Toothpaste Filling Machine: The Complete Buying Guide In 2024

Are you ready to transform your business by adopting one of the best packaging means of supplying liquid in tubes? You must be eager to facilitate your customers by providing your products in the most convenient way! Therefore, we are here to disclose you the Allpack's premier toothpaste filling machine which can assist you in accomplishing the task of filling all types of liquid and semi-liquid substances into tubes.

This toothpaste filling machine has been made with cutting edge technology through which it performs the primary function of filling pastes and fluids into tubes. Apart from that, the machine has simple operational procedure and maintenance, compact structure and extensive application in range of industries which will be explained in this buying guide. So, don't waste your precious time and let's start exploring this innovative machine!

1.What Is Meant By A Toothpaste Filling Machine?

Toothpaste Filling Machine-Allpack

Toothpaste is a paste or gel like substance derived from various natural and artificial sources in order to be used with brush for cleaning teeth. As toothpaste is necessary for the oral health of humans, it becomes obligatory to process it in a safe hygienic environment for which a toothpaste filling machine has been employed.

Toothpaste filling machine is used for the filling of viscous pastes and semisolid substances into different types of tubes and containers. It is made with antibacterial stainless steel which fully assures the safety of toothpaste and similar substances during process.

Moreover, the machine is equipped with multi function capabilities including filling, sealing and batch embossing. Therefore, it undertakes the principal task of toothpaste filling into plastic, aluminum or paper tubes by delivering predetermined amount through a piston, gravity or overflow filler.

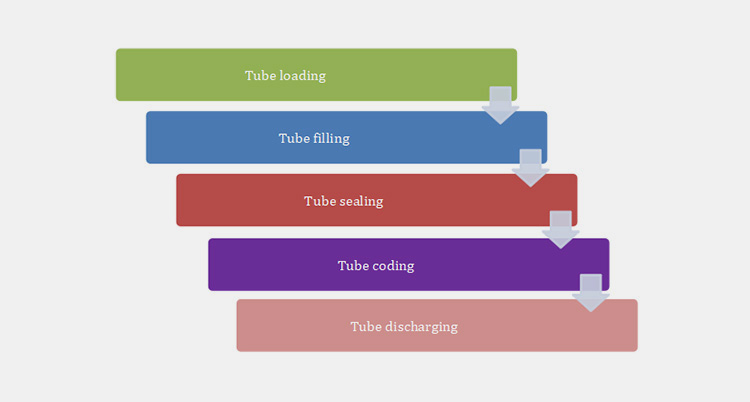

2.Which Working Principles Are Essential For Operating A Toothpaste Filling Machine?

In order to understand the working of a toothpaste filling machine, underlying principles are can be helpful:

Tube Loading

Tubes feeding-Picture Courtesy: npackmachine.com

The process of toothpaste filling begins with operator loading bulk tubes into hopper in order to supply the machine with empty tubes for filling.

Tube Filling

Tubes under filling nozzles-Picture Courtesy: bzmachinery.net

Now, the empty tubes start moving towards the turntable where each tube is inserted into the molds located on turntable. Similarly, these tubes firmly adjusted on the rotary workbench for filling. Here the filling of tubes takes place, when filling nozzles dispense accurate volume of paste. It is worthy to mention here that several types of filling nozzles may be used for filling pastes including vacuum filling, volumetric filling, piston filling and volumetric filling etc.

Tube Sealing

Tube sealing-Picture Courtesy: bzmachinery.net

After the tubes get filled with paste, the turntable will instantly adopt rotary movement for the sake of delivering tubes under sealing station. Thus, the sealing of tubes occurs here with the help of mechanical clamps.

Tube Coding

Tubes undergoing coding during operation-Picture Courtesy: npackmachine.com

Coding is another step which is carried out by the machine. The purpose of coding it to print a batch no and expiry date on the tubes for convenient identification and safe usage.

Tube Discharging

Finally, after tube filling, sealing and coding the tubes are ready to discharge. In some cases, if the tale of tube is larger than usual, the machine cut it down before discharging the tube through chute.

3.What Benefits You Can Get By Using A Toothpaste Filling Machine?

Bringing the technology of a toothpaste filling machine into your production line can give you significant advantages including:

Increase in Productivity

Multiple tubes-Picture Courtesy: Dieline

The prime concern of every manufacturer is to enhance the level of productivity which can be easily achieved by using a toothpaste filling machine. In addition, the automatic transmission mechanism, high speed filling and sealing of tubes lead to the completion of around 60 pieces in a single minute.

Reduction in Waste

Chocolate releasing from tubes-Picture Courtesy: Dieline

Filling tubes manually is a tiresome job which can cause continuous product loss. Therefore, a toothpaste filling machine is designed in such a way that there is zero chance of product waste due to its filling of precise and exact volume of pastes into tubes.

High Adaptability

Toothpaste filling machine is highly adaptable due to its processing of pastes and liquids with diverse viscosities. Moreover, it can be adjusted for small to large size tubes making it more resilient.

Decrease Labor Cost

Unlike traditional machines, toothpaste filling machine do not require multiple labors for executing the machine rather it is standalone due to high level of automation. Consequently, requirement of only one operator for the monitoring of machine cut down the cost of labor.

Versatile

Tube sealing-Picture Courtesy: npackmachine.com

The machine is extensively versatile for the reason of being able to perform multi-tasking operation. For instance, it has the ability of tube filling, sealing, coding and tale cutting in one go.

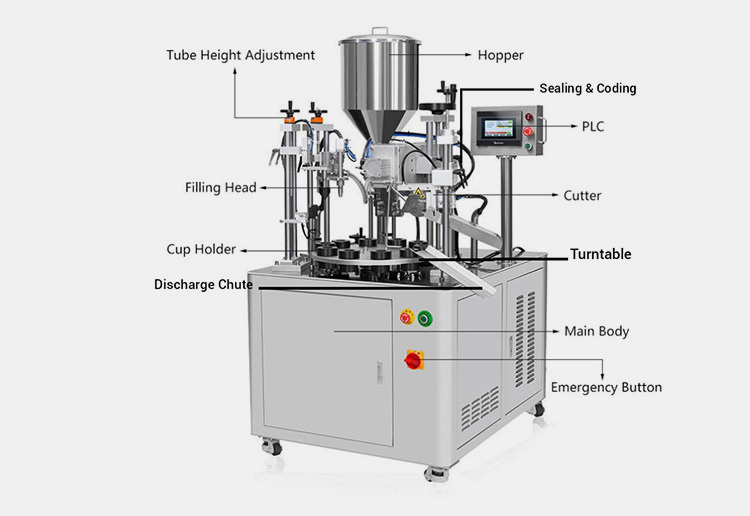

4.Describe The Composition Of A Toothpaste Filling Machine?

The structure of a toothpaste filling machine consists of the following components:

Components of toothpaste filling machine-Picture Courtesy: bzmachinery.net

Hopper

Hopper in toothpaste filling machine is a large inverted pyramidal funnel which holds the emulsion of toothpaste or other pastes, which are meant to be filled in tubes.

Tube Height Adjustment

Tube height adjustment is a tool integrated in machine to assist the operator for adjustment of machine as per the size of various tubes.

Sealing & Coding

There is a station in toothpaste filling machine where two units of tubes sealing and coding are fixed together. The sealing unit is composed of mechanical clamps and heating system for the sealing of tubes, while as, coding unit has integrated ink system which adhere to the tube for printing batch no.

PLC

Programmable logic controller is a computer with touch screen display which is integrated to a toothpaste filling machine for the sake of providing platform through which user can communicate commands to the machine.

Filling Head

Filling heads are long narrow stainless steel nozzles which dispense the pastes into tubes without any waste.

Cutter

The number of cutter comes after the coding unit, and it is responsible for cutting the additional tale of tubes.

Turntable

Turntable is an important component of a toothpaste filling machine and is also known as a workbench. It comprised of medium size molds for the fixation of tubes. These tubes are then processed by machine when turntable adopts revolutionary motion.

Discharge Chute

It is a flat stainless steel slippery device located at the discharging area of machine. When the filling and sealing of tubes get completed, the machine uplift the tubes from molds which fall over the discharge chute and collected in a tray.

Main Body

Main body of the machine consists of an electric box, supporting stand, cooling system and movable wheels. All of these parts except casters are made up of durable stainless steel which enable the machine to withstand heavy workload and remain stable during operation.

Emergency Stop

A toothpaste filling machine has a safety mechanism in form of emergency stop which allow user to instantly break the process in case of malfunctions caused by the machine.

5.Enumerate The Various Products Filled By A Toothpaste Filling Machine?

A toothpaste filling machine is capable of processing large number of liquids with varying degrees. Some of these are enumerated below:

Pastes

Tomato paste presentation idea-Picture Courtesy: Cento

Pastes are semi-liquid emulsions usually made from the mixture of solid and liquid substances such as toothpaste, tomato paste and herbal pastes etc. All of these pastes can be perfectly filled by a toothpaste filling machine.

Sweets

Various sweets in tubes-Picture Courtesy: Behance

Liquid sweets such as chocolate, condensed milk and peanut butter etc., are often delivered in beautiful tubes for the convenience in usage especially for outdoor picnic. Therefore, a toothpaste filling machine can be used for achieving this goal responsibly.

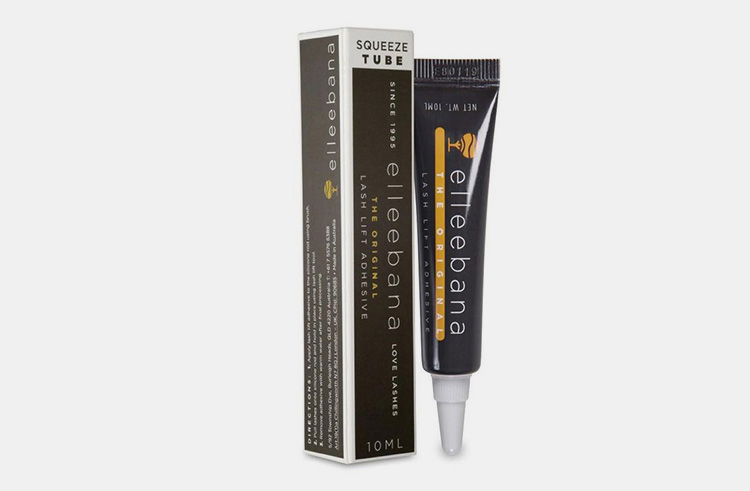

Adhesives

Adhesive tube-Picture Courtesy: carrefour.fr

Adhesives and glue are liquid substances meant for holding things together which may be paper, fabrics, and other hardware products. Due to their vulnerability to evaporate immediately, adhesives are stored in tubes for protection against air. Therefore, a toothpaste filling machine can be used for the safe filling of adhesives into tubes.

Ointments

Use of ointment tube-Picture Courtesy: naturesgold.global

Ointments are oil-based topical preparations which are meant for external application such as skin. They contain drug to give relief from pain and cure injury. In pharmacy, almost all types of ointments are packed in tubes for which a toothpaste filling machine is best applicable.

Lotions & Cream

Moisturizer tube-Picture Courtesy: apostrophereps.com

Cream and lotion are liquid formulations prepared for the purpose of cosmetic or medical use. Like other liquids, they are also eligible to be processed by a toothpaste filling machine.

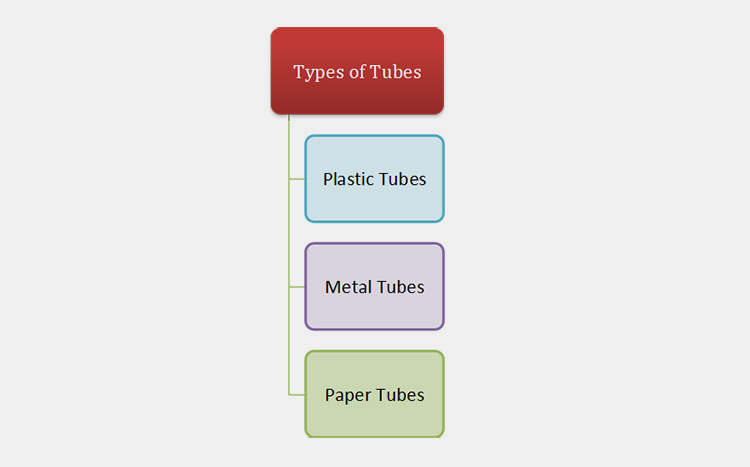

6.Which Kind Of Toothpaste Tubes Can Be Filled By A Toothpaste Filling Machine?

Several kinds of tubes can be filled by a toothpaste filling machine such as:

Plastic Tubes

Various color plastic tubes-Picture Courtesy: sephora.com

Plastic tubes are made up of HDPE (High Density Polyethylene) which are highly flexible and convenient to squeeze. Although, plastic tubes are less environmental friendly, their interior has a laminated aluminum layer which protects the content quality and flavor.

Metal Tubes

Various metal tubes-Picture Courtesy: beautypointofview.com

Metal Tubes are made up of safe aluminum with high resistance against temperature, ultraviolet light and moisture. Most of the highly sensitive toothpastes, ointments and facial creams are filled in metal tubes which can be processed by this machine.

Paper Tubes

Paper tubes-Picture Courtesy: ifdesign.com

Another type of tubes which can be filled by a toothpaste filling machine are Paper tubes. Paper tubes are the most eco-friendly storage tubes adopted for packaging purposes. It has internal layer of thin plastic for retaining the pastes quality intact. Paper tubes have 80% lower environmental degradation chances than that of plastic tubes. Moreover, consumers can use the inside content till last drop by simply tearing the paper tubes.

7.Disclose The Diverse Forms Of Toothpastes Which A Toothpaste Filling Machine Is Capable Of Processing?

There are multiple varieties of toothpaste in terms of color, texture as well as ingredients. In the upcoming paragraphs, some of the prominent types of toothpastes, which can be filled by a toothpaste filling machine, have been highlighted:

Unicolor Toothpaste

Unicolor toothpaste-Picture Courtesy: kanereviews.com

As the name indicates, unicolor toothpaste consists of a single color which can be easily filled by a toothpaste filling machine.

Double Color Toothpaste

Double color toothpaste-Picture Courtesy: Aileen Feldishi Tetlassova

Double color toothpastes contain two different types of toothpaste emulsion. Therefore, it is necessary to keep these emulsions unmixed till consumer usage which is done by a toothpaste filling machine.

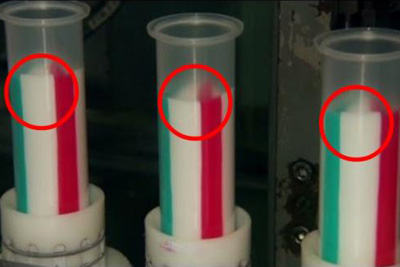

Multi-Color Toothpaste

Multicolor toothpaste-Picture Courtesy: ireceptar.cz

Similar to double color toothpaste, multi color toothpastes can be also processed by this machine.

Toothpaste with Particles

Particles toothpaste dispenses over brush-Picture Courtesy: creativemarket.com

There are toothpastes with gel-like texture having particles inside. These particles release when combined with water to create freshness. Hence, to keep these particles remain undissolved in toothpaste during packaging, a toothpaste filling machine can be used.

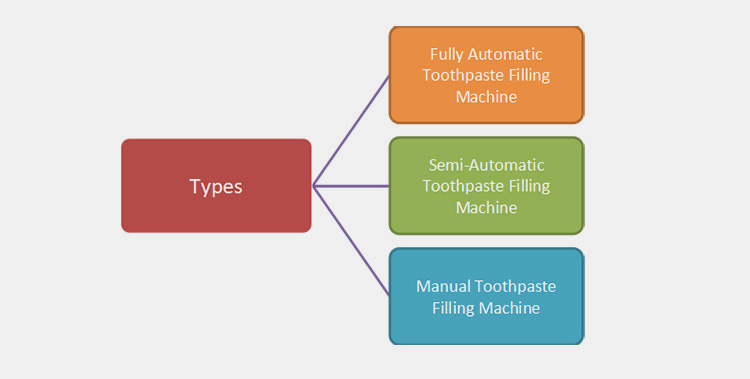

8.Write Down The Different Types Of Toothpaste Filling Machine?

Toothpaste filling machine are of different types on the basis of automation. They can be used as per the requirement of your production volume. Below description will better enable you to opt for the best suitable machine:

Fully Automatic Toothpaste Filling Machine

Fully automatic toothpaste filling machine-Allpack

Fully automatic toothpaste filling machine is the assembly of well engineered parts controlled by fully automatic system. It is capable of performing the three functions of tube filling, sealing and embossing automatically without any interruption and error. The advance feature of detection system enable machine to follow the principle of no tube no filling. Moreover, the Allpack's fully automatic toothpaste filling machine has high adaptability ratio, GMP's standard quality stainless steel construction for safe processing and high speed performance which makes the filling of over 120 tubes in a minute. Therefore, companies with excessive manufacturing can better take advantage of this machine.

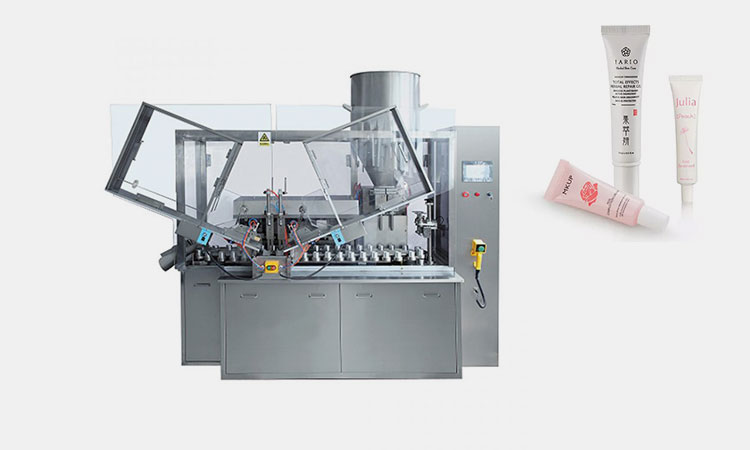

Semi-Automatic Toothpaste Filling Machine

Semi-automatic toothpaste filling machine is an effective equipment made with easy operational and maintenance structure. The machine is composed of a PLC controller, automatic filling system, sealing system, and adjustable tooling system. It works by following the simple operational procedure where operator manually feeds the empty tubes onto turntable and machine automatically fill the desired volume of pastes into tubes. After filling, tubes are sealed and discharged by the machine. By filling up to 30 tubes in a minute, this semi-automatic toothpaste filling machine is suitable for medium scale production facilities such as herbal industry and adhesive manufacturing industries etc.

Manual Toothpaste Filling Machine

Manual toothpaste filling machine-Allpack

Manual toothpaste filling machine is compact structured machine with few parts and convenient usability. The machine does not require electric power for execution, therefore allows more cost-effective way for packaging of your pastes in tubes. It consists of a hopper, handle, filling nozzle and supporting stand. The operator place an empty tubes under filling nozzle and push the handle for starting operation. It leads to the dispensing of paste from filling nozzle into tube and operator pick the filled tube. This manual toothpaste filling machine is reliable and good for small level business.

9.Enlist The Various Industries Where A Toothpaste Filling Machine Can Be Employed?

Toothpaste filling machine plays a significant role in diverse industries due to its ability of processing liquids and pastes. Therefore, we have highlighted some of the areas where this machine can be employed:

Cosmetic Industry

Various cream tubes & containers-Picture Courtesy: ladywritesblog.com

Cosmetic industry revolves around the manufacturing of products which are meant for caring and beautifying the outer appearance of body such as skin and hairs etc. Therefore, most of the cosmetics items including lotion, sunblock, gel, face mask and hair colors are delivered in tubes due to which the industry has popular demand for toothpaste filling machine.

Medical Industry

Ointment tube-Picture Courtesy: Glams Secret

Medical industry encompasses all the fields including pharmaceutical, herbal industry, surgical sector and dental industry. All of these sectors have their relevant demand for a toothpaste filling machine to pack their vary products such as ointments, medicated toothpastes and creams etc.

Food Industry

Food paste tubes-Picture Courtesy: Moody Foodie

Like other industries, food industry is also now engaged in the packaging of various pastes and viscous liquids such as chocolate, butter, tomato ketchup and mayonnaise etc., in tubes for which the use of a toothpaste filling machine is inevitable.

Adhesive Manufacturing Industry

Adhesive tube packaging-Picture Courtesy: paradisecityhawaii.com

The extensive use of adhesives in various sectors including construction, paper, textile and packaging industries indicates their significance. Hence, different types of adhesives and glue are filled in tubes for which a toothpaste filling machine is needed.

10.Which Machines Can Be Integrated With A Toothpaste Filling Machine?

There are two essential machines which can be directly integrated with a toothpaste filling machine including vacuum emulsifying mixer and cartoning machine. Following is the description of these machines:

Vacuum Emulsifying Mixer

Vacuum emulsifying mixer-Allpack

Vacuum emulsifying mixer is the crucial machine necessary for preparing the liquid formulations which are processed by a toothpaste filling machine. It is made up of a stainless steel body to ensure safe environment for food and non-food mixtures. It works by mixing the liquid and solid ingredients into a mixing pot through agitators and prepare homogeneous solution.

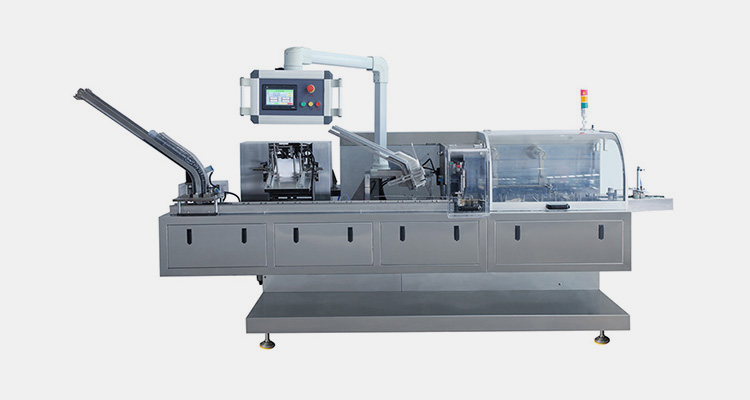

Cartoning Machine

Cartoning machine-Allpack

Cartoning machine is designed for the purpose of packing toothpaste filled tubes in cardboard boxes. The machine adopts automatic mechanism of box opening, tube inserting, box sealing, marking and waste rejecting. Hence, the final packaging of toothpaste tubes is done by this machine.

11.Explain The Procedure For Cleaning And Maintenance Of A Toothpaste Filling Machine?

Toothpaste filling machine is the assembly of high quality components which together make it possible to perform efficiently and precisely. In order to retain its performance frequency, you must have to regularly and maintain your machine as per the following directions:

Cleaning

Operator cleaning machine-Picture Courtesy: ichemysol.com

Washing Parts

Firstly, it is necessary to clean the surface of your machine on daily basis. For this, you have to clean the hopper, filling nozzles, turntable and molds etc. To clean these parts, pour boiling water into the grooves and also use cotton balls. Wipe the machine with clean cloth and repeat the process several times for best cleaning.

Lubrication

Lubrication is an undeniable need of every toothpaste filling machine due to the moving parts and machine which are integrated with it. For instance, you have to grease the guide rail, turntable and eccentric wheel etc. However, it is important to take care of avoiding excessive lubrication as it can ruin the machine performance as well as create mess.

Maintenance

Operator maintaining machine-Picture Courtesy: pressnewzroom.com

Parts Changeover

During process, keep examining the parts of machine and especially check the ground wire for stable performance. If the parts of machine are loose they can be corrected by tightening. However, in case they get damaged or worn out, you are required to change them timely.

Structural Adjustment

The machine you are using is adaptable for the reason of filling small to large size tubes. Therefore, you have to make the structural adjustment of machine such as tube height adjustment, filling unit and sealing unit height etc.

Parameters Setting

It is important to keep modifying the parameters of your machine for achieving desired results. Most importantly, the sensor of machine is a crucial device which must be all time monitored and kept free of debris.

12.What Are The Possible Faults Of A Toothpaste Filling Machine? Also Give Solutions To Them?

Generally, a toothpaste filling machine is effective enough to fill all kinds of viscous and free flowing substances into tubes, however, there might arise spontaneous problems during operation which are necessary to counter timely. These are shown in the table below:

| No | Fault | Causes | Solution | Picture |

| 1 | Insufficient filling | There compressed air hedge transformer may be blocked due to particles | Stop the machine and check the compressed air device for examining cause. If it is blocked, remove out all the accumulated particles to allow free flow of air |

Encircled compressed air mechanism-Picture Courtesy: bjfillingmachine.com |

| 2 | The filling is excessive than desired volume | If the power button is damaged it will have direct effect on cylinder to either fill less or more than required volume | It can be corrected by changing the power button |

Encircled overflow tube paste-Picture Courtesy: instagram.com |

| 3 | The diving filling heads do not work | The problem lies in air pressure which has been affected by the leak air line connected with to the diving heads | Check the pressure valve for releasing adequate air and also examine from where the air is leaking. In case the internal elastic diaphragm perforation, change it, and if it is misplaced, bring the diaphragm back to its place |

Encircled filling heads-Picture Courtesy: bzmachinery.net |

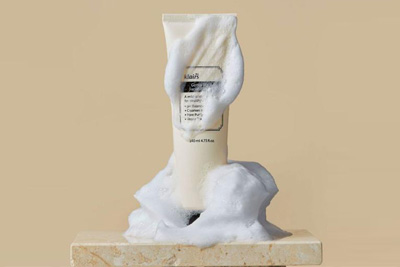

| 4 | Too much foam in bottles | Some fluids may get foamy during filling like shampoo or face wash etc., due to gravity fillers | To solve this issue, it is better to use overflow, level-based fillers which can precisely fill tubes without excessive foaming |

Foam on tube-Picture Courtesy: Yan li |

| 5 | Filling is not leveled | There are multiple causes including the unleveled floor on which machine sits, the inaccurate spacers in nozzles or the incorrect fill time | Make sure that your machine sits on a flat surface, the spacers in your nozzles are accurate and the time of filling is equal for all heads |

Encircled toothpaste tubes-Picture Courtesy: CNN |

13.Which Factors Must Be Followed For Making Sound Purchase Of A Toothpaste Filling Machine?

If you really want to innovate your production by bringing a robust and effective toothpaste filling machine, there is no need to rush. Just take time and consider some of the essential points highlighted below to get the perfect machine:

Production Requirement

Coconut cream packaging idea-Picture Courtesy: ultralinx.com

The most important factor to look for is the level of your production requirement. Is it large scale or of mediocre nature? If you are running medium scale business it is better to go for a semi-automatic machine, however, large scale industries require fully automatic toothpaste filling machine due to the heavy workload it can bear every day.

Specifications

Another aspect which must be taken into account the specifications of machine. For this, you can check the automation of machine, the degree of precise filling and multi-tasking features such as filling, sealing, cutting and embossing etc. By looking into these factors, you will ultimately reach to the point for making a sound purchase.

Quality

Quality icon-Picture Courtesy: isa.org

Toothpaste filling machine is supposed to be used for both food and non-food substances. Therefore, it is significant for its surface to be fully free from antibacterial presence, corrosion chances and abrasive material. And to know that the machine is made up of safe material, you can check several international quality standards which it complies. For instance, GMP, ISO and FDA are the most common quality standards essential for validating the quality of machine.

Price

Last but not the least, it is not possible to decide for purchasing a toothpaste filling machine without considering your budget. Ergo, you must keep in mind to get the machine which is cost-effective and affordable for your pocket.

Conclusion

To summarize, a toothpaste filling machine is the most versatile, advance and efficient machine that can process wide range of free flowing to highly viscous fluids. In today's modern era, where people look for convenience in every thing, toothpaste filling machine is giving the manufacturers an opportunity to have popularity among people for providing the desired convenience through tube packaging. Moreover, Allpack is also one of the greatest suppliers of a toothpaste filling machine along with one year of warranty and 24/7 remote support. If you are a keen purchaser do not miss the opportunity to be our worthy customer!

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide

Tell us your material or budget, we'll reply to you ASAP within 24 hours