Rotary Tablet Machine: The Complete Buying Guide In 2024

With unprecedential advancements in technology, manufacturers are now looking forward for sophisticated equipment to boost their production instead of just switching the mode from manual to automatic. In such a scenario, when focus is more on efficiency, precision, and performance a rotary tablet machine is always the best choice for making tablets.

Rotary Tablet Machine is a complex machine designed with innovative features to tackle tablets manufacturing targets. It can raise your current output rate to the best possible one. But, how it can be possible with a single machine? What is the exact working mechanism of a rotary tablet machine? Are there further models of a rotary tablet machine? Just take a pause, as we are about to answer all of these queries. So, let's get started!

1.What Is A Rotary Tablet Machine?

Allpack Rotary Tablet Press Machine ZP-5B

Rotary tablet machine, also known as multi-station tablet press, is an electric machine created to compress powders and granules into tablets. The machine uses automatic technology to carry out this task in a way where the dry mixture is precisely poured into relevant die cavities, compressed hardly, and the formed tablets are ejected out of machine.

This machine is highly efficient in its production while taking care of dosage. It is made up of GMP's regulated stainless steel body and a protected window. Moreover, it is highly versatile in terms of manufacturing different types of tablets. That's why its significance is realized in almost every sector.

2.Why Rotary Tablet Machine Is Important In Pharmacy?

Doctor picking drug pack- Picture Courtesy: wolterskluwer.com

The presence of a rotary tablet machine is inevitable in pharmaceutical industry due to the nature of manufacturing in this field. This machine has gained a position of importance in pharmacy due to multiple reasons among with the prominent one is efficiency.

Rotary tablet machine produces thousands of tablets in an hour which make it possible to deliver required drugs to patients all around the globe. Another reason is the protection of medication mixture which is highly considered in pharmacy because minor mistake can ruin the effect of drugs. But here the machine is proficient in forming precise tablets.

3.Write Down The Benefits Of A Rotary Tablet Machine?

Rotary tablet machine can be advantageous for you in multiple ways. Below highlighted benefits are some of the prominent ones:

Efficiency

Bilayer tablets discharging from machine- Picture Courtesy: ibermaticoss.com

Rotary tablet machine is known for its consistent working process which ultimately leads to the production of myriad of tablets in a single run. Hence, its efficiency can enhance your manufacturing output.

Safety

Drug safety presentation idea- Picture Courtesy: iStock

By using a rotary tablet machine, you will not be bothered to take the risk like manually intervening into the operation if spontaneous error occurs, rather pressing emergency button will stop the machine. Similarly, the protected body of machine is highly antibacterial that it safely processes the mixture without modifying its characteristics.

Convenience

Rotary tablet machine promotes user convenience due to its easy-to-use operation panel through which operator can communicate with the machine. Moreover, the machine does not require number of labours, but single user is enough to run the machine.

Resilience

Bilayer tablets- Picture Courtesy: europeanpharmaceuticalreview.com

Rotary tablet machine is highly resilient due to its capability to press eclectic sizes and shapes of tablets. Moreover, there is wide collection of rotary tablet machine models which enable you to form bilayer, multilayer, and effervescent tablets.

Reliability

Manufacturers look for cost-effective machines to cut the production costs of tablets. In this way, a rotary tablet machine is extremely reliable which requires low maintenance, single operator, and ultimately reducing the additional expenses.

4.What Type Of Tablets Can Be Made By A Rotary Tablet Machine?

All kinds of small to large with different sizes and shapes tablets can be made by a rotary tablet machine. Below is the glimpse of these all:

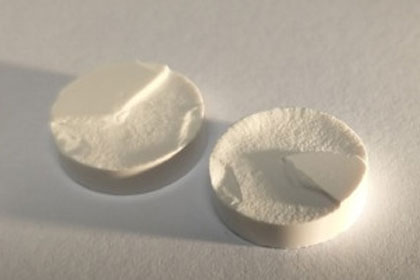

Single Layer Tablets

Patient holding single layer tablet in hand- Picture Courtesy: usana.com

Single layer tablet is a standard type of tablet where single Active Pharmaceutical Ingredient is delivered to patients. Such tablets are always perfectly formed by a rotary tablet machine.

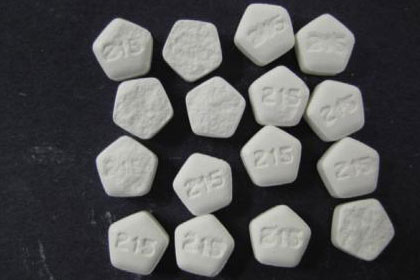

Bilayer Tablets

Bilayer tablets- Picture Courtesy: Fette Compacting

As the name indicates, bilayer tablets are tablets containing two separate powered mixture compacted together. Their process of formation occurs in a way where first powder mixture is compressed and then second powder mixture is introduced over the formed tablets and compressed together. Such bilayer tablets can be easily made by a rotary tablet machine.

Multilayer Tablets

multilayer tablets- Picture Courtesy: bharatagritech.com

Multilayer tablets refer to the tablets having three distinct dosages compacted together. The purpose of making multilayer tablets is to provide three different Active Pharmaceutical Ingredients in a single tablet paving the way for effective drug delivery. Therefore, a rotary tablet machine is capable to form multilayer tablets.

Effervescent Tablets

Effervescent tablets- Picture Courtesy: solife.blog

Effervescent tablets are also called carbon tablets which are extra large in size than standard tablets. They are designed to quickly dissolve in liquid, therefore, most of the effervescent tablets contain calcium dosage and energy dosage. Here, it is pertinent to mention that a rotary tablet machine can be used to form effervescent tablets.

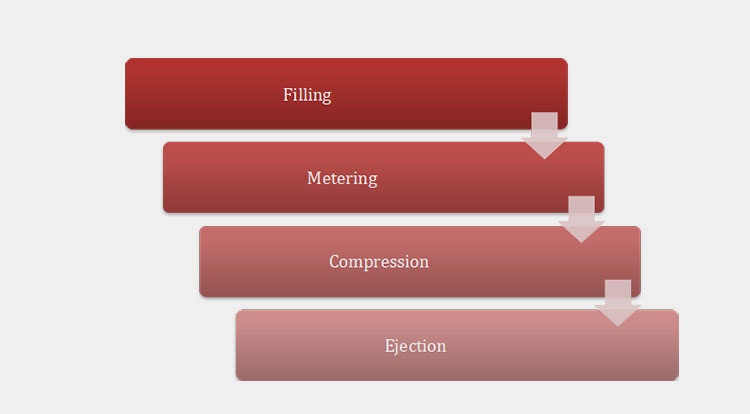

5.How Does A Rotary Tablet Machine Function?

The working process of a rotary tablet machine is based on certain steps where a turret moves in rotary direction and lead the powder to turn into tablets. This process can be better understood in by reading the underlying explanation:

Filling

Powder Filling- Picture Courtesy: LFA Machines

The first step is filling where bulk powder or granules mixture is filled into the hopper of machine. From hopper, the powder flows to feeding unit known as feed frame. This feed-frame then evenly distribute the powders into each passing die cavity.

Metering

Powder Metering- Picture Courtesy: LFA Machines

The second step is metering which is also known as dosage or weighing. In this step, the precise amount of powder is weighed after which the lower punches move upward to remove excess powder from die bore.

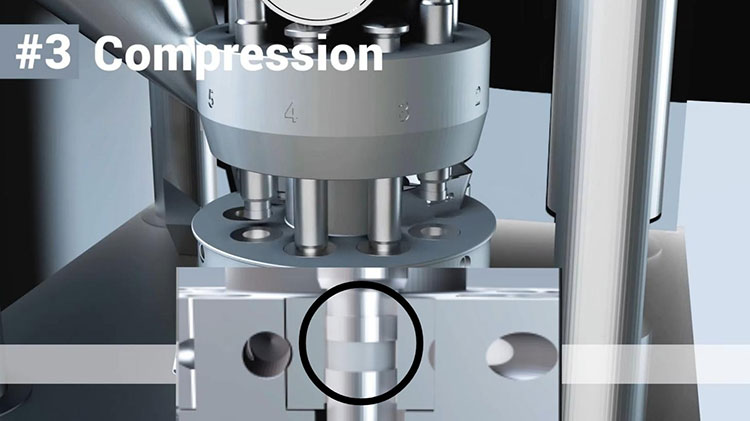

Compression

Tablets compression- Picture Courtesy: LFA Machines

In third step, the upper and lower punches are brought together with force to form the tablets. The compression stage can be further divided into pre-compression and main compression.

In pre-compression, the upper punch descends to press powder with little force for creating a slug to remove air pockets. After this, in main compression, both the upper and lower punches are brought together with much force which result in the formation of uniform tablets.

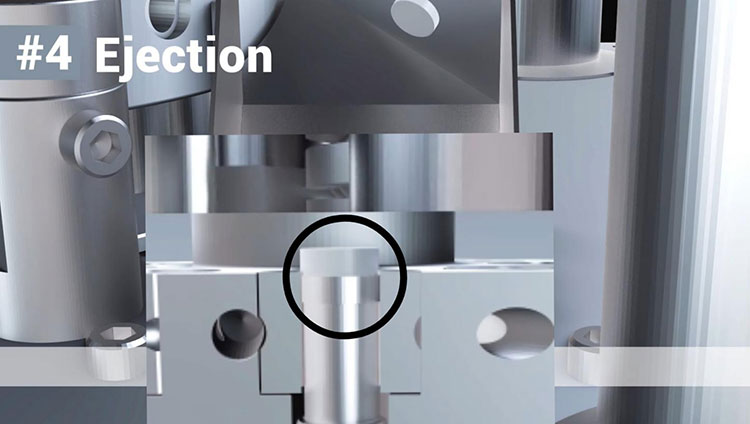

Ejection

Tablets ejection- Picture Courtesy: LFA Machines

In last step, the upper punches move upward followed by the rise of lower punches in ejection can. Similarly, the tablets are ejected out of the die bore towards scrapper. The scraper then moves down the formed tablets down the ejection track into the container.

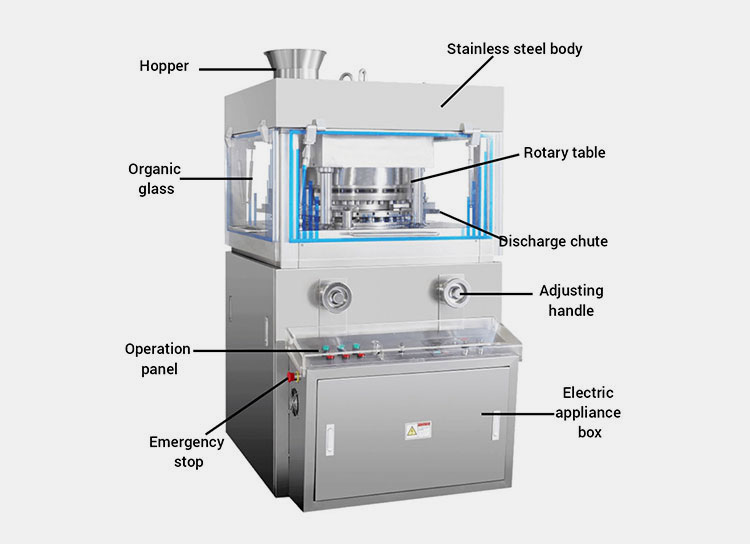

6.Describe The Various Components Of A Rotary Tablet Machine?

Rotary tablet machine consists of several components which together help the machine to form tablets making function. These parts are explained below in detail along with the main task each perform. So, consider the following description:

Components of Allpack ZP25 effervescent rotary tablet press machine

Hopper

Hopper is sometimes called the feeder system of a rotary tablet machine. You will always find the location of a hopper on the top side of machine. The number of hoppers depends upon the type of machine; however, the common hopper is one or two in number. It provides the machine with dry powdered or granulated mixture.

Stainless Steel Body

The body of the machine is compact and robust that greatly contributes to supporting a stable operation. It is made up of GMP's regulation stainless steel material, which is fully protected against bacteria and corrosion, therefore, material is processed inside it.

Rotary Table

Rotary table is the core component of a rotary tablet machine which distinguishes it from other types of machines. The table itself is made up of further parts including:

Turret:It is the vital part of a rotary tablet machine with round structure having multiple holes where dies and punches are adjusted. During tablets compression, this turret rotates and lead dies and punches to compress powder.

Punches:Rotary tablet machine has two punches; upper punch and lower punch. These are durable stainless steel rod type tools having on their tips or heads the specific shape. Punches are vital in compressing powders into tablets through exertion of force.

Dies:Dies are among crucial components of a rotary tablet machine. They are small round tools with a single or multiple grooves where the lower and upper punch meet in order to compress the powder into tablets.

Compression Rolls:Compression rollers are cylindrical rollers who perform the function of pressing powder. They are two in number including pre-compression rolls and main compression rolls. The former compress powder to remove air, while as, the latter exert excessive pressure to form tablets.

Cam Tracks:As the name indicates, cam tracks are tools which provide track for the synchronized movement of punches.

Organic Glass

Rotary tablet machine has a transparent protected window that enable the user to monitor tablets making process without touching it.

Operation Panel

Operation panel is a board containing touch screen display and certain knobs through which the user set commands in machine such as the quantity of powder for each tablet, the thickness of tablets, and compression force etc.

Emergency Stop

Emergency stop is a red colored large size button located on the front of a rotary tablet machine. It is a safety switch used to shut down the machine in an emergency.

Electric Appliance Box

It is consistent the most vital component of a rotary tablet machine where all the electrical components are collectively placed for supporting smooth functioning.

Adjusting Handle

Adjusting handle is used to modify the force of compression roller.

Discharge Chute

This part of machine is responsible to exit the formed tablets from machine into a collection container.

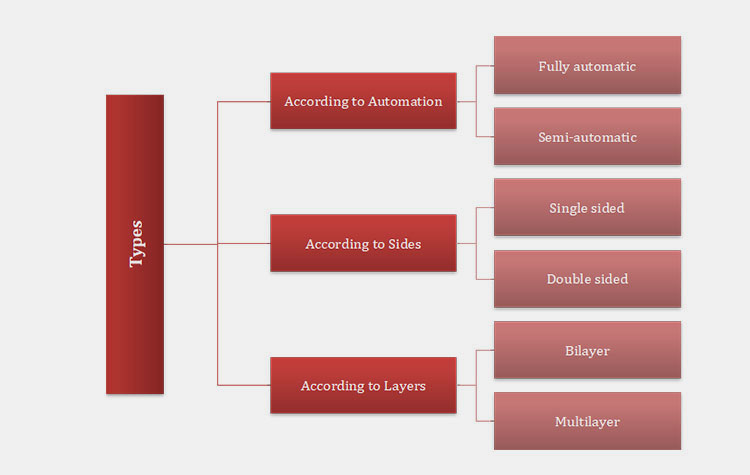

7.Are There Any Types Of A Rotary Tablet Machine?

There are multiple types of rotary tablet machine available in market today. This wide classification has been introduced to meet the growing demands on part of manufacturers. So, let's explore these types in detail!

According to Automation

Automatic Rotary Tablet Press Machine

Automatic Rotary Tablet Press Machine

Automatic rotary tablet press machine is the most advanced form of rotary tablet machine. It is fully automatic in technology with production output reaching the figure of 17000 tablets per hour. This machine can be integrated with other machines to further enhance the efficiency.

Structure

The structure of machine is robust and complex which is an assembly of several small to large components. These include a stainless-steel body, transparent window, control system, electric enclosure, turret, hopper, punches, dies, compression rollers, and a touch screen penal.

Working Process

It is fully automatic, therefore, automatically dispense the powder from hopper onto feed frame and die cavities simultaneously. Afterwards, the pre-compression and main compression take places. At last, the formed tablets are removed out from die bores through ejection.

Semi-Automatic Rotary Tablet Press Machine

Semi-Automatic Rotary Tablet Press Machine

Semi-Automatic rotary tablet press machine is small design machine with good production capacity of producing 1000 tablets per hour. The machine is easy-to-use and cost-effective in price. Different small to medium size industries can take advantage of this machine.

Structure

The structure of machine is small made up of several components including a metallic base, stainless steel hopper, turret, control board, compression rollers, and a motor etc.

Working Process

The machine is manually loaded with powder formula and powered on. It then automatically fills the die cavities, compresses the powder and eject formed tablets from die bore and discharge into the laying container.

According to Sides

Single Sided Rotary Tablet Press

Single Sided Square GMP Mini Tablet Press- Picture Courtesy: deepujpharmamachinery.com

Single sided rotary tablet machine is a common type of machine with single hopper and single rotary table. However, despite being a single sided equipment this machine can give you excellent production rate of compressing 4800 to 18000 per hour.

Structure

The structure of machine is medium size compared to double sided rotary tablet machine. It mainly consists of a single hopper, one turret, operation panel along with certain knobs, and an electric appliance box.

Working Process

It follows the conventional working procedure by filling the dies with powder. Afterwards, precise amount of powder is kept inside the dies and rest is removed. The filled powder is then compressed to form tablets. When the punches reach to ejection cam track, the formed tablets are ejected from the machine.

Double Sided High Speed Rotary Tablet Press

Double Sided High Speed Rotary Tablet Press- Picture Courtesy: deepujpharmamachinery.com

This is another type of a rotary tablet machine which is tailored with excellent tools and double rotary punches to achieve utmost productivity. In this machine, the powder is fed into two turrets from double sides. Therefore, its production efficiency is double than a single rotary tablet machine with compressing 2,66,400 tablets in an hour.

Structure

The structure of machine is a composite whole of double turrets, two hoppers, four adjusting handle, enclosed body, control system, and electromechanical tools etc.

Working Process

It simply works in a way where one hopper is responsible to provide powder to the die cavities located in upper turret, while as, another hopper feed the die cavities of the lower turret. Similarly, both these turrets undergo compression stage and ultimately, discharge the compressed tablets through single discharge chute.

According to Layers

Bilayer Tablet Compression Machine

Bilayer Tablet Compression Machine- Picture Courtesy: deepujpharmamachinery.com

Bilayer rotary tablet machine is featured with innovative technology to form bilayer tablets by compressing two formulations into single tablet. It has high efficiency level and can be used in nutraceucal, pharmaceutical, and food industries.

Structure

This machine has relatively a precise body with several parts accounting for its construction including two funnels, single turret, pre-compression and main compression rollers, multiple adjusting handles, and electric enclosure etc.

Working Process

It works by infusing the first formulation into die cavities and compress them. The turret them move and leading these die cavities to be filled with second formulation. After this, the main compression exert force on punches leading the creation of uniform bilayer tablets. Finally, tablets are ejected from the dies.

Multilayer Tablet Press Machine

Multi Layer Tablet Press Machine- Picture Courtesy: deepujpharmamachinery.com

Multilayer tablet press machine is the most updated model of a rotary tablet machine with the ability to form three-layer tablets. It greatly ensures the precision of each dosage layer with the help of integrated sampling facility for weighing and checking. Moreover, it can be employed in food, medical, and chemical industries.

Structure

It consists of three hoppers, heavy-duty machinery, feeder system, compression rollers, emergency stop, turret, control panel, and discharge chute etc.

Working Process

The working process of a multi layer tablet machine is a bit unconventional with intermittent filling of powders into dies and their subsequent compression. Firstly, individual powder mixtures are poured in separate feeding hoppers. Secondly, when the turret start moving, one powder mixture is filled in die cavity and get compressed.

This die cavity is then filled with another powder mixture and compressed where two layers get formed. Thirdly, the same die cavity is then filled with distinct powder mixture and a final compression take place. Finally, the formed tablets are ejected and discharged.

8.Differentiate Between Rotary Tablet Machine And Single Punch Tablet Machine?

Rotary tablet machine and single punch tablet machine are used for making tablets but their structure, working process, and many other aspects are different from each other. Therefore, we have explained these differences in the table below for your clear understanding:

| No | Factors | Rotary Tablet Machine | Single Punch Tablet Machine |

| 1 | Definition | Rotary tablet machine is a multi station rotary press machine that compress powder with upper and lower punch. | Single punch tablet machine is the earliest form of a tablet press machine with single punch. |

| 2 | Structure | Its structure is complex and containing different components. | While as single punch tablet machine is small in size and consists of fewer parts. |

| 3 | Number of punches | It has set of upper and lower punch. | On the other hand, this type of machine has only a single upper punch. |

| 4 | Process | Its process is convenient due to automation but has several stages. | In contrast, the working process of a single punch tablet machine is straight forward. |

| 5 | Speed | It is highly efficient with capacity of producing 800 tablets in a minute. | In contrary, this machine can compress 80 tablets per minute. |

| 6 | Cost | It is expensive than a single punch tablet machine. | While as, this machine is cost-effective. |

| 7 | Picture |

Allpack Rotary tablet press machine ZP-7B |

Allpack TDP series Single punch tablet press |

9.What Are The Uses Of A Rotary Tablet Machine?

A rotary tablet machine has extensive applications which can be better understand by looking into the below highlighted sectors:

Pharmaceutical Industry

Coated oblong tablets- Picture Courtesy: tabletscapsules.com

Rotary tablet machine is widely used in pharmaceutical industry to meet the excessive need for producing different kinds of tablets and pills with varying shapes and sizes.

Nutraceucal Industry

Nutraceucal drugs display- Picture Courtesy: depositphotos.com

As the growth rate of nutraceucal industry is surpassing other sectors, it can be said that demand for formation of large number of tablets is also growing. Hence, a rotary tablet machine is inevitable to fulfill this production target.

Veterinary Industry

Doctor treating a dog- Picture Courtesy: stock.adobe.com

Tablet is considered the most convenient and desirable form of dosage which can be easily swallowed by pets and animals as well. Therefore, veterinary industry uses a rotary tablet machine to make abundant tablets.

Food Industry

Malt tablets packaging- Picture Courtesy: roscela.com

Among other areas food sector is the notable one. Here, you will find number of confectioneries in form of bilayer and multilayer tablets like milk tablets, chocolate tablets, and other tablets made from compacting salt and dyes. So, a rotary tablet machine can be used in various food industries.

Chemical Industry

Chlorine tablets in hand- Picture Courtesy: tennisamatoriale.it

The application of a rotary tablet machine can also be found in chemical industry where chemical powders are compressed to form tablets and then used for different purposes. In this way, chlorine tablets are the common example.

Pesticide Industry

Tree & shrub tablets- Picture Courtesy: marriedtoplants.com

We are familiar with the fact that the health of plants is always in danger due to harmful pests and insects. That's why different techniques have been employed to tackle this issue by restricting the access of these organisms to plants. Similarly, pesticides have been enclosed in tablets for which a rotary tablet machine is used.

10.How To Examine The Quality Of A Rotary Tablet Machine?

In order to examine the quality of a rotary tablet machine, you can simply check the certifications of the company. In this way, below highlighted quality standards are internationally recognized ones whose compliance will indicate that the machine is made up of quality material:

ISO

International Organization for Standardization is an international organization established to ensure the credibility and safety of goods and products. Therefore, if a rotary tablet machine is ISO certified, it is made up of quality material.

GMP

Good Manufacturing Practices is yet another platform created to guarantee the hygiene and purity of a rotary tablet machine. So, a machine complying with GMP regulations will be of high-quality standard.

FDA

Food and Drugs Administration is USA based agency with primary goal to provide safe and healthy drugs and associated equipment. Therefore, a rotary tablet machine which is used for making drugs must meet with the FDA's rules.

CE

CE is the collective marking of European Union made to allow the mobilization of only those products which are conforming the Union's health, safety, and environmental protection standards. Hence, presence of this mark on a rotary tablet machine will strengthen its quality.

11.What Machines Can Be Integrated With A Rotary Tablet Machine?

Rotary tablet machine can be integrated with other machines to facilitate larger production output. The list of these machines has been provided below:

Tablet Deduster Machine

Allpack Top rotation type tablet deduster machine SZS230

Tablet deduster machine is one of the essential equipment that can be attached to a rotary tablet machine. It is used to remove out the dust and residues from tablets after their pressing. It consists of a main frame, chassis, vacuum device, dust collection plate, infeed, and outlet etc. It works by following the principle of vibration.

The mechanical force generate vibration which results in tablets scattering and moving over perforated plate. At this point, the dust is collected through vacuum device and tablets are free from dust.

Tablet Coating Machine

Allpack tablet coating machine BYA-600

Tablet coating machine is another equipment that can be integrated with rotary tablet machine. It is employed for coating the tablets with thin coating film. Several components constitute its body including a coating pot, heating device, control panel, and machine base etc. It coats the tablets by continuously rotating them in a coating chamber where fluidized coating formula is sprayed over the tablets resulting in even coating.

Tablet Counting Machine

Allpack APC-8 Automatic Tablet Counting Machine

Tablet counting machine is the most important machine which go side by side with rotary tablet machine. It has been designed with automatic technology to count the tablets through sensors and vibratory trays and then fill these counted tablets into various bottles and containers. It is made up of several parts comprising a hopper, vibratory channel, counting compartment, filling head, and automatic detection system.

Blister Packaging Machine

Allpack DPP-180H High Speed Tablet/Pill/Capsule Alu Alu Blister Packaging Machine

It is a primary packaging machine mostly used for tablets packaging. This blister packaging machine is used to create blister packs in round or oblong shape to hold tablets and pills. The machine uses, film roll, thin aluminum foil, heating system, and detection system to precisely form the blister packs, accurately place the tablets in blister packs, and seal them through aluminum foil.

12.How To Maintain A Rotary Tablet Machine For Smooth Functioning?

Regularly maintaining your rotary tablet machine can enhance the working life of the machine and also keep its pace at good condition. In this way, below discussed are some of the notable tips whose following will help you achieve the maintenance of a rotary tablet machine:

Lubricating mechanical parts of machine- Picture Courtesy: geartechnology.com

Dusting & Cleaning:No doubt, cleaning is the obligatory part of maintaining a rotary tablet machine. So, you need to dedust the parts of machine after the machine complete one round and wash these parts when daily task gets done. These parts include the hopper, fill parts, compression rollers, dies and punches. Parts like control panel, handle, and control board can be wiped out with cloth.

Lubrication:Lubrication is another important step in maintenance of a rotary tablet machine. Here, you need to lubricate the transmission parts of machine-like rollers to improve their motion fluency.

Parts Changeover:After cleaning and lubrication, it is significant to have a look towards the damaged parts of machine. If you find components in unsuitable condition, then make sure to timely change them with new spare parts.

13.Troubleshoot The Common Pitfalls Of A Rotary Tablet Machine?

