Vinegar 3 Side Sealing Packing Machine: The Complete Buying Guide In 2024

Are you a vinegar manufacturer and distributor looking to improve the way of your product’s packaging? The limits of traditional packaging techniques regarding efficiency, quality, and visual appeal might be frustrating. Herein lies the value of the invention of the vinegar 3 side sealing packing machine.

Apple Cider Vinegar - Picture Courtesy: Bali Buda

This cutting-edge device has the potential to revolutionize your product’s packaging. It offers several benefits that will satisfy your production requirements and the exacting demands of your customers. Whether you belong to the food sector or other industries that deal with liquid packaging, this device is an incredible option to elevate their product’s quality.

In this complete buying guide, we will explore everything you need to know about the vinegar 3 side sealing packing machine. So, let’s delve deeper into the topic together.

1.What is a vinegar 3 side sealing packing machine?

Vinegar 3 Side Sealing Packing Machine

A vinegar 3 side sealing packing machine is a specialized equipment designed to package liquid products into various forms of sachets and effectively seal them. It is an efficient device offering numerous benefits to businesses, like robust production, efficient and precise filling, and effective sealing, dealing with liquid goods.

Apart from the precise packaging of vinegar and other liquid food items, it can also be employed in industries, like pharmaceuticals, chemicals, and cosmetics, to produce liquid sachets.

2.What are the advantages of installing a vinegar 3 side sealing packing machine?

The vinegar 3 side sealing packing machine is equipped with cutting-edge technology, providing several key benefits and propelling you towards new horizons of productivity and performance. Some major advantages it can offer to your business are;

| Efficient Sealing

The vinegar 3 side sealing packing machine is tailored with an efficient sealing mechanism, ensuring the product is safe and fresh. The features of heat sealing, temperature regulation according to the product and packaging material, clear texture of sealing, and firmness make the device an incredible tool for any industry. |

|

| Productivity

The automated functions of the vinegar 3 side sealing packing machine let you achieve higher production with accurate and quality packaging. |

|

| Precise Filling

Different models have different filling mechanisms installed for various liquids. The device can accurately fill sachets with the predetermined volume of liquid, avoiding volume variations and unwanted spills. |

|

| Easy Modification

The vinegar 3 side sealing packing machine can be modified easily, handling different forms of liquids and packaging sizes and shapes. |

|

| Cost Benefit

The initial cost of the vinegar 3 side sealing packing machine is high but in the longer run it has a significant benefit in terms of labor and resource cost. |

|

3.What are the industrial applications of a vinegar 3 side sealing packing machine?

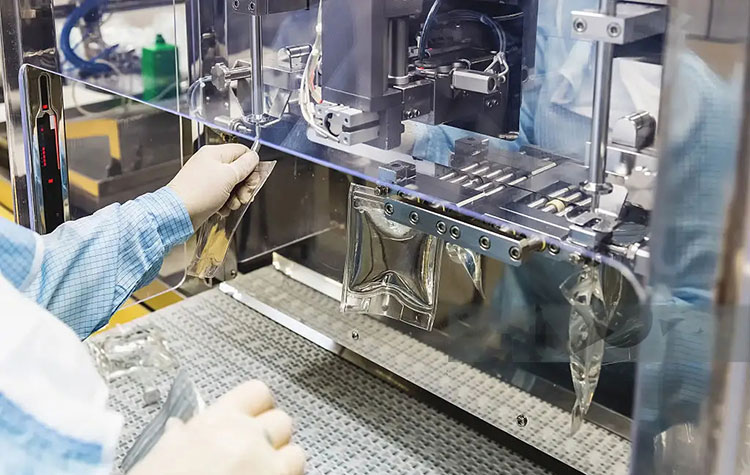

A vinegar 3 side sealing packing machine has all the features for effective liquid packaging. It lets you mechanize the entire packaging process, from sachet formation to feeding, filling, and sealing. This device is widespread in the food and beverages, pharmaceuticals, chemicals, and cosmetics sectors.

Food and Beverages

Applications of Vinegar 3 Side Sealing Machine in the Food & Beverage Industry

In the food sector, various liquid products are packaged in multiple sachets using a vinegar 3 side sealing packing machine. Some common liquid products are vinegar, sauces, juices, coffee, and oils.

Pharmaceuticals

Applications of Vinegar 3 Side Sealing Machine in the Pharmaceuticals Industry

In the drug industry, the vinegar 3 side sealing packing machine can also be employed to package various liquid dosage forms into sachets. The most common example is cough syrups.

Chemicals

Applications of Vinegar 3 Side Sealing Machine in the Chemicals Industry

In the chemical industry, certain liquid chemicals are packaged into sachets and effectively sealed to avoid their hazardous effects using a vinegar 3 side sealing packing machine.

Cosmetics

Applications of Vinegar 3 Side Sealing Machine in the Chemicals Industry

Yes, if you belong to the cosmetic industry, you can also install a vinegar 3 side sealing packing machine for your liquid cosmetic agents' packaging.

4.What are the basic components of a vinegar 3 side sealing packing machine?

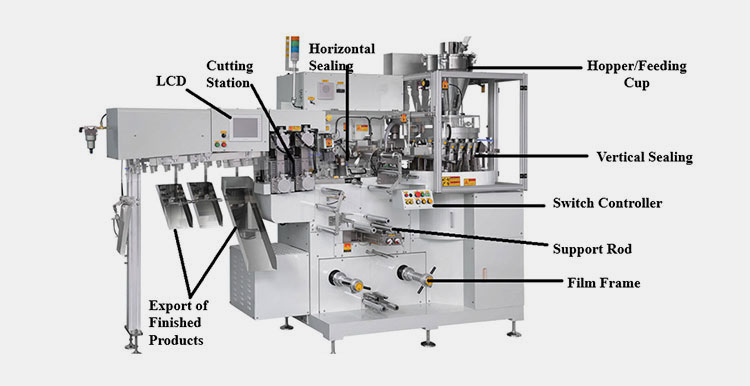

The key components of a vinegar 3 side sealing packing machine and their respective functions are described below;

Components of a Vinegar 3 Side Sealing Packing Machine

Hopper/Feeding Cup

It is a part of the device in which the material is poured and directed toward the filling station. It is an enclosed structure temporarily holding a significant volume of the material.

Vertical Sealing

The side edges are sealed via sealing bars, forming the film into a tube-shaped structure.

Support Rod

It supports the film and ensures the proper unwinding of the film during processing to avoid sachet size variances.

Film Frame

It is also known as a solid plated rod, where a film roll is placed firmly to get smoothly unfolded during operation.

Horizontal Sealing

The bottom edge is sealed to form a sachet, which is then filled, and the top edge gets sealed to finish the process.

Cutting Station

This component is responsible for the accurate cutting of the sachets from the continuous film and the sachets are then exported. It includes a tear notch cutter, a dash line cutter, and a slitting cutter.

Export of Finished Product

It is an outlet through which the finished sachets exit from the device.

LCD

It is a screen panel through which the processing parameters are monitored and adjusted accordingly.

Switch Controller

It connects the device to the power supply required for the device’s work.

5.How does a vinegar 3 side sealing packing machine work?

Working of Vinegar 3 Side Sealing Packing Machine

The vinegar 3 side sealing packing machine has several components working in synchronicity for a streamlined workflow. The basic functional procedure of a vinegar 3 side sealing packing machine is described below.

A significant volume of the liquid product to be filled is poured into the hopper. It can be done manually or using an automatic integrated device.

A suitable packaging material film roll is placed on the rod/frame. The film gets unrolled and is fed to the machine for sachet formation.

The shaping tube section is responsible for the sachets formation of specified size from the packaging film. The vertical sealing bars seal the edges or one edge, as specified while the horizontal sealing clamps seal the top and bottom or one side, as the case may be, to form a single-sided opened pouch.

The sachets are then filled with the predetermined volume of liquid through the filling nozzle. The funnel is tailored with a piston, cup, or pump mechanism to facilitate the filling process.

The open end of the filled sachets is then sealed effectively and the sachets are cut from the continuous film.

The finished product is expelled out of the device through the outlet.

6.Classify the vinegar 3 side sealing packing machine.

There are a variety of models of the vinegar 3 side sealing packing machine available, each having unique characteristics and advantages. It can be classified based on various aspects such as

Here is the classification of the vinegar 3 side sealing packing machine based on these criteria:

Orientation-Based Classification

Based on orientation, the vinegar 3 side sealing packing machine can be classified into 2 types.

Vertical Form Fill Seal (VFFS) Vinegar 3 Side Sealing Packing Machine

Vertical Form Fill Seal (VFFS) Vinegar 3 Side Sealing Packing Machine – Picture Courtesy: Finopack

In this type of machine, different processing stations (feeding, bag forming, sealing, filling, and exit) are placed in a vertical orientation. It occupies less space and has efficient operational modes. It is the most widely employed model of the vinegar 3 side sealing packing machine.

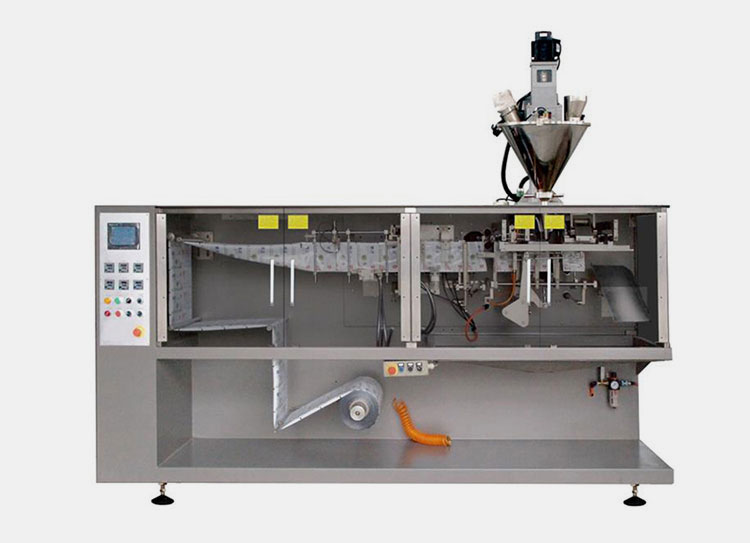

Horizontal Form Fill Seal (HFFS) Vinegar 3 Side Sealing Packing Machine

AIPAK Horizontal Form Fill Seal (HFFS) Vinegar 3 Side Sealing Packing Machine

This type of machine occupies a large area. It subsequently has processing stations in a horizontal direction. It offers close monitoring of different steps of the process.

Filling Mechanism Based Classification

Based on the filling mechanism installed, the vinegar 3 side sealing packing machine is categorized into;

Piston Filler Vinegar 3 Side Sealing Packing Machine

Piston Filler Vinegar 3 Side Sealing Packing Machine

Piston filler is usually used for handling viscous liquids but it can process free-flowing liquids as well. Viscous liquids do not flow easily so they require a little push during filling. In this type of device, the liquids are first fed into a calibrated cylinder then it is pushed using a piston into the sachets via the nozzle.

Gravity Filler Vinegar 3 Side Sealing Packing Machine

Gravity Filler Vinegar 3 Side Sealing Packing Machine – Picture Courtesy: Technopack Corporation

The operator of a gravity filler machine may adjust the fill time for each nozzle on the device. This makes it possible to more precisely distribute the appropriate amount of liquid substance into each sachet.

This type of device is suitable for thin liquids that flow easily. The liquid is filled into the sachets with the help of gravity via nozzles.

Pump Filler Vinegar 3 Side Sealing Packing Machine

Pump Filler Vinegar 3 Side Sealing Packing Machine

Various forms of pumps can be selected as per your product. Certain pumps are suitable for thick liquids while some are appropriate for free-flowing liquids. The pumps push the liquids via nozzle into the sachets.

Operation Based Classification

Based on operation frequency, the vinegar 3 side sealing packing machine can be classified into 2 types.

Intermittent Motion Vinegar 3 Side Sealing Packing Machine

Intermittent Vinegar 3 Side Sealing Packing Machine – Picture Courtesy: Propac Industrial

This type of device operates in a series of distinct steps. The device stops momentarily to perform each step of the process. It is a suitable option where accurate filling is crucial. However, it is usually used for small-scale operations, as it has a lower production rate comparatively.

Continuous Motion Vinegar 3 Side Sealing Packing Machine

Continuous Motion Vinegar 3 Side Sealing Packing Machine – Picture Courtesy: Propac Industrial

This type of machine operates continuously, without stopping between distinct processing steps. It is suitable for high production needs. It is often employed in sectors where efficiency and high throughput are primary priorities.

Automation Based Classification

Based on the degree of automation, the vinegar 3 side sealing packing machine is classified into;

Semi-Automatic Vinegar 3 Side Sealing Packing Machine

Semi-Automatic Vinegar 3 Side Sealing Packing Machine

As the name indicates, this type of vinegar 3 side sealing packing machine operates in a combination of manual and automatic mechanisms.

The operators perform some of the functions manually, such as liquid feed, placement of packages under nozzle (some models), and discharging of filled sachets. The rest of the process is done by the machine through the automated mechanism.

Automatic Vinegar 3 Side Sealing Packing Machine

Automatic Vinegar 3 Side Sealing Packing Machine – Picture Courtesy: Multiko Packaging

This is the advanced form of the vinegar 3 side sealing packing machine. It is equipped with the latest technological features offering a robust and efficient operation that is entirely automatic. Industries with large production requirements employ this form of device.

The operators only need to adjust the process parameters through the screen panel.

7.What types of vinegar can a vinegar 3 side sealing packing machine process?

A vinegar 3 side sealing packing machine can process different types of vinegar as long as the packaging material is appropriate for the particular type of vinegar. The following are some typical vinegar varieties that may be processed using such a machine:

White Vinegar

White Vinegar

This is the most widely available vinegar, derived from distilled alcohol. It is transparent and tastes sharp and acidic.

Apple Cider Vinegar

Apple Cider Vinegar

This type of vinegar is derived from fermented apple juice. It has a slight fruity flavor and a light amber color. It is popular for its health benefits.

Red Wine Vinegar

Red Wine Vinegar

This is made from fermented red wine. It has a flavorful taste that is somewhat sweet and contains tannins from the wine.

Malt Vinegar

Malt Vinegar

It is derived from malted barley and has a sweet malty taste.

Balsamic Vinegar

Balsamic Vinegar

It originated in Italy, derived from freshly ground grape juice that is aged in wooden barrels. It tastes sweet and tangy and with a flavor of wood and fruit.

8.Are there packaging material compatibility requirements for vinegar packaging using a vinegar 3 side sealing packing machine?

Yes, there are certain requirements for packaging material compatibility with vinegar. Given the acidic nature of vinegar, it may react with specific packaging materials, jeopardizing both the product’s quality and the package’s integrity.

Here are some considerations for packaging material compatibility:

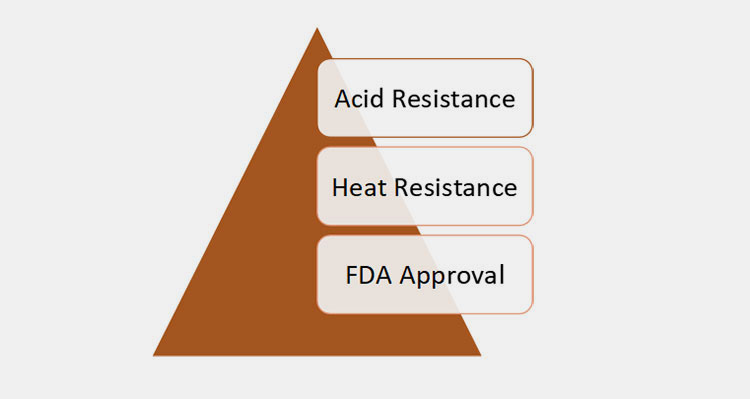

Packaging Material Compatibility Requirements

Acid Resistance

As we know vinegar has a slightly acidic nature and the packaging material used for its packaging must be resistant to acid to avoid chemical reactions that may result in a reduction in the product’s quality, the package’s integrity, and the customer’s safety.

Heat Resistance

Since the sealing process usually involves heat, the material used for packaging must be able to withstand high degree temperature without deformation or melting to ensure an effective seal.

FDA Approval

As vinegar is an edible product and the packaging material will be in direct contact with it, the material must be certified by the FDA (Food & Drug Administration) to guarantee the safety of the product.

Polyethylene Terephthalate (PET) Film Roll

Some common packaging materials that are used for vinegar packaging and fulfill the compatibility requirements are Nylon, Polyethylene (PE), Polypropylene (PP), Metalized Films, and Polyethylene Terephthalate (PET).

9.What is the typical production output of a vinegar 3 side sealing packing machine?

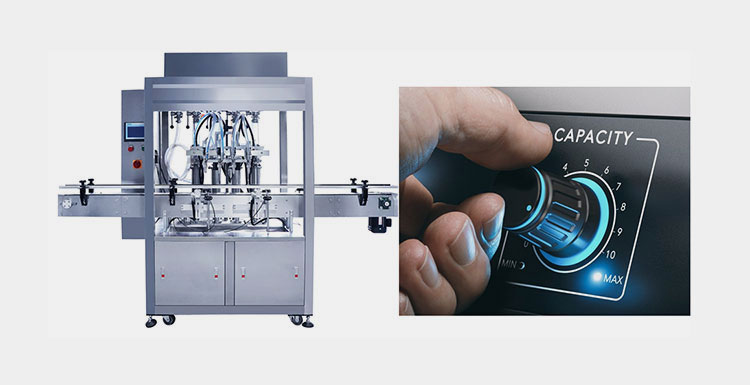

Production Capacity of Vinegar 3 Side Sealing Machine

The production output of a vinegar 3 side sealing packing machine can vary depending on several factors, such as the design of the machine, technical specs, automation level, and the packaging type being used. Nevertheless, in general, these devices can produce at a high rate of speed to satisfy the requirements of large-scale packing operations.

The production capacity of the device is often measured in the number of sachets produced each minute or each hour by the device. For a vinegar 3 side sealing packing machine, the production capacity can range from hundreds to thousands per minute.

10.What kind of maintenance is required for the vinegar 3 side sealing packing machine?

Vinegar 3 Side Sealing Machine Maintenance – Picture Courtesy: iStock

After installing a vinegar 3 side sealing packing machine, your maintenance procedures should be started as soon as possible to ensure the lifetime and functionality of your device. One of the vital things to maintain it is keeping it clean.

The cleaning techniques, maintenance frequency, and detergents to use depend on the processed product properties. Extend the life of your vinegar 3 side sealing packing machine with a regular maintenance plan.

Cleaning

A regular cleaning process should be conducted to guarantee the top condition of the device. Thoroughly clean the device with a soft cloth or a suitable cleansing agent. Clean all the sensors, sealing bars/clamps, and cutters. Make sure all the cleaning procedures are compliant with the standard specifications.

Lubrication

Continuous working of the device can cause friction in the moving parts, resulting in the breakdown. To avoid such circumstances, perform a routine lubrication of all the moving components.

Assessment

Inspect the machine components for any damage or tear, particularly the cutters, sealing clamps/bars, filling nozzle, and moving parts. Replace the worn components to avoid any mishaps.

11.What are the common problems that can be encountered while using a vinegar 3 side sealing packing machine and how to resolve them?

Some electrical and mechanical problems might result from prolonged, continuous, and excessive operation of the vinegar 3 side sealing packing machine. You should know about the potential reasons for the faults to resolve them in time and avoid the breakdown.

Some commonly encountered problems and their remedies are discussed here:

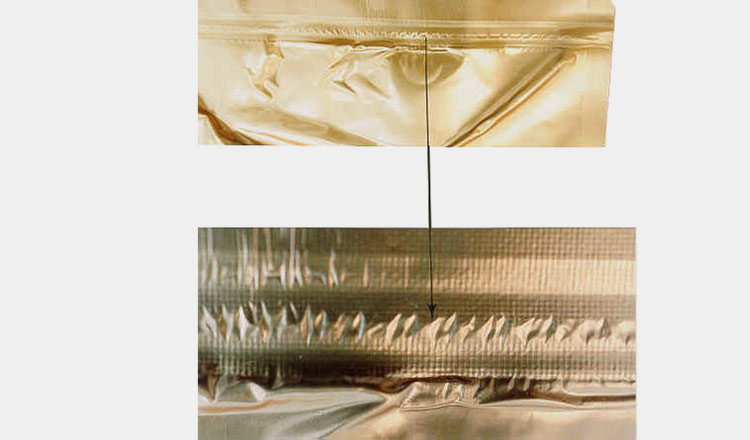

Improper Sealing

Defective Sealing

The issue may arise due to several reasons such as the improper adjustment of sealing temperature, inadequate pressure applied, worn sealing clamps, or dirty sealing surface. It can cause defective or wrinkled seals resulting in the product spill or quality degradation.

Solution: properly monitor and adjust the sealing temperature and pressure. Repair or replace the clamps. Regularly clean the sealing station.

Packaging Variances

Packaging Variations

The difference in the sachet dimensions can be caused by defects in the shaping tubes, improper film feed, or dull blades.

Solution: repair or replace the shaping tubes or cutting blades. Properly align the film roll to ensure the appropriate feed.

Creased Film

Wrinkled Film Issue

Sometimes the film may stuck or creased during the process. It may be because of improper alignment of the film roll or defect in the dancing rollers or a foreign material is stuck in the machine.

Solution: center-align the film roll. In case of defective rollers, replace or tighten them. Clear the obstruction, if any.

Uneven Filling

Non-Uniform Filling

The variations in the filling volume of liquids may result in the unnecessary loss of resources. Maintaining a proper volume in each sachet is crucial in pharmaceutical products. The potential causes include clogged or damaged nozzles, air entrapment in the filling system, or incorrect filling parameters.

Solution: replace, repair, or clean the filling nozzles. Remove the air from the system. Regulate the filling parameters.

12.What are the factors to consider in selecting the right vinegar 3 side sealing packing machine for your business?

Buying a vinegar 3 side sealing packing machine for businesses dealing with liquid products is a significant investment. However, selecting the right option necessitates serious consideration and a clear grasp of your goals.

Here are some questions to answer before buying a vinegar 3 side sealing packing machine.

What are the properties of your product?

Product Properties – Picture Courtesy: Allrecipes

The properties of the materials, viscous or non-viscous, you will be processing dictate the type of vinegar 3 side sealing packing machine you require. It is the key factor to consider. The right option will be able to satisfy your needs efficiently and accurately.

What is the available budget?

Budget Factor – Picture Courtesy: The News International

It is one of the key factors to look for when investing in a vinegar 3 side sealing packing machine. You must assess your budget, including the cost of the device plus the maintenance and operation costs, and then choose the suitable option that meets your requirements efficiently.

What is the required production capacity?

Production Capacity

Understanding the requirements of your production helps you set realistic expectations for what a machine should be able to accomplish. Different models vary in the production rate and you should opt for the device that matches your needs.

For example, for small setups manual or semi-automatic variants will do the job while for larger manufacturing, automatic vinegar 3 side sealing packing machine should be considered.

Moreover, it is crucial to think about the future objectives along with the current needs, so that you may not end up with expensive replacements.

What filling accuracy is demanded?

Accurate Filling – Picture Courtesy: Depositphotos

Based on your product and target market, filling precision can be quite significant/crucial. A precise filling is crucial for medicinal products where dosing is key or cosmetic/edible goods where overfilling reduces revenue. Therefore, you need a device with well-defined variances that conform to your product limits.

What about the device maintenance?

Maintenance Ease

A vinegar 3 side sealing packing machine requires routine maintenance for optimal performance and hygiene maintenance. For edible items such as vinegar or drugs, you need a device that can be maintained easily and quickly to avoid the build-up of microbes.

CONCLUSION

Finding the right vinegar 3 side sealing packing machine for your needs might take a lot of time. However, you might benefit greatly from having a thorough understanding of the essential components of these devices. The vinegar 3 side sealing packing machine is a robust, efficient, and accurate device, offering numerous benefits and easing the production process. It is advised that you pick a reputable manufacturer of vinegar 3 side sealing packing machine that can assist you with the selecting procedure for better outcomes. If you are looking for such assistance, freely contact the AllPack Team.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide