Tube Sealing Machine: The Complete Buying Guide In 2024

Are you planning to invest in a tube sealing machine to enhance the efficiency of your production? Or got tired of the inaccuracies caused by manual filling and sealing of tubes? If the reasons are not genuine you are probably desiring to opt for a cost-effective packaging mode for your liquids and pastes. If so, then you are few steps away from the bright destination of your business.

So, let us introduce you with this informative buying guide about a Tube Sealing Machine which is going to be an interesting one answering all of your conundrums. Not only that but helping you out to deal with the complexities of modern technology in advance. Have a look towards it and become the best runner of a Tube Sealing Machine!

1.How Would You Define A Tube Sealing Machine?

Allpack NF-60 automatic tube filling machine

Tube sealing machine refers to the assembly of several components fitted in stainless steel body. It is an advanced equipment designed to efficiently perform the filling of certain liquids and pastes into tubes and their tight sealing, thus, reducing common packaging errors and product waste.

The machine uses innovative technology to carry out its function automatically by orienting the tubes, supplying them with precisely measured liquids, and creating a stringent closure through sealing. In addition, it is capable of processing different materials and available in different shapes, sizes, as well as automation.

2.What Benefits Can You Get By Using A Tube Sealing Machine?

Before delving deep into the details of a tube sealing machine let's discover what are the different benefits and attributes of a tube sealing machine!

High Efficiency

Users holding various cosmetic tubes- Picture Courtesy: jergens.com

Filling and sealing tube manually not only require large number of labours but also take greater time and have precision uncertainty as well. However, tube sealing machine is a totally magnificent apparatus which resolves all these issues and give you optimal production turnover in less time.

Multi Tasking

Another attribute of a tube sealing machine is that it performs multiple tasks in a single run. For instance, an automatic tube sealing machine is capable of supplying empty tubes, their filling, sealing, and coding simultaneously.

Product Versatility

Two different sizes of cream tubes- Picture Courtesy: carolinehiros.com

Most of the manufacturers work on producing different types of products and their packaging. Therefore, they need a machine which can process both thin and viscous substances. Here, these qualities are found in a tube sealing machine which also supports full structural adjustment to accommodate small to large sizes of tubes.

Reduce Waste

Squeezed cream tubes- Picture Courtesy: makeupstore.com

Tube sealing machine provides a safe way for filling your liquids and pastes into tubes by accurately weighing the material. In this way, the possibility of product waste caused by manual filling is reduced and stringent sealing further strengthens the barrier against contamination throughout their shelf life.

Robust

The overall structure of a tube sealing machine is highly robust and compact which can be easily mobilized. Its body is made up of a protected stainless steel with availability for upgradation. Together these qualities enable the machine to support a stable and consistent operation.

3.Enlist The Products Which Can Be Processed By A Tube Sealing Machine?

Tube sealing machine is highly resilient in terms of processing different materials taken from thin fluids to thick and viscous pastes. These products are enumerated below:

Lotions & Creams

Hand cream tube presentation idea

Lotions and creams are homogeneous liquid preparation made for skin application. Although the use and purpose of these products vary from medical to cosmetic, they are often delivered in tubes, therefore, can be processed by a tube sealing machine.

Ointment

Healing ointment tubes- Picture Courtesy: makeupandbeautyblog.com

Ointment is an oily therapeutic formulation prepared for treating injuries or external skin disorders like rashes, burns, and itches etc. That's why the most convenient means for delivering ointments is tubes, so, the machine is suitable here.

Gel

Transparent gel- Picture Courtesy: mollysims.com

Gel is a transparent, thick, and sticky substance often used for hairs, nails, and insects killing. For its easy application, gel is packed in small to large tubes indicating the machine's compatibility to process it.

Edible Pastes

Multiple tubes of food spreads Picture Courtesy: migipedia.ch

Apart from medical and cosmetic products, food liquids and pastes such as ketchup, mayonnaise, honey, and chocolate etc., can also be packed in tubes by using this tube sealing machine.

Glue

Glue out of tube- Picture Courtesy: fishmancorp.com

Glue and all kinds of thick to thin adhesive agents can also be filled and sealed by a tube sealing machine in various types of tubes.

4.What Kind Of Tubes Are Supported By A Tube Sealing Machine?

Well, there are multiple types of tubes available in market today and their sphere is increasing day by day due to the growing environmental concerns about tubes' material. Below explanation provide a glimpse of these tubes which can be processed by a tube sealing machine:

Plastic Tubes

Plastic tubes- Picture Courtesy: jafra.com

Plastic tubes are the most frequently used tubes due to their easy squeezing. They are made from flexible plastic materials including polypropylene (PP) and polyethylene (PE). Therefore, they get back to original shape even after continuous squeezing. These tubes can be filled, and heat sealed by a tube sealing machine.

Aluminum Tubes

Aluminum ointment tube- Picture Courtesy: turbosquid.com

Another type of tube which can be supported by a tube sealing machine is aluminum tubes. They are made from durable layer of aluminum and have high thermal conductivity due to which they are good for placing in freezer. Therefore, most of the ointment, medicated creams, and adhesives are packed in these tubes.

Paper Tubes

Paper tube- Picture Courtesy: ifdesign.com

Keeping in mind the environmental sustainability of ecosystem, manufacturers are now trying to look for alternatives to plastic. Hence, paper tubes are made with a plastic laminate inside. These paper tubes are perfect to store liquids and pastes, therefore, can be processed by a tube sealing machine.

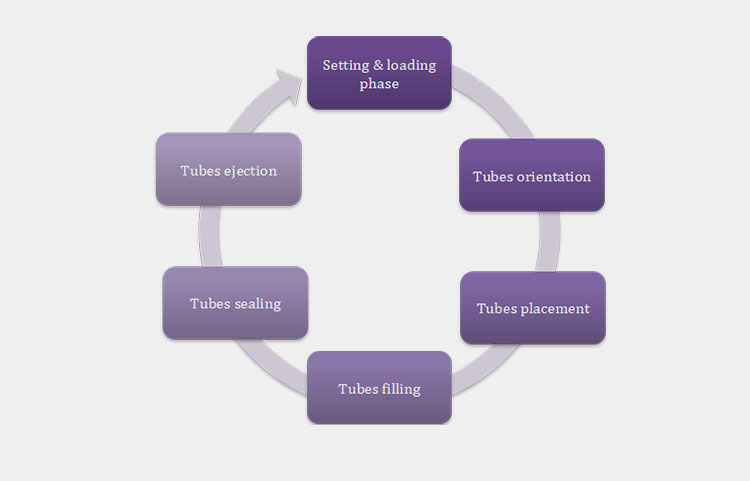

5.How Does A Tube Sealing Machine Function?

Although, the working principles of a tube sealing machine is simple but imperative to have proper knowledge about. Moreover, depending upon the type of tube sealing machine such as fully automatic, semi-automatic, or manual tube sealing machine the working steps will also vary which you will know in the next question.

Below provided working process is of a fully automatic linear tube sealing machine:

Setting and Loading Phase

Before starting the machine, it is obligatory to set the machine and load it with material. For this, magazine of machine will be loaded with empty tubes and material hopper with the desired material. Afterwards, the parameters are fixed such as the amount of material to be filled in each tube and the speed of filling etc.

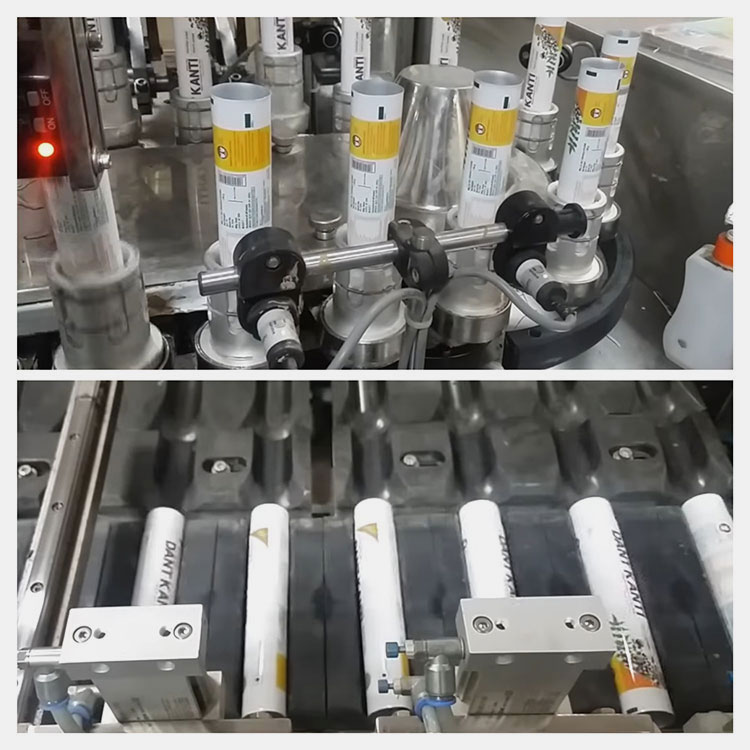

Tubes Orientation

Tubes orienting- Picture Courtesy: Pacmac Solutions

Now, when the machine has been loaded with material and tubes and its basic parameters are fixed, the operator will power the machine. Here, the very first step will be the tubes orientation. It takes place when empty tubes are moved in a sequential order from the magazine onto the conveyor.

Tubes Placement

Tubes placement & conveying- Picture Courtesy: Pacmac Solutions

Moving forward, these empty tubes fall over conveyor where they get fitted into individual sections. These tubes are then pushed forward and placed into the guide rail's tubular moulds.

Tubes Filling

Tubes filling process- Picture Courtesy: Pacmac Solutions

At this point, the guide rail takes the empty tubes towards the filling station. Firstly, the presence of tubes is detected by a sensor and then multiple filling heads start depositing accurately weighed material into these tubes.

Tubes Sealing

Tubes sealing- Picture Courtesy: Pacmac Solutions

Once the filling of tubes gets done, they are mobilized for sealing. Here, the sealing of plastic filled tubes is carried out through heat sealing and that of aluminum tubes is taken place by folding their ends. For precision, the extra tails of tubes are trimmed by the machine and at the same time batch no and date is printed over these tubes.

Tubes Ejection

Tubes discharging- Picture Courtesy: Pacmac Solutions

At last, the finished tubes are mobilized towards discharging. The guide rail's interval at discharging station leads the spindle inside tube holders to move upward, thus, resulting in the falling of tubes over chutes.

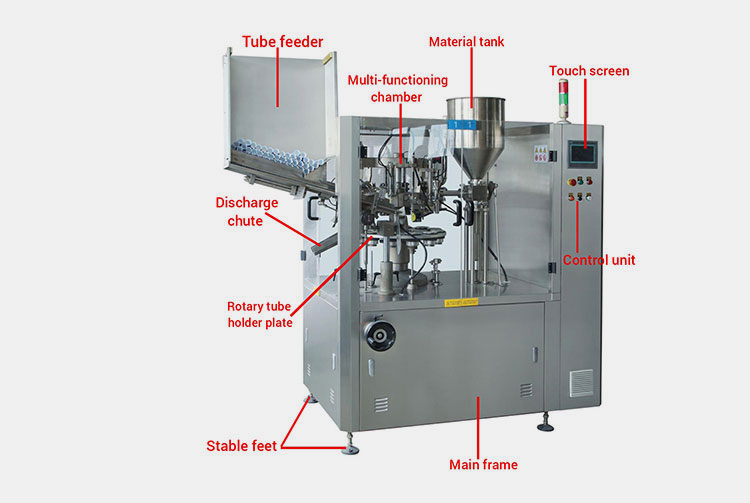

6.Describe The Structure Of A Tube Sealing Machine?

The structure of a tube sealing machine is a composite whole of different parts. These comments along with their functions are discussed below:

Components of Allpack NF-80 Automatic Al Aluminum/Plastic Soft Tube Filling and Sealing Machine Lotion

Tube Feeder

Tube feeder is a large hopper attached to the tube sealing machine to hold bulk cartridges of tubes. It also performs the task of feeding the main machine with empty tubes in a sequential order.

Multi-functioning Chamber

Multi-functioning chamber is the core part of a tube sealing machine. It is an assembly of several other components performing different functions. These are as follows:

Filling Nozzle:Filling nozzles are small but long narrow tubes often made up of stainless steel and occasionally of plastic. These are attached to the material hopper through which the machine dispense precisely weighed volume of material into tubes.

Sealing Head:Sealing head is another device on the chamber with an assigned task to seal the tubes. It can be heat sealer, intense sealer, or a roller depending upon the type of tubes such as plastic or aluminum.

Crimper/ Tail Cutter:Tail cutter is fitted in the machine to cut down the excess tube material for enhancing packaging accuracy. Similarly, crimper is used to crimp the tube in order to create ridges at the end for tight sealing.

Printing Device:Printing or coding device is another crucial part of the multi-functioning chamber of a tube sealing machine which print a batch no and date etc., on tubes.

Material Tank

Material tank is a large stainless-steel container with broad opening and narrow bottom. It is used to hold a large volume of liquid material inside it during operation such as toothpaste, lotion, and cream etc.

Touch Screen

A touch screen is a human machine interface located at the top front of machine. This device is extremely helpful in setting the basic configurations of the machine including temperature of the hopper, material quantity for filling, and filling speed etc.

Control Unit

Control unit is the collection of certain knobs and switches. These are generally installed to control the machine through power button and emergency stop.

Main Frame

Main frame is the backbone of a tube sealing machine because it supports all other components whether internal or external. It is made up of durable stainless steel and a transparent window for clear observation. The machine is highly resistant to corrosion, weather, and physical damages.

Stable Feet

Tube sealing machines have four integrated feet or in some cases universal wheels for easy mobilization. The feet greatly contribute to machine's stable functioning.

Rotary Tube Holder Plate

Another major component of tube sealing machine is a rotary tube holder plate which has certain moulds in its surrounding for holding tubes. During operation, this plate moves at relatively high speed, take intervals at different stations, and let the tubes filled, sealed, crimped, and coded.

Discharge Chute

Discharge chute is a stainless-steel slippery device attached to the machine. Through this device, finished tubes are discharged out of machine and assembled in relevant containers.

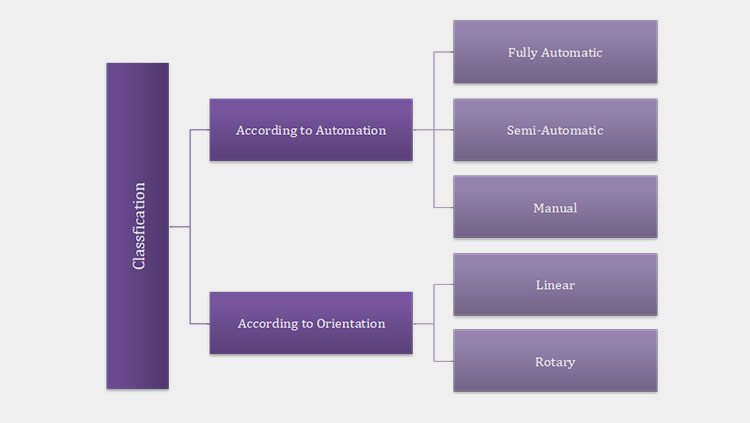

7.What Is The Classification Of A Tube Sealing Machine?

Tube sealing machines can be classified into two categories on the basis of automation and orientation. These are described below in detail:

According to Automation

Fully Automatic Tube Filling/ Sealing Machine

NF-120 Fully Automatic Plastic Tube Aluminum Filling Sealing Machine

A fully automatic tube sealing machine is a type of machine that comes with 100% of automation. It gives extraordinary performance in terms of production, accuracy, and material processing. Hence, you can benefit from this machine in your diverse industries which can provide you with high output ratio of 120 tubes per minute.

Structure

The structure of the machine is a complex assembly of different components. It mainly consists of a tube infeed, tube orientation, tube filling, hot air station, tube sealing, and pick/ place unit etc.

Working Process

The machine follows fully automatic processing with no manual interference. Just an operator is required to set the machine and observe its functioning. The tubes are automatically released from dual stations onto conveyor, oriented sequentially, and placed upright in a guide rail. Similarly, these tubes are detected by machine, after which their filling, sealing, trimming, and printing goes on simultaneously and the function ends with tubes discharging.

Semi-Automatic Tube Filling Machine

Allpack NF-30 semi-automatic tube filling sealing machine

Another type of tube sealing machine is semi-automatic in nature. It has comparatively low cost, small footprint and high product versatility to that of other types of machines. You can use it for low to medium scale facilities and get extremely efficient results by getting up to 30 filled tubes in a minute.

Structure

The machine features a compact body comprised of a stainless-steel main frame, a turret, product hopper, control board, universal wheels, discharge chute, material filling head, tube sealer, crimper, and printer etc.

Working Process

It follows a convenient working process by requiring one operator to place the empty tubes on a rotary plate manually and set basic functional parameters of the machine. Afterwards, turning the power button on will result in machine's automatic weighing and filling of empty tubes. These tubes are then tightly sealed, trimmed, gone through crimping of seal, data coding and ultimately the discharging through chute.

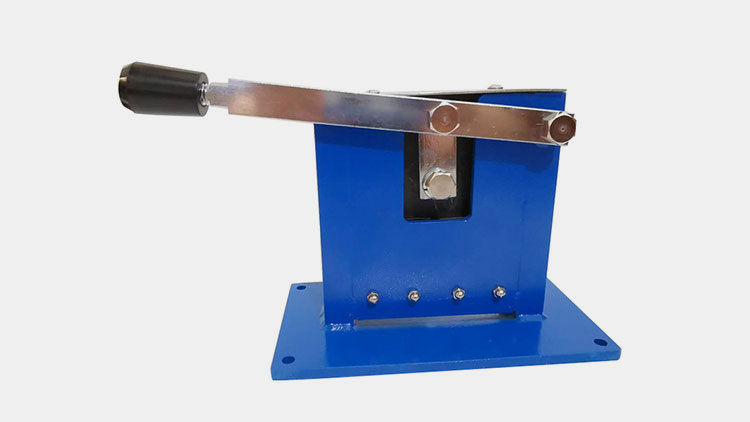

Manual Tube Sealing Machine

Manual Heavy Duty Aluminum Laminate Tube Sealing Machine

Manual tube sealing machine is another type of machine which is affordable in price for low-income small-scale home businesses. It also features the date and batch no coding facility. Moreover, by using this manual tube sealing machine you can seal 20 tubes in a minute.

Structure

It has a small body made from hard metal which consists of a handle, tube crimping flat metal, and data coding unit.

Working Process

It entirely depends upon the user for functioning where the user manually places the tube in machine and manually press the handle which seals the tube. The operator then picks out the tube and roll its sealed tail through machine. After repeating this step 3 times, tube is tightly sealed and placed in a coding section where coding takes place.

According to Orientation

Linear Tube Filling Machine

Linear tube filling machine

Linear tube filling machine has a synchronized system to carry out the tube filling and sealing in one run. This machine is the most advanced in technology and help you out in meeting the largest possible targets of your production.

Structure

The structure of the machine is long and horizontal in body. It has an expanded dual guide rail on opposite sides with capacity to hold 50 tubes at a time. Other parts include double tube feeders, a large material hopper, control system, safety system, and a stainless-steel body.

Working Process

It follows a linear mechanism for processing where multiple empty tubes are drawn out from feeder and fixed on guide rail in sequential manner. Similarly, the presence and absence of tubes are detected by machine according to which these tubes are loaded with pre-measured volume of material. Afterwards, tubes are sealed, coded, and ejected from machine.

Rotary Tube Sealing Machine

VK-UTS-006D Rotary ultrasonic tube sealing machine- Picture Courtesy: vkpak.com

As the name indicates, rotary tube sealing machine has rotary system to simultaneously process the tube filling, sealing, trimming, and coding. By adjusting the machine, you can process different kinds of tubes and material and get the desired output.

Structure

It has a relatively precise body with rotary plate as the main operating component that holds in it tubes. Other parts include a material hopper, filling pump, sealing mechanism, and coding device etc.

Working Process

It follows a rotary mechanism where all the tube holders are supplied with empty tubes. The plate by continuous rotation and intermittent intervals undergoes the tubes through filling, sealing, cutting, coding, and finishing phase.

8.What Are The Different Ways Of Sealing Used By A Tube Sealing Machine?

Tube sealing machines use different techniques for the sealing of various types of tubes. In other words, each tube sealing machine offers any of the below mentioned sealing method for the sealing of tubes:

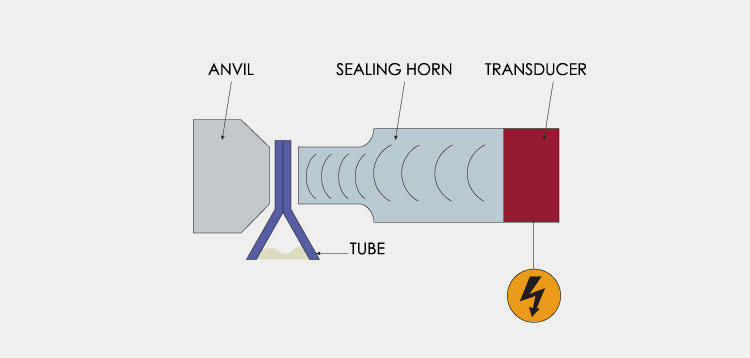

Ultrasonic Sealing

Ultrasonic tube sealing- Picture Courtesy: tube.org

Ultrasonic sealing is the most commonly used method for sealing due to its hygienic way that completely prohibits product contamination. It basically uses a horn attached to the heating device. This horn continuously adopts vibratory effects towards tube end against an anvil. Thus, stringent, and clear sealing takes place.

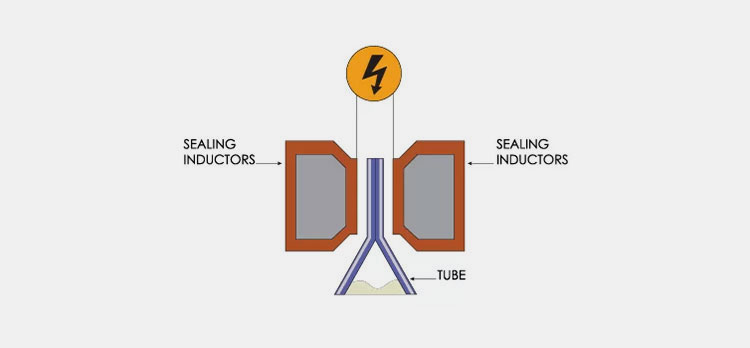

Impulse Sealing

High frequency tube sealing- Picture Courtesy: vkpak.com

Impulse sealing refers to the technique where the opening of tube is tightly pressed between heated elements. This method of sealing tubes is also known as high frequency tube sealing because the time taken, and the temperature intensity are both excessive.

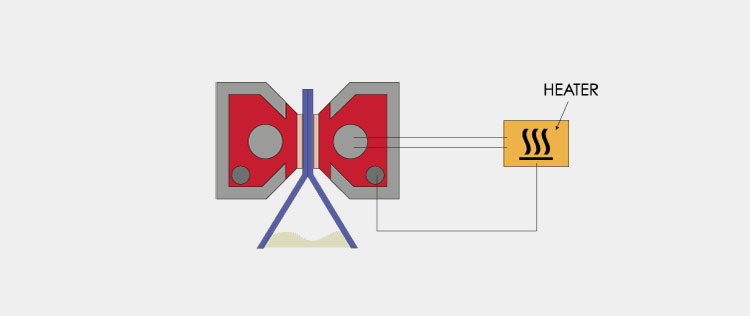

Dual-Chamber Sealing

Dual-Chamber tube sealing- Picture Courtesy: tube.org

Dual chamber sealing or hot jaw sealing method is the most affordable and efficient way to seal tubes. Here, heated jaws are used to melt the tubes and join the ends of tubes together simultaneously.

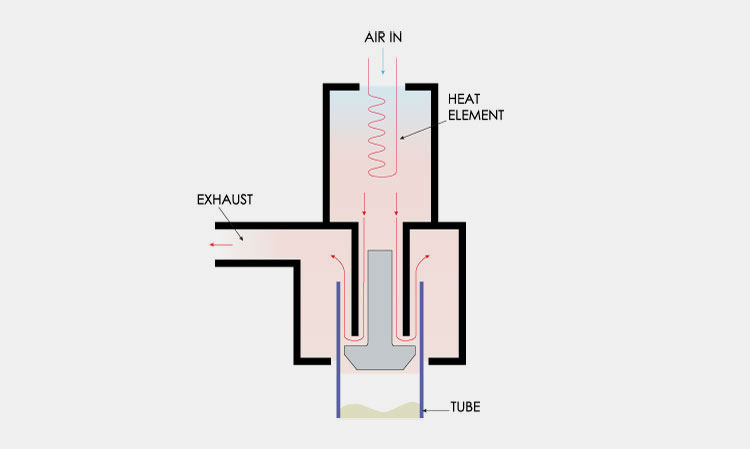

Hot Air Sealing

Hot air tube sealing- Picture Courtesy: thewholepkg.com

Hot air sealing is one of the most suitable sealing methods used for plastic and laminated tubes. It creates highly professional sealing where the inner walls of tube's end are softened through hot air after which these ends of tube are tightly welded through sealing jaws.

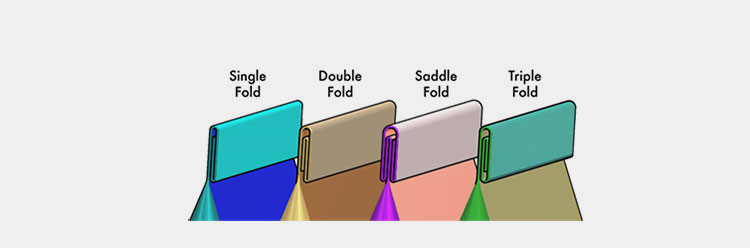

Aluminum Tube Crimping

Samples of multiple types of aluminum tube crimping- Picture Courtesy: thewholepkg.com

Unlike plastic tubes, aluminum tubes require folding or crimping techniques for creating strong sealing. In this way, various kinds of folds can be applied for aluminum tubes sealing. For instance, free flowing liquids require little pressure compared to viscous substances during squeezing. Hence, single and double folds are good for the latter while the former require saddle fold and triple fold.

9.Highlight The Areas Where A Tube Sealing Machine Can Be Used?

A tube sealing machine can be used in underlying industries:

Cosmetic Industry

Multiple cosmetic cream tubes- Picture Courtesy: jergens.com

Cosmetic industry is the most prominent sector where tube sealing machine is the prerequisite. It is due to the constant production and packaging of different creams, gels, and toothpastes for which tubes are the first choice of manufacture.

Medical Industry

Healthcare industry- Picture Courtesy: fatbit.com

The medical industry is another field where the relevance of a tube sealing machine is realized. The reasons vary from material susceptibility which is better preserved by this enclosed protected machine to the ease and of cure delivery.

Food Industry

Ketchup paste- Picture Courtesy: Behance

As the convenience of customers is becoming the top priority of manufacturers, the food producers have now added the tubes in their packaging. Now, you will find ketchup, mayonnaise, honey, chicken spread and many other liquid eatables which are packed in tubes. For their airproof sealing, a tube sealing machine can be used.

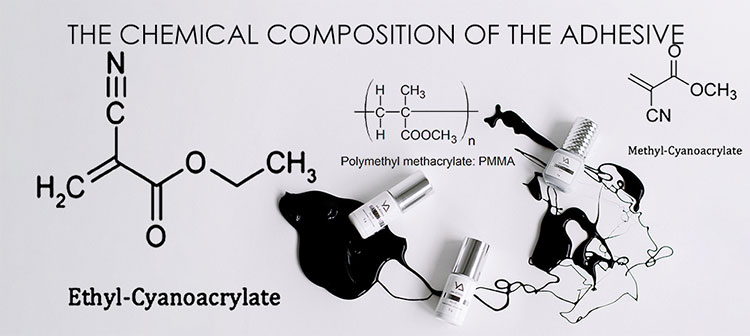

Chemical Industry

Chemical composition of adhesive- Picture Courtesy: yalashes.de

The chemical industry can also take advantage of a tube sealing machine in one way or another. In addition, different types of free-flowing and adhesive glues are often filled in tubes and tightly sealed by this machine.

Stationary Industry

Multiple color paint tubes- Picture Courtesy: zippypixels.com

Tube sealing machine is also popularly utilized in stationary industry where different types of glitters, paints, and liquid colors are packed in tubes for which its use is realized.

10.What Are The Cleaning And Maintenance Requirements Of A Tube Sealing Machine?

Machine cleaning & maintenance- Picture Courtesy: b2bcoffee.ie

Cleaning and maintenance determine the performance level, efficiency, and working life of a tube sealing machine. So, regular working on these two things is essential. Consider the cleaning and maintenance guidelines below:

Cleaning

It is important to regularly clean your tube sealing machine for hygienic processing. For this you need to clean the main body of machine every time. When daily work gets done, disassemble the parts of a tube sealing machine including material hopper, filling heads, and rotary plate. Then, clean these parts with boiling water and get them dry via clean dry cloth. Cleaning of attached tools like window, control panel, and guide rail is also important.

Maintenance

For maintaining a tube sealing machine, you are required to first adjust the different parts and tools of machine on their right place in accordance with the size of tubes. Secondly, modify the internal setting of machine each time before starting the operation.

Thirdly, observe the machine during operation, in case you find any inconsistencies in the filling or obstruction in transmission make sure to take note of these changes and take quick measures for correction. Fourthly, lubricate the transmission parts of machine such as guide rail and motor etc.

11.What Is The Troubleshooting Of A Tube Sealing Machine?

Troubleshooting of a tube sealing machine is extremely easy to understand. You just have to examine the error, find its actual cause, and take suitable action. For this, the table below will be helpful:

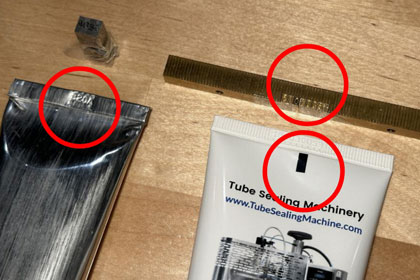

| No | Fault | Cause | Solution | Picture |

| 1 | Material overfilling in tube | The close overflow control valve results in inaccurate filling of tube. | Hence, open the overflow control valve, so, that the product will be dispensed in accurate volume. |

Encircled overfilled tube- Picture Courtesy: truster.pharma.com |

| 2 | The heating temperature of machine does not rise | It may be due to poor electrical contact or the burnt heating element. | Replug the machine and if the heating device is worn out then replace it with new one. |

Indicating heat- Picture Courtesy: space.com |

| 3 | Despite turret rotation, the sealing does not occur | Either the sealing button is not powered on or there is issue in pneumatic mechanical valve causing obstruction of in sealing. | Make sure the sealing switch in on and check the pneumatic mechanical valve if damaged replace with new one. |

Encircled tube sealing jaws- Picture Courtesy: truster.pharma.com |

| 4 | Machine sealing the tube but not filling it | It occurs when the infrared probe or sensor unable to detect the presence of tubes. | You need to check the sensor and rightly place it. If it is damaged, then replace it. |

Encircled infrared probe- Picture Courtesy: Pacmac Solutions |

| 5 | Misaligned tubes | The distance between tubes and sensor can cause misalignment of tubes. | To solve it, adjust the sensor sensitivity and locate it on right place. |

Encircled sensor- Picture Courtesy: bhagwatipharma.com |

| 6 | Blurr coding | It happens either due to inaccurate installation of characters or the characters worn out themselves. | Accurately and tightly place the the characters. If they are worn out, then install new characters. |

Marked tube coding over tubes and coder- Picture Courtesy: thewholepkg.com |

12.Tips For Purchasing An Effective Tube Sealing Machine?

Whenever you plan to invest in a tube sealing machine make sure you are fully satisfied with the machine's quality, capacity, and the buyer itself. These factors together with other considerations will help you take the right decision. Have a look at a few of important ones!

Machine's Specifications

Searching specifications- Picture Courtesy: kintronics.com

The most crucial tip for purchasing an effective tube sealing machine is to consider the specifications of the machine. Now, the question arises how? So, the answer is simple! You just need to have knowledge about your product. For instance, free flowing liquids are efficiently filled by a gravity filler while as, viscous substances need piston filler. Similarly, aluminum tubes need crimping technique and plastic tubes require heat sealing.

Production Capacity

Multiple laminated tubes- Picture Courtesy: vkpak.com

Another important factor is to know the capacity of tube sealing machine. If you are running home-based business, then manual tube sealing machine is an affordable choice. Similarly, for medium and large-scale production, semi-automatic and fully automatic tube sealing machines are having high capacities respectively.

Quality Assurance

Quality assurance icons- Picture Courtesy: learnqctools.in

If you are going to incorporate a tube sealing machine in your packaging line, it is necessary to have quality assurance regarding the machine. For this, make sure the machine meets international quality standards and have warranty policy.

13.What Is Allpack's Line Of Tube Sealing Machine?

Allpack is offering you the latest technology tube sealing machines. An overview of these machines is displayed in the table below:

| No | Machine Model | Automation | Speed per minute |

| 1 | NF-30 semi-automatic tube filling sealing machine

|

Semi-Automatic | 30 tubes |

| 2 | NF-60 Automatic Plastic/Laminated Tube Filling & Sealing Machine

|

Fully Automatic | 50 tubes |

| 3 | NF-80 Automatic Al Aluminum/Plastic Soft Tube Filling and Sealing Machine Lotion

|

Fully Automatic | 80 tubes |

| 4 | NF-100 Cream Soft Tube Filling Sealing Machine

|

Fully Automatic | 95 tubes |

| 5 | NF-120 Fully Automatic Plastic Tube Aluminum Filling Sealing Machine

|

Fully Automatic | 100 tubes |

Conclusion

In a nutshell, Tube Sealing Machine is the need of modern-day businesses. Whether it is in the food sector, medical sector, or of cosmetic, everywhere you will find the use of a tube sealing machine for tubes packaging. That's why, the above detailed description about tube sealing machine is covering not only the machine but all of its diverse facets. Did you find it helpful and wish to buy a tube sealing machine? If yes! We have much more for your guidance. Contact us for further information!

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide