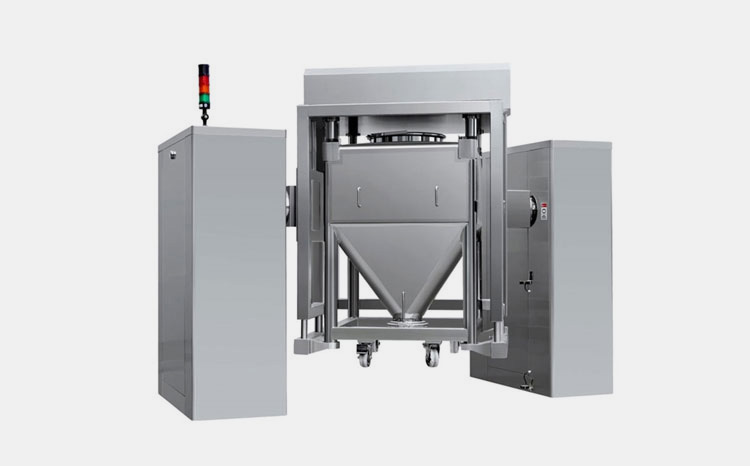

HDT Bin Blender- Allpack

From milk powder to detergent powder and medicine dosage, the use of powders is inevitable in our daily life. Similarly, their production and processing become responsibility of manufacturers for which they also need a dry powder blending machine.

Dry powder blending machine is the most crucial machine tailored with cutting edge technology to facilitate the mixing of broad range powders as well as granules. It is made with hygienic stainless steel to make sure the processing is done in a safe environment.

2.Enumerate The Benefits Of Dry Powder Blending Machine?

Dry powder blending machine is highly beneficial due to its precise structure, uniform mixing, and consistent performance. Some of the prominent features of dry powder blending machine are enlisted below:

Uniform Mixing

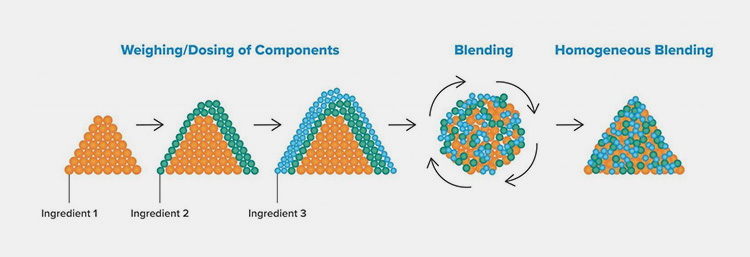

Homogeneous mixture of dry powders-Picture Courtesy: crbgroup.com

By using a dry powder blending machine, you can achieve the uniform mixing of your two or more types of powders and granules. For instance, the rotation of ribbon and paddle from inside and movement of bin from outside result in mixing all the particles accurately.

Ensures Safety

Dry powder blending machine is highly safe and hygienic for your environment as well as product itself. For instance, the machine provide enclosed structure to powders like condiments and chemicals which can otherwise flow in the air and get into operator eyes. Moreover, in case if any problem occurs, you can simply stop the machine by pressing safety button to ensure the material as well as machine security.

Convenient Handling

Automatic forward & reverse dry powder blending machine-Picture Courtesy: amazon.ca

The machine has convenient handling system with 360° forward and reverse body which can automatically move to discharge the mixed powder into container.

Time Saving

Dry powder blending machine uses ultrafast technology to meet the excessive production target. It can be also integrated with other machines such as storage tank, filter machine, and powder filling machine for getting efficient result. Therefore, you can mix multiple powders and granules in a less time with low human labor.

Reduce Waste

Various multicolor dry powders-Picture Courtesy: amixon.com

Mixing powders manually is a difficult job, especially, when amount is excessive. However, this problem has been resolved by a dry powder blending machine which can reduce the possibility of your powder waste to zero.

User-friendly

easy-to-use presentation through keyboard-Picture Courtesy: intellect.com

The machine is extremely easy-to-use control panel system where you can find all the essential parameters necessary for operating machine. Hence, it can be operated with a basic knowledge only.

3.What Are The Working Principles Of Dry Powder Blending Machine?

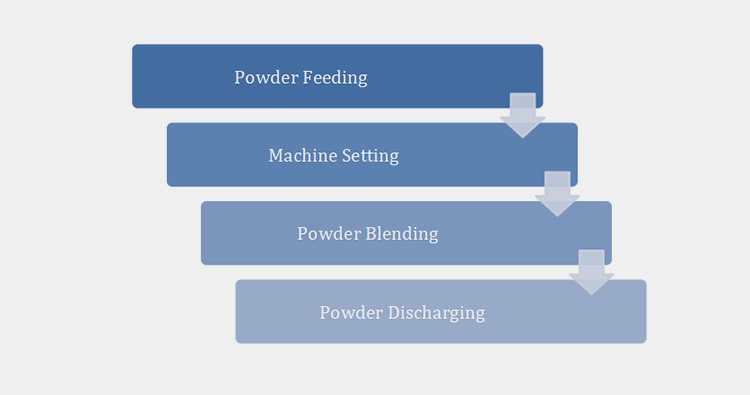

Understanding the working process of a dry powder blending machine is crucial for accurate using. Otherwise, you may face challenges in its operation and ultimately the waste of valuable material and machine damage may occur. Hence, to make you familiar with the right working of dry powder blending machine, we have explained the key principles below:

Powder Feeding

Spices loading into dry powder blending machine-Picture Courtesy: sampackindia.com

Before starting your dry powder blending machine you will require enough amount of powder to feed into the machine. For this, you can load the bin of dry powder blending machine manually, or feed the bulk volume of desired powders into a tank integrated with automatic machine. Therefore, the machine will automatically take powders from tank.

Machine Setting

Operator setting dry powder blending machine-Picture Courtesy: amixon.com

After the machine is loaded with powder, it is necessary to set the basic parameters for powder blending. Here, with the help of control board, you can fix the timing for powder mixing, frequency of ribbon and paddle rotation, and direction of movement changes etc.

Powder Blending

Powder blending working process-Picture Courtesy: powderprocess.net

Once the machine setting gets done, you can simply turn the machine on. The machine will start blending powder with the help of rotating ribbon or paddles (depending on the type of machine). Consequently, the consistent movement of bin will fall the various powders over each other and form a uniform mixture.

Powder Discharging

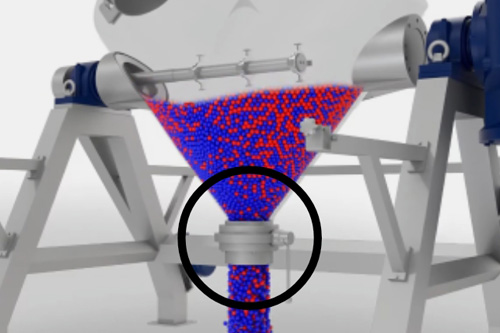

Mix powder discharging-Picture Courtesy: virtual Element Studios

Finally, the mixture is ready to be discharged from the machine by pressing a discharge valve.

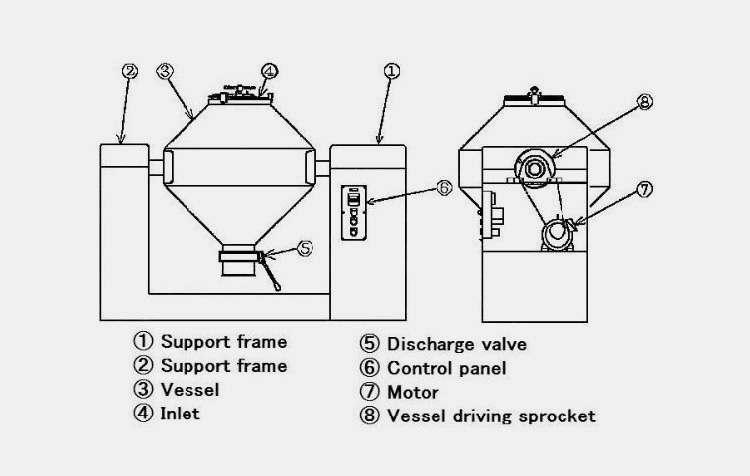

4.Describe The Structure Of Dry Powder Blending Machine?

Dry powder blending machine is composed of small to large components each performing unique function. Let's know their role by looking into underlying descriptions:

Structure of double cone dry powder blending machine-Picture Courtesy: yindamachinery.com

Control Panel

Control panel is one of the main components of dry powder blending machine which holds in it multiple knobs for increasing or decreasing the speed of agitators. By using it, user can conveniently fix the commands in machine. It has has an emergency button over it to be pressed in uncertain condition.

Inlet

Inlet is the opening of a vessel through which various powders can be easily poured into machine. The inlet has a stainless steel lid attached with it to avoid escaping powders during process.

Motor

Motor is fitted into dry powder blending machine. Its function is to change the electric energy into mechanical energy and enable the ribbon or paddles to move swiftly.

Vessel

It is the most important part of a dry powder blending machine and is also called a bin. Various types of powders are loaded here for blending and the entire process of powder mixing is carried out inside this blending vessel. It has multiple agitators inside to blend the powders.

Vessel Driving Sprocket

Vessel driving sprocket is responsible for moving the blending vessel. When machine is switched on these sprockets move the machine in a rotary direction to give you uniform mixing of different powders.

Support Frame

The main frame of machine is made up of stainless steel including supporting stand, movable casters, bin, control cabinet, and lid etc.

Discharge Valve

Discharge gate of dry powder blending machine is located right below the bin. From here, the mix powder can be simply taken out from the machine into collection container or tray. It has an attached discharge valve in form of a handle. When it is pushed downward, the discharge gate get open and the powder fall from machine.

5.Explain The Major Classification Of Dry Powder Blending Machine?

Dry powder blending machine has such vast classification that you will be amazed after knowing. Although, most of the manufacturers get confused by looking into these machines, however, we have explained them for you in an easy and straight forward way, that you will understand each type along with their benefits and functions. Let's discover these all!

Laboratory Dry Powder Blending Machine

Laboratory dry powder universal mixer/blender machine-Picture Courtesy: alibaba.com

Laboratory dry powder blending machine is a resilient and precise machine designed for universal blending of all types of dry powders including spices, milk powder, herbal powders, and chemicals etc. It is available in different capacities such as 5kg, 10kg, 20kg, 50kg and so on.

Structure

Structure of dry powder mixer blender-Picture Courtesy: amazon.com

The machine is composed of a stainless steel barrel, durable mixing rack, finished product outlet, lid, and a control system located at the bottom of machine. It mainly include the speed switch for adjusting the speed, time shutdown mechanism, and a steering controller.

Working Process

For operating this machine, user has to load the bulk powder manually into barrel close the lid tightly and plug on machine. Now, the barrel will start moving in a circular motion causing powders to mix homogeneously. After the time for each cycle gets completed, machine will stop automatically, so, you can discharge the mixture.

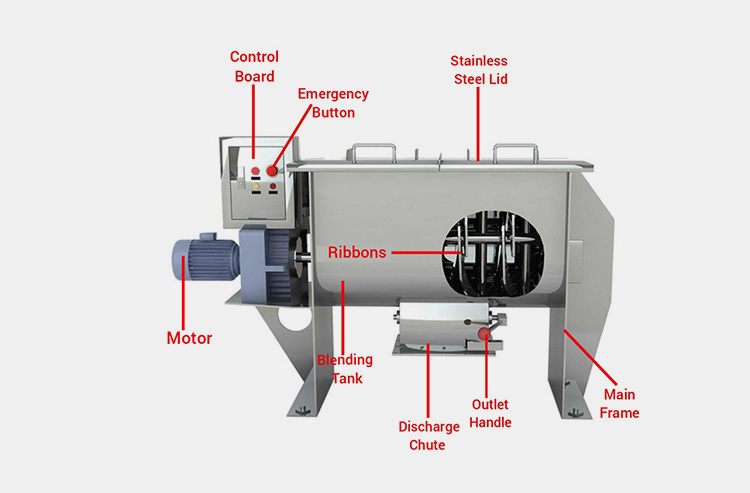

Ribbon Dry Powder Blending Machine

Double screw ribbon dry powder mixing machine-Picture Courtesy: alibaba.com

Ribbon dry powder blending machine is designed to mix diverse powders uniformly. It has a u-shaped horizontal mixing tank inside of which double screw ribbon is fitted. The machine has high blending speed due to which it form fine mixture of multiple powders. It is applicable for chilli powder, grains powder, flour, and seasoning powders etc.

Structure

WLDH horizontal ribbon bin mixer-Allpack

Ribbon dry powder blending machine is composed of a control board, emergency button, motor, stainless steel lid, screw ribbons, blending tank, discharge chute, outlet handle, and main frame.

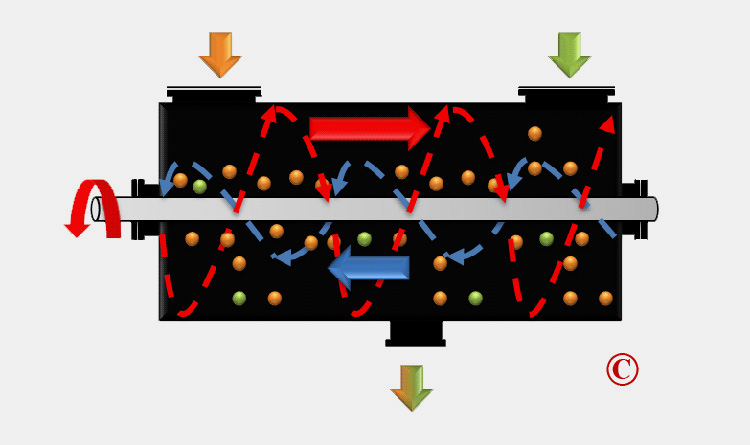

Working Process

After getting loaded with powders, the machine start blending particles in such a way that outer ribbon push the powder from edges towards center and central ribbon displace it towards ends. This cross mixing result in the formulation of perfect mixture.

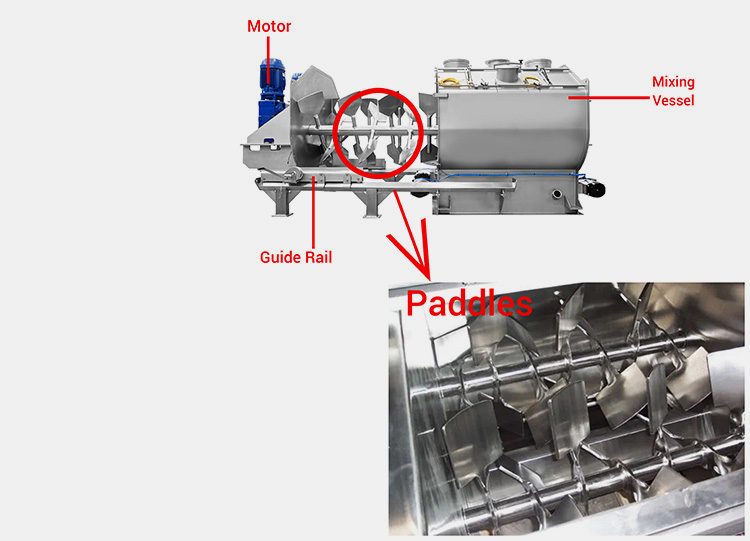

Paddle Powder Blending Machine

Horizontal paddle blender powder mixer-Picture Courtesy: permix-mixer.com

This machine as the title illustrates has an integrated paddle shaft which enable it to mix range of dry powders and granules. Paddle powder blending machine may come in various shapes like cylindrical, horizontal, and vertical. It is desirable for sensitive powders like pharmaceutical and food powders which require gentle mixing.

Structure

Structure of paddle powder blending machine-Picture Courtesy: cem.int.com.au

The machine is an assembly of various components including motor, guide rail, mixing vessel, paddles, control system, and discharge valve etc.

Working Process

It functions after getting filled with 30% to 70% of the total capacity for proper mixing. During operation, the paddles move in opposite direction to each other, thereby, creating axial and radial pushing materials to move throughout the blending tank. The blended mixture is then discharged while machine is running to avoid particle segregation.

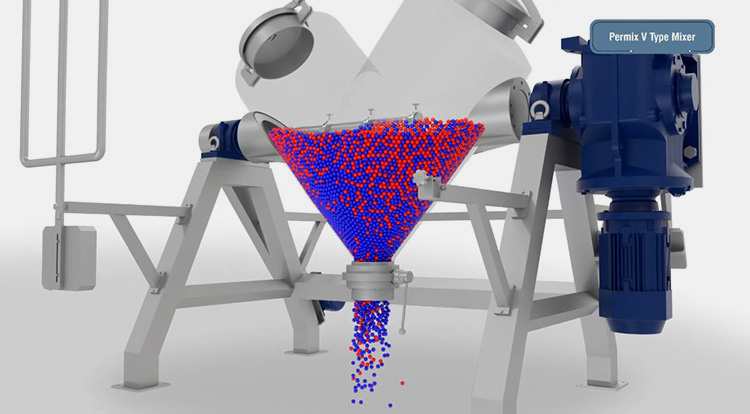

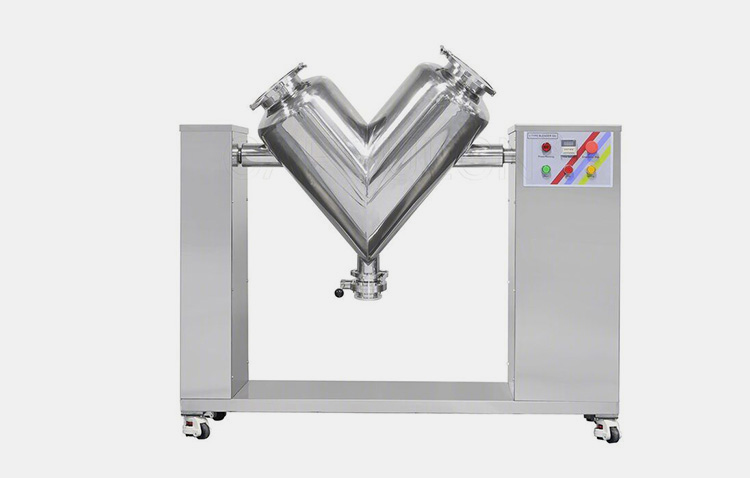

V-type Dry Powder Blending Machine

V Dry Powder Mixer Blending Machine V50 - V300-Picture Courtesy: ipharmachine

V-type dry powder blending machine has unique design with double compartments which meet at a single point and form the shape of v. This type of machine is suitable for all kinds of dry powders including baby milk powder, medicine powder, chocolate, and coffee powder etc. Its capacity range is from 50L to 300L.

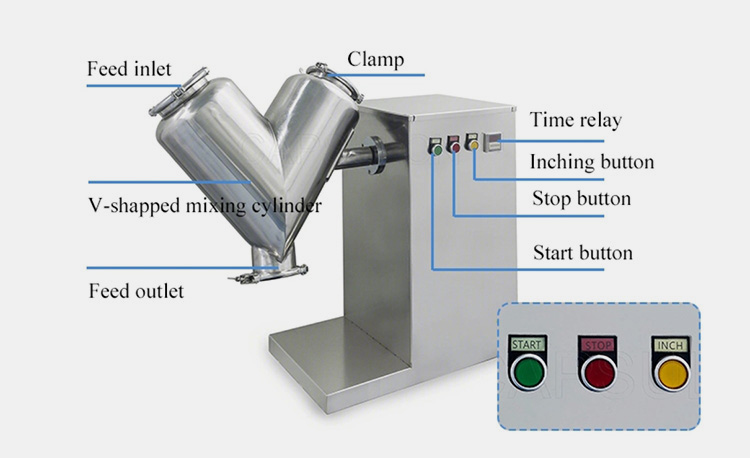

Structure

Structure of dry powder blending machine-Picture Courtesy: m.made.in.china.com

Several components together make the structure of machine including feed inlet, v-shaped mixing cylinder, feed outlet, clamp and control board, comprised of various knobs.

Working Process

During operation, v-type vessel adopt rotary movement. Here, 25% of material move towards other compartment in a single cycle. Similarly, the radial and horizontal movement further blending the powders to make a uniform mixture.

6.What Are 2D And 3D Dry Powder Blending Machine Used For Dry Powder Blending?

In the realms of dry powder blending machine technology you will find myriad of machines being applicable for blending dry powders. Among them, the most innovative and compact machines are 2D and 3D blending machine which are designed with unique features. Let's understand both of them:

| No | Points | 2D Dry Powder Blending Machine | 3D Dry Powder Blending Machine |

| 1 | Definition | 2D dry powder blending machine is two dimensional machine which comes in multiple capacities and require less energy for mixing powders | 3D dry powder blending machine is a multi dimensional machine supporting three different patterns to make your dry powders mix homogeneously |

| 2 | Structure | It consists of a rotary drum, swing frame, supporting frame, inlet, discharge hole, and control box etc. | It is composed of basement, driving system, three dimensional motion system, and blending vessel, and control mechanism. |

| 3 | Working Process | Blending cylinder rotates during operation and the material get mixed in a direction from right to left and vice versa | During operation, powders move in random direction from center to end, downward, and right/ left in horizontal direction |

| 4 | Dimension | Two dimensions supporting right and left movement in horizontal direction | Three dimensions including rolling, horizontal moving, and vibration etc. |

| 5 | Picture |

Dry powder mixing machine-Picture Courtesy: cecle.net |

Dry powder blending machine-Picture Courtesy: cecle.net |

7.Differentiate Between The Categories Of Powders Processed By Dry Powder Blending Machine?

Powders can be fundamentally categorized into free flowing and non-free flowing powders on the basis of their properties. Knowing these properties and ultimately their flowing ratio greatly assist in the accurate mixing of these powders. The table below will be helpful in this way:

| No | Factors | Free Flowing Powders | Non-Free Flowing Powders |

| 1 | Definition | Free flowing powders refers to powders with good flowability speed and less or no cohesiveness. | Non-free flowing powders are also called cohesive powders due to their stickiness during flowing. |

| 2 | Flow resistance | No resistance to flow | High resistance to flow |

| 3 | Particle size | Comparably coarse and big | Small size particles |

| 4 | Porosity | Low porosity and high smoothness result in free flowing | High porosity and roughness of particles make them stick together |

| 5 | Shape | Spherical shape | Irregular shape |

| 6 | Density | High density | Low density |

| 7 | Examples | Detergent powder, salt, and spices etc. | Custard powder, starch, and milk powder etc. |

| 8 | Pictures |

Free flowing salt-Picture Courtesy: blossomingwidow.com |

Non-free flowing starch powder-Picture Courtesy: jessicagavin.com |

8.Write Down The Applications Of Dry Powder Blending Machine?

The applications of dry powder blending machine can be found in diverse sectors among which some of the prominent are discussed below:

Pharmaceutical Industry- For Drug Powder Blending

Tablets and powder in spoons-Picture Courtesy: coherentmarketinsights.com

Powder blending is one of the key practice carried out in pharmaceutical industry to well mix the multiple powders. Otherwise, improper mixing can affect the uniformity and drug quality. Therefore, dry powder blending machine is popularly used in this sector to blend myriad of pharmaceutical and herbal powders for tablets, capsules, and even powder for suspension.

Food Industry- For Condiments Blending

Various whole & powdered spices-Picture Courtesy: amixon.com

Most of us enjoy the mouthwatering and vibrant colored cuisines which are indeed the result of multiple spices and condiments. These condiments are well mixed before packaging with the help of dry powder blending machine. Apart from that, powdered food colors, preservatives, and protein powders can also be processed by this machine.

Cosmetic Industry- For Makeup Powder Blending

Multiple makeup items-Picture Courtesy: thebeautylookbook.com

Either it is face powder, blush on, or eye shade, all are compressed powders which undergo a mixing step. And this step has been achieved by employing a hygienic dry powder blending machine.

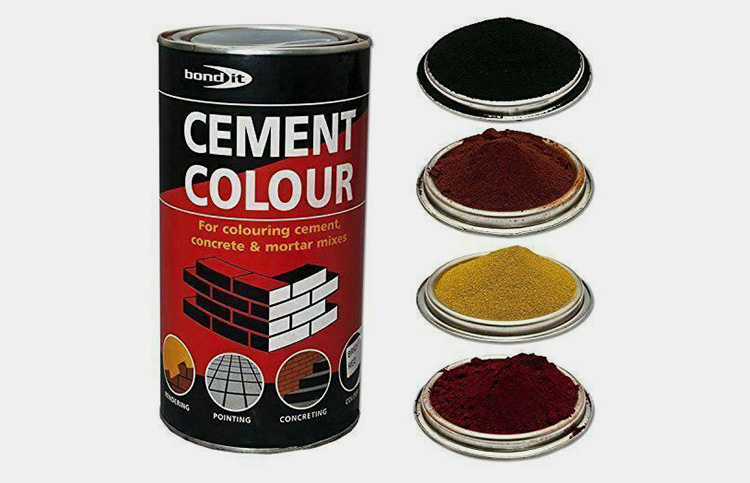

Chemical Industry- For Blending Chemicals

Cement color powders-Picture Courtesy: ebay.co.uk

Among other industries, chemical industry is also notable one where the use of a dry powder blending machine can be found for mixing range of chemicals including cement, explosives, and dyes etc.

