Water Bottle Machine: The Complete FAQ Guide In 2024

With drastic increase in requirement of pure water and its supplies, water bottle machines are now found in almost each of the and food, beverages, chemical and pharmaceutical industry. It not only enhances the productivity but performs efficient filing, capping, labeling and packaging of these water bottles. The quality of water remains at superior priority and also gives uniform filling solutions.

Water bottle machines can fill bottles of any size and shape upon slight adjustment ant this is why they demand is increasing rapidly. But it always remains the problem that how best water bottle machine can be selected for any processing line. Allpack provides its customers with variety of water bottle machines. This buying guide is designed to better guide you regarding water bottle machine and its application. So take the most of it!

1.What Is A Water Bottle Machine?

A water bottle machine uses highly accurate and precise type of filling technique for filling of bottles of different sizes. The bottles are placed onto the system that are filled either manually or automatically.

In majority of the water machines there is a water purification and filtration system that is used to purify the water first. This purified water is then filled into the bottles that ensure better health conditions. Water bottle machine are precise and accurate in their filling process and produce identical bottles. Large batches of water bottles can easily be filled using a water bottle machine.

2.What Are The Applications Of Water Bottle Machine?

Some of the applications of a water bottle machine are

Beverages Industry

Mostly water bottle machines are applied in beverages industry where bulk quantity bottles are filled with different types of beverages products. These products are filling in different types of bottles and each one of them shows identical filling properties. Mostly mineral water, soda drinks, juices, oil, sauces and some viscous liquids are filled in bottles using a water bottle machine.

Pharmaceutical Industry

For filling of liquid medicines, drips, drugs, liquid antibiotics, syrups and many other products, pharmaceutical industry preferred water bottle machine so that a quick and precise process may be carried out. These bottles are also further sealed and capped so that the liquid spillage may be avoided.

Water Filling Stations

Numerous water filling stations are now present in each part of the world and every individual prefers their water as it is hygienic and filtrated. To fulfill the requirement of a certain area, these water filling stations also prefer water filling machines so that large quantities of water bottles are supplied to the customer. Water filling stations mostly prefer filling of mineral water, distilled water and also sometimes de-ionized water into water bottles.

Chemical Industry

Different chemicals that contain iron and resins are also filled using a water bottle machine. The filling ensures that the chemical compound remains pure for a longer period of time and does not get contaminated. Liquid chemicals like acids, detergents, liquid soaps and other products are filled using water bottle machine. Also the sealing and capping property of a water bottle machine also controls the internal property of these chemicals in any situation.

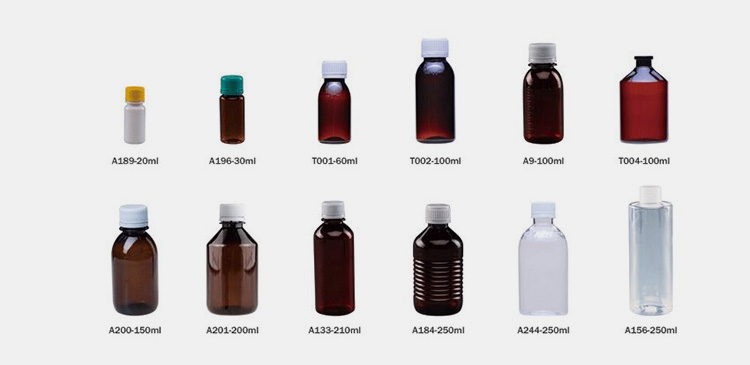

3.What Type Of Bottles Are Filled By A Water Bottle Machine?

Varieties of bottles with different properties are filled using a water bottle machine. Some of these types of bottle are

Plastic Bottles

Globally supply of water and liquid products are recommended to be in plastic bottles. These bottles are less expensive and also have recycling ability. Water bottle machine mostly fill plastic bottles that are made up of polyethylene terephthalate (PET) and high-density polyethylene (HDPE) due to its transparent and durability factor.

Glass Bottles

Other than plastic bottles, glass bottles are also accepted for filling of water using a water bottle machine due to its material strength and environment friendly nature. These bottles are a bit expensive than plastic ones but provide pure water without any harmful effect.

Aluminum Containers

Due the light weight and also better leakage protection, aluminum bottles are also filled with water using a water bottle machine. These products are nowadays very common to get and are highly volatile in nature that the filled water remains secure from any type environmental influence.

4.What Are The Advantages Of A Water Bottle Machine?

Water bottle machine provides variety of benefits from filling to packaging of water bottles. Out of these some of the advantages of a water bottle machine are

Hygienic Filling

The most important benefit that can be taken from a water bottle machine is its hygienic water filling and packing ability. The machine is designed in a way that its internal filter purifies the water to a greater level that can never harm human body. Further the packaging also prevents entrance of any type of microbes and also keeps the product and machine safe from contamination.

Identical Packaging

The process of a water bottle machine involves high pressure and highly active sensors. These actuators allow accurate amount of water to be dispensed and form identical packaging in each of the product.

Variety Of Bottles Filling

Water bottle filling machine has a diverse construction that it can fill variety of bottles with just minor changes in bottle opener. The manufacturer has not to purchase different types of water bottle machine for different filling procedures. A single machine is enough that directly reduces the production cost to a distinct level.

Quality Products

The manufacturers are now producing highly advanced water bottle machine that has sensors, actuators, display and other to have a keen eye on products quality. If any irregularity occurs, these sensors are there to detect the problem and stop the system for proper checking. This is one of the unique advantages that can be gained from a water bottle machine.

Working Efficiency

Water bottle machines are highly efficient in terms if precise water filling and then attractive packaging at the end. The systems efficiency is the reason that high level of productions can easily be meet using a water bottle machine.

5.What Are The Working Principles Of Water Bottle Machines?

A water bottle machine works as follow

The empty bottles are fed in to the system through conveying system and conveyor belts and it pushes the PET bottles towards the rinsing and cleaning system.

Here the bottle neck gets locked into the bottle neck support that is present at the support ring. The shaft rotates the bottle completely opposite so that its face tend towards the ground. The process of cleaning is done here by jetting high pressure water into the bottle.

Once the bottles are washed, the conveyor carries them to the filling station. Here water tanks are present at the above of filling system that carries purified water. As the bottle gets its position the filling nozzle dispenses the required level of waters and the valve shuts down once it reaches its maximum position.

The filled bottles are then moved towards the capping system where the capper applies its top cap. Finally, at the end the labeling and indicating process is done if required.

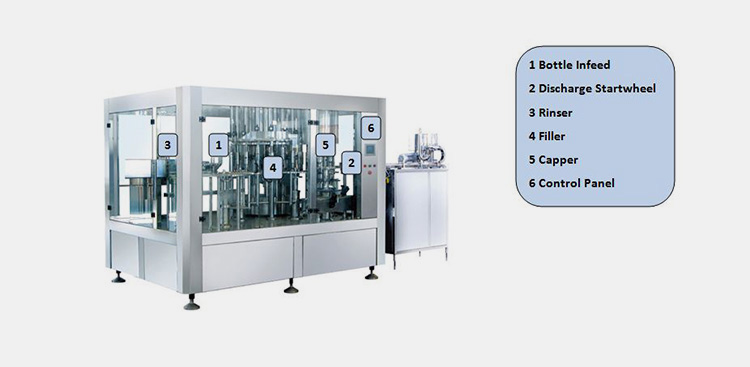

6.What Are The Main Components In Water Bottle Machines?

Some of the main components of a water bottle machine are

Bottle Infeed

A bottle infeed is prior to the rinsing system and allows the PET bottle to enter the system. The bottles that are moved with the help of a conveying system are first jam at bottle infeed and from here they are loaded for further rinsing and filling procedure.

Discharge Startwheel

A discharge startwheel is similar to an infeed part but present at the end of process. It is used to discharge the filled water bottles out of a water bottle machine.

Rinser

A rinser is present at the start of filling process and is responsible to clean the water bottle by applying a high water pressure into these bottles. The collar of bottles is hold by neck support and it turns the bottle at 180°. Washing of bottles ensures that no microbes are present in it.

Filler

Fillers are the station where filling of water bottle takes place. Fillers contain filling nozzles from where the water is released in water bottles. These filling nozzles are also changed according to the opening of water bottle and can be adjusted accordingly. Fillers also have automatic sensors that sense the presence of bottles and their directions.

Capper

A capper or capping system is present just after the filling station and is responsible to apply the top capping on bottles. An automatic water bottle machine usually holds it as an essential component of the machine itself.

Control Panel

All the parameters including pressure, voltage, current, conveyor speed at other are set through this control panel. By this operator can also monitor easily the process of a water bottle machine.

7.What Are The Types Of Water Bottle Machines?

Some of the types of a water bottle machine are

Manual Water Bottle Machine

This is the simplest type of a water bottle machine as it involves complete human involvement and the operator is responsible for filling, capping and packaging of water bottles. Manual water bottle machine is most preferred in small scale industries where less productivity is present.

Semi-automatic Water Bottle Machine

A semi-automatic water bottle machine involves both man and machines processes. The bottle is placed into the system manually and then the machine fills it accordingly after its verification. Further capping and packaging process are also mostly carried out by the machine.

Fully Automatic Water Bottle Machine

Complete automation is involved in a fully automatic water bottle machine. From water bottle placement to its movement within the system, all are performed by the machine in a highly efficient manner. Large scale industries mostly prefer fully automatic water bottle machine because it fills and packs thousands of bottles in a day.

Rotary Water Bottle Machine

In a rotary water bottle machine the empty bottles are moved in a circular path where large number of bottles is filled together. This type of machine is highly versatile and can be used for filling of pharmaceutical liquid products.

Piston Water Bottle Machine

Piston water bottle machines are mostly manual or semi-automatic in type as the operator places the bottle beneath the filling nozzle and fills it accordingly. The to and fro movement of piston creates internal pressure and forces the liquid water to come out of the system. These machines are preferred by low and medium scale production setups.

Volumetric Water Bottle Machine

A volumetric water bottle machine is used to displace a measured amount of material from the filling nozzle to get accurate filling of water bottles. As high accuracy is one of the features of volumetric water bottle, it ensures perfect weight in each of the bottles.

8.What Are The Important Controlled Parameters In A Water Bottle Machine?

Some of the important controlling parameters in water bottle machine are

Pressure

Pressure for both bottle making and bottle filling is much critical. Specific amount of pressure is required for filling of water otherwise the bottle could get damage in overpressure conditions.

Speed

Conveyor belts or rollers are the main element for the movement of empty and filled water bottles. To achieve consistent filling in each of the bottle it is necessary to maintain the speed at a standard level so that even and identical products should be produced. Fast speed can support in collision that can damage the shape of bottles.

Filling Duration

The total time for filling of water bottles using a water bottle machine is also different for different shapes. Each of the shape required proper filling time to maintain the quality. The duration for filling of whole batch can be adjusted according to its requirements to obtain efficient filling.

Filling Nozzle Thickness

As different bottle openings are there in water bottles, it is necessary to select the right type of filling nozzle. This can avoid material spillage and also prevents delays in filling of water bottles.

9.What Are The Different Systems That Are Associated With A Water Bottle Machine?

Water bottle machine is a highly versatile option for filling of water bottles and has various associated systems in it. These systems depend upon the construction and design of a water bottle machine. Some of the water filling systems present in a water bottle machine is

Water Purification System

This is the most important system where the water is purified and filtered by the process of reverse osmosis. The microbes, bacteria’s and other organisms are removed from water in this system and are transferred to the filling station.

Blow-Molding Machine

PET or plastic bottles are created by the process of blow-molding. The resins are initially filled into the machine and are heated to a certain temperature until it gets melted. The melted plastic is then filled into the specific designed dies of bottle and with the help of high pressure blowing, the bottles are created. The process can be done either fully automatically or semi-automatically.

Rinsing System

As water bottles are of various types, it is important to clean and make sure they are contamination free before filling process. For this purpose the bottles are passed through a rinsing system where the bottles observe cleaning through pressure. This removes the dust or contamination from bottles.

Automatic Filling And Capping System

The core system of a water bottle machine is the automatic filling and capping system. Initially the filling system has specific pressure, gravity, vacuum that allows the filling purified water into the bottles.

Once the filling is done, the bottle undergoes capping process in the capping system. These cappers are also different in nature as some bottle use snap and other screw type cappers.

Label Applicator

Labels are then applied on these filled bottles in a label applicator machine. These labels include the entire product and brand related information to make the customer know all the details about its product.

Shrink Wrapping Machine

To combine number of bottles together and make them easier to handle while travelling, the bottles are shrink together in a shrink wrapping machine. The machine wraps foil on these bottles that allows the supplier to ship the bottles with less space consumption.

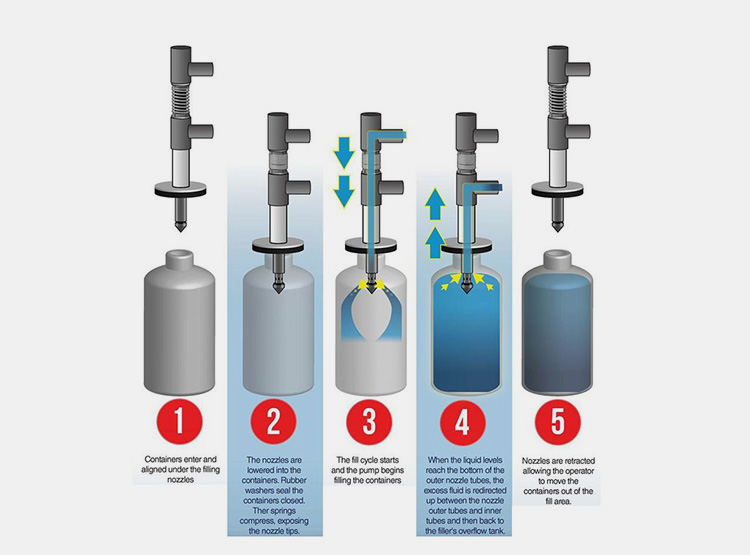

10.How Is The Overflow Level Maintained In A Water Bottle Machine?

The overflow level in a water bottle machine can be maintained using some components and controlling parameters. These together are involve in achieving accurate amount of filling and also assist the operator for any unwanted situation. Some of the ways to maintain overflow level are

Filling Set Point

The most important feature of a water bottle machine is that the user can define its set value before the process starts. Once the set point is set to a defined value, the filling nozzle will only dispense that certain amount of water and then shut its operation. This operation is supported by solenoid and pressure regulators.

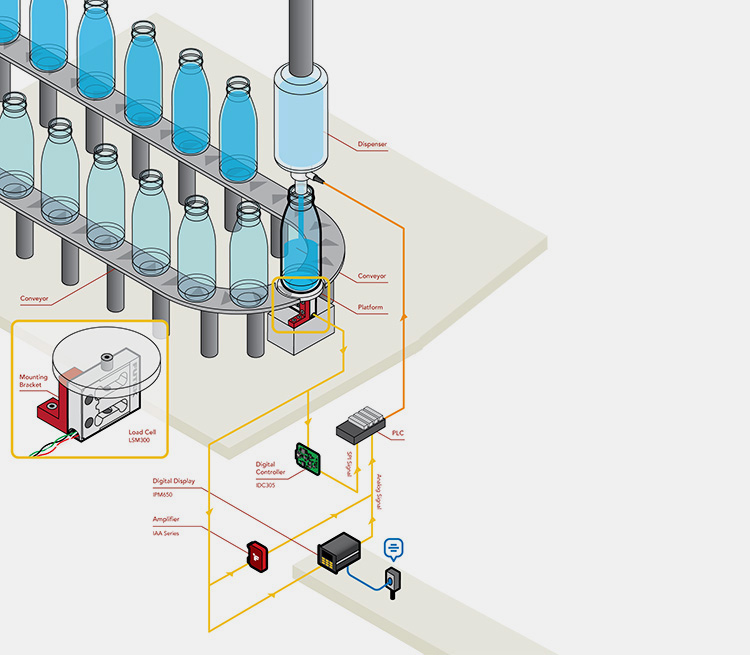

Sensors

Sensors are also one of the primary sources that are used to maintain the level of overflow. These sensors are mostly ultrasonic or level based that support the system in controlling the dispensing of water. Once the maximum range of filling is obtained, the sensor activates and directs the system to end the dispensing process.

Controlling System

A water bottle machine continuously gives its feedback during the running cycle. This feedback is closely monitored by the controlling system comprising of PLCs, drivers, actuators and etc. The controlling system is responsible to manage the over and under flow of water and helps to fill at an accurate level without any wastage.

11.How Can A Water Bottle Machine Be Adjusted To Different Types Of Bottle Openings?

Some of the methods to adjust a water bottle machine for different types of water bottles are

Bottle Gripper Adjustment

For a water bottle machine it is important to adjust the bottle gripper according to its opening. The gripper can easily be loose or tight with the help of screws and bolts. This allows a single machine to fill different types of bottles sizes and shapes.

Height Of Filling

Another mechanism is to adjust the filling nozzle at a certain height that it directly dispenses the liquid into the bottle. This can avoid spillage and wastage of any type. Different heights of bottles can easily be filled through a single water bottle machine by simply adjusting the height of filling nozzle.

Bottle Holder

Finally, a bottle holder helps the water bottle to be adjusted at a certain position where filling process can be carried out smoothly. Also during the capping process this bottle holder base and its holder arms are maintained according to the width of bottle.

12.What Should Be Considered Before Purchasing A Water Bottle Machine?

The factors that are important to be considered before purchasing of water bottle machine are

Machine Durability

The buyer should consider machines durability on priority due to the continuous flow of water. As water can cause contamination easily, it is important to select a robust water bottle machine that can resist for a longer period and gives high quality standards.

Standard Regulations

Due to the consumption of water by living creatures, it is always a risk to provide them unhygienic and dirty water. The buyer should select the machine that follows all the standards regulations provided by ISO and WHO.

Operational Efficiency

Variety of water bottle machine are available that causes greater intake of input energy. This can directly increase the operational cost to a greater level. The buyer should consider the machine that has high operational efficiency and consumes less energy.

Machine Feasibility

For filling of different sizes and shapes of water bottles, it is important to select a machine that can easily fill all these. Feasibility of machine is always an important thing to consider as it can directly affect the space and revenue of any manufacturer.

Conclusion

Due to the versatile nature of a water bottle machine and its efficient filling feature, these machines are highly recommended by global users. But it always brings its buyer to a confusing state that which type of machine can best suit their productions setup. Allpack also manufacturer’s variety of water bottle machines and supplies it globally. If you still find any query or feel confusing, call to our customer representatives or visit our website https://www.allpackchina.com/.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide

Tell us your material or budget, we'll reply you ASAP within 24 hours