When operating a rotary tablet machine, it might show malfunctions that can lead to bigger challenges like tablets breaking and capping etc. These pitfalls are caused due to technical issues that occur inside the machine. To troubleshoot these errors timely you need to have relevant knowledge about it which is given in the table below:

| No | Pitfalls | Causes | Solutions | Pictures |

| 1 | Tablets capping happening after compression | The reasons are trapped air inside die cavity and the excessive dry nature of powder. | It can be tackled by increasing the dwell time of pre-compression stage, so, the air will get more time to come out. Also, make sure the powder has enough lubrication to make it compact. |

Capping of tablets- Picture Courtesy: romaco.com |

| 2 | Lamination of tablets | Over compression is the core reason for lamination of tablets where they get cracked. Another reason can be the use of inappropriate dies. | So, you need to enhance the pre-pre-compression time to lead powders stick together and use tapered dies which are best for avoiding tablets lamination. |

Laminated tablets- Picture Courtesy: sciencedirect.com |

| 3 | Tablets particles stick to the punch tips or heads | It is one of the serious issues that occurs as a result of particles being wet from inside leading them to stick to punch head. In some cases, the punching tools are also responsible for particles picking. | The solution lies in properly drying the powder mixture after its wet granulation tool place. Moreover, increasing the dwell time of pre-compression roller will give time to powders for drying. Along with that, daily polishing of punching tools will highly reduce the chances of tablets sticking to their heads. |

Tablets sticking to punches heads- Picture Courtesy: researchgate.net |

| 4 | Tablets binding happen inside the die restricting way for tablets ejection | Too much binding agent causes tablets' sides to take hold in die cavity which can make them crumble when ejected. | Reduce the lubrication or binding agent in tablets and make sure the mixture is well dried. |

Tablets with rough sides- Picture Courtesy: asme.org |

| 5 | Tablets friability | Tablets’ friability leads to challenges in their coating, packaging and delivery. It has various reasons encompassing the low number of binders, excessive compression speed, and large granules with no fine powder. | Solution is simple, you need to add sufficient binders into mixture, reduce the compression force of machine to suitable level, and reduce the size of granules. |

Broken tablet- Picture Courtesy: eastmedpharmacy.co.nz |

14.What Are The Instrumental Considerations For Purchasing A Rotary Tablet Machine?

Purchasing a rotary tablet machine means including in your production line a determiner who will determine critical things about your business such as the manufacturing output, size and shapes of tablets, and cost of production. So, make sure you are choosing this machine attentively!

Production Capacity

Capacity puzzle- Picture Courtesy: adults.ccinform.co.uk

The first and most critical factor to look for is the production capacity which you are planning to have. Since, there rotary tablet machine is available both in automatic, semi-automatic, single sided and double sided form, you can opt according to your needs.

Shape & Size of Tablets

Different sizes & shapes of tablets- Picture Courtesy: shutterstock.com

Another crucial consideration comes on part of the tablets' shape and size. Here, you have to pick for right assembly of punches and dies whose specifications are compatible to your desired ones.

Type of Feeding System

Rotary tablet machines come with two types of feeding system: open feeder and closed feeder. Open feeder has poor flow ratio, which is good for granulated mixture compression, while as, closed feeder has fluent feeding frequency and is suitable for powders. So, make sure you opt for the rotary tablet machine with an intended feeding system.

15.What Is Allpack Line Of Rotary Tablet Machines?

Allpack is providing a suitable collection of rotary tablet machines. Have a look towards it!

| No | Machine | Production Capacity Per Minute | Number of Dies |

| 1 | Allpack rotary tablet press machine ZP-5B

|

9000 tablets | 5 |

| 2 | Allpack Rotary tablet press machine ZP-7B

|

12600 tablets | 7 |

| 3 | Allpack Rotary tablet press machine ZP-9B

|

16200 tablets | 9 |

| Allpack Rotary tablet press machine ZP-7B

|

17000 tablets | 11 |

Conclusion

We are wrapping up this buying guide about a Rotary Tablet Machine with great enthusiasm and a hope that you have found this piece of writing a helpful one. Rotary tablet machine is the answer to all problems that are being faced by today's manufacturers in medical field, food sector, and pesticide industry. It is the most updated version of tableting machinery as proved by the above discussed vast classification of a rotary tablet machine. So, now it's your turn to revolutionize your tablet making business. If you are eager to learn more, stay in contact with us!

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide