Tablet Making Machine: The Complete Buying Guide In 2024

Did you know that tablets are the most popular form of dosage? You may be wondering how? The reasons not only stood at their relatively convenient manufacturing and low production cost but also their esthetic appearance and precision of dosage. That's why medical industries whether pharmaceutical, nutraceutical or veterinary tend to adopt this way for delivering their drugs.

In this way, the use of a Tablet Making Machine becomes inevitable leading the manufacturers to discover the machine in order to make its use the best one. Therefore, this buying guide about a Tablet Making Machine has peculiarly composed to assist you in your struggle and provide every possible information regarding it. So, make sure not to miss any part of it!

1.Define A Tablet Making Machine?

Allpack ZP5/7/9 Top Quality of Single Punch Tablet Press Machine

Tablet making machine is a durable and compact machine that entails various loots and components to perform the function of tablet making. The machine process dry powder or granulated formula in a way that their precise volume is pressed with much exertion inside a die cavity through punches. In this way, powder turns into solid tablets.

The machine is designed in a unique way to give all the tablets and pills the same weight, structure, and homogeneous size. Therefore, it is vital in pharmaceutical, nutraceucal, and animal care industries where accuracy in dosage is the condition for quality manufacturing.

2.What Are The Various Features Of A Tablet Making Machine?

No doubt, a tablet making machine comes with substantial features which ultimately become its benefits. Let's explore them in detail:

High Accuracy

Stacked precise tablets- Picture Courtesy: freepik.com

Tablets is the most popular and desirable form of medication dosage why? It is because the quantity, weight, and density of tablets are consistent. This consistency is the feature of a tablet making machine which conducts extraordinary precise and accurate tablets making both in terms of structure and hygiene.

Production Efficiency

Production efficiency indicator- Picture Courtesy: vietnambix.com

The multi-station turret of tablet making machine greatly assist in uninterrupted process of tablets formulation. This ultimately increases the ratio of tablets produced per hour.

Affordable

Tablet making machine is affordable as it does not require additional labours but only one operator is enough thus reducing labour cost. Moreover, the machine has low maintenance cost.

Flexibility

Various sizes of round tablets- Picture Courtesy: shefinds.com

Another specification of a tablet making machine is that it is extremely resilient and flexible. By mere changing the turret tools and modifying machine's parameters, you can make different sizes and shapes of tablets.

Reduce Waste

Tablets along with powder medication formula

Manual tablet making not only consumes your valuable time but also leads to much waste of product as well. However, with tablet making machines the product waste is limitize to greater extent.

3.Enlist The Kinds Of Tablets Produced By A Tablet Making Machine?

Most of the manufacturers get confused when they confront the question about tablet making machine's sphere of processing. However, it has a simple answer that this machine can produce all kinds of tablets which are explained below:

Different Shaped Tablets

Group of tubular and round tablets- Picture Courtesy: goodrx.com

Tablet making machines can be used to form any shape of tablets depending upon the mould of die cavity and punches. The common shapes which can be processed by using this machine include round, square, oval, triangle, cylindrical, heart shaped and many others.

Different Sized Tablets

Different sized round tablets

Tablets are most preferred dosage form because of the ease in delivering small to medium and large quantity of medication. That's why a tablet making machine can simply be employed to form all sizes of tablets and pills.

Effervescent Tablets

Effervescent tablets with tube- Picture Courtesy: glassdoor.com

Effervescent tablets are also called carbon tablets which are designed to provide quick intake of dosage where the tablet is quickly dissolved in water. As these tablets are large sized and round in shape, a separate effervescent tablet making machine has been introduced to form these tablets.

Different Colored Tablets

Double colored tablets- Picture Courtesy: depositphotos.com

Tablets come in uni color, dual color, or multicolor depending upon the dosage. Here it is surprising to say that a triple layer tablet can be made by a tablet making machine but yes, this machine is capable to do so.

4.How Would You Explain The Working Principles Of A Tablet Making Machine?

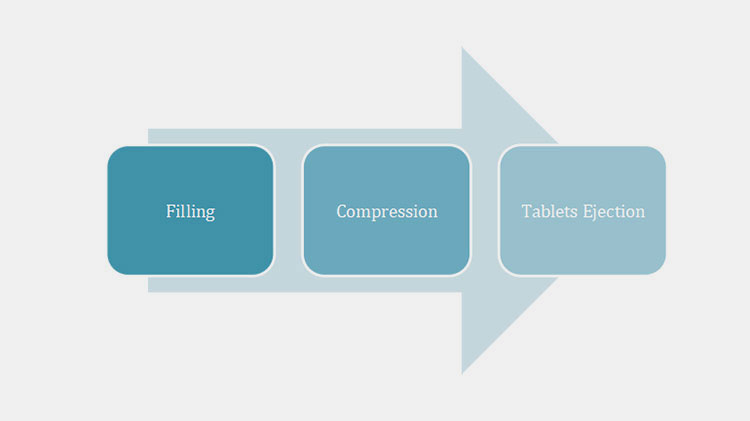

The working principles of a tablet making machine vary according to machine type. Below describes method is used by a single punch tablet making machine:

Filling

In the initial step when the machine is powered on, the filling of powder or granules takes place. It occurs in a way, that upper punch moves upward, and lower punch moves downward creating the cavity in die. Similarly, the cavity is filled with dosage and excess powder gets out of the die.

Compression

Tablets compression process- Picture Courtesy: www.korsch.com

In the second step, powder inside die cavity is compressed by the upper punch resulting in creation of compact and solid tablets. Here, the thickness and hardness of tablets depends upon the pressure exerted by the upper punch in a hammering position.

Tablets Ejection

Tablets ejection- Picture Courtesy: www.korsch.com

Ultimately, the pressed tablets are now ejected from the cavity through a spindle which moves upward and remove out the tablet. These tablets are discharged through chute and the same cycle of tablet making continues till the desired production is achieved.

5.What Components Constitute The Structure Of A Tablet Making Machine?

A tablet making machine is a heavy-duty machine that assemble in it various parts. What are these different components, and which function they perform is what we have answered below:

Components of Allpack ZP25 effervescent rotary tablet press machine

Hopper

A hopper is a large stainless-steel pot or container where the powered or granulated mixture is poured prior to operation.

Organic Glass

Organic glass is a transparent window surrounding the rotary table. It helps in ensuring the pollution free compression of tablets and at the same time allows operator to observe the processing.

Stainless Steel Body

The body of the tablet making machine is made up of a durable stainless steel. It is a material mainly used in tablet making machines due to its high level of protection against corrosion, bacteria, and support easy cleaning way.

Rotary Table

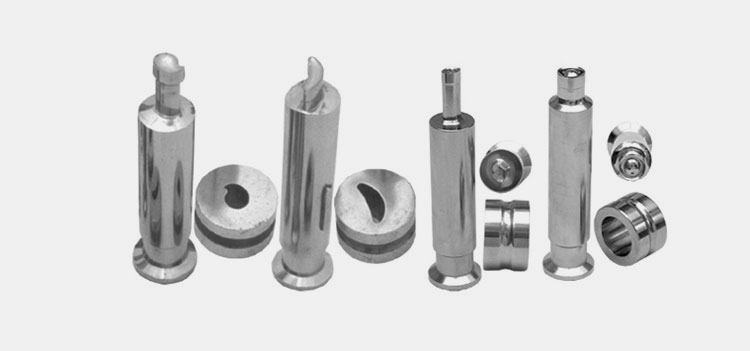

Rotary table is the core component of a tablet making machine. It consists of certain tools which actually perform the tablet making function. These include:

Punches:Punches are hard objects comprised of upper and lower punches. They are used to turn the powders and granules into different shapes of tablets through punching.

Die Cavity:Die cavity is the hollow workpiece where the punching of tablets takes place. The die cavity determines the size, thickness, and diameter of tablets.

Cam Truck:It is responsible to guide the position of tablet punches during rotation.

Discharge Chute

A discharge chute is a small stainless-steel port on the side of machine that aids the process of tablets' discharging after compression. Through this, finished tablets are ejected from the machine to the collection container.

Operation Panel

Operation panel is a long board comprised of different knobs and buttons which allows the user to control and operate machine by setting its parameters.

Emergency Stop

It is sometimes called a danger button that is located on front of the machine and is easily accessible to operator. Whenever the machine starts malfunctioning, pressing this button will result in stopping the machine quickly.

Electric Appliance Box

As a tablet making machine has fitted motor and other electrical components to regulate the operation, an electric appliance box is the part where all these tools and machinery have been placed.

Adjusting Handle

Adjusting handle is an important part of the tablet making machine which is used to increase or decrease the tablet’s compression force. Moreover, the number of powders or granules to be used for each tablet is adjusted through this handle. Therefore, it determines the weight and density of tablets.

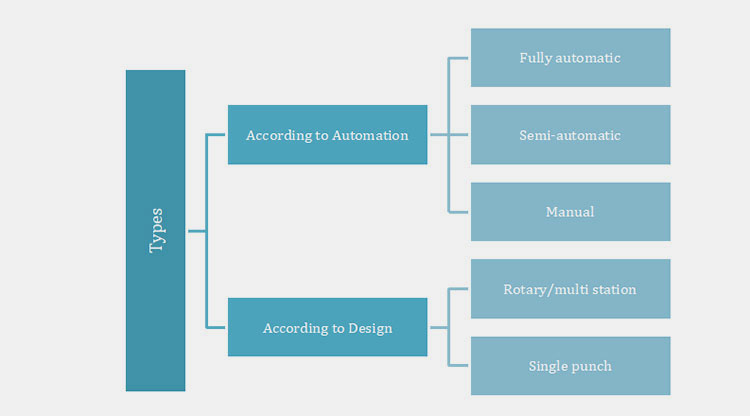

6.Describe The Different Types Of Tablet Making Machine?

Tablet making machine comes in different types which can be better understand by looking into the underlying classification:

According to Automation

Fully Automatic Tablet Press Machine

Fully Automatic Tablet Press Machine Zpt-27D

A fully automatic tablet press machine is an excellent equipment employed to make the tablets of all shapes and sizes. It supports extremely safe and dustproof formation of tablets. The machine can also be directly integrated with other machines to enhance production efficiency. Moreover, it can make 81000 tablets per hour.

Structure

The structure of the machine is compact and vertical composed of different tools and components such as dual hoppers, a turret, discharge port, power button, electric enclosure, touch screen penal, and adjust handles etc.

Process

It follows an automatic way for making tablets. The precise dosage of powdered or granulated mixture is gradually introduced into dia cavity. Proceeding further, the dosage is punched by upper and lower punches resulting in creation of tablets. Afterwards, the tablets are ejected from the die cavity and discharged from the machine through discharge port.

Semi-Automatic Tablet Making Machine

Tdp Semi-automatic tablet making machine

Semi-automatic tablet counting machine has comparatively low level of automation to make various kinds of tablets. It is cost-effective with small footprint and good output ratio of pressing 6000 pills per hour.

Structure

It consists of a durable stainless-steel body along with other small components including a fly wheel, feeding hopper, motor, v-belt, drive gear, punching tools, die cavity, and outlook hopper etc.

Process

The machine is dependent upon the operator to feed it with material and set the parameters. Afterwards, when it is powered on, the machine automatically starts supplying the die cavity with precisely weighed dosage, press it, and discharge it out through ejection. The finished tablets are then collected in a container and manually taken by the operator.

Manual Tablet Press Machine

Allpack TDP-0 Pharmaceutical Desktop Manual Single Punch Tablet Press Machine

It is a manual type of tablet making machine which provides extremely convenient and cost-effective way to turn your powders and granules into tablets. It features multiple shapes for tablets. It can produce 2000 tablets per hour provided that the speed of hand is fast and continuous.

Structure

It has an extremely small footprint that can be easily placed on any table for processing. The major components include single punch die, small hopper, rotating handle, metallic body, and discharge hose.

Process

Its working process is simple, requiring one operator to process the machine. The user pour powder in hopper, places the collection container inside discharge hose, and start rotating the side handle. Completion of one round cycle of handle results in the formation of one tablet which is then ejected by the machine.

According to Design

Rotary Tablet Press Machine

Allpack Rotary tablet press machine ZP-9B

Rotary tablet making machine has double movable punches to compress machine. That's why it has a high output ratio and safe operation due to dust free mechanism. Here, the hardness and thickness of tablets depends upon the distance between two punches.

Structure

The structure of a rotary tablet press machine is a bit complex comprising stainless steel body, adjusting handle, hopper, rotary turret, electric enclosure, and control system etc.

Process

It works by filling the die cavity with powder after metering the dosage. Afterwards, the upper and low punches collectively excert pressure over the powder from opposite sides which formulate a uniform hard tablet. Finally, the finished tablets are taken out of the machine through discharge chute.

Single Punch Tablet Press Machine

Allpack Single punch tablet press machine THDP-6

Single punch tablet making machine refers to the equipment which follows hammer punching mechanism. Unlike rotary tablet making machine, it has a single punch system to form the tablets and the lower punch is immovable.

Structure

The machine has a comparatively small structure made up of few components including a motor, power button, flywheel, motor, hopper, base, control box, and punching tools.

Process

Firstly, it feeds the die cavity with powder and then removes the excess material through feed shoe. Secondly, the upper punch compresses the powder by punching. Thirdly, the formed tablets are ejected by the machine.

7.What Are The Applications Of A Tablet Making Machine?

The application of a tablet making machine can be found in large to small production facilities whether associated with medical background, food sector, or others. Therefore, some of the prominent sectors are enlisted below:

Pharmaceutical Industry

Patient holding tablets bottle

Pharmaceutical industry is an area with constant involvement in the drugs testing and production. This is the reason why tablet making machine is the need for small to large pharmaceutical laboratories and industries to make medicated pills and tablets.

Nutraceucal Industry

Vitamin E tablets- Picture Courtesy: drnicollemd.com

Proceeding further, nutraceucal industry refers to the field where numerous vitamins, minerals, and proteins are assembled in small tablets and pills to help patients get their supplementary diet. Therefore, in the manufacturing of the large volume of nutraceucal pills, a tablet making machine is used.

Veterinary Industry

Doctor treating pet- Picture Courtesy: infoguidenigeria.com

Like humans, animals and pets also require proper treatment when get injured and ill. This is how the establishment of veterinary industry took place. Hence, among other drug types, tablets is one of the popular dosage form to treat animals for whose making the help of a tablet making machine is taken

Food Industry

Milk tablets pouch presentation idea- Picture Courtesy: 99designs.com

You might have experienced the alluring and delicious tablets in food industries found in multiple colors. These chocolate, milk, and soir tablets are actually made through a tablet making machine which can make dual layer, multi layer, and effervescent tablets as well.

Chemical Industry

Chlorine tablets- Picture Courtesy: deepbluepoolsupplies.co.uk

The practice of pressing tablets is also carried out in chemical industry for various purposes. Therefore, a tablet making machine can be used to perform this task responsibly.

8.How Would You Maintain A Tablet Making Machine?

Maintaining a tablet making machine on regular basis is the key for its successful functioning and smooth performance. Therefore, make sure you are following proper maintenance routine for your tablet making machine. For this, consider the following guidelines:

Operator maintaining machine- Picture Courtesy: har-tech.com

Structural Adjustment:Structural adjustment here indicates that your tablet making machine should be well assembled along with all screws tight, dir cavity, and punches on relevant place, and cam truck on right location.

Before Operation Maintenance:Before operation maintenance require you to alter the internal parameters of machine each time before starting operation. It will include the quantity of dosage for each tablet, punching force, and time duration etc. Neglecting this step, can result in machine's inaccuracies.

Cleaning:Cleaning of the tablet making machine is obligatory to make sure the safe process of tablets. For this, you need to remove the dust and residues from machine through a cloth. Sometimes, the oxidation of dosage material cause machine to rust. Hence, you have to remove it through spraying agent. Moreover, the cleaning of hopper and punches is also necessary which can be done through washing them separately.

Lubrication:In order to retain the machine's fluency, you need to keep your tablet making machine all time greased. So, add lubrication oil or grease into transmission parts, belts, and oil cups.

Parts Changeover:It is a matter of fact, that every machine requires parts replacement at some point. Therefore, timely replacement of worn yand damaged parts is necessary to run the machine efficiently.

9.What Quality Standards Should A Tablet Making Machine Comply?

Tablet making machine is made under the strict regulations because of its highly responsible task which is making tablets. Below mentioned quality standards are few of the notable ones which a tablet making machine must comply:

GMP quality certification marks- Picture Courtesy: qccertification.com

ISO

International Organization for Standardization is a non-governmental international organization established to provide safety principles for goods and products across the globe. ISO 13485 is a quality standard for tablet making machine which is essential for its quality management.

GMP

Good Manufacturing Practices is a system developed to make sure that machines used for tablets processing are following quality standards. So, a tablet making machine should be certified by it.

FDA

Food and Drugs Administration is a principal agency with prime focus of promoting safe drugs and associated equipment. Hence, the machine must adhere FDA's regulations.

CE

CE is the trademark of European Union. If a tablet making machine has this certification, it means the machine is fulfilling all relevant prerequisites.

10.How To Diagnose The Common Technical Errors Of A Tablet Making Machine?

Mostly, when a tablet making machine create trouble during operation or do not start the operation, it is because of human error or technical fault. Therefore, the problem needs to be properly addressed which is only possible if you have prior information such as the one give below:

| No | Errors | Causes | Solutions | Pictures |

| 1 | Tablets capping | It happens when the amount of binder agent is low or the powder is too fine. | So, resolve it by adding sufficient binding agent to the powder and reduce the amount of fine produce in fluid bed dryer.wqa |

Tablets capping- Picture Courtesy: scientistlive.com |

| 2 | Tablet lamination: the separation of tablets into two or more parts | The reasons vary from excessive drying, large sized granules, and high lubrication. | You need to balance the moisture content, reduce granules size as well as lubrication added. |

Tablet lamination- Picture Courtesy: merlin-pc.com |

| 3 | Sticking and Picking | Either the punch area is rough or the pressure of pressing is low. | You need to polish the punching surface and adjust the pressure of compression. |

Tablet sticking to die- Picture Courtesy: tabletscapsules.com |

| 4 | Tablets friability | It occurs when less amount of binder agents are added or high tablets hardness. | It can be solved by adding sufficient binding agent and modify the thickness of tablets. |

Friable tablets |

| 5 | Inaccurate embossing over tablets | It is when the lower punches move freely. | Make sure to use and accurately fix the low punches. |

Uneven tablet embossing- Picture Courtesy: pharmaceutical-tech.com |

11.Factors To Look For When Choosing A Tablet Making Machine?

If you are looking forward for choosing the right tablet making machine for your business, then must consider certain essential factors which are highlighted as under:

Output Ratio

Tablets formatted in different styles- Picture Courtesy: helpguide.org

It is important to have clear knowledge about your current production rate. For instance, if you are running a full scale large pharmaceutical plant, then opting for a fully automatic and multi-station rotary tablet press machine can give you output of making thousands of tablets in an hour. So, considering the machine output capacity is crucial.

Specifications

Dies & punches- Picture Courtesy: shaktipharmatech.com

The shape and size of tablets entirely depends upon the type of punching tools and die cavity. So, make sure the tooling of machine along with other specifications are compatible to your requirements.

Convenience

One of the pertinent factors for a successful business is that you should avoid complex design machine consider the tablet making machine which is easy-to-use. It is because simple design machine follows straight forward way for execution, while as, complex machines may bother you in terms of training and troubleshooting the errors.

Cost

Examining cost- Picture Courtesy: happay.com

Tablet making machines come in different price range. So, it is necessary to purchase a machine that is under your economic range. Otherwise, high initial cost on capital often leads you to have expensive selling products that can reduce your customers.

Conclusion

To summarize, Tablet Making Machine is the must have machine for manufacturing tablets and pills. The modern-day pharmacies and other tablets producing plants are fully dependent upon the tablet making machine for precise, homogeneous, and compact solid dosage creation. If you are also among them and have an intention to buy a new tablet making machine, then must consider Allpack where you will find the type of machine compatible to your needs and budget along with one year of warranty. For further information please contact us!

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide