Boba Sealing Machine: The Complete Buying Guide In 2024

When it comes to sealing of plastic cups containing drinks, boba sealing machine stands out as the most efficient and accurate sealing machine present in modern world. They create an airtight seal and prevent any type of spilling or leakage of material.

But it always remains a concern for many manufacturers that what type of boba sealing machine can best suit their business. Allpack provides you variety of solutions for boba sealing machine. This buying guide will completely assist you in understanding what boba sealing machines are and what their applications are. Go through it and get the most of it.

1. What Is Boba Sealing Machine?

A boba sealing is a type of sealing machine in which bubble tea drinks are sealed within plastic or paper cups. The top of these cups are efficiently sealed using a boba sealing machine. Boba sealing machines mostly uses heat as a factor to seal the lid made up of onto the cups. This sealing creates an airtight seal that helps in keeping the liquid content fresh and prevents any type of spillage.

For making it cups more presentable and easy to access, sealing lids are also with small openings that allows the entrance of straw into the cup. The consumer can easily drink the boba (tapioca pearls) and other fresh liquids that are mixed with bubble tea drinks. Boba Sealing machines are usually used in tea shops and cafes where quick and efficiently sealed cups are served to their customers and also ease them to take away.

2. What Can Be Packed Using A Boba Sealing Machine?

Boba sealing machine is a modern technology to seal cups in an efficient manner. Some of the materials that are packed using a boba sealing machine are

- Bubble Tea Drinks

Boba sealing machine is used to pack drinks. These drinks are typically consists of milk, tea mixed with chewy tapioca pearls (boba). Then this mixture is poured and filled into plastic cups. Boba sealing machine then seals the top of the cup with a plastic lid to create airtight sealing.

- Juices

Other than bubble tea, some boba sealing machines also pack other types of juices. These drinks are typically packaged in plastic cups and sealed with lids in a similar manner as bubble tea drinks. Some of the juices are also sealed in paper cups but are not considered to be an ideal packaging solution.

- Sluchies and Smoothies

The plastic cups are filled with sluchies and smoothies, and then the boba sealing machine is used to create an air tight and secure sealing on top of the cup to prevent any type of leakage or spillage. Sluchies require environmental safety to secure their taste and life and that is what a boba sealing machine delivers.

The main disadvantage of a boba sealing machines is that it is not compatible with solid or food material and only support sealing of drinks or liquids. Particular type of boba sealing machine is used for packaging of particular type of liquid.

3. What Types Of Cups Can And Cannot Be Sealed Using A Boba Sealing Machine?

Cups That Can Be Sealing Using A Boba Sealing Machine

Plastic, paper cups are typically compatible with a boba sealing machine. As these materials are heat-resistant and durable, they are suitable to be packaged using a boba sealing machine.

- Plastic Cups

The most popular choice for boba drink packaging is plastic cups. This is due to their durability and affordability. Plastic cups are available in wide range of sizes and colors. The needs of customer can easily be fulfilled using a boba sealing machine.

- Paper Cups

Boba sealing machine also offers packaging of paper cups as it is eco-friendly and biodegradable. Some paper cups with plastic coated layer also make them moisture resistant and prevent leakage of drinks.

Cups That Cannot Be Sealing Using A Boba Sealing Machine

All types of cups other than aluminum, plastic and paper are not consider to be sealed using a boba sealing machine.

Cups made of certain materials may not be compatible with a boba sealing machine, or may require special considerations.

- Glass cups

Glass cups are not suitable for use with boba sealing machine. This is due to that a glass cups are not heat resistant and can break during the heating and sealing process.

- Ceramic cups

Other than glass cups, ceramic cups are also not suitable to use with boba sealing machine. It could also break or damage the head when kept under a sealing process.

- Biodegradable Cups

Some biodegradable or compostable cups may also not be compatible with boba sealing machine as the heat and pressure during the sealing process could breakage or leakage of. It is important to check the specifications of these types of cups before using them with a boba sealing machine.

4. What Are The Applications Of A Boba Sealing Machine?

Boba sealing machines are not popularly used in industries due to their compact size. These types of sealing machines are commonly available in food and beverages facilities, tea shops and cafes where liquid products are packaged. Some of the other applications of a boba sealing machine are

- Food and Beverages Facility

Boba sealing machines are used in small scaled food and beverages production facilities for packaging of juice bars, sluchies, bubble tea drinks and other type of drinks. These machines can also use in special events for providing convenient and portable packaging to the people.

- Take Away Deliveries

For takeout or deliveries, boba sealing machine are ideally used to quickly package drinks for that can prevent spillage during transportation.

- Restaurants

Restaurants also use boba sealing machines to provide proper packaging to juice, beverages and other smoothies. This allows the restaurant to present their products in front of the customer in a very delightful manner.

- Retail and Whole Sales

Retails and whole sale distribution centers also apply boba sealing machine for packaging of their products and selling them to other stores, outlets and supermarkets.

5. What Are The Advantages Of A Boba Sealing Machine?

Some of the advantages of boba sealing machine are

- Automatic Cup Alignment

An automatic cup alignment feature is incorporated in some of the boba sealing machines that ensures proper positioning of each cup that is kept for sealing. This advantage reduces risk of error and result in saving of material.

- Consistency

A boba sealing machine provides a consistent. This means that air tight seal is done on each cup and ensure product safety.

- Adjustable Sealing Temperature And Pressure

Like sealing time, temperature and pressure of a boba sealing machine can easily be adjusted. This feature allows plastic lid to melt and seal.

The applied pressure if not adjusted on standard values can crack or break the packaging material. So, the best thing which a boba sealing machine provides is adjusting both temperature and pressure according to the used material.

- Construction

Boba sealing machine are usually made up of stainless steel and can easily be moved from one place to another. Its construction also prohibits environmental effects like humidity or moisture and maximizes the useable life of machine.

- Hygiene

The risk of contamination is reduced when cups are packaged using a boba sealing machine. It provides hygienic sealing option in regards for packaging of drinks.

6. What Is The Working Principle Of Boba Sealing Machine?

A boba sealing machine follows a simple working procedure like other sealing machines and offers both heating and sealing functions. The steps involved in the working of a boba sealing machine are

- Initially the heating element is responsible to heat the plastic lid. This heated plastic lid is placed on the cup when it comes underneath the sealing head.

- As the heated lid come on the top of cup a particular pressure is applied on it and that creates an air tight seal around the opening.

- Once the sealing is done, the cutting mechanism gets activated and trims off the excess plastic film. This plastic film is recycled to make other byproducts.

- As a result of it, neat, clean and secured sealing is performed in an efficient and precise manner.

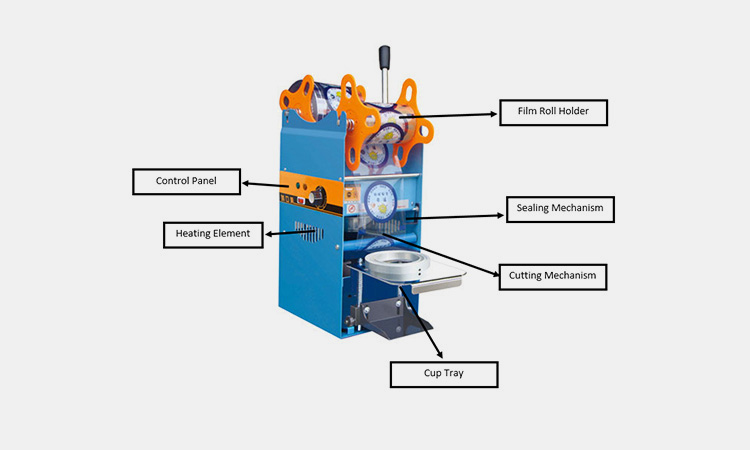

7. What Are The Main Components Of A Boba Sealing Machine?

Boba sealing machine typically has few main components. These are

- Heating Element

Heating element or heating head of a boba sealing machine melts the plastic film and creates an airtight seal around the cup. It is usually made of metal and can be controlled to adjust the temperature.

- Sealing Mechanism

Specific pressure is applied onto the product through this sealing mechanism. The melted plastic film is pressurized onto the top of cup and sealing of it is carried out. A sealing mechanism is usually of two metal plates that come together to apply the pressure.

- Cutting Mechanism

After sealing mechanism, cutting process is performed to remove the excess plastic film that is present around the cup. A blade or a roller is used to cut the plastic film after heating is performed properly.

- Film Roll Holder

The plastic film roll that is used to seal a cup is mounted on this film roll holder. The machine design is done in such a way that is dispenses the film into the sealing mechanism in a completely controlled manner.

- Cup Tray

Within the sealing mechanism, the cup in placed in a cup holder for sealing purpose. It is adjusted according to the size and shape of a cup.

- Control Panel and Power Supply

The operator gets a direct access to the machine through this control panel. Various aspects like sealing process, temperature, pressure, and sealing time adjustment is done by the operator through this control panel.

In addition, electrical power supply unit is there to operate the machine and support in smooth production.

8. What Types Of Boba Sealing Machines Are There?

According to the working operation of a boba sealing machine, there are two types of boba sealing machine. These types are manual and automatic boba sealing machine. The important feature in both of the machine is

- Manual Boba Sealing Machine

Manual boba sealing machine typically uses a manual hand crank mechanism for pressing a heated plastic lid over a cup. Manual boba sealing machines are commonly used in small scaled boba shops or cafes that have low volume of sales. Machines are portable and compact in size. A single person can easily operate a boba sealing machine without any prior experience.

- Semi-automatic Boba Sealing Machine

Semi-automatic boba sealing machine seals the top of boba cups with both manual and automated processes. Unlike to a fully automatic boba sealing machines, semi-automatic boba sealing machines has manual intervention at various stages. The mechanism of machine is to hold the cup and apply plastic film on the top.

The operator manually places the cup into the machine and removes it once the sealing process is complete. Manual adjustment for setting of cup size and sealing temperature is also done by operator.

- Automatic Boba Sealing Machine

An automatic boba sealing machine unlike a manual boba sealing machines operates with highly automated features like cup handling, film dispensing, and sealing process. Automatic boba sealing machines has automatic dispensing of heated lid onto the cup and then sealing of it. The process remains of high efficiency with greater productivity.

9. Boba Sealing VS Tray Sealing?

Boba sealing and tray sealing are two common methods used to package and preserve food and beverages. However there are many differences between the both of the methods. Some of them are

- Working Principles

Boba sealing is a method of packaging drinks or beverages by using boba sealing machine. Plastic lids are sealed on to the cup and create an airtight seal. This method is commonly used for drinks with a thicker consistency added toppings in it.

In a tray sealing process a plastic film is sealed in the top of a trays or containers and creates an airtight seal around the food. This sealing preserves the freshness of food and extends its shelf life.

- Packaging Products

Milk tea, fruit juices, smoothies, energy drinks, jellies with spreads, puddings and ice coffee with beans and etc. are the products that are packaged using boba seal.

Tray sealing method is used for packaging of food products like fresh meats, fruits, vegetables, and dairy products into trays made up of plastic.

- Packaging Material

Polypropylene or polyethylene terephthalate are packaging material used for boba sealing process. These materials are highly durable and light weight and that is why they are well suited for protection of food and beverage material.

Trays can easily be sealed using plastic material like Polyethylene (PE), polypropylene (PP), and polyethylene terephthalate (PET). Other than this food and frozen products also use aluminum and paper for their tray packaging.

- Application

Boba seals are applied for packaging of beverages like fresh juices, bubble tea and smoothies produced in cafes, beverage shops, stores and also for take away.

Food, eatables, vegetables, fruits, baked items, dairy products and others that are packaged and sealed in trays using a tray sealing machine are available in all types of retail stores, super markets, food packaging facilities, restaurants and cafes.

10. Why Do Boba Sealing Machine Have Adjustable Temperature Setting For Different Types Of Cups?

Adjustable temperature settings for different types of cups can be observed in a boba sealing machine because different types of cups have different heat-resistance properties. Heating of plastic film is also included in this sealing process and then the pressure is applied to perform airtight sealing.

If the temperature is too high for a particular type of cup, the cup may deform or become brittle and or break during the sealing process. If the temperature is too low, the film may not seal properly, resulting in an ineffective seal or leaks.

11. What Are The Auxiliary Components That Are Associated With A Boba Sealing Machine?

Some of the auxiliary components that are associated with a boba sealing machine are

- Foam seals

Foam seals are often used to seal hot drinks and provide insulation to keep them hot. Some of the boba sealing machines are designed in a way that they work with foam seals while majority of them do not accompany this factor.

- Film Cutting Blade

This is a component that is used to cut the sealing film for gaining an appropriate size. The film cutting blade is typically located on the side or back of the boba sealing machine.

- Electric Pedal

Some boba sealing machines come with a foot pedal. This allows the operator to activate the sealing process without using their hands. This can be helpful for speeding up the sealing process and improving efficiency.

- Film Dispenser

A film dispenser is used to dispense the sealing film from the roll to the sealing machine. This component can be located on the side or back of the boba sealing machine.

- Film Splicer

A film splicer is used to join two rolls of sealing film together. This component can be located on the side or back of the boba sealing machine.

12. Is Boba Sealing Machine Compatible With Different Types Of Sealing Films Or Foams?

Yes, boba sealing machines are compatible with different types of sealing films or foams. The type of film or foam used depends on the specific boba sealing machine, as well as the type of cup and drink being sealed.

Common types of sealing films used in boba sealing machines include

- Polypropylene (PP)

- Polyethylene (PE)

- Polyethylene terephthalate (PET)

Each type of film has its own unique properties and benefits, such as resistance to heat and moisture, clarity, and durability. Some boba sealing machines may also be compatible with foam seals, which are typically used for hot drinks and provide insulation to help keep the drink hot.

Conclusion

Boba sealing machines are famous worldwide for their effective and efficient packaging of liquid products. These machines are difficult to select when it comes to their operation. For this purpose we Allpack have provided you complete buying guide its entire feature. You can directly call to our customer care center for further information regarding boba sealing machine or visit our website http://www.allpackchina.com.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide