Vitamin Capsule Filler: The Complete Buying Guide in 2024

Do you know that buyers and sellers prefer capsules more than tablets? It is because capsule filling is an ideal way to fill active ingredients because of its quick dissolution, taste disguising, and prolonged shelf-life. With capsule filler, vitamin capsule filler comes to mind.

Vitamin capsule filler is known for its extreme efficiency, high accuracy, and, clean operation. This machine is leading the medicinal market and brings exceptional quality results to the brands. It has a prominent place in not only the healthcare sector but also holds a special place in the cosmetic industry.

This informative guide will impart useful knowledge about various mechanical parts, operations, and computerized technology in the vitamin capsule filler.

1.How Can You Define Vitamin Capsule Filler?

Allpack Vitamin Capsule Filler

A vitamin capsule filler is a machine that admits the pharmaceutically active ingredients and vitamin powders inside the empty capsules using filling rings. It is also termed as vitamin encapsulator and vitamin capsule-filling machine.

It performs processes such as alignment, rectification, separation, packing, and, counting of vitamin capsules. It is the main part of the pharmaceutical and nutraceutical industry and has a vital role in feeding powders, granules, pellets, oils, pastes, and gels inside the two-piece vitamin capsules. It has the benefits of precise vitamin dosing, capsule sorting, and visual inspection of empty capsules.

2.How Does Vitamin Capsule Filler Benefits Businesses?

High demand for vitamin supplements propels the expansion of the vitamin capsule filler market. This machine increases production efficiency and fills accuracy. Here is the list of benefits that vitamin capsule filler offers businesses:

Fulfills Stringent Demands

Fulfills Stringent Demands by Vitamin Capsule Filler- Picture Courtesy: Kesri Clinic

FDA and other drug regulatory authorities have strict manufacturing guidelines for filling drugs and other supplements and vitamin filling in capsules is no exception to the rule. Vitamin capsule filler has a hygienic configuration that allows the manufacturer to meet stringent capsule-filling guidelines. Its clean design ensures vitamin supplement safety and prevents contamination.

Boosts Productivity

Boosts Productivity with Vitamin Capsule Filler

Servo-driven motors and high-speed gadgets allow manufacturers to fill vitamin capsules at a higher rate. These automated controls boost productivity, resulting in the loading of more dosage per hour. Manufacturers prefer vitamin capsule filler to hand filler because of its higher speed and extreme filling rates.

Precise Dosing

Precise Dosing with Vitamin Capsule Filler

With the aid of weight-control systems, the vitamin capsule filler uniformly and precisely fills a combination of vitamin ingredients and other excipients inside the capsule. Weight-control systems and level sensors in the hopper monitor fill volume during capsule filling, therefore, there is no error during vitamin capsule filling.

Customization

Customization of Vitamin Capsule Filler

The modular configuration of vitamin capsule filler allows brands to adapt machines according to their capsule sizes. Moreover, this machine is easily customized to fill a variety of ingredients with its toolless disassembly.

Automation

Automation of Vitamin Capsule Filler- Picture Courtesy: PTK-GB

Modern vitamin capsule filler has technologically advanced components, with which it not only executes the functions of dosing and locking but also performs functions of capsule sorting and counting. These automated systems reduce human supervision and aid in accomplishing set targets in less time.

Optimal Quality Capsules

Optimal Quality Capsules

With its minimal human involvement, there is less chance of fill error, hence this machine outputs optimal quality capsules. Furthermore, with its high-tech mechanical and computerized systems, there is no chance of capsule and raw material wastage.

3.In What Productions Vitamin Capsule Filler is Found?

Every production that involves capsule formulation, uses the vitamin capsule filler. It increases the output rate of the production. The production applications of vitamin capsule filler are discussed below:

Nutraceutical Industry

Use of Vitamin Capsule Filler in Nutraceutical Industry- Picture Courtesy: Health Vision

Capsules are more popular for ingesting vitamin supplements because they mask the taste and smell of ingredients. For filling such an effective dosage, vitamin capsule filler is routinely employed in the nutraceutical industry. In addition to vitamins, it also fills dietary fibres, mineral supplements, probiotics, prebiotics and protein mixes in the hardgel capsules.

Pharmaceutical Industry

Use of Vitamin Capsule Filler in Pharmaceutical Industry

It is increasingly utilized in the pharmaceutical industry for dosing high-potency active ingredients, drug medications, and other therapeutic agents in capsules. It is important in the pharmaceutical industry to prevent overdosing and underdosing of the medications.

Biotechnology Industry

Use of Vitamin Capsule Filler in Biotechnology Industry- Picture Courtesy: Healthgains

In the biotechnology industry, vitamin capsule filler is utilized for filling biopharmaceuticals, biologics, hormones, and other oral vaccines. Moreover, this machine is also used for formulating temperature-stable oral capsules for test and trial purposes.

Herbal Industry

Use of Vitamin Capsule Filler in Herbal Industry- Picture Courtesy: Wikifarmer

Yes, vitamin capsule filler is employed in the herbal industry for filling herbal and Ayurvedic medication inside empty capsules. Herbal brands use vitamin capsule filler to deliver high tamping force for dosing herbal capsules.

Food Industry

Use of Vitamin Capsule Filler in Food Industry- Picture Courtesy: ConsumerLab.com

In the food industry, this machine is used for filling portion-control spice and herbal blends. It is also used for filling capsules with flavoring agents, coloring agents, and artificial sweeteners for simplifying baking and culinary preparations.

Cosmetic Industry

Use of Vitamin Capsule Filler in Cosmetic Industry- Picture Courtesy: b3engineering.com.sg

Vitamin capsule filler has a prime place in the cosmetic industry for loading various beauty products like perfumes, skin care masks, dyes, bath bombs, gels, and pastes. Its high-quality control and extremely safe operations make it popular in the cosmetic industry.

Chemical Industry

Use of Vitamin Capsule Filler in Chemical Industry- Picture Courtesy: Health

In the chemical industry, vitamin capsule filler encapsulates different high-potency chemicals, primers, and adhesives. Vitamin capsule filler is primarily utilized in the chemical industry because of its extreme accuracy and speed.

4.What are the Basic Types of the Vitamin Capsule Filler?

Vitamin capsule filler is typically classified into three major types that are discussed below:

Manual Vitamin Capsule Filler

Manual Vitamin Capsule Filler

It is a simple handheld or portable desktop vitamin capsule filler. It is a cost-effective unit, usually found in small home-based and pharmacy settings. It prepares small batches of capsules and thus has low productivity. Loading and unloading of vitamin capsules and powders is performed manually by the operators.

Some models of manual capsule filler have levers and handles to perform capsule separation as well while other models carry out just vitamin capsule filling.

Semi-automatic Vitamin Capsule Filler

Allpack Semi-automatic Vitamin Capsule Filler

This machine has a compact construction and a smaller footprint. This machine has more productivity than manual vitamin capsule filler but comes at a lower price than automatic vitamin capsule filler. It is an excellent addition for medium-sized productions that have more production needs but have budget constraints.

Vitamin capsule separation, filling, and locking are done by the machine itself while loading and unloading are carried out by the operators.

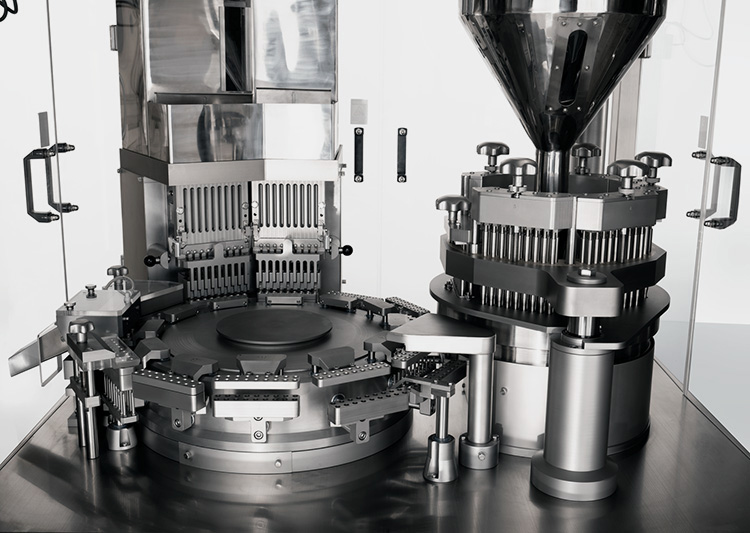

Automatic Vitamin Capsule Filler

Allpack NJP-5500C fully automatic capsule filling machine

This machine is the latest innovation in vitamin capsule filler and has technologically advanced monitoring and computerized systems that increase its output capacity. Every process from loading to unloading, filling to locking, rectification to capsule separation is carried out by the machine itself.

It has a vertical configuration and thus needs more head space. It is mostly a prominent part of the large pharmaceutical and nutraceutical industries.

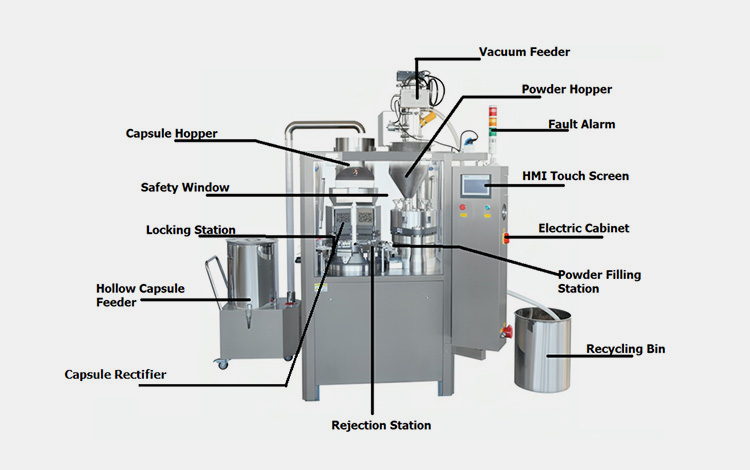

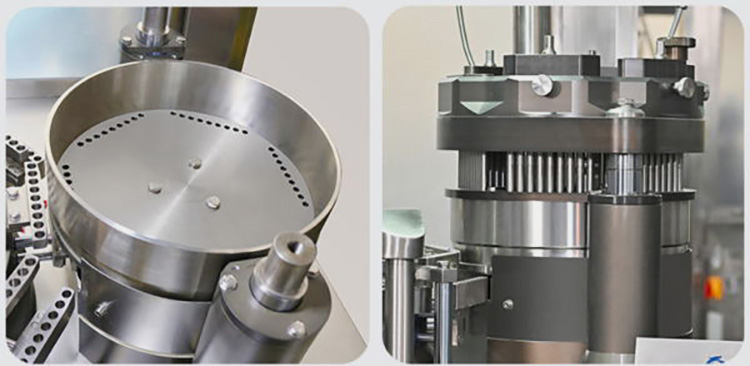

5.What are Parts of Vitamin Capsule Filler?

Vitamin capsule filler consists of high-efficiency electronic, mechanical, and technological components that act consistently to carry out vitamin capsule filling. Some parts of vitamin capsule filler:

Parts of Vitamin Capsule Filler

| Capsule Hopper | This conical-shaped capsule hopper stores capsules for continuous vitamin capsule-filling operations. |

| Safety Window | It is also known as an isolation window and its function is to separate operators from machines. It is a clear window that minimizes direct contact of operators with the machine while allowing them to view inside operation. This prevents capsule contamination. |

| Locking Station | The capsule bodies and caps are joined at this station after capsule filling. Cams and levers present at this station lock the halves of vitamin capsules. |

| Hollow Capsule Feeder | Before the vitamin capsule filling operation, the bulk quantities of empty capsules are loaded inside the hollow capsule feeder. |

| Vacuum Feeder | It is a feeding system that operates using a vacuum and transports the empty capsules to the filling station. |

| Powder Hopper | A bulk volume of vitamin powders is loaded inside the powder hopper at the start of the vitamin capsule loading operation. |

| Fault Alarm | It is the alarm system that automatically detects any faults, for instance, jamming, empty hoppers, etc. in the vitamin capsule filler. It sounds an alarm and lights up to notify users. |

| HMI Touch Screen | It is an intuitive display screen with which users program the vitamin capsule filler. Users supervise and troubleshoot equipment with this system. |

| Electric Cabinet | Different wires, cables, switches, and circuit breakers are housed in the sturdy electric cabinet to prevent electric and fire hazards. |

| Powder Filling Station | Empty capsules body travel to the powder filling station, where the required volume of vitamin powders is dispensed inside them. |

| Recycling Bin | In this part of the machine empty, unused, defective, and poor-quality capsules are collected. |

| Rejection Station | It is present at the edge of the vitamin capsule filler and consists of a rejection pin. These pins are responsible for the rejection of faulty capsules from the vitamin capsule filler. |

| Capsule Rectifier | It consists of a capsule loading board, horizontal fork, and vertical fork that properly orients the capsule for separation. It aligns the capsule upside down with capsule bodies facing downward. |

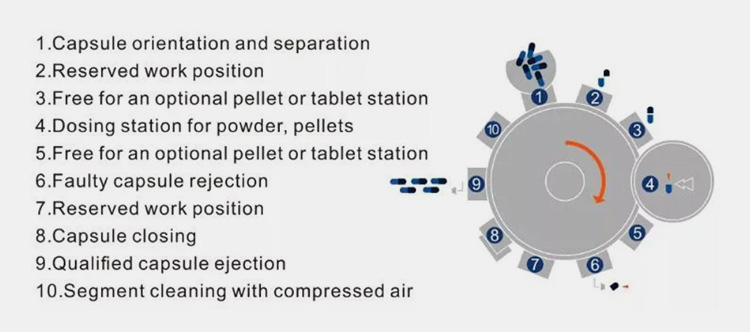

6.What is the Working Principle of Vitamin Capsule Filler?

The components of vitamin capsule filler have their specific role in the working of vitamin capsule filler. These working stages of vitamin capsule filler are given below:

Working of Vitamin Capsule Filler

Loading of Powders and Capsules

Loading of Powders and Capsules- Picture Courtesy: Aipak

The bulk volumes of empty capsules and vitamin granules and powders are fed inside the hollow capsule feeder and powder hopper, respectively. The empty capsule via pump travels to the capsule hopper from where it moves to the capsule delivery plate. The vitamin powder travels to the capsule filling station.

Capsule Orientation

Capsule Orientation- Picture Courtesy: iPharmachine

The empty capsules must be separated into bodies and caps for the correct vitamin capsule filling. For this, capsules are deposited in the delivery plates containing numerous pockets for capsules. From these pockets, empty vitamin capsules drop down to the horizontal fork.

The latter grips the capsules around its center while the vertical fork positions the capsules in the right orientation, so the capsules' bodies are facing down.

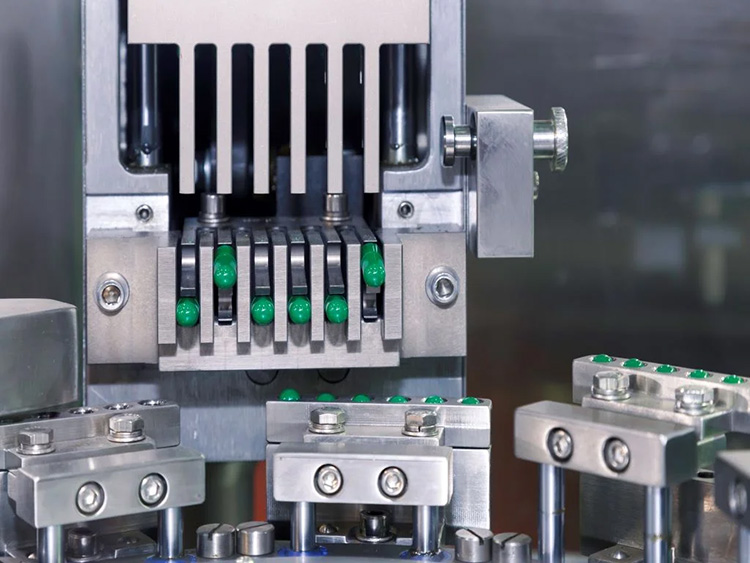

Capsule Separation

Capsule Separation- Picture Courtesy: adalbon.is

In this step, capsule trays are moved to the separation area. The capsules are split into two halves-caps and bodies- by the vacuum divider. After separation, the capsule bodies are left in the lower capsule tray and the caps go to the upper portion of the capsule tray.

Dosing of Vitamin Materials

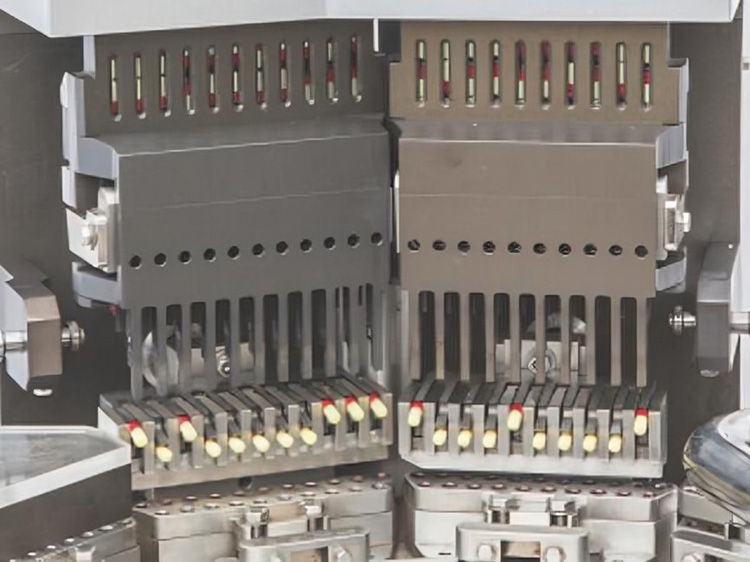

Dosing of Vitamin Materials-Picture Courtesy: PTK-GB

The lower capsule tray with capsule bodies is carried to the filling area. The powders from the hopper are loaded inside the empty capsule bodies. The powders are uniformly distributed inside the bodies by tamping pins.

Faulty Vitamin Capsule Rejection

Faulty Vitamin Capsule Rejection- Picture Courtesy: Smputra

Upon dosing, the defective capsules, for example, intact capsules, and dented capsules are removed from the machine using rejection pins. These pins push the vitamin capsules from molds and move them to the recycling bin.

Vitamin Capsule Closing

Vitamin Capsule Closing- Picture Courtesy: TES Equipment Supplier

Good quality vitamin capsules are closed by the overlapping of upper and lower capsule trays. During overlapping, the baffles present at the upper side of the cap tray and the pins located at the lower portion of the body tray simultaneously move to close vitamin capsules.

Capsule Ejection

Capsule Ejection- Picture Courtesy: Pharmaceutical Machinery

In the end, ejection pins push the closed vitamin capsule out of the capsule tray and the compressed air drives them to the outfeed chute.

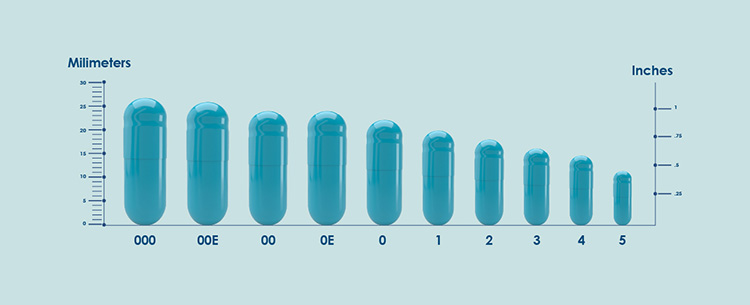

7.What Capsules Sizes are Processed by Vitamin Capsule Filler?

Capsule Size Chart- Picture Courtesy: Capsuline

Vitamin capsule filler dose versatile capsule sizes. These capsule sizes are used for different purposes in the pharmaceutical and nutraceutical industries. There are eight capsule sizes 000, 00, 0, 1, 2, 3, 4, and 5 which are the same for both gelatin and vegetarian capsules. The details of capsule sizes are discussed below:

| Capsule Size 000

It is one of the biggest capsule sizes processed by vitamin capsule filler. Its volume is 1.37 ml and its length is 26.1 mm. It encapsulates about 1000 mg of drug dose. It is widely employed for filling nutraceutical and herbal supplements. |

Capsule Size 000-Picture Courtesy: CapsulCN |

| Capsule Size 00

It is the second largest capsule size processed by vitamin capsule filler. Its typical length is 23.4 mm and can enclose 0.9 ml of medication which is about 735 mg in weight. It is the most common capsule size and is good for holding nutraceutical supplements. |

Capsule Size 00- Picture Courtesy: CapsulCN |

| Capsule Size 0

It is another frequently used capsule size, having a length of 21.6 ml. It can hold about 0.68 ml of vitamin powders and granules. |

Capsule Size 0 |

| Capsule Size 1

It is the smallest capsule with a length of 19.4 mm. It can enclose 0.48 ml of vitamin powders which is around 400 mg. |

Capsule Size 1 |

| Capsule Size 2

It is frequently utilized in the pharmaceutical industry but is not the preferred choice of nutraceutical brands. It has a length of 17.6 mm and its holding volume is 0.36 ml. |

Capsule Size 2 |

| Capsule Size 3

It is the smallest capsule size processed by the vitamin capsule filler. Its overall length is 15.7 mm and it can contain a dose of 0.27 ml. It is the preferred size for pediatric and elderly patients. It is also a suitable capsule size for small pets. |

Capsule Size 3 |

| Capsule Size 4

It has a length of 14.3 mm and is the second smallest capsule size processed by the vitamin capsule filler. It contains a volume of 0.2ml of medication. |

Capsule Size 4- Picture Courtesy: CapsulCN |

| Capsule Size 5

It is the tiniest strand capsule with a length of 11.1 mm usually used in pharmaceutical industries for clinical drug trials. It holds a drug dose of 0.13ml. |

Capsule Size 5-Picture Courtesy: CapsulCN |

8.What Kind of Industry Standards Should the Vitamin Capsule Filler Comply With?

The vitamin capsule filler should comply with different industrial standards to ascertain the quality of filled vitamin capsules and the safety of operators. Here are some basic industrial regulations for vitamin capsule filler:

Good Manufacturing Practices

GMP- Picture Courtesy: GMP Labs

This certification is a must-have for the vitamin capsule filler. Having this certification ensures manufacturers and users that vitamin capsule filling and other manufacturing procedures in this machine fulfil the necessary safety regulations.

ISO:13485

ISO:13485- Picture Courtesy: Arena Solutions

This certification is important for the vitamin capsule filler employed in the pharmaceutical industry. It ascertains that medical devices (vitamin capsules) are consistently manufactured using the highest quality standards. It states that there is minimal possible risk associated with the usage of vitamin capsule filler.

Food and Drug Administration

FDA- Picture Courtesy: BioWorld

Compliance with FDA standards is necessary for GMP certification. This certification ensures the effectiveness and security of human and pet vitamin capsules prepared by vitamin capsule filler.

Pharmacopeial Standards

Pharmacopeial Standards- Picture Courtesy: nutraingredients-asia.com

Conformity with different pharmacopeial regulations certifies that the capsule dosing process in vitamin capsule filler is performed while adhering to quality and safety protocols.

Occupational Safety and Health Administration

OSHA Certification- Picture Courtesy: OSEA

OSHA certification is necessary for the safety of the workplace. This certification is necessary for operating the machine and ensuring the health and safety of the workforce and industrial space.

9.What are the Safety Features of Vitamin Capsule Filler?

Safety features in vitamin capsules are essential in creating optimal quality vitamin capsules and for the protection of the operator and workplace. Some of the safety features of this machine are penned below:

Safety Doors or Enclosure

Safety Doors or Enclosure- Picture Courtesy: iPharmachine

These are the clear glass panels located at the front side of the vitamin capsule filler. This is integral in protecting operators from electric shocks while the machine is running.

Emergency Stop Button

Emergency Stop Button

A red-coloured circular button is conspicuously present on the control panel of the vitamin capsule filler. Pressing this button in case of fire hazards and emergencies stops the machine quickly.

Capsule Detection Sensor

Capsule Detection Sensor

This sensor detects the presence of capsules in the filling system and stops the capsule dosing if no capsule is detected. It is important in preventing wastage of vitamin powders.

Low-Level Sensor

Low-Level Sensor

These sensors are usually present in the capsule and powder hoppers and prevent the machine from running if the materials are too low in these hoppers.

Dust Extraction Device

Dust Extraction Device

Dust generation is inevitable when vitamin capsule filling and its production during filing could spark leading to accidents; hence, dust extraction device is found in numerous vitamin capsule fillers for the safety of the workplace.

10.What are the Various Issues and their Solutions in Vitamin Capsule Filler?

Even high-tech vitamin capsule filler is bound to have unexpected issues that result in lengthy production delays. However, there are easy tips for troubleshooting them, for instance:

Capsules Separate After Locking

Splitting of Vitamin Capsule

The capsules' halves (caps and bodies) separate from each other after locking.

Cause

Overdosing of vitamin powders inside the vitamin capsules and high filling speed.

Solution

Adjust the dose fill, it should be according to the weight threshold of the vitamin capsule. Lower the fill speed.

Incorrect Vitamin Capsule Rectification

Incorrect Vitamin Capsule Rectification- Picture Courtesy: phar-machine.com

Sometimes capsules are not oriented in the right direction, causing wrong capsule separation.

Cause

When plastic containers are employed for carrying vitamin capsules, it leads to the development of electric charges that disrupt rectification

Solution

It is best to use stainless steel containers for transporting empty vitamin capsules.

Deformation of Vitamin Capsules

Deformation of Vitamin Capsules

The vitamin capsules are distorted after capsule locking.

Cause

Incorrect overlap between upper and lower capsule tray when capsules are closed.

Solution

Inspect and fix the positioning of the upper and lower capsule tray for proper overlap.

Telescoping of Vitamin Capsules

Telescoping of Vitamin Capsules- Picture Courtesy: tabletcapsules.com

Sometimes, the capsule body spills and covers a small part of the capsule cap.

Cause

Poor alignment of upper and lower capsule segments. It is also due to the large distance in the bearing system that causes poor locking of capsules.

Solution

Check and align the machine parts. Close the distance between the bearing parts for accurate alignment.

Failure in Capsule Separation

Failure in Capsule Separation

The vitamin capsule bodies and caps fail to disjoin from each other.

Cause

This can be due to incorrect vacuum settings, a dirty filter bag, poor timing of the solenoid valve, and poor alignment of the upper and lower capsule tray.

Solution

Fix the vacuum setting and it should be between 15 and 18 inches of mercury. Clean the filter bag, adjust the timing of the solenoid valve and realign the upper and lower capsule trays.

11.What are the Future Trends of Vitamin Capsule Filler?

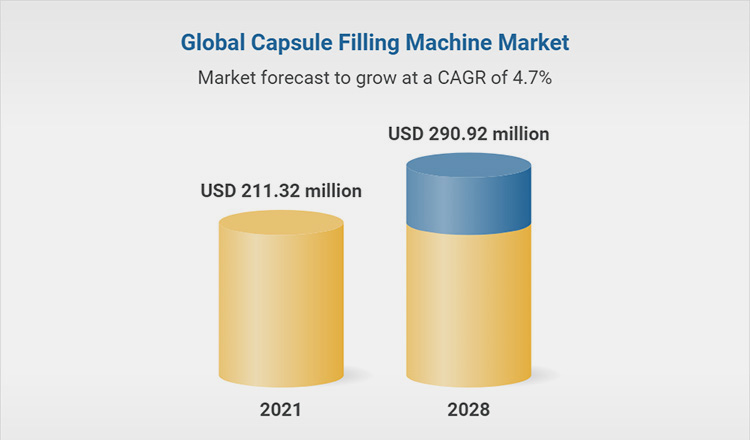

Future Trends of Vitamin Capsule Filler- Picture Courtesy: Research and Market

The market of vitamin capsule filler is progressing day by day and it was valued at about US$ 211.32 million in 2021. It is predicted that it will grow to US$ 290.92 million in 2028 by accumulating a CAGR of 4.7%.

More and more innovations in vitamin capsule filler improve its filling capacity and accuracy. Modern vitamin capsule filler will have a weight-checking system, camera vision system, and dust control system to ensure the highest possible precision in capsule dosing.

Upcoming vitamin capsule fillers will have smart systems like enhanced sensors, IoT, and data analytics. With internet connectivity, this machine will output operational data that will be used in predicting the machine maintenance schedule. This diagnostic data will help improve machine running performance, set program parameters, and, generate optimal-quality vitamin capsules.

Conclusion

Vitamin capsule filler is needed in the pharmaceutical and nutraceutical industry because of its high productivity, automation, efficiency, precise dosing, and customization. It comes in handy for contamination-free filling of vitamin capsules. Moreover, it is equipped with the latest technology, detection sensors, and safety control systems to comply with industrial regulations and the safety of operators. Still confused or have more queries regarding vitamin capsule filler, then contact Allpack customer representatives.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide