Continuous Bag Sealer: A Complete Buying Guide In 2024

Many industries like pharmaceutical, chemical and food industry produce hundreds of thousands of products which are then stored in bags or pouches. These bags and pouches need a method through which thousands of them can be sealed quickly and efficiently. Since manual labor is expensive and time-consuming, the use of a machine would be more feasible to seal these bags. For this reason, continuous bag sealers are the perfect choice to seal thousands of bags and pouches quickly and efficiently.

1.What Is A Continuous Bag Sealer?

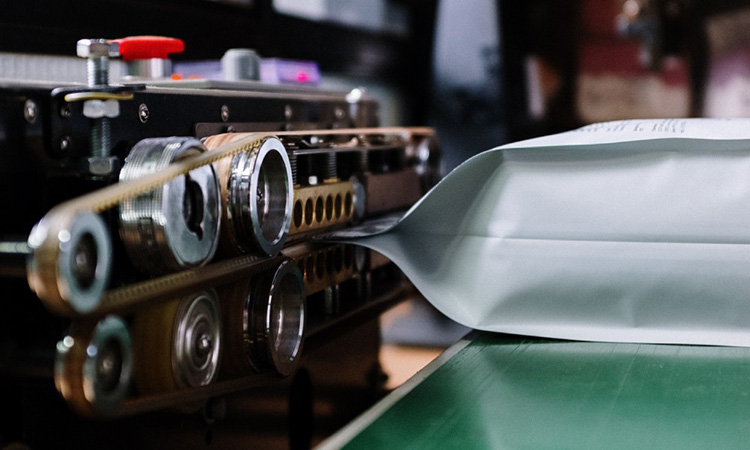

A continuous bag sealer is a machine that uses a conveyor belt to seal different kinds of bags and pouches. These machines seal the bags in a clean and secure manner, providing them with an excellent strength seal that is also visually pleasing to the eyes.

This machine is employed in various industries and its demand has been increasingly growing over the past few years due to several benefits it offers. This machine is fast, sealing thousands of bags in a single day. If used, it can increase the profit margin of the customer to a considerable degree.

2.What Is The Working Principle Of the Continuous Bag Sealer?

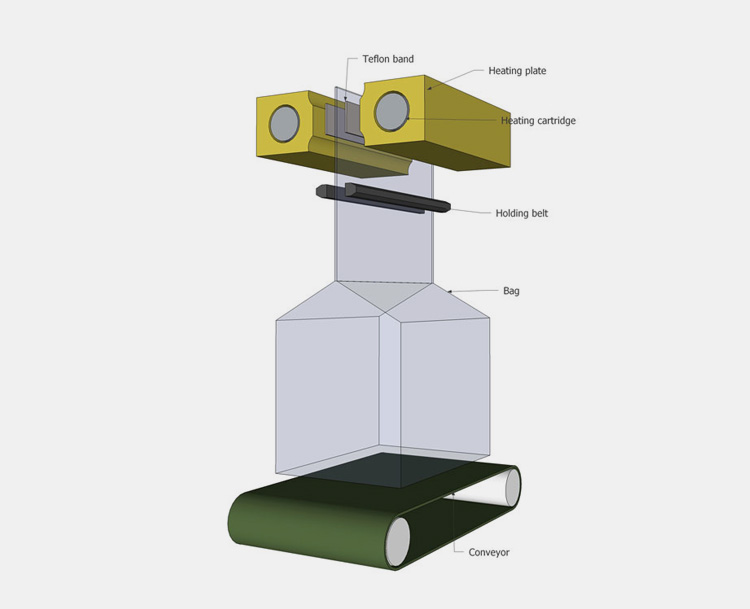

The working principle of a continuous bag sealer is simple. This machine uses heat and pressure to seal the bags and pouches in an orderly manner. It requires a power supply to produce heat at the top and bottom of the heating blocks. Firstly the operator puts the bag or pouch between the two sealing bands. Secondly, the bag or the pouch is then sent to the heating field which is situated between the heating blocks which then seals off the bag or the pouch with the help of a roller.

The bag or the pouch is made to go through a conveyer belt where the sealing process is done by bands made up of PTFE.

3.What Are The Components Of Continuous Bag Sealer?

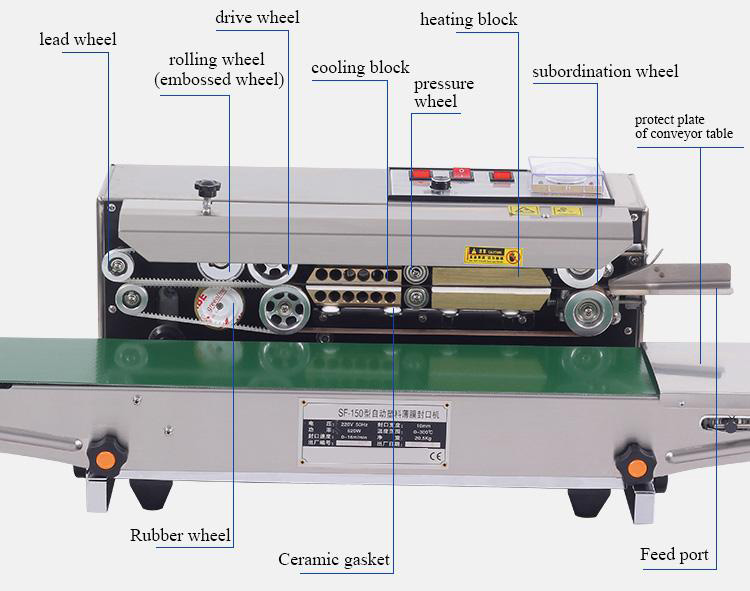

Let us discuss some of the parts of continuous bag sealer

Electric Motor

An electric motor is the main power supply of this machine and is one of the most important components since the machine won’t work in its absence.

Silicon Wheel

After the bag or the pouch is sealed off using heat, this silicon wheel is used to put pressure on the bag so that it sticks together.

PVC Chain Roller

This PVC chain roller is used to rotate the roller shaft.

Rubber Roller

Rubber roller is also used to press the pouch or the bag with the help of a rubber roller.

Conveyer Belt

This conveyor belt is automatic, it moves the bags or pouches to seal between heating jaws, this heating allow bags to pass from one part of the machine to the other part.

Gear Set

The gear set makes a connection with the gearbox.

Potentiometer

This device has the ability to control the speed of the electric motor.

Thermo Couple Wire

This wire senses the temperature.

4.What Is The Purpose Of a Continuous Bag Sealer?

Various industrial sectors like pharmaceutical, chemical and food industries manufacture thousands of products every day. These products are put into bags or pouches to increase the self-life of product. These bags need to be sealed off to protect them from any damage and save them from any contamination during their transport. In order to fulfill all these obligations, the use of a continuous bag sealer would make perfect sense.

Since thousands of these bags need to be sealed off each day as quickly as possible, its advanced technology, easy to operate and maintain quality, less power usage make it more versatile and this machine would be an excellent choice to seal your products.

It could be in various shapes and designs; vertical bag sealer is used for sealing liquid goods packaging and horizontal bag sealer is used for sealing dry articles.

5.What Are The Different Types Of Continuous Bag Sealer?

There are 3 different types of continuous bag sealer available in the market.

Horizontal Band Sealer

A horizontal continuous bag sealer is used to seal bags with liquid solution, solid products like powders, granules, nuts, tools etc. that’s why equipment is highly recommended for medical and food industries as sealing technology ensure proper bags sealing with ideal height for the technician or user.

As the name suggests, the bags or the pouches are placed horizontally placed on the conveyor belt in this machine which are then made to go through the whole machine, sealing them off through the heating process.

Vertical Band Sealer

A continuous vertical bag sealer is the best fit for sealing stand up pouches, square or bottom or gusted bags as it can be sealed appropriately using vertical position.

In this type of machine, as the name suggests, the bags or pouches are vertically placed in the conveyor belt. The bags then move through the heating blocks after which the rollers put pressure on the bags to seal them.

Machine is ideal for packaging products belongs to medical, foods, and non-food sectors.

Band Sealers With Nitrogen Flush

This machine works by filling nitrogen gas in the bag or the pouch. Nitrogen gas is a non-reactive gas and stops oxygen (a highly reactive gas) from oxidation, thus preserving the freshness of the food items inside the bag.

Depending on the thickness of the bag, the pressure of the nitrogen gas can be adjusted accordingly and filled inside the packet and sealed.

6.Differences Between Continuous Bag Sealer and Impulse Heat Sealer.

There are two three basic types of sealing implemented for various tasks depends upon type of applications. Such as:

| Continuous Bag Sealer | Impulse Heat Sealer | |

| Description | A continuous or constant bag sealer provides a constant temperature where jaws are remained hot throughout the procedure. Machine once hot require maintained temperature. | A heat sealer is used for sealing, but way of sealing is different; instead, specific rise in temperature and maintained heat, it remains heats up when required. The system utilizes an impulse electricity for this job |

| State of heat | A constant heat radiation | Heat radiations are less than constant heat sealers. |

| Working Principle | A constant heat is used between sealing bars. An object is placed between heated bars and subjected to heat till prescribed sealing. | Material to be sealed is positioned close to the jaws where mechanical or pneumatic pressure is applied followed by momentarily electric current. The jaws continuously hold the object till heat cycle is done after a predetermined time. |

| Suitable Material | These are perfect for sealing bags incorporated with metalized material that requires high temperature to seal. | They are perfect for sealing plastics such as Polyethylene or Polypropylene. |

7.Advantages Of Using Continuous Bag Sealer

Installing continuous bag sealer in an industry is the perfect choice to seal different kinds of pouches, bags, and packets due to a number of benefits it offers. Let us discuss some of its advantages below

Quick speed

This machine is very efficient and quick since it has the ability of sealing thousands of pouches or bags in one day. The machine has a conveyer belt which automatically transfers the pouches from one part of machine to another, thus saving time and quickly finishing the process.

Easy To Maintain

This machine is made of stainless steel, so it doesn’t allow corrosion to happen. Since it is lightweight, it can easily be transferred from one place to another without any hindrance. Its simple design allows an easy cleaning process for the machine.

User Friendly

This machine is quite user friendly and doesn’t require a lot of manual labor for its operation since the process is automated.

Cost Effective

Given the benefits this machine offers and its relatively cheap cost price, this machine allows the customer to earn more profits by using this machine.

Adaptability

One of the most beneficial factors of using this machine is its versatility. This machine has the capability of sealing various kinds of pouches, bags and packets. Thus it can be used by various number of industries.

Low Space Requirement

This machine has low space requirements and doesn’t occupy a lot of space, making it easy to fit it into the production line.

8.Industrial Applications of Continuous Bag Sealer

Due to its versatility, continuous bag sealer can be used in various industrial sectors such as pharmaceutical, chemical, food and agriculture industries. Let us discuss each of the industry below

Pharmaceutical Industry

Pharmaceutical industry deals in the manufacture of medicines, drugs to cure patients and improve their lifestyle. These medicines ore drugs are put into bags, packets or pouches. They must be properly sealed to prevent contamination of medicines and maintain their purity. The use of bag sealing machine will be the best way to seal these bags and prevent the entry of foreign particles into them.

Food Industry

Many food items like chips, biscuits and various snacks are manufactured in food industry. These edible items need to be preserved in the best way possible. The use of bag sealing machine with nitrogen gas in food industry will not only protect the nutrients in the food and prevent microbial growth but it will also stop oxygen from reacting with the food inside, thus maintaining the freshness of it.

Nutraceutical Industry

Nutraceutical industry deals with the production of food tablets, nutritional supplements to improve lifestyle and provide health benefits. These supplements are put into various bags and pouches. Continuous bag sealer would be a great way to seal these bags containing vitamins and supplements, preserving their freshness and maintaining their purity.

Chemical Industry

Chemical industry is a vast industry which is capable of producing hundreds to different kinds of chemicals such as solvents, fertilizers, cleaning agents etc. these chemical can then be used in other types of industries to make final product.

The packaging of these products is extremely critical since their purity has to be maintained to avoid any chemical degradation. Also, some of these chemicals are volatile and would evaporate if exposed to air. So sealing these chemicals in a pouch or packets is important to prevent all these problems. The use of continuous bag sealer would cater to all these needs.

Agriculture Industry

Agricultural industry deals with the cultivation of plants and livestock which are then processed and made into various food commodities for humans and livestock such as rice, wheat, pulses, animal fodder, etc. these products are stored in large-sized bags and then shipped to various places for sale. Continuous bag sealer can seal these bags and protect these food items from any damage or contamination.

Cosmetic Industry

Cosmetic industry produces various beauty products such as serums, facial masks, moisturizers, lotions etc. these beauty items can be stored in bags or pouches and sealed with the help of a continuous bag sealer for protection.

9.What Type of Material and Style a Continuous Bag Sealer Can Seal?

When working with continuous bag sealer you need check what material is compatible with it. They are capable to seal various material bags with thickness between 500 micron to 10 mm giving a neat and firm seal. Mentioned below are the popular materials used in different industries like pharmaceutical industry, agriculture, food etc. The machine can seal thermoplastic materials such as:

Material

Polyethylene

The most commonly used bags are light and translucent in color that allows end-user to see their items. A low-density polyethylene bags allows maximum protection with high heat resistant properties, so a continuous bag sealer smoothly seal it without any harming the product.

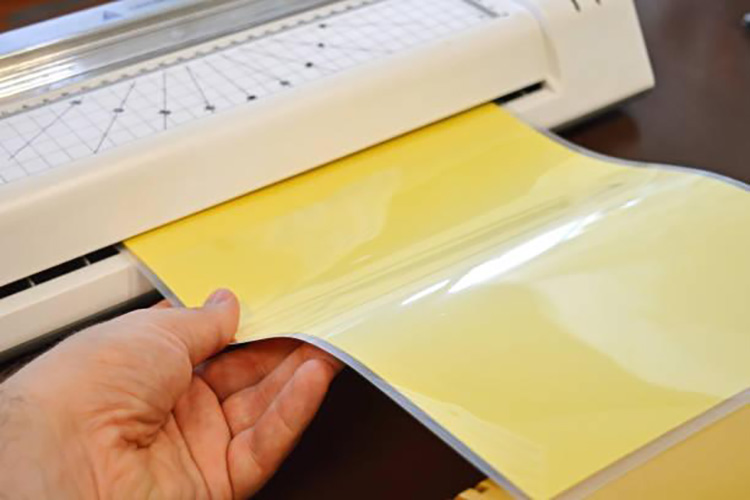

Lamination

The bags material is composed of a white base layer where a thin polypropylene sheeting is printed that is laminated over a top layer of substrate (white layer). These two layers are bonded strongly hence able to tolerate high heat during sealing procedure.

Polypropylene

A strong material composed of synthetic plastic polymer polypropylene that is strong and flexible when it comes to heat sealing by a continuous bag sealer. That’s why it is widely used on commercial scale for sealing job.

Style

Standard Bag

You must have familiar with sachet bags; they are also known as standard bags. A continuous bag sealer is good and suitable tool when it comes to seal them. Whether liquid or powder, the machine is able to preserve your product with flexibility and reliability.

Medical Pouch

They are commonly used to store medical tools or items till end user. A continuous bag sealer is well-suited for surgical and medical equipment medical pouches. They are almost similar to standard bags except the composition where a breathable material is used on either side for sterilization process.

Plastic Pouch

A plastic pouches are frequently used for various purposes in your daily life. A continuous bag sealer is in demand when it comes to pack material of various sizes and applications.

Block Bottom Bag

This style of packaging is popular among cosmetic, food, and chemical industry where a vertical bag is designed with a flat bottom and pinched top.

Pull to Open Bag

These bags are designed with easy or flexible loop where a customer can tear in a hassle-free manner.The zipper is fixed behind a tear away strip that serve as a tamper proof agent. The filling material is sealer just above the zipper/slider where a zipper/slider protects the content throughout the usage.

10.How To Clean And Maintain A Continuous Bag Sealer?

Like every machine, this machine also requires cleanliness and maintenance to increase its life and work as efficiently as possible. For this, there are a few ways in which this machine can be maintained.

Here some instructions are given below for your assistance that you must follow on regular basis.

Caution: power-off machine if it is on, and let it to restore its normal temperature.

Blow off loose dust particles with air blower that has accumulated on the packaging machine.

Safety first: wear gloves and use safety glasses to protect your eyes.

► Firstly, the electric motor should be inspected regularly to check if all its parts are working correctly. Secondly the conveyor belt should be cleaned to wipe off any residues.

►The PVC chain roller and rubber roller should be checked if they are applying pressure on the bag efficiently or not.

►The heating temperature and pressure should be monitored so that the optimum temperature and pressure are being applied to the bag for near to perfect sealing.

► Clean the grease from belt and metal body with grease remover.

► Clean the sealing jaws, wheels, and the front faces of both jaws with hot soapy water and wipe down with dry light cloth.

► Wipe down, rubber roller, chain roller, silicon wheel and dry.

►Greased down the lower plate, pressure bars, wheels, electrical motor, and other transmission parts to ensure the best performance of the continuous bag sealer.

11.Problems And Troubleshooting Of Continuous Bag Sealing Machine

Every machine has a specific life after which they stop working or does not work as efficiently as it did before. This machine too has a limited life after which some of its parts may become nonfunctional. But there’s nothing to worry about since all components of this machine are easily replaceable at a relatively cheap cost or if they malfunction, they can be easily fixed quickly. Below are some of the problems this machine can face and their solutions.

| Problems | Solutions |

| Sometimes the drive wheel and passive wheel are not parallel or are too tight or do not move in its own axis. | Adjust the screws on the passive wheel so that it lines with the drive wheel. |

| The sealing band has a crease | Replace the sealing band |

| The surface of the sealing belt has been contaminated by dirt or some adherent film. | Purify the sealing belt and remove any dirt on it. |

| The sealing belt is vulnerable to burning | Adjust the temperature to an appropriate level |

| The embossing roller has worn out | Change the embossing roller |

| The compression spring of embossing roller is not fitted tightly | Adjust the spring till it is fitted tightly |

| The gap between heating blocks is too small which is causing a lot of friction | Increase the distance between heating blocks. |

| The active roller shaft is not in line with the passive roller shaft | Adjust the two conveyer belt tension adjustment knobs of the passive roller so that the two shafts come in line with each other. |

| The conveyer belt is loose | Adjust the active roller and intermediate shaft belts so they are in contact with each other. |

| The sealing temperature is unable to reach the desired temperature | Adjust the temperature controller |

12.How To Choose A Continuous Bag Sealer

Do you know, the most important element for a high-quality packaging is perfect sealing.

For this purpose, choosing a right equipment is not an easy task.

Here you will find some important tips for your correct choice.

While choosing the sealer you should know:

The number of bags you need to seal each day?

If your production is less than 100 bags each day, then pick a simple impulse sealer.

In case of high production, then choose an easy-to-operate tabletop or foot-operated sealer.

Thus, a continuous bag sealer would also be a wise option for your higher volume seal.

What is the material of your bag?

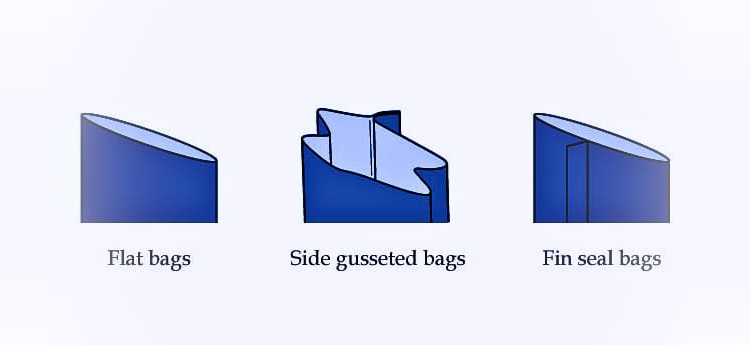

There are numerous kinds of bags, but if, you are sealing fin seal bags or side gusseted bags choose a double heat bag sealer because normal simple heat sealer will not be able to seal their folded layers.

What is the thickness of your bag?

If you are using laminated kraft-paper bags, or stand- up foil bags, choose double heat continuous bag sealer because these bags are thicker and difficult to seal than normal bags.

What is the size of the bag?

You need to assess your bag size than just the width. Try to opt for machine that can manage sealing procedure for various sizes.

Vertical or horizontal continuous bag sealer

What materials do you need to seal? If you are packaging a dry product then choose horizontal continuous bag sealer but if product is liquid then choose vertical continuous bag sealer for liquid packaging articles.

Conclusion

After discussing all the points mentioned above, it is safe to say that continuous bag sealer is an excellent option for many industries to seal their bags in a quick, simple, and economical way. It does not have many disadvantages and would be an ideal machine for customers to bring in large profit margins. If you’re interested to buy a continuous bag sealer; Allpack is a trustworthy manufacturer and provider that offer excellent machines, where you can reach your business goals and consumer trust. Contact us Now!

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide

Tell us your material or budget, we'll reply you ASAP within 24 hours