Detergent Industry- For Detergent Powder Blending

Detergent powder bag-Picture Courtesy: www.behance.net

We all are well-familiar with detergent powders which we use in our daily life for washing clothes, households, floor, and other objects. These detergent powders are composed of different types of granules with varying colors and sizes. For their uniform mixing, a dry powder blending machine is used.

Agrochemical Industry- For Fertilizer Blending

Fertilizer effects on agriculture production-Picture Courtesy: biologywise.com

Agrochemical industry processes wide range of powdery substances for sound agriculture promotion and safety. These include fertilizers, pesticides, insecticides, and herbicides etc. As their formulation occurs through blending eclectic powders, a dry powder blending machine becomes applicable here.

9.What Are The Maintenance Requirements Of Dry Powder Blending Machine?

Dry powder blending machine in all of its forms is an integral part of processing powders in multifarious industries. If you take proper time for the maintenance of your dry powder blending machine it will undoubtedly last for decades, otherwise, you may find its life last for limited time. Hence, to avoid such situation, below description will be helpful:

Maintenance of dry powder blending machine motor-Picture Courtesy: elmatechnology.com

Proper Lubrication

Lubrication is an inevitable step your machine is always in need of. You must be careful and responsible in lubricating various parts of the machine including movable parts, drive, shaft bearings, and reducer etc., to make them properly work and extend the work life of machine.

Regular Cleaning

Whether you are using dry powder blending machine for pharmaceutical, food, chemical, or any other industry, you will process different types of powders. Then, it becomes obligatory to regularly clean your machine, so that, all sorts of debris and dirt will be removed out of machine.

Maintaining Components

Maintaining various components of machine such as drive tension, mixer tub, reducer belt, seals, and discharge operation gate will help you restrict the entrance of dirt and pollution to the powders and reduce the chances of material escaping from the bin.

Inspect Electrical System

After all, it is the electrical system of dry powder blending machine which enable you to set parameters and take these commands for performing desired processing. Therefore, you are obliged to inspect the wiring system of machine, check electrical cords for breaks, and damaged cords, because a minor ignorance can cause issue in form of explosion or fire.

10.What Quality Standards Standards Should Dry Powder Blending Machine Meet With?

Adherence to quality standards icon-Picture Courtesy: vectorstock.com

As dry powder blending machine is used for both food and non-food products, it is necessary for it to comply certain quality standards, so that, it may be declared safe for all types of powders. Below are some important quality standards essential for dry powder blending machine:

Food & Drug Administration

FDA is working on international level to promote safety of public health by certifying quality drugs and associated machines. Therefore, a dry powder blending machine must comply the safety regulations of FDA.

International Organization for Standardization

ISO is another agency established with the aim to set standards for companies who manufacture goods and machinery. This agency work all around the globe to facilitate local industries by providing them certificates after checking their compliance to fixed standards.

Good Manufacturing Practices

GMP comes under the auspices of World Health Organization, thus, working as a spectator to keep an eye on the goods and products produced around the globe. For this purpose, GMP has established its rules and principles which must be fulfilled by all industries so as by dry powder blending machine.

11.Identify The Common Problems Of Dry Powder Blending Machine? Also Give Solutions?

Discussing the possible malfunctions of dry powder blending machine and giving solutions to them can help you to nip the problems in the bud or it will lead to bigger challenges. Hence, below table is better illustrating the troubleshooting:

| No | Problem | Causes | Solution | Picture |

| 1 | The machine requires much time for mixing | It is because you have overload mixing tank than its capacity which has blocked its way for efficient mixing | Reduce the amount of powder to 60% of the total capacity of mixing tank |

Overload dry powder blending machine-Picture Courtesy: ribbonblendermixer.com |

| 2 | Not good homogeneity of mixed powders | Either the speed of mixer is too low or you have put excessive or too low amount of powders | Make sure you leave enough empty head space for uniform mixing and don't go for inadequate volume in bin. Also check whether the speed of paddle or ribbon is at good pace |

Inhomogeneous mixture of powders-Picture Courtesy: asiamixer.com |

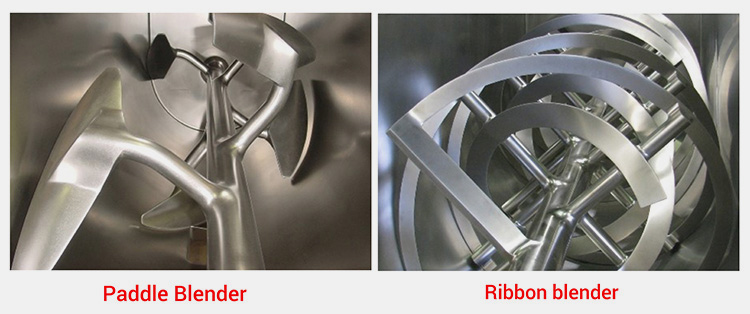

| 3 | Reduction of particles size | It occurs due to the sharp agitators with high speed which cause material breakage | It can be solved by choosing right type of dry powder blending machine. For instance, ribbon blender has high proclivity to degrade particle size, while as, paddle blender process the powders gently without reducing their size |

Particle size reduction-Picture Courtesy: pion-inc.com |

| 4 | Discharging of mixture takes too long | The only reason is that agitator is not ON | Make sure, while discharging mixture, agitator is on, so that, powder will fall swiftly |

Slow discharging of mixed powders-Picture Courtesy: Virtual Element Studios |

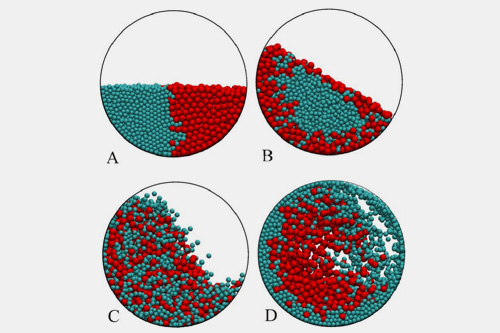

| 5 | Dynamic segregation happen even after uniform mixing | This is a serious problem that arise when light and heavy weight powders are mixed. Resultantly, heavy powders fall on the bottom and light powders on top | Such issues can be tackled by adopting different discharging techniques like compact packing and vacuum packing |

Dynamic powder segregation forms-Picture Courtesy: core.ac.uk |

12.How To Choose Right Dry Powder Blending Machine?

Choosing a right type of dry powder blending machine in such vast types available in market often result in difficulty. However, it can be solved by considering certain factors which are explained below:

Examine Production Need

Various powdered spices in bowls-Picture Courtesy: Pinterest

The foremost thing you cannot ignore while buying a dry powder blending machine is to consider whether the powder you want to mix is fully dry or moist, free flowing or non-free flowing? And most importantly what is the desired outcome you want from dry powder blending machine. These questions will enable you to opt for right machine.

Evaluate Specifications

Ribbon blender & paddle blender-Picture Courtesy: marionsolutions.com

The specifications and features of each type of dry powder blending machine vary from one another. For instance, some have ribbon agitator while others are paddle type. Similarly, IBC Bin blenders adopt rotary movement while as, 2D and 3D blenders have greater movement dimensions. Therefore, you should ask your vendor about their specifications and benefits each machine offer.

Consider Your Budget

Budget-Picture Courtesy: techx.pk

Dry powder blending machines come in variety of designs, sizes, and ultimately different prices. Here, you need to assess your budget that how much you can afford to pay for the machine. For example, if you want efficient but cost-effective machine then laboratory bin dry powder blending machine is the best choice.

Quality Certification

It is important to check the quality certifications of a machine you want to purchase. It is helpful in determining that the machine is made from quality stainless steel and food grade material, so, that your valuable powders may be processed under safe conditions.

Warranty

Warranty icon-Picture Courtesy: oratefinanceinstitute.com

Last but not the least, warranty policy is a must-have thing which your supplier should provide. It is because, warranty give you assurity of the machine and you can ask for change in case of any problem that occurs within valid time period.

Conclusion

To wrap up the discussion, it can be concluded, that dry powder blending machine is the prerequisite for attaining quality production in the extensive fields of pharmacy, food industry, agrochemical, and many other areas. It has also been proven by the most comprehensive list of dry powder blending machine's classification, which allows you to opt for the most stunning machine. So, what are your thoughts regarding it? Are you planning to make this machine part of your production line? Then don't make delay to contact Allpack, where all these machines are available with one year of warranty. For further information and guidelines please contact us!

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide