Tablet Machine Press: The Complete Buying Guide In 2024

Is your business related to tablet manufacturing? Does your process involve usage of a tablet machine press for making different types of tablets? Are you looking for a high quality and efficient tablet machine press? Does your system require a tablet machine press to enhance productivity and meet customer expectations?

If you want to know more related to a tablet machine press; then you are on the right platform. You will get all related information that will help you in selecting the right type of tablet machine press. Go through the complete guide and get solutions to your queries.

1.What Is A Tablet Machine Press?

Automatic Rotary Tablet Press Machine

A tablet press machine is highly efficient and precise equipment used to produce uniform sized tablets of different shapes and formulations.

Pharmaceutical, food, cosmetics and chemical industries widely apply these machines in their tablet forming processes to get desired outputs with high productivity rate. These machine presses are mostly used in large scale industries where bulk tablets are produced with accuracy and same dosage formulation.

2.What Are The Industrial Applications Of A Tablet Machine Press?

Due to its ability to produce large numbers of tablets in a short period of time, a tablet machine press has variety of applications in daily life. Most of the industries that prefer these machines for their operations are:

Pharmaceutical Industry

Pharma Applications Of Tablet Machine Press - Picture Courtesy: Adinath International

Pharmaceutical industry widely uses tablet machine press for producing mass number of tablets with different tablet formulations. Each of the tablets has its own chemical composition and used to diagnose its relative disease. These machines are used due to their ability to form accurate drug content tablets keeping the dosage unique throughout the process. Also, tablets are of effective designs with brand name punched on it during production

Food & Nutraceutical Industry

Whole Food Multi-Vitamin - Picture Courtesy: Wholesome

Other than pharmaceutical industry, food and nutraceutical industries also have several applications of a tablet machine press. It is used produced different types of vitamins and minerals supplements that are consumed to improve physical health conditions. Some flavored candies and mints that in the shape of tablets are also produced using these machines.

Chemical Industry

Agricultural Tablets For Farm Growth

Chemically processed tablets that are employed in chemical, agricultural and refinery industries are manufactured using a tablet machine press. These tablets are used to enhance industrial process, fertilize agricultural lands and increase reaction rates respectively.

Cosmetics Industry

Hand wash Refill Tablets- Picture Courtesy: Jason

In terms of cosmetics, tablets that are used to promote human health both internally and externally are ideally produced using a tablet machine press. Unique types of tablets used for body wash purpose like fizzy coloring tablets and skin care tablets are also produced in an efficient way.

3.What Are The Advantages Of A Tablet Machine Press?

Some of the advantages of a tablet machine press are:

Efficient Production

Multi-Vitamin Tablets- Picture Courtesy: Efficient Group

The most important benefit of a tablet machine press is that it gives high rate of production in just a short interval of time with pure efficiency and precision. From loading of material to ejection of tablets, the complete process is performed in an efficient way without any chances of risk or improper formulation.

Uniformity

Uniform Tablet Punching - Picture Courtesy: Pharmaceutical Online

Each of the tablets produced in a tablet machine press is of same shape, size and dosage formation. This benefit makes the machine to ensure proper uniformity and consistency throughout the process that as it remain crucial of human health.

Dosage Control

Control Dosage Formation - Picture Courtesy: NB

A tablet machine press is capable of controlling dosage of different types of medicines in a precise manner that no over or under filing of material can be found.

Versatility

Pharmaceutical Dosage Form - Picture Courtesy: Walrus Health

A tablet machine press is versatile in a way that numbers of tablets can be produced in a single machine and there is no need to buy different machine for different shapes and sizes. Variety of formulations can easily be handled in it by just changing the turret size or dies according to the required shape.

4.What Are The Different Types Of Tablets Are Processed In A Tablet Machine Press?

Variety of tablets can be processed in a tablet machine press irrespective of their chemical composition and texture. These tablets highly obey regulatory compliances and international standards during their formation. Few of them are:

Chewable Tablets

IROWHIZ Plus Chewable Tablets - Picture Courtesy: Whiz Laboratories

Tablet machine press is also designed in a way that chewable tablets consumed by children can be produced in it easily. Supplements made of vitamins and antacids are included in the category of chewable tablets.

Effervescent Tablet

Benefits Of Effervescent Tablets - Picture Courtesy: Wellbeing Nutrition

Effervescent tablets are the tablets that contain sodium bicarbonate or citric acid in them that play their role as an effervescent agent. These tablets can easily be produced using effervescent type rotary tablet machine press that allows the impact remain for a longer period.

Laundry Tablet

Laundry Washing Machine Tablets - Picture Courtesy: Wash Wink

Laundry or solid tablets that are used for washing or detergent purpose are also manufactured using a tablet machine press. It completely dissolves in water and releases its active ingredient that supports in clean and authentic neatness of cloths and cottons.

Medicine Tablet

Antibiotics Tablets - Picture Courtesy: Anhui Medipharm Co. Ltd.

Simple pharmaceuticals tablets that contain an active ingredient and can easily be swallowed are termed as medicine tablets. These are punch in different shapes and size depending upon their stability and used for specific medical treatments.

Single Layer Tablets

Single Layered Tablet - Picture Courtesy: Medelpharm

Tablets that have a single layer of powder and compressed with force to form a tablet are single layer tablets. These are coating further to improve their stability and to make their taste remain for longer durations.

Multi-layer Tablets

Formulating Bi-Layer Tablets

Tablets with more than one layer of different formulations are called bi or multi layered tablets. These are consumed for treatment of controlled diseases with having more than one drug in its layer. Antidiabetic and antihypertensive drugs tablets are the example of multi-layered tablets.

5.How Is A Tablet Formed In A Tablet Machine Press?

Application Of Rotary Tablet Machine Press - Picture Courtesy: SED Pharma

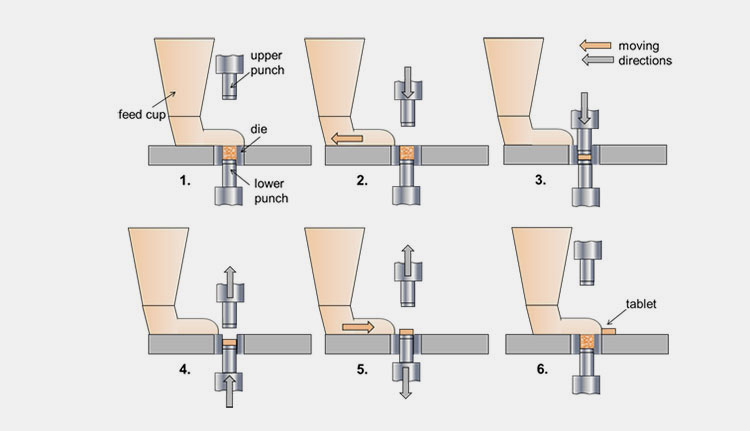

A tablet machine press has following operational steps in formulation of a tablet:

STEP 1: Material Feeding

In the initial stage the formulated material in the form of powder or granule is filled into the hopper present at the top of a tablet machine press. From here the material in a homogeneous manner passes the feeding system and is entered into the die cavity.

STEP 2: Compression

In the second step once the material settles down properly in the die cavity, both the upper and lower punches are forced to compress the material to form the desired dimension and shape of tablet. Certain pressure is exerted so that the formation may be carried out in a controlled atmosphere and no material spillage may occur.

STEP 3: Ejection

The last step of a tablet machine press is ejection of tablets. Once the tablets are properly pressed according to the desired shape and size, the ejection system gets activated that removes the tablet from the die cavity. A conveying mechanism is incorporated here for travelling and collection of these tablets.

6.What Are The Types Of Tablet Machine Press Available Globally?

Tablet machine presses are classified on the basis of their working, production capacity and product type. Some of the common types of a tablet machine press are

Based On Working

Single Punch Tablet Machine Press

Single Punch Tablet Machine Press - Picture Courtesy: SED Pharma

Single punch tablet machine press is mostly used in small scale industries where the productivity remains low. This type of machine presses only a single tablet in the die cavity in a single punch and allows the second once it gets completely ejected from the system. The punching capability of this type of machine ranges 55 to 90 tablets per minute.

Flower Basket Tablet Machine Press

High Pressure Flower Basket Tablet Machine Press - Picture Courtesy: Changzhou Machinery

A flower basket tablet machine press is also used in small scale industries where smaller batches or tablets are produced. These machines are highly versatile that it can be used for electronics components, coffee pill formation and other tablets formation regardless of their nature.

A flower basket tablet machine has both force feed and compression principle that supports in efficient manufacturing of tablets. The working wheel of machine looks like a flower and this is why it is named according to it.

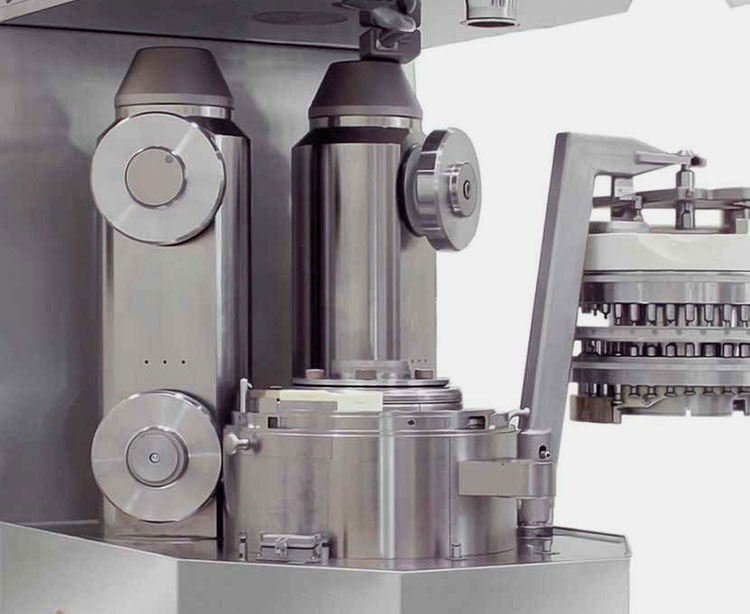

Rotary Tablet Machine Press

Rotary Tablet Machine Press

This type of tablet machine press is the most featured and arranged equipment that can accumulate large number of tablets in shorted periods. The turret of a rotary tablet machine press continuously moves and allows the feeding material to the die cavities. With series of punch sets, variety of shapes and sizes are punched in a single round. These machines are mostly used in large scale industries where the productivity remains high.

Based On Capacity

Depending upon the production requirement, tablet machine press is divided into two types

Small Capacity Tablet Machine

Low Capacity Tablet Machine Press - Picture Courtesy: Aipak

As the name indicates, this type of tablet machine press is designed for low-capacity manufacturing facilities that produce tablets for either testing or research purposes. Different types of granular or powdered material can easily be punched to produce many kinds of tablets.

Large Capacity/High-Speed Tablet Machine Press

High-Speed High Capacity Series Rotary Tablet Machine Press - Picture Courtesy: Aipak

A high-speed tablet machine press allows more than one tablet formation in a single round. It is most suitable for mass production setups where a greater number of tablets are produced in a shorter period. It is applicable to both medium and large-scale industries that produced irregular tablets, round shaped tablets and double sided engraved tablets.

Based On Products

Some of the tablet machine press are also classified depending upon the product they produce. Example of such type are:

Compressed Rotary Block Tablet Machine Press

Rotary Block Press (Compressed Biscuit Making Machine) - Picture Courtesy: Aipak

This type of tablet machine press is used in food industry due to compressed biscuits manufacturing. The biscuit powder undergo high pressure compression applied by both upper and lower punches and as a results gives tablet like compressed biscuits. These biscuits are used for a longer period as it remains fresh and preserved.

Effervescent Rotary Tablet Machine Press

Effervescent Rotary Tablet Machine Press - Picture Courtesy: Aipak

Some of the tablet machine presses also produce effervescent and aromatic tablets. These tablets are produced in a way that their aroma remains preserved for longer periods. It is a highly advanced machine that is developed with latest rotary mechanism in it.

Multi-Color Tablet Machine Press

Multi-Color Tablet Machine Press - Picture Courtesy: Aipak

Multi-color tablet machine press is used to produced large number of tablets with more than two colors in its formation. These machines have double press rollers in their structure that supports compression of multi colored layers with precision and accuracy.

7.What Are The Main Components Of A Tablet Machine Press?

Components Of A Tablet Machine Press – Picture Courtesy: Aipak Pharma

Some of the components of a tablet machine press are

Hopper

It is the main part of the feeding mechanism in a tablet machine press that holds the powdered or granule material used for tablet formation. The hopper is mostly made-up of stainless steel so that contamination can be avoided and it can be used for a longer period.

Organic Glass

The outer most transparent glass surface is made up of organic glass in a tablet machine press. This organic glass contains acrylic material composition that helps in safe guarding the inner part of the machine from external microbes or environmental factors.

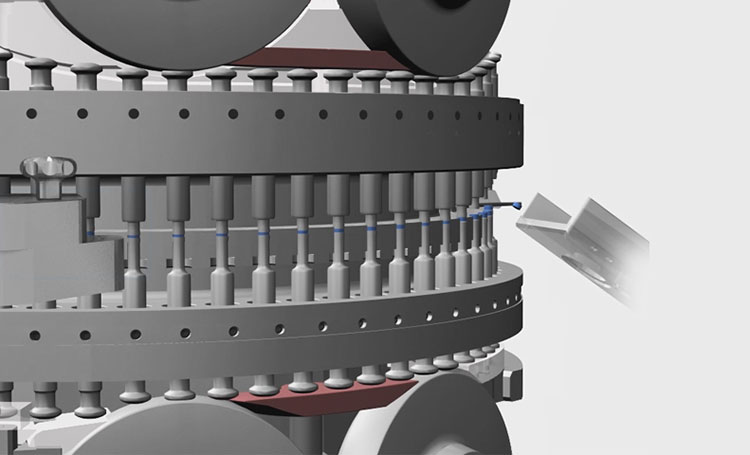

Rotary Table

In a rotary tablet machine press, a rotary table is the place that contains the die cavities, upper and lower punches and cam turrets that are responsible for making of tablets. The upper punch moves up and down continuously for tablet formation whereas the movement of turret allows new material to enter and formed tablets to exit the system.

Adjusting Handle

The adjusting handle is used to adjust the speed of the rotary table and prevents material spillage.

Cam Truck

Tablet Press Cam Truck

Cam trucks are the one that supports and guide the movement of punches. Both of the upper and lower punch movement is first guided so that the material can be filled accurately first and then compressed to produce tablets.

Die Cavity

Die Cavities Of Tablet Machine Press - Picture Courtesy: Aipak

It is a hollow surface that is responsible to store the powdered or granular material in it that is to undergo tablet manufacturing. A die cavity is designed according to the shape of tablet and can easily be replaced for variety of batches.

Punches

Right Type Of Punch And Dies - Picture Courtesy: LFA Tablet Presses

Punches are mostly made up of stainless steel and in pair of upper and lower punch. Once the material is filled in the die cavity, both the punches compress the material with a certain force to form tablet.

Tablet Adjuster

Tablet Adjusting Mechanism - Picture Courtesy: LFA Machines

To avoid over and under filling of material, tablet adjuster is there to maintain the level of material and regulates the excess amount of tablet to maintain the composition and formulation.

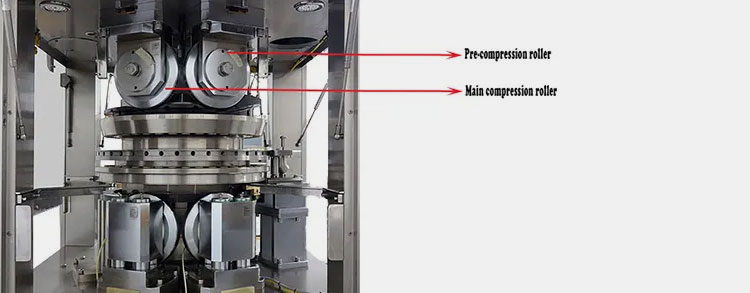

Compressing Unit

Tablet Compression - Picture Courtesy: Pharma Education

A compressing unit a tablet machine press helps in providing the compression force in an automatic manner. The pre-compressor force exits air content from the die cavity and the main compressor force helps in forming tablets.

Operational Panel

An operational contains all the machine controls that are involved in the manufacturing of tablets. The speed of turret, upper and low punch, material feeding speed, temperature and other controls are present here that are directly in contact with the operator so adjustment can be done when required.

Discharge Port

This is the place from where the completely punched and produced tablets are taken out of the system. The discharge port acts as an ejection system in a tablet machine press.

Danger Button

A danger button is used in case of any emergency or machine failure. It directly stops the whole process and avoids any unwanted incident.

Electric Box

The relays and other electrical connection of a tablet machine press are present in the electrical appliance box that support machines working.

The electrical power whether its 110V, 220V or 440V is supplied to the machine through this power plug. It is used to power up the machine to perform its operation in a smooth manner.

8.What Is Tablet Tooling Of Tablet Machine Press?

Tablets tooling has the most fundamental role in tablet formation as it specifies which type, size and shape of tablet will be formed. The tablet tooling of a tablet machine press contains the die cavities and both upper and lower punches that are the essential blocks of any tablet formation. These can easily be changed according to the requirement.

Die Cavity

Die Table Of Tablet Machine

The die cavity holds both the upper and lower punches that are fixed with a turret. It is mostly made up of metal and has a defined shape and size according to that of a tablet. These are arranged properly to perform the compression process in an efficient manner.

Punches

Tablet Compression Tooling - Picture Courtesy: VORTEX

With the spinning of this turret, the upper punch moves downward to perform compression. The lower punch on the other hand holds the material that is to be compressed. The tablet tooling performs a synchronous operation for every punch so that each of the tablets remains identical and uniform.

9.What Are Different Diameter Of Tablet Dia Used In Tablet Machine Press?

Tablet Die And Punches Of Different Dia- Picture Courtesy: Shree Bhagwati

Different diameters of tablets dia are used in a tablet machine press according to the size and shape of tablet. These are mainly classified into B, D, BB and DB with standard barrel and outer diameters for lower and upper punches. The standard sizes of these tooling types are

| S.NO | Tooling Type | Tablet Punch Barrel Diameter | Tablet Outer Diameter Of Die |

| 1 | D | 25.40 mm | 38.10 mm |

| 2 | B | 19.00 mm | 30.16 mm |

| 3 | DB | 19.00 mm | 24.00 mm |

| 4 | BB | 25.40 mm | 30.16 mm |

These standards diameters of tablet tooling are used depending upon the size and shape of any manufacturing batch.

10.How Can Different Sizes Of Turrets Used In A Single Tablet Machine Press?

Tablet Press Turret - Picture Courtesy: Elizabeth Companies

Yes, Turret is a highly versatile equipment that it can easily be changed with respect to the tablet tooling set. They are interchangeable by easily swapping the base and allow the operator to adjust them according to the requirement. In this way a single machine can accommodate variety of turrets with flexibility.

In the operation of a tablet machine press, turret plays an important role as it is responsible to hold both the punch set and die cavity. Different types of machine use different number of turrets depending upon their productivity and structural support. A turret can support die sets ranging from 15 to 75 depending upon the size of machine.

11.What Are The Major Differences Between A Handheld Tablet Press And A Tablet Machine Press?

Difference Between Handheld And Tablet Machine Press

Some of the differences between a handheld tablet press and tablet machine press are:

| S.NO | Parameter | Handheld Tablet Press | Tablet Machine Press |

| 1 | Structure | A handheld tablet press is smaller in size and can easily be moved from one place to another. It is lighter in weight and mostly made up of stainless steel to prevent corrosion. | The structure of a tablet machine press is quite complex as it has various components involved in tablet press process. These machines are designed in a way that continuous production can be support without any involvement of operator. |

| 2 | Productivity | Handheld tablet presses are operated by the operator and this is why its productivity is very low. The speed of the operator is directly related to the outcome of press. | Highly automated machines are now available that ease the manual operation and run the process in a smooth manner. Thousands of tablets can be produced in just a small fraction of time. |

| 3 | Precision | Due to the involvement of operator, the precision and accuracy of tablet formation remain limited as compare to the tablet machine press. Inconsistency can also be observed if the operator does not monitor the process continuously. | The productivity remains highly precise and accurate with consistent material composition in each of the tablet. Uniform tablets are produced using a tablet machine press. |

| 4 | Application | Handheld tablet presses are applied in industries that have small scale production volume or for research and development purpose. | Both medium and large-scale industries are the users of tablet machine press where tablets are produced in bulk quantity. |

12.How Can The Efficiency Of Tablet Formation Remain Same Using A Tablet Machine Press?

It is always a crucial thing to maintain the efficiency of a tablet machine press same throughout the process so that tablets of identical shape and accurate composition can be formed. Some of the important factors to consider are:

Compression Force

Healthcare Medication- Picture Courtesy: Freepik

It is always important to check the applied compression force of upper and lower punch after a certain production batch. It is done to ensure that no over or under force is applied in tablet formation and the efficiency of system remains same.

Uniform Depth Filling

Uniformity In Tablets - Picture Courtesy: Natural Products Insider

Each of the tooling die cavity must be filled to its depth so that the desired tablets can be formed in an efficient manner. If the depth is not filled properly it will give uneven and improperly formed tablets.

Right Type Of Tooling Set

Tablet Tooling Sets - Picture Courtesy: Elizabeth Companies

Before performing tablet formation, it is always important to ensure that the right type of tablet tooling sets is fit into the turret. If this is not observed keenly than it can result a bulk amount of material loss.

13.How To Maintain A Tablet Machine Press For Its Smooth Operation?

Operation And Maintenance

A tablet machine press can be maintained by following ways:

Preventive Maintenance

Preventive Maintenance- Picture Courtesy: Korsch

It is always important to maintain a preventive maintenance chart and decide its frequency. Each of the part of a tablet machine press should be monitored according to its turn and replace if required to maintain the efficiency of the system.

Lubrication

Lubrication of Movable parts

As a tablet machine press has few moveable parts, it is important to keep them lubricated so that any type of wear and tear can be avoided. It can help in long usage of these parts in an efficient and precise way.

Controlling Excessive Wear

Controlling Excessive Wear- Picture Courtesy: Korsch

One of the important factors that can support in maintaining a tablet machine press is control of excessive wear. If the alignment of punches or die cavity is disturbed, it will automatically result in inconsistent movement and the compression process cannot be carried out in a smooth manner. It is always important to control this wear so that the operation can be performed efficiently.

Conclusion

A tablet machine press has variety of applications due to its high reliability and tablet formation features. It produces highly precise and uniform tablets of various sizes and shapes. But when it comes to buying a tablet machine press it is always important to understand its applications, types available and all related information. For this, Allpack is always here to provide you assistance and guidance related to a tablet machine press. If you still have any query feel free to contact our customer representatives that are available 24/7 for your guidance.